Professional Documents

Culture Documents

Corn Starch and Pregelatinized Starch

Uploaded by

Sagita WidiyastutiOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

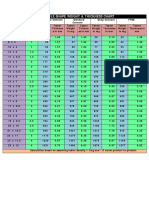

Report this DocumentCopyright:

Available Formats

Corn Starch and Pregelatinized Starch

Uploaded by

Sagita WidiyastutiCopyright:

Available Formats

Corn Starch and Pregelatinized Starch 1 Nonproprietary Names None adopted. 2 Synonyms StarCap 1500.

3 Chemical Name and CAS Registry Number See Section 8. 4 Empirical Formula and Molecular Weight See Section 8. 5 Structural Formula See Section 8. 6 Functional Category Binding agent; compression aid; disintegrant; tablet and capsule diluent; tablet and capsule filler. 7 Applications in Pharmaceutical Formulation or Technology Corn starch and pregelatinized starch can be used in both capsules and tablets to improve flowability, enhance disintegration and improve hardness. 8 Description Corn starch and pregelatinized starch occurs as a white free-flowing powder. It is a coprocessed mixture of predominantly corn starch together with pregelatinized starch. 9 Pharmacopeial Specifications Both corn starch and pregelatinized starch are listed as separate monographs in the JP, PhEur, and USPNF, but the combination is not listed. See Starch, and Starch, Pregelatinized. See also Section 18. 10 Typical Properties Acidity/alkalinity 4.57.0 for StarCap 1500 Iron 40.001% for StarCap 1500 Loss on drying 713% for StarCap 1500 Microbial content Total aerobes count 4100 cfu/g; molds and yeasts 4100 cfu/g (Escherichia coli, Pseudomonas aeruginosa, and Salmonella species absent) for StarCap 1500. Particle size distribution 942% retained on #120 mesh (125 m), 2550% retained on #200 mesh (74 mm), 2055% passing #200 mesh (74 mm) for StarCap 1500 Solubility Insoluble in water for StarCap 1500 Sulfur dioxide 40.005% for StarCap 1500 11 Stability and Storage Conditions Store in sealed containers at below 308C, avoiding high humidity. 12 Incompatibilities See Starch, and Starch, Pregelatinized. 13 Method of Manufacture Corn starch and pregelatinized starch is produced by a proprietary

spray-drying technique. 14 Safety See Starch, and Starch, Pregelatinized. 15 Handling Precautions Observe normal precautions appropriate to the circumstances and quantity of material handled. 16 Regulatory Status Corn starch and pregelatinized starch is a coprocessed mixture of two materials both of which are regarded as nontoxic: Starch GRAS listed. Included in the FDA Inactive Ingredients Database (buccal tablets, oral capsules, powders, suspensions and tablets; topical preparations; and vaginal tablets). Included in nonparenteral medicines licensed in the UK. Included in the Canadian List of Acceptable Non-medicinal Ingredients. Pregelatinized starch Included in the FDA Inactive Ingredients Database (oral capsules, suspensions, and tablets; vaginal preparations). Included in non-parenteral medicines licensed in the UK. 17 Related Substances Starch; starch, pregelatinized. 18 Comments Corn starch and pregelatinized starch are two of the materials that have been selected for harmonization by the Pharmacopeial Discussion Group. For further information see the General Information Chapter <1196> in the USP32NF27, the General Chapter 5.8 in PhEur 6.0, along with the State of Work document on the PhEur EDQM website, and also the General Information Chapter 8 in the JP XV. StarCap 1500 is a free-flowing, low-dust excipient with disintegration and dissolution properties independent of medium pH, which help promote deaggregation of the powder mass into primary drug particles and speeds up the dissolution rate of the drug substance, providing rapid disintegration across the pH range present in the human digestive tract.(13) The coprocessed product has been designed specifically for use in capsules and directly compressed tablets, and has enhanced physical properties that cannot be achieved by single blend. It has been reported as having excellent properties for high-dose, high-solubility capsule formulations, with low weight and good content uniformity.(1) The product acts as a compression aid, diluent, and disintegrant, which allows for robust but simple capsule and directly compressible tablet formulations. 19 Specific References 1 Colorcon. Technical datasheet, version 1: StarCap 1500. StarCap 1500 utilized in a direct-fill capsule formulation of a high dose/high solubility active drug gabapentin capsules 300 mg, August 2007. 2 Colorcon. Product information sheet, version 3: Why StarCap 1500 in

capsules? February 2006. 3 Colorcon. AAPS annual meeting and exposition poster reprint: Evaluation of StarCap 1500 in a propranolol hydrochloride capsule formulation, November 2005. 20 General References Colorcon. Product specification: StarCap 1500 co-processed starch, January 2007. Deorkar N. High-functionality excipients: a review. Tablets and Capsules 2008: 2226. http://www.tabletscapsules.com (accessed 3 March 2009). European Directorate for the Quality of Medicines and Healthcare (EDQM). European Pharmacopoeia State Of Work Of International Harmonisation. Pharmeuropa 2009; 21(1): 142143. http://www.edqm. eu/site/-614.html (accessed 3 February 2009). Gohel MC, Jogani PD. A review of co-processed directly compressible excipients. J Pharm Pharm Sci 2005; 8(1): 7693. Nachaegari SK, Bansal AK. Coprocessed excipients for solid dosage forms. Pharm Tech 2004; 28: 5264. 21 Authors ME Quinn, RC Rowe. 22 Date of Revision

Tragacanth 1 Nonproprietary Names BP: Tragacanth JP: Tragacanth PhEur: Tragacanth USP-NF: Tragacanth See also Section 18. 2 Synonyms E413; goats thorn; gum benjamin; gum dragon; gum tragacanth; persian tragacanth; trag; tragant; tragacantha. 3 Chemical Name and CAS Registry Number Tragacanth gum [9000-65-1] 4 Empirical Formula and Molecular Weight Tragacanth is a naturally occurring dried gum obtained from Astragalus gummifer Labillardie`re and other species of Astragalus grown in Western Asia; see Section 13. The gum consists of a mixture of water-insoluble and watersoluble polysaccharides. Bassorin, which constitutes 6070% of the gum, is the main water-insoluble portion, while the remainder of the gum consists of the water-soluble material tragacanthin. On hydrolysis, tragacanthin yields L-arabinose, L-fucose, D-xylose, Dgalactose, and D-galacturonic acid. Tragacanth gum also contains small amounts of cellulose, starch, protein, and ash. Tragacanth gum has an approximate molecular weight of

840 000. 5 Structural Formula See Section 4. 6 Functional Category Suspending agent; viscosity-increasing agent. 7 Applications in Pharmaceutical Formulation or Technology Tragacanth gum is used as an emulsifying and suspending agent in a variety of pharmaceutical formulations. It is used in creams, gels, and emulsions at various concentrations according to the application of the formulation and the grade of gum used. Tragacanth gum is also used similarly in cosmetics and food products, and has been used as a diluent in tablet formulations. 8 Description Tragacanth gum occurs as flattened, lamellated, frequently curved fragments, or as straight or spirally twisted linear pieces from 0.52.5mm in thickness; it may also be obtained in a powdered form. White to yellowish in color, tragacanth is a translucent, odorless substance, with an insipid mucilaginous taste. 9 Pharmacopeial Specifications See Table I. Table I: Pharmacopeial specifications for tragacanth. Test JP XV PhEur 6.3 USP32NF27 Identification Botanical characteristics Microbial limits Flow time Lead 40.001% Heavy metals 420 ppm Methylcellulose Acacia Foreign matter 41.0% Karaya gum Sterculia gum Ash 44.0% 44.0% 10 Typical Properties Acidity/alkalinity pH = 56 for a 1% w/v aqueous dispersion. Acid value 25 Moisture content 415% w/w NIR spectra see Figure 1. Particle size distribution For powdered grades 50% w/w passes through a 73.7 mm mesh. Solubility Practically insoluble in water, ethanol (95%), and other organic solvents. Although insoluble in water, tragacanth gum swells rapidly in 10 times its own weight of either hot or cold

water to produce viscous colloidal sols or semigels. See also Section 18. Specific gravity 1.2501.385 T 744 Tragacanth Viscosity (dynamic) The viscosity of tragacanth dispersions varies according to the grade and source of the material. Typically, 1% w/v aqueous dispersions may range in viscosity from 1004000 mPa s (1004000 cP) at 208C. Viscosity increases with increasing temperature and concentration, and decreases with increasing pH. Maximum initial viscosity occurs at pH 8, although the greatest stability of tragacanth dispersions occurs at about pH 5. See also Sections 11 and 12. 11 Stability and Storage Conditions Both the flaked and powdered forms of tragacanth are stable. Tragacanth gels are liable to exhibit microbial contamination with enterobacterial species, and stock solutions should therefore contain suitable antimicrobial preservatives. In emulsions, glycerin or propylene glycol are used as preservatives; in gel formulations, tragacanth is usually preserved with either 0.1% w/v benzoic acid or sodium benzoate. A combination of 0.17% w/v methylparaben and 0.03% w/v propylparaben is also an effective preservative for tragacanth gels;(1) see also Section 12. Gels may be sterilized by autoclaving. Sterilization by gamma irradiation causes a marked reduction in the viscosity of tragacanth dispersions.(2) Tragacanth dispersions are most stable at pH 48, although stability is satisfactory at higher pH or as low as pH 2. The bulk material should be stored in an airtight container in a cool, dry place. 12 Incompatibilities At pH 7, tragacanth has been reported to considerably reduce the efficacy of the antimicrobial preservatives benzalkonium chloride, chlorobutanol, and methylparaben, and to a lesser extent that of phenol and phenylmercuric acetate.(3) However, at pH < 5 tragacanth was reported to have no adverse effects on the preservative efficacy of benzoic acid, chlorobutanol, or methylparaben.( 1) The addition of strong mineral and organic acids can reduce the viscosity of tragacanth dispersions. Viscosity may also be reduced by the addition of alkali or sodium chloride, particularly if the dispersion is heated. Tragacanth is compatible with relatively high salt concentrations and most other natural and synthetic suspending agents such as acacia, carboxymethylcellulose, starch, and sucrose. Ayellow colored, stringy, precipitate is formed with 10% w/v ferric chloride solution. 13 Method of Manufacture Tragacanth gum is the air-dried gum obtained from Astragalus

gummifer Labillardie`re and other species of Astragalus grown principally in Iran, Syria, and Turkey. A low-quality gum is obtained by collecting the natural air-dried exudate from Astragalus bushes. A higher-grade material is obtained by making incisions in the trunk and branches of the bush, which are held open with variously sized wooden pegs. The exudate is left to drain from the incision and dry naturally in the air before being collected. The size and position of the wooden wedges determine the physical form of the exudate, while the drying conditions determine the color of the gum. After collection, the tragacanth gum is sorted by hand into various grades, such as ribbons or flakes. 14 Safety Tragacanth has been used for many years in oral pharmaceutical formulations and food products, and is generally regarded as an essentially nontoxic material. Tragacanth has been shown to be noncarcinogenic.(4) However, hypersensitivity reactions, which are occasionaly severe, have been reported following ingestion of products containing tragacanth.(5,6) Contact dermatitis has also been reported following the topical use of tragacanth formulations.( 7) The WHO has not specified an acceptable daily intake for tragacanth gum, as the daily intake necessary to achieve a desired effect, and its background levels in food, were not considered to be a hazard to health.(8) LD50 (hamster, oral): 8.8 g/kg(9) LD50 (mouse, oral): 10 g/kg LD50 (rabbit, oral): 7.2 g/kg LD50 (rat, oral): 16.4 g/kg 15 Handling Precautions Observe normal precautions appropriate to the circumstances and quantity of material handled. Tragacanth gum may be irritant to the skin and eyes. Eye protection, gloves, and a dust mask are recommended. 16 Regulatory Status GRAS listed. Accepted for use as a food additive in Europe. Included in the FDA Inactive Ingredients Database (buccal/ sublingual tablets, oral powders, suspensions, syrups, and tablets). Included in nonparenteral medicines licensed in the UK. Included in the Canadian List of Acceptable Non-medicinal Ingredients. 17 Related Substances See Section 18. 18 Comments Tragacanth gum is a naturally occurring material whose physical properties vary greatly according to the grade and source of the material. Samples can contain relatively high levels of bacterial contamination.(10,11) Hog gum (caramania gum), obtained from species of Prunus,

and sterculia gum have been used in industrial applications as substitutes for tragacanth. Powdered tragacanth gum tends to form lumps when added to water, and aqueous dispersions should therefore be agitated vigorously with a high-speed mixer. However, aqueous dispersions are more readily prepared by first prewetting the tragacanth with a small quantity of a wetting agent such as ethanol (95%), glycerin, or propylene glycol. If lumps form, they usually disperse on standing. Dispersion is generally complete after 1 hour. If other powders, such as sucrose, are to be incorporated into a tragacanth formulation the powders are best mixed together in the dry state. Some pharmacopeias, such as JP XV, contain a specification for powdered tragacanth. 5.0 0.0 6.0 10000 [2nd deriv. log(1/R) 0.5 1388 1166 1435 2246 2481 2365 2326 2222 2010 1886 2349 2261 1921 1721 log(1/R) 0.2 Wavelength/nm 1100 1300 1500 1700 1900 2100 2300 2500 Figure 1: Near-infrared spectrum of tragacanth measured by reflectance. T Tragacanth 745 19 Specific References 1 Taub A et al. Conditions for the preservation of gum tragacanth jellies. J Am Pharm Assoc (Sci) 1958; 47: 235239. 2 Jacobs GP, Simes R. The gamma irradiation of tragacanth: effect on microbial contamination and rheology. J Pharm Pharmacol 1979; 31: 333334. 3 Eisman PC et al. Influence of gum tragacanth on the bactericidal activity of preservatives. J Am Pharm Assoc (Sci) 1957; 46: 144147.

4 Hagiwara A et al. Lack of carcinogenicity of tragacanth gum in B6C3F1 mice. Food Chem Toxicol 1992; 30(8): 673679. 5 Danoff D et al. Big Mac attack [letter]. N Engl J Med 1978; 298: 1095 1096. 6 Rubinger D. Hypersensitivity to tablet additives in transplant recipients on prednisone [letter]. Lancet 1978; ii: 689. 7 Coskey RJ. Contact dermatitis caused by ECG electrode jelly. Arch Dermatol 1977; 113: 839840. 8 FAO/WHO. Evaluation of certain food additives and contaminants. Twenty-ninth report of the joint FAO/WHO expert committee on food additives. World Health Organ Tech Rep Ser 1986; No. 733. 9 Lewis RJ, ed. Saxs Dangerous Properties of Industrial Materials, 11th edn. New York: Wiley, 2004; 3500. 10 Westwood N. Microbial contamination of some pharmaceutical raw materials. Pharm J 1971; 207: 99102. 11 De La Rosa MC et al. Microbiological quality of pharmaceutical raw materials. Pharm Acta Helv 1995; 70: 227232. 20 General References Fairbairn JW. The presence of peroxidases in tragacanth [letter]. J Pharm Pharmacol 1967; 19: 191. Verbeken D et al. Exudate gums: occurence, production, and applications. Appl Microbiol Biotechnol 2003; 63(1): 1021. 21 Author PJ Weller. 22 Date of Revision 12 January 2009.

You might also like

- FDA CFR Title 21 Cleaning Equipment RulesDocument2 pagesFDA CFR Title 21 Cleaning Equipment RulesAlokNo ratings yet

- Capsule & Tablet Size ChartDocument1 pageCapsule & Tablet Size ChartMahesh Patil KahatulNo ratings yet

- Capsugel DBcaps Sizing Information 1Document1 pageCapsugel DBcaps Sizing Information 1luismanolo09No ratings yet

- CPR-18 - Ed 2010 IIDocument4 pagesCPR-18 - Ed 2010 IIMin Min ZawNo ratings yet

- Kasus-Film Coated TabletsDocument25 pagesKasus-Film Coated TabletsCitra Ariani EdityaningrumNo ratings yet

- Dissolution - DisintegrationDocument10 pagesDissolution - DisintegrationKathryn Faith Malabag100% (1)

- GS Coating Equipment enDocument8 pagesGS Coating Equipment enAkber LakhaniNo ratings yet

- Capsugel ConiSnap Sizing Information 2Document2 pagesCapsugel ConiSnap Sizing Information 2CRD NEOMEDICNo ratings yet

- Carrs Index Hausner RatioDocument1 pageCarrs Index Hausner Ratiopharmashri5399No ratings yet

- STP Montelukast Sa.Document6 pagesSTP Montelukast Sa.ShagorShagor100% (1)

- Eskag Pharma Pvt. LTD., Haridwar, Unit-I Department: Quality Assurance Product MatrixDocument20 pagesEskag Pharma Pvt. LTD., Haridwar, Unit-I Department: Quality Assurance Product MatrixMohit ChauhanNo ratings yet

- Standard Operating Procedure Department: ProductionDocument2 pagesStandard Operating Procedure Department: Productionasit_mNo ratings yet

- Sanet - ST - Formulation Science and Technology Vol 3Document364 pagesSanet - ST - Formulation Science and Technology Vol 3palkybd100% (1)

- Abstract Book JCDMCOP FinalDocument173 pagesAbstract Book JCDMCOP FinalKapil SoniNo ratings yet

- Formulation of Topical Products With Antiviral and AntibacterialDocument114 pagesFormulation of Topical Products With Antiviral and AntibacterialMuhammad Masoom AkhtarNo ratings yet

- Echnology AND Nowledge Ransfer: K S I MDocument9 pagesEchnology AND Nowledge Ransfer: K S I Mvijayns_250355172No ratings yet

- Legacy 6100Document6 pagesLegacy 6100Shameem P0% (1)

- SOP For Password For Computers and Software in PharmaceuticalDocument4 pagesSOP For Password For Computers and Software in PharmaceuticalMubarak PatelNo ratings yet

- Visitors And Supervision Corridor Pharmaceutical Process AreasDocument1 pageVisitors And Supervision Corridor Pharmaceutical Process AreasBilal AbbasNo ratings yet

- CTD Checklist DummyDocument1 pageCTD Checklist Dummydaizhussain004No ratings yet

- Capsule Filling Guide Answers Common QuestionsDocument5 pagesCapsule Filling Guide Answers Common Questionsluismanolo09No ratings yet

- Liquid Dosage FormDocument29 pagesLiquid Dosage FormALIMAH MOSARWANo ratings yet

- 704-Aloe Vera After Sun GelDocument1 page704-Aloe Vera After Sun Gelnancy seijasNo ratings yet

- Tablet Coating ExperimentDocument4 pagesTablet Coating ExperimentShivraj JadhavNo ratings yet

- Price Book PDFDocument193 pagesPrice Book PDFaasma100% (1)

- Wet Granulation Resolves Tablet Reformulation Challenges PDFDocument5 pagesWet Granulation Resolves Tablet Reformulation Challenges PDFAlejandro RestrepoNo ratings yet

- WHO Certificate E120 2019Document4 pagesWHO Certificate E120 2019Risen ChemicalsNo ratings yet

- Report On CompressionDocument23 pagesReport On CompressionKusum Shrestha100% (1)

- WHO CSDT SampleDocument120 pagesWHO CSDT SampleYen-Yee Lim JacqNo ratings yet

- Vivapur MCGDocument8 pagesVivapur MCGZochabeht MartinezNo ratings yet

- Article Tabletting Resolving Tablet DefectsDocument5 pagesArticle Tabletting Resolving Tablet DefectsTueNo ratings yet

- CPV - Option 2Document23 pagesCPV - Option 2DiemTrinhNguyenThienNo ratings yet

- Amlodipine and Celecoxib Tablets PDFDocument38 pagesAmlodipine and Celecoxib Tablets PDFNarongchai PongpanNo ratings yet

- After Sun With Insect Repellent PDFDocument1 pageAfter Sun With Insect Repellent PDFnancy seijasNo ratings yet

- Pharmaceutical Development PDFDocument2 pagesPharmaceutical Development PDFibraheem aboyadak100% (1)

- Florfenicol Oral Solution RecipeDocument7 pagesFlorfenicol Oral Solution RecipeBejoy KarimNo ratings yet

- 202727orig1s000 Lanzoprazole 15Document164 pages202727orig1s000 Lanzoprazole 15giovanni zegarraNo ratings yet

- Analysis of The Tablet Coating ProcessDocument17 pagesAnalysis of The Tablet Coating Processشروق سعد الدينNo ratings yet

- Preformulation MaterialDocument10 pagesPreformulation MaterialRajesh NayakNo ratings yet

- Material Management, Planning of Production, Batch RecordDocument39 pagesMaterial Management, Planning of Production, Batch RecordShaban DanishNo ratings yet

- Role of Excipients in Moisture Sorption andDocument64 pagesRole of Excipients in Moisture Sorption andgeoaislaNo ratings yet

- Microemulsion Process For The Preparation of Sucrose Esters Osipow1967Document3 pagesMicroemulsion Process For The Preparation of Sucrose Esters Osipow1967Alfonso Dominguez GonzalezNo ratings yet

- SOP For HPLC Shimadzu LabSolutionsDocument6 pagesSOP For HPLC Shimadzu LabSolutionsfawaz khalilNo ratings yet

- Capsicum Oleoresin Sr. No 10Document63 pagesCapsicum Oleoresin Sr. No 10Arnold RafiqNo ratings yet

- Ibm ProjectDocument12 pagesIbm ProjectEr Chakshu Goyal0% (1)

- Applying QBD Principles For The Development of A Pharmaceutical Dosage FormDocument31 pagesApplying QBD Principles For The Development of A Pharmaceutical Dosage FormSneha KaduNo ratings yet

- MCC GradeDocument14 pagesMCC GradeAnonymous IVUj0uiNo ratings yet

- IP Reference Standard CatalogDocument12 pagesIP Reference Standard CatalogUrva VasavadaNo ratings yet

- Dissolution MethodsDocument59 pagesDissolution MethodsShiraz KhanNo ratings yet

- Eneric: G G D DDocument75 pagesEneric: G G D Dlalooprasad15No ratings yet

- Asiklovir tablet product profileDocument16 pagesAsiklovir tablet product profileAnita RuliyaniNo ratings yet

- Quality by Design Process Analytical Technology: (QBD) & (PAT)Document45 pagesQuality by Design Process Analytical Technology: (QBD) & (PAT)Sharon DsouzaNo ratings yet

- Patented Technology in Soft Gelatin Capsule A ReviewDocument16 pagesPatented Technology in Soft Gelatin Capsule A ReviewFatimahAhmat100% (1)

- Extruder Spheronizer PDFDocument2 pagesExtruder Spheronizer PDFKevinNo ratings yet

- Formulation and DevelopmentDocument38 pagesFormulation and Developmentapi-3810976100% (2)

- Promise Pharma LabsDocument7 pagesPromise Pharma LabsprinceamitNo ratings yet

- VP-08-107 - Protocol For Hold Time of Softgel EquipmentsDocument7 pagesVP-08-107 - Protocol For Hold Time of Softgel EquipmentsprakashNo ratings yet

- Hard Gelatin CapsulesDocument21 pagesHard Gelatin Capsulesavn6No ratings yet

- Cleaning and disinfection of food factories: a practical guideFrom EverandCleaning and disinfection of food factories: a practical guideNo ratings yet

- Bioprocessing Technology for Production of Biopharmaceuticals and BioproductsFrom EverandBioprocessing Technology for Production of Biopharmaceuticals and BioproductsClaire KomivesNo ratings yet

- Compressed Tablets Are One of TheDocument1 pageCompressed Tablets Are One of TheSagita WidiyastutiNo ratings yet

- AntifungalsDocument8 pagesAntifungalsSagita WidiyastutiNo ratings yet

- AntifungalsDocument8 pagesAntifungalsSagita WidiyastutiNo ratings yet

- Formulasi MethampyronDocument1 pageFormulasi MethampyronSagita WidiyastutiNo ratings yet

- BestfriendDocument1 pageBestfriendSagita WidiyastutiNo ratings yet

- 13 TerjemhkanDocument3 pages13 TerjemhkanSagita WidiyastutiNo ratings yet

- Ek Sample EeDocument1 pageEk Sample EeSagita WidiyastutiNo ratings yet

- Am J Clin Nutr-1999-Sabaté-500s-3sDocument11 pagesAm J Clin Nutr-1999-Sabaté-500s-3sSagita WidiyastutiNo ratings yet

- Green: InsuranceDocument80 pagesGreen: InsuranceTreatment Plant Operator MagazineNo ratings yet

- CalibrationDocument13 pagesCalibrationAmanjit SinghNo ratings yet

- Valvula Antirretorno Norgren t60Document1 pageValvula Antirretorno Norgren t60Base SistemasNo ratings yet

- Aits 2223 CRT Ii Jeem OfflineDocument15 pagesAits 2223 CRT Ii Jeem OfflineBHOOMI B100% (1)

- Ftir Coffee Okok PDFDocument10 pagesFtir Coffee Okok PDFcentro surcolombiano de investigación en café uscoNo ratings yet

- Oil-Dri Catalog v.17Document24 pagesOil-Dri Catalog v.17Jelly TepskincareNo ratings yet

- API 510 QuestionsDocument8 pagesAPI 510 QuestionsTAYYAB FAROOQ100% (2)

- Descriptions: PEG-4000 Is A Water-Soluble, Waxy Solid That Is Used Extensively in The Several Industries Such AsDocument1 pageDescriptions: PEG-4000 Is A Water-Soluble, Waxy Solid That Is Used Extensively in The Several Industries Such AsKeremNo ratings yet

- 24029962Document269 pages24029962smrndrdasNo ratings yet

- UST-IACUC Animal Care ReviewDocument8 pagesUST-IACUC Animal Care ReviewKate Montenegro0% (1)

- The Potential of Jackfruit Sap As Alternative GlueDocument6 pagesThe Potential of Jackfruit Sap As Alternative GlueKshiki MikaNo ratings yet

- Dabur ReportDocument42 pagesDabur ReportMudit Misra0% (1)

- Chem 110 Highligts 40 43Document28 pagesChem 110 Highligts 40 43dsarathy1No ratings yet

- 3m Scotchbrite Quick Clean Griddle Cleaning SystemDocument12 pages3m Scotchbrite Quick Clean Griddle Cleaning Systemarturo gmoNo ratings yet

- Unit2.SP - Mill.setting and ImbibitionDocument15 pagesUnit2.SP - Mill.setting and ImbibitionHari kantNo ratings yet

- HSSC Chemistry Revised List of PracticalsDocument2 pagesHSSC Chemistry Revised List of PracticalsMunir ZafarNo ratings yet

- Budgetary Offer 2 X 9 MVA Furnace Anx - IDocument5 pagesBudgetary Offer 2 X 9 MVA Furnace Anx - Ialok_agitNo ratings yet

- Laporan Keuangan Isi Ulang Air 3Document6 pagesLaporan Keuangan Isi Ulang Air 3Safarah Mulia AnwarNo ratings yet

- Hard and Soft Acids and BasesDocument17 pagesHard and Soft Acids and BasesSalmi Seprianti100% (2)

- E213-Ultrasonic Examination of Metal Pipe and TubingDocument5 pagesE213-Ultrasonic Examination of Metal Pipe and Tubingsolrac4371No ratings yet

- Statistics 2 For Chemical Engineering: Department of Mathematics and Computer ScienceDocument37 pagesStatistics 2 For Chemical Engineering: Department of Mathematics and Computer ScienceKhuram MaqsoodNo ratings yet

- Bright Cutting Steel Bar SpecificationDocument2 pagesBright Cutting Steel Bar SpecificationashokkumarNo ratings yet

- Application Note Aflatoxins EngDocument5 pagesApplication Note Aflatoxins EngLan HuongNo ratings yet

- Distillation: Enthalpy Concentration Methods (HX) Diagram or Ponchon Savarit MethodDocument9 pagesDistillation: Enthalpy Concentration Methods (HX) Diagram or Ponchon Savarit MethodRose Dane Escobedo DiestaNo ratings yet

- Listening + Reading Test 1Document19 pagesListening + Reading Test 1Faisal JavedNo ratings yet

- Sediments and ErosionDocument17 pagesSediments and ErosionRavi UraiyaNo ratings yet

- Pump AshkDocument131 pagesPump AshkashkansoheylNo ratings yet

- CBSE Class 9 Science Notes Atoms and MoleculesDocument43 pagesCBSE Class 9 Science Notes Atoms and MoleculesArjunNo ratings yet

- Thwaites MethodDocument1 pageThwaites MethodJen ChaiNo ratings yet

- Evaporator Data Sheet - SKO0501049 Rev0Document10 pagesEvaporator Data Sheet - SKO0501049 Rev0chublackNo ratings yet