Professional Documents

Culture Documents

Student Handout 19 2014

Uploaded by

kietniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Student Handout 19 2014

Uploaded by

kietniCopyright:

Available Formats

Incompressible viscous fow 1:

shell balances

CHEE 3363

Spring 2014

Handout 19

Reading: Fox 8.1--8.4

1

Learning objectives for lecture

1. State the criterion for the transition from laminar to turbulent

fow.

2. Use shell balances to obtain the velocity distribution in 1-D

geometries.

3. Describe the phenomenology of entrance length.

2

Recall: transition from laminar to turbulent

We have now shown that the Reynolds number can be seen as the ratio of

inertial to viscous forces:

Reynolds number Re =

High Reynolds numbers are associated with turbulent fow:

laminar

turbulent

This transition is approximate and depends on how carefully the

experimental system is controlled.

The next two lectures focuses on the features of laminar and turbulent fow,

while developing an approach that can be used to solve for fow in ducts.

3

yx

+

yx

y

dy

2

dxdz

yx

+

yx

y

dy

2

dxdz

p +

p

x

dx

2

dy dz

p +

p

x

dx

2

dy dz

p,

yx

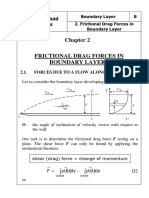

Laminar fow: parallel plates 1

NB: on homework you did a slightly harder version of

this using EoM. Here we will use a CV approach

(shell balance) using the macroscopic equations,

which is valid for 1-d fow that depends on one

spatial variable.

h

x

y

Consider the fow across a CV of volume dx dy dz:

dx

dy

Assumptions:

1.

2.

3.

4

Laminar fow: parallel plates 2

Force due to pressure:

5

x momentum equation:

Sum of surface forces: note that

Laminar fow: parallel plates 3

Integrate:

Note: LHS function of y, RHS function

of x, thus both sides must be constant!

6

Force due to friction:

Laminar fow: parallel plates 4

7

Boundary conditions:

Shear stress distribution:

Laminar fow: parallel plates 5

Volume fow rate per unit depth L (in z direction):

Flow rate versus pressure drop:

8

Laminar fow: parallel plates 6

9

Average velocity:

Maximum velocity: solve for y in

Laminar fow: parallel plates 7

Second example: upper plate moving with constant speed U

Boundary conditions:

after algebra:

NB: reduces to

stationary top plate

solution when U = 0

10

Laminar fow: parallel plates 8

Shear stress distribution:

This solution: linear superposition of a linear velocity profle and a parabolic

velocity profle:

11

Volume fow rate per unit depth L (in z direction):

Laminar fow: parallel plates 9

Average velocity:

Maximum velocity: solve for y in

12

p2r dr

p +

p

x

dx

2r dr

rx

2r dx

rx

+

d

rx

dr

dr

2(r + dr) dx

p,

rx

Laminar fow: circular pipe 1

h

x

r

dx

dr

Assumptions:

1.

2.

3.

Consider forces acting on CV:

2R

In x momentum equation, all terms

except surface force term F

Sx

vanish

13

CV for laminar fow in a pipe: annulus

Laminar fow: circular pipe 2

14

Force due to pressure:

Force due to friction:

Laminar fow: circular pipe 3

function only of x

(uniform pressure at each section)

function only of r

(fully developed)

15

Integrate:

Laminar fow: circular pipe 4

16

Boundary conditions:

Substitute stress and integrate again:

Laminar fow: circular pipe 5

Shear stress distribution:

Volume fow rate:

Flow rate versus pressure drop:

17

r = 0

Laminar fow: circular pipe 6

Average velocity:

Maximum velocity: solve for r in

maximum at

18

Duct analysis

Flow in a horizontal circular pipe:

Goal: evaluate pressure changes resulting from

incompressible fow in pipes, ducts, fow systems

Need to account for losses due to friction

- Major losses: caused by friction in constant-area portions of

system

- Minor losses: resulting from fow through valves, tees,

elbows, and other non-constant-area portions

Stress on the wall (= and opposite to stress in fuid at wall):

Laminar fow:

Turbulent fow: no equivalent equation; need semi-empirical results

19

Entrance length 1

Phenomenology:

At entrance (1):

- Boundary layer develops, in which surface exerts retarding

shear force

- Velocity:

Downstream from entrance (2):

- Effect of solid surface felt further into fuid

- Required to satisfy conservation of mass:

20

(1) (2) (3)

Far from pipe entrance (3):

- Distance downstream at which fully-developed fow begins:

entrance length

- Velocity:

Cartoon is for fully-developed laminar fow

- Can be solved for some geometries by simplifying

equations of motion

- Entrance length:

Turbulent fow: enhanced mixing causes more rapid growth of

boundary layer

Entrance length 2

Phenomenology:

(1) (2) (3)

21

You might also like

- Experiment 12 Fluid Friction 1Document4 pagesExperiment 12 Fluid Friction 1Shahid KhanNo ratings yet

- Tutorial Software SGeMSDocument26 pagesTutorial Software SGeMSEdi Setiawan100% (3)

- Chapter 4Document106 pagesChapter 4lockas222No ratings yet

- External Incompressible Viscous Flow: CHEE 3363 Reading: Fox 9.1 - 9.3Document24 pagesExternal Incompressible Viscous Flow: CHEE 3363 Reading: Fox 9.1 - 9.3Ahmad SayyedahmadNo ratings yet

- ENSC 283 Introduction To Fluid Mechanics: Chapter 7 - Flow Past Immersed BodiesDocument16 pagesENSC 283 Introduction To Fluid Mechanics: Chapter 7 - Flow Past Immersed BodiesArjun CpNo ratings yet

- Steady Conduit FlowDocument13 pagesSteady Conduit FlowEyuelAdamNo ratings yet

- Fluid Mechanics II: B.S. Mechanical Engineering 4 SemesterDocument80 pagesFluid Mechanics II: B.S. Mechanical Engineering 4 Semesternaeema_58No ratings yet

- Flow Friction Factors Tubes Group 5Document16 pagesFlow Friction Factors Tubes Group 5Nishanth ChandranNo ratings yet

- Boundary Layer FlowsDocument28 pagesBoundary Layer FlowsAmy RamirezNo ratings yet

- T 2Document31 pagesT 2Vinay Gupta100% (1)

- Fluid 08Document159 pagesFluid 08Marco MeraNo ratings yet

- FLUID MECHANICS: VISCOUS PIPE FLOWDocument61 pagesFLUID MECHANICS: VISCOUS PIPE FLOWking4lifeNo ratings yet

- Sistem Instalasi MekanikalDocument156 pagesSistem Instalasi MekanikalDharmestha DewantoroNo ratings yet

- Open Channel Flows - Fluid MechanicsDocument47 pagesOpen Channel Flows - Fluid Mechanicsnaeema_58No ratings yet

- Pipe Flow: 1 Basic PrinciplesDocument6 pagesPipe Flow: 1 Basic PrinciplesadityaNo ratings yet

- Topic T2: Flow in Pipes and Channels AUTUMN 2013Document30 pagesTopic T2: Flow in Pipes and Channels AUTUMN 2013Bernard PalmerNo ratings yet

- Cornish MethodDocument30 pagesCornish MethodEverlasting MemoriesNo ratings yet

- Fluid Mechanics - Module 4 - Part1Document10 pagesFluid Mechanics - Module 4 - Part1Sk Jahidul IslamNo ratings yet

- Cve341lecturenotes1 220921133246 9aa9c294Document61 pagesCve341lecturenotes1 220921133246 9aa9c294Krishna P. YadavNo ratings yet

- Chapt4 Edited RBMDocument130 pagesChapt4 Edited RBMIfa IsmailNo ratings yet

- 13 - Fluids at Rest and Piped FluidsDocument7 pages13 - Fluids at Rest and Piped FluidsVinay GuptaNo ratings yet

- Finite Volume For Dam BreakDocument4 pagesFinite Volume For Dam BreakArnasli YahyaNo ratings yet

- Milestones Achieved: Viscous Flow in Pipes ??Document74 pagesMilestones Achieved: Viscous Flow in Pipes ??Portia ShilengeNo ratings yet

- Fluid Mechanics Assignment Topic: - Laminar and Turbulent Flow Through Pipes:stress and Velocity DistributionDocument9 pagesFluid Mechanics Assignment Topic: - Laminar and Turbulent Flow Through Pipes:stress and Velocity DistributionJatin kuharNo ratings yet

- Flow in Circular Pipes: ObjectiveDocument35 pagesFlow in Circular Pipes: ObjectivemamunruetNo ratings yet

- Chapter 1Document199 pagesChapter 1Mohd Syafiq AkmalNo ratings yet

- Other 04042022222516671Document8 pagesOther 04042022222516671Yasin EgeNo ratings yet

- Chen 2610 Faculty CH 7 ADocument17 pagesChen 2610 Faculty CH 7 ASwamy RakeshNo ratings yet

- Lecture-Notes: Part 2: Non-Dimensionalization, Buckingham-Pi Theorem, Boundary Layer, Flow MetersDocument72 pagesLecture-Notes: Part 2: Non-Dimensionalization, Buckingham-Pi Theorem, Boundary Layer, Flow MetersAbhishek ChauhanNo ratings yet

- Viscous Flow in Pipes: Internal Flow External FlowDocument9 pagesViscous Flow in Pipes: Internal Flow External FlowShanzib Sadhukhan ShubhoNo ratings yet

- 8b. Multiple Particles & Porous MediaDocument6 pages8b. Multiple Particles & Porous MediaLiuShangMingNo ratings yet

- Unit-6 Flow Through PipesDocument54 pagesUnit-6 Flow Through PipesS PrathebaNo ratings yet

- Lec 2-Pipe Flow TheoriesDocument64 pagesLec 2-Pipe Flow Theoriesjunaid205569No ratings yet

- 20AE30019 Exp7Document13 pages20AE30019 Exp7Ritik MishraNo ratings yet

- CH 9 Flow Over Immersed BodiesDocument165 pagesCH 9 Flow Over Immersed BodiesMujtaba Rizvi67% (3)

- Soil Mechanics Seepage Theory (ENG2001MDocument17 pagesSoil Mechanics Seepage Theory (ENG2001MlkhdasouNo ratings yet

- Department of Mechanical Engineering: Seacom Skills UniversityDocument40 pagesDepartment of Mechanical Engineering: Seacom Skills UniversitykadamsnNo ratings yet

- Student Handout 20 2014Document20 pagesStudent Handout 20 2014kietniNo ratings yet

- Chapter 2: Turbulent Flow in Pipes Characteristics of Turbulent Flow in PipesDocument27 pagesChapter 2: Turbulent Flow in Pipes Characteristics of Turbulent Flow in PipesNigel Joseph KabigtingNo ratings yet

- Pipe FlowDocument25 pagesPipe Flowdlot22No ratings yet

- Air-Condtioning: Course No. ME40107Document34 pagesAir-Condtioning: Course No. ME40107bhalchandrapatilNo ratings yet

- Guide 1 (19.10.2022)Document5 pagesGuide 1 (19.10.2022)Iyad AboissaNo ratings yet

- MAE 3130: Fluid Mechanics Lecture 10: Internal and External Flows Spring 2003Document36 pagesMAE 3130: Fluid Mechanics Lecture 10: Internal and External Flows Spring 2003Kiki Putri SisvianaNo ratings yet

- Flow in Pipes Faculty - Washington.eduDocument18 pagesFlow in Pipes Faculty - Washington.eduils411No ratings yet

- REE 307 Fluid Mechanics II: Sep 27, 2017 DR./ Ahmed Mohamed Nagib Elmekawy Zewail City For Science and TechnologyDocument48 pagesREE 307 Fluid Mechanics II: Sep 27, 2017 DR./ Ahmed Mohamed Nagib Elmekawy Zewail City For Science and TechnologyAhmed AhmedNo ratings yet

- Jayam College of Engineering & Technology Fluid Mechanics & Machinery Me1202Document17 pagesJayam College of Engineering & Technology Fluid Mechanics & Machinery Me1202Muthuvel MNo ratings yet

- Boundary layer friction drag forcesDocument15 pagesBoundary layer friction drag forcesAnonymous ncBe0B9bNo ratings yet

- Department of Mechanical Engineering: Seacom Skills UniversityDocument40 pagesDepartment of Mechanical Engineering: Seacom Skills UniversityShubham MahajanNo ratings yet

- Experiment No.1 FLOW THROUGH PIPES Background TheoryDocument8 pagesExperiment No.1 FLOW THROUGH PIPES Background TheoryMradul YadavNo ratings yet

- Hydraulics - Chapter 3Document8 pagesHydraulics - Chapter 3thuaiyaalhinaiNo ratings yet

- Internal FlowDocument41 pagesInternal FlowTusanita MapuolaNo ratings yet

- FM-2 Lecture 2 AND 3Document32 pagesFM-2 Lecture 2 AND 3SalmanNo ratings yet

- Convection ProcessDocument162 pagesConvection ProcessMuzammil AzaiauddinNo ratings yet

- Fluid Mechanics II Pipe Flow Head Loss and Pressure DropDocument29 pagesFluid Mechanics II Pipe Flow Head Loss and Pressure DropAmmar WahabNo ratings yet

- Question One: EZRA AHUMUZA AEBD 2004/HD16/2447UDocument31 pagesQuestion One: EZRA AHUMUZA AEBD 2004/HD16/2447UEzra AhumuzaNo ratings yet

- Friction IntroDocument13 pagesFriction IntroblozzerNo ratings yet

- Quasi-Two-Dimensional MHD Duct Flow Around A 180-Degree Sharp Bend in A Strong Magnetic FieldDocument4 pagesQuasi-Two-Dimensional MHD Duct Flow Around A 180-Degree Sharp Bend in A Strong Magnetic Fieldkoushikthephoenix1No ratings yet

- One-Dimensional Compressible Flow: Thermodynamics and Fluid Mechanics SeriesFrom EverandOne-Dimensional Compressible Flow: Thermodynamics and Fluid Mechanics SeriesNo ratings yet

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1Rating: 4.5 out of 5 stars4.5/5 (5)

- Compressible Flow EquationsDocument19 pagesCompressible Flow EquationskietniNo ratings yet

- Petroleum Production Economics Course SyllabusDocument2 pagesPetroleum Production Economics Course SyllabuskietniNo ratings yet

- AADE 2014 TC STUDENT Registration Form CompleteDocument1 pageAADE 2014 TC STUDENT Registration Form CompletekietniNo ratings yet

- Itough2 - Gslib Users GuideDocument43 pagesItough2 - Gslib Users GuidekietniNo ratings yet

- External Incompressible Flow Over BodiesDocument22 pagesExternal Incompressible Flow Over BodieskietniNo ratings yet

- Student Handout 23 2014Document19 pagesStudent Handout 23 2014kietniNo ratings yet

- Student Handout 26 2014Document19 pagesStudent Handout 26 2014kietniNo ratings yet

- Student Handout 25 2014Document9 pagesStudent Handout 25 2014kietniNo ratings yet

- Student Handout 14 2014Document18 pagesStudent Handout 14 2014kietniNo ratings yet

- Student Handout 22 2013Document11 pagesStudent Handout 22 2013kietniNo ratings yet

- Student Handout 19 2014Document21 pagesStudent Handout 19 2014kietniNo ratings yet

- Student Handout 18 2014Document19 pagesStudent Handout 18 2014kietniNo ratings yet

- Student Handout 20 2014Document20 pagesStudent Handout 20 2014kietniNo ratings yet

- Student Handout 17 2014Document22 pagesStudent Handout 17 2014kietniNo ratings yet

- Student Handout 16 2014Document14 pagesStudent Handout 16 2014kietniNo ratings yet

- Student Handout 15 2014Document12 pagesStudent Handout 15 2014kietniNo ratings yet

- Student Handout 07 2014Document18 pagesStudent Handout 07 2014kietniNo ratings yet

- Student Handout 12 2014Document15 pagesStudent Handout 12 2014kietniNo ratings yet

- Macroscopic Energy Balance HandoutDocument15 pagesMacroscopic Energy Balance HandoutkietniNo ratings yet

- Student Handout 13 2014Document19 pagesStudent Handout 13 2014kietniNo ratings yet

- Student Handout 11 2014Document12 pagesStudent Handout 11 2014kietniNo ratings yet

- Student Handout 08 2014Document16 pagesStudent Handout 08 2014kietniNo ratings yet

- Student Handout 09 2014Document16 pagesStudent Handout 09 2014kietniNo ratings yet

- Student Handout 06 2014Document21 pagesStudent Handout 06 2014kietniNo ratings yet

- Fluid statics I: Applying hydrostatics to manometers and gasesDocument17 pagesFluid statics I: Applying hydrostatics to manometers and gaseskietniNo ratings yet

- Student Handout 07a 2014Document3 pagesStudent Handout 07a 2014kietniNo ratings yet

- Student Handout 04 2013Document11 pagesStudent Handout 04 2013kietniNo ratings yet

- Student Handout 02 2014Document24 pagesStudent Handout 02 2014kietniNo ratings yet

- Student Handout 03 2014Document7 pagesStudent Handout 03 2014kietniNo ratings yet