Professional Documents

Culture Documents

Student Handout 20 2014

Uploaded by

kietniOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Student Handout 20 2014

Uploaded by

kietniCopyright:

Available Formats

Incompressible viscous fow 2:

fow in ducts

CHEE 3363

Spring 2014

Handout 20

Reading: Fox, 8.6--8.8

1

Learning objectives for lecture

1. Describe phenomenology of turbulent fows.

2. Calculate major and minor head losses.

3. Apply conservation of energy to calculate head loss, pressure

drop, and fow rates in pipe systems.

2

turb

0

Turbulence 1

Reynolds stress: reduction in velocity gradient due to randomly fuctuating

velocity components u and v

As wall is approached: and = 0 at wall

wall layer: viscous shear is dominant

elsewhere: both viscous and turbulent shear are important

where u, v are fuctuating velocity components in the x and y

directions that transfer momentum between adjacent layers of fuid.

No universaI reIationship between stress and mean veIocity eIds.

1. Estimating stresses in turbulent fows:

3

Turbulence 2

4

Defect law:

At greater distances:

velocity defect (hence shape near

centerline) only function of distance

ratio, not fuid viscosity

Near the wall (viscous sublayer):

2. Velocity profles in turbulent fows:

Divide stress equation by density:

Friction velocity:

(Recall: = /

kinematic viscosity)

Turbulence 3

Power-law equation for fully-developed turbulent fows in smooth pipes:

with

Ratio of average velocity to centerline velocity U:

3. Approximating turbulent fow in smooth pipes:

5

Energy considerations 1

Q

W

s

W

shear

W

other

=

CV

e dV +

CS

(u + pv +

v

2

2

+ gz)v dA

Assumptions:

1.Rate of work terms = 0

2.Steady fow

3.Incompressible fow

4.Internal energy and pressure are uniform across relevant pipe sections

For fow in a pipe from section 1 to section 2:

6

Energy considerations 2

7

A

v

2

2

v dA =

A

v

2

2

v dA = m

v

2

2

Defne: kinetic energy coeffcient s.t.:

Laminar fow:

Turbulent fow (using power-law):

Energy considerations 3

Rearrange:

Divide by g (historical, to get units of energy / unit weight):

head (units: length)

8

Divide by mass fow rate:

1

v

2

1

2

=

2

v

2

2

2

Calculation of head loss 1

Major losses:

Fully developed fow through constant-area pipe, h

lm

= 0, and

Laminar fow:

9

Calculation of head loss 2

10

Turbulent fow:

f: friction factor (determined experimentally)

NB:

(general, from dimensional

analysis, any Re)

Turbulent approximations:

Calculation of head losses 3

Minor losses:

Compute in two ways:

where K = loss coeffcient must be determined via

experiment for each situation

1.

2. where L

e

= equivalent length of straight pipe

K varies with pipe size similarly to f

11

Solution of pipe fow problems

For any two points 1 and 2 in a single-path pipe system:

Major losses: where f is the friction factor:

- Laminar fow:

- Turbulent fow:

Minor losses:

- Given the device loss coeffcient K:

- Given the equivalent length of pipe L

e

:

h

l

= f

L

D

V

2

2

f =

64

Re

1

f

= 2.0 log

e/D

3.7

+

2.51

Re

h

l

m

= K

V

2

2

h

l

m

= f

L

e

D

V

2

2

p

1

+

1

V

2

1

2

+gz

1

p

2

+

2

V

2

2

2

+gz

2

= h

l

T

=

h

l

+

h

l

m

12

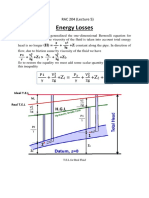

Example 1: calculating head, loss 1

Given: Water pumped at rate Q = 0.075 m

3

/s

from reservoir 20 m above pump to free

discharge 35 m above pump. Pressure on

intake p

2

, pressure on discharge p

3

; pipes are

commercial steel, D = 15 cm.

Determine:

(a) head supplied by pump

(b) total head loss between pump and point of free

discharge

Assumptions:

1.

2.

3.

4.

Head from pump from (2) to (3):

13

Example 1: calculating head, loss 2

Head loss from (3) to (4):

Head loss from (3) to (4) evaluated:

Then for pump:

(exercise: plug in numbers to get value)

(exercise: plug in numbers to get value)

14

Example 2: calculating p 1

Given: Water fows through sudden enlargement from 25 mm to 50 mm, at

a fow rate Q = 1.25 L/min.

Determine:

(a) pressure rise across enlargement

(b) comparison with value for frictionless fow

Assumptions:

1.

2.

3.

4.

Energy equation:

Head loss:

15

K = 0.56

Example 2: calculating p 2

Continuity:

For an area loss of 1/4, Figure 8.14 in Fox gives:

Obtain velocity from fow rate:

Combining all information:

(exercise: plug in numbers to get value)

16

Energy equation becomes:

Example 2: calculating p 3

Frictionless fow:

(exercise: plug in numbers to get value, calculate ratio)

17

Example 3: iteration procedure 1

Given: Water fows through 4-in. diameter pipe. Over 300 ft length,

pressure drop of 40 psi. Pipe roughness is 0.01 ft, water temperature 68F.

Determine: fow rate

Energy equation:

Assumptions:

1.

2.

3.

4.

(eq. 1)

18

Example 3: iteration procedure 2

19

In addition:

(recall: = kinematic viscosity = / )

Kinematic viscosity at 68F can be determined from a table (e.g. A.7 in Fox)

= 1.08 10

5

ft

2

s

Equation for frictional factor:

Assume fow is turbulent (will confrm with values):

(eq. 3)

From table:

(eq. 2)

Example 3: iteration procedure (2/2)

Equations 1, 2, 3 form a series of 3 equations for the unknowns f, V, Re

To solve:

1.

2.

3.

4.

(Exercise!)

Finally:

20

You might also like

- Experiment 1 - Friction Losses in PipesDocument34 pagesExperiment 1 - Friction Losses in PipesKhairil Ikram33% (3)

- Other 04042022222516671Document8 pagesOther 04042022222516671Yasin EgeNo ratings yet

- Engineering Hydraulics/Pipeline CalculationsDocument29 pagesEngineering Hydraulics/Pipeline Calculationsbasher rajabNo ratings yet

- Expt 1 - Friction Loses in PipesDocument20 pagesExpt 1 - Friction Loses in PipesFauzi Helmi67% (6)

- 13 - Fluids at Rest and Piped FluidsDocument7 pages13 - Fluids at Rest and Piped FluidsVinay GuptaNo ratings yet

- Experiment 1 - Friction Losses in Pipes-ReportDocument41 pagesExperiment 1 - Friction Losses in Pipes-ReportKhairil Ikram69% (52)

- Ch8 Steady Incompressible Flow in Pressure Conduits (PartB)Document66 pagesCh8 Steady Incompressible Flow in Pressure Conduits (PartB)avinash_friends21No ratings yet

- Experiment 1 - Friction Losses in Pipes-ReportDocument41 pagesExperiment 1 - Friction Losses in Pipes-ReportKhairil Ikram67% (3)

- Cive1400 200203Document7 pagesCive1400 200203naefmubarakNo ratings yet

- Indo 1Document29 pagesIndo 1Michael TinambunanNo ratings yet

- 10 Analysis of Pipe Flows: The Moody ChartDocument8 pages10 Analysis of Pipe Flows: The Moody ChartMiguel Angel Alvarez BoreaNo ratings yet

- Momentum EquationDocument43 pagesMomentum Equationnsbaruaole100% (3)

- 4th Sem - Mech Engg - Fluid Mechanics-P-1Document29 pages4th Sem - Mech Engg - Fluid Mechanics-P-1Narinder SharmaNo ratings yet

- Hydraulics - Chapter 3Document8 pagesHydraulics - Chapter 3thuaiyaalhinaiNo ratings yet

- Flow Through PipesDocument29 pagesFlow Through PipesMichael TinambunanNo ratings yet

- Energy Conservation Explained in 40 CharactersDocument17 pagesEnergy Conservation Explained in 40 Charactersozgurturunc4No ratings yet

- Lecture 5 2Document15 pagesLecture 5 2IbrahimDewaliNo ratings yet

- Pressure Losses in Pipe Network Name: University: CodeDocument7 pagesPressure Losses in Pipe Network Name: University: CodeshagsNo ratings yet

- Oana Tatiana Nedelcu, Victor Moagar-PoladianDocument4 pagesOana Tatiana Nedelcu, Victor Moagar-PoladianChandra SekarNo ratings yet

- Fluids - IIIDocument29 pagesFluids - IIINitin GandhareNo ratings yet

- GR 3Document28 pagesGR 3Dale BelchesNo ratings yet

- Review Notes on Pipes and HydraulicsDocument15 pagesReview Notes on Pipes and HydraulicsMelvin EsguerraNo ratings yet

- PlumbingDocument16 pagesPlumbingMelvin EsguerraNo ratings yet

- Pipe Flow: 1 Basic PrinciplesDocument6 pagesPipe Flow: 1 Basic PrinciplesadityaNo ratings yet

- Open Ended Full Report CEWB121Document18 pagesOpen Ended Full Report CEWB121Nur FarehaNo ratings yet

- Week 8 10 Hydraulic Structures Part I WEIRSDocument50 pagesWeek 8 10 Hydraulic Structures Part I WEIRSgeorgedytrasNo ratings yet

- Viscous Flow in Pipes: OverviewDocument40 pagesViscous Flow in Pipes: OverviewPaulo BuenoNo ratings yet

- EI6603 - Industrial - Instrumentation - II - University - QP - Answer - KeyDocument16 pagesEI6603 - Industrial - Instrumentation - II - University - QP - Answer - KeyMadhusudhanan Ramaiah100% (1)

- Topic 4c Minor Losses Turbulent Flow in Circular Pipes 2021Document23 pagesTopic 4c Minor Losses Turbulent Flow in Circular Pipes 2021Nor SyamimiNo ratings yet

- Chapter-12 PumpDocument39 pagesChapter-12 PumpSalehin AnamNo ratings yet

- Fluids - IIIDocument9 pagesFluids - IIIPOONAM RANINo ratings yet

- PS9Soln 2014Document13 pagesPS9Soln 2014Eddz Del Rosario RodriguezNo ratings yet

- Practical flow experimentsDocument14 pagesPractical flow experimentsEngr Muhammad Asif JavaidNo ratings yet

- Fluid Mechanics Test and Exam DetailsDocument8 pagesFluid Mechanics Test and Exam DetailsDiego FungNo ratings yet

- Topic T2: Flow in Pipes and Channels AUTUMN 2013Document30 pagesTopic T2: Flow in Pipes and Channels AUTUMN 2013Bernard PalmerNo ratings yet

- Convection SummaryDocument10 pagesConvection SummarycacafaruqNo ratings yet

- Fluid Flow Piping SystemsDocument15 pagesFluid Flow Piping SystemsJack SantosNo ratings yet

- CEWB1021 Exp 5Document18 pagesCEWB1021 Exp 5alolqigoNo ratings yet

- Piping SystemsDocument6 pagesPiping SystemsThomas LiewNo ratings yet

- T 2Document31 pagesT 2Vinay Gupta100% (1)

- Elementary Mechanics of Fluids ExplainedDocument23 pagesElementary Mechanics of Fluids ExplainedAndre Amba MatarruNo ratings yet

- Am 1198281647Document5 pagesAm 1198281647Abdo ShairNo ratings yet

- Fluids - IvDocument29 pagesFluids - IvSam SawyerNo ratings yet

- Solved Problem 04Document8 pagesSolved Problem 04Abdullah SimpsonNo ratings yet

- Faculty of Engineering & Technology Mechanical Engineering Lab Report Fluid MechanicsDocument11 pagesFaculty of Engineering & Technology Mechanical Engineering Lab Report Fluid MechanicsTan YikcongNo ratings yet

- Cornish MethodDocument30 pagesCornish MethodEverlasting MemoriesNo ratings yet

- HW Set 1Document6 pagesHW Set 1GsusKrystNo ratings yet

- Viscous Diss Tern in Energy EquationsDocument14 pagesViscous Diss Tern in Energy EquationsJohn Jonnalagadda100% (1)

- Experiment 8Document9 pagesExperiment 8Nor FhairnaNo ratings yet

- E4 Lab Sheet Minor Losses in PipeDocument17 pagesE4 Lab Sheet Minor Losses in PipeHoongNo ratings yet

- Backup of Flowloss - CSDocument6 pagesBackup of Flowloss - CSSri E.Maheswar Reddy Assistant ProfessorNo ratings yet

- CHE 45 - A: Chemical Engineering Design 1: Recomputed Example Problem 5.8 in SinnotDocument7 pagesCHE 45 - A: Chemical Engineering Design 1: Recomputed Example Problem 5.8 in SinnotDarnell HendersonNo ratings yet

- Feynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterFrom EverandFeynman Lectures Simplified 2C: Electromagnetism: in Relativity & in Dense MatterNo ratings yet

- Modern Electrical Installation for Craft StudentsFrom EverandModern Electrical Installation for Craft StudentsRating: 4.5 out of 5 stars4.5/5 (4)

- Electronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1From EverandElectronic Devices and Circuits: The Commonwealth and International Library: Electrical Engineering Division, Volume 1No ratings yet

- Strength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresFrom EverandStrength of Materials and Structures: An Introduction to the Mechanics of Solids and StructuresRating: 4 out of 5 stars4/5 (1)

- Electronic Devices and Circuits: In Three VolumesFrom EverandElectronic Devices and Circuits: In Three VolumesRating: 3.5 out of 5 stars3.5/5 (2)

- Petroleum Production Economics Course SyllabusDocument2 pagesPetroleum Production Economics Course SyllabuskietniNo ratings yet

- Compressible Flow EquationsDocument19 pagesCompressible Flow EquationskietniNo ratings yet

- AADE 2014 TC STUDENT Registration Form CompleteDocument1 pageAADE 2014 TC STUDENT Registration Form CompletekietniNo ratings yet

- Tutorial Software SGeMSDocument26 pagesTutorial Software SGeMSEdi Setiawan100% (3)

- Student Handout 25 2014Document9 pagesStudent Handout 25 2014kietniNo ratings yet

- Student Handout 19 2014Document21 pagesStudent Handout 19 2014kietniNo ratings yet

- Student Handout 23 2014Document19 pagesStudent Handout 23 2014kietniNo ratings yet

- External Incompressible Flow Over BodiesDocument22 pagesExternal Incompressible Flow Over BodieskietniNo ratings yet

- Itough2 - Gslib Users GuideDocument43 pagesItough2 - Gslib Users GuidekietniNo ratings yet

- Student Handout 20 2014Document20 pagesStudent Handout 20 2014kietniNo ratings yet

- Student Handout 26 2014Document19 pagesStudent Handout 26 2014kietniNo ratings yet

- Student Handout 22 2013Document11 pagesStudent Handout 22 2013kietniNo ratings yet

- Macroscopic Energy Balance HandoutDocument15 pagesMacroscopic Energy Balance HandoutkietniNo ratings yet

- Student Handout 16 2014Document14 pagesStudent Handout 16 2014kietniNo ratings yet

- Student Handout 17 2014Document22 pagesStudent Handout 17 2014kietniNo ratings yet

- Student Handout 11 2014Document12 pagesStudent Handout 11 2014kietniNo ratings yet

- Student Handout 18 2014Document19 pagesStudent Handout 18 2014kietniNo ratings yet

- Student Handout 12 2014Document15 pagesStudent Handout 12 2014kietniNo ratings yet

- Student Handout 15 2014Document12 pagesStudent Handout 15 2014kietniNo ratings yet

- Student Handout 14 2014Document18 pagesStudent Handout 14 2014kietniNo ratings yet

- Student Handout 13 2014Document19 pagesStudent Handout 13 2014kietniNo ratings yet

- Student Handout 09 2014Document16 pagesStudent Handout 09 2014kietniNo ratings yet

- Student Handout 07 2014Document18 pagesStudent Handout 07 2014kietniNo ratings yet

- Student Handout 08 2014Document16 pagesStudent Handout 08 2014kietniNo ratings yet

- Student Handout 07a 2014Document3 pagesStudent Handout 07a 2014kietniNo ratings yet

- Fluid statics I: Applying hydrostatics to manometers and gasesDocument17 pagesFluid statics I: Applying hydrostatics to manometers and gaseskietniNo ratings yet

- Student Handout 04 2013Document11 pagesStudent Handout 04 2013kietniNo ratings yet

- Student Handout 06 2014Document21 pagesStudent Handout 06 2014kietniNo ratings yet

- Student Handout 02 2014Document24 pagesStudent Handout 02 2014kietniNo ratings yet

- Student Handout 03 2014Document7 pagesStudent Handout 03 2014kietniNo ratings yet