Professional Documents

Culture Documents

Ficha Tecnica Proteccion Mecanica 95515202530

Uploaded by

Carlos TarquinoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Ficha Tecnica Proteccion Mecanica 95515202530

Uploaded by

Carlos TarquinoCopyright:

Available Formats

System Description

Polyken #955 is a protective pipeline outerwrap that is used where a complete bond of outerwrap to tape is specified.

Because it is a polyethylene film with a bonding adhesive, it stays with the tape and never disappears or disintegrates.

The adhesive assures a complete bond and eliminates the need for tie-downs on the outerwrap. Designed for machine

application at the same time the primary coating is applied, Polyken #955 is available in various thicknesses. The

standard color of #955 is white, but it is also available in black .

D

S

-

9

5

5

-

R

E

V

4

-

0

2

0

8

Mechanical Protection

Outerwrap

Proven Performance

Polyken #955 is one of a family of Polyken outerwraps

that have proven themselves on pipeline throughout

the world over the past twenty-five years.

TIghI 8ond

The recommended outerwrap wherever a complete

bond to tape is required. Tough, pressure-sensitive

adhesive means the outerwrap bonds and stays

permanently.

Backing

Adhesive

Lasy kppIIraIIon

Engineered to achieve a taut, smooth machine wrap

over a wide range of primary coatings, Polyken #955 is

the first choice when an adhesive bond of the

outerwrap to the primary coating is specified. Gives a

smooth, tough protection to the pipeline under all

climatic conditions, in any terrain, anywhere in the

world.

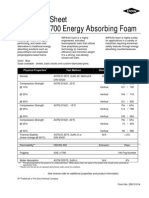

FrodurI FroparIIas

TasI MaIhod LngIIsh MaIrIr

Total Thickness ASTM D 1000 15 20 25 30 mils 0.381 0.508 0.635 0.762

Breaking Strength ASTM D 1000 20 25 25 25 lb/in w. 3.57 4.47 4.47 4.47 kg/cm w.

Elongation ASTM D 1000 300 300 300 200 % 300 300 300 200%

Temperature Range: ASTM D 1000

Normal Application -30 to 160F -34 to 71C

(ambient temperature)

Normal Service -30 to 185F -34 to 85C

(operating temperature)

#955

Berry Plastics warrants that the product conforms to its chemical and physical description and is appropriate for the use stated on the technical data sheet when used in compliance with Berry Plastics

written instructions. Since many installation factors are beyond the control of Berry Plastics , the user shall determine the suitability of the products for the intended use and assume all risks and liabilities

in connection herewith. Berry Plastics liability is stated in the standard terms and conditions of sale. Berry Plastics makes no other warranty either expressed or implied. All information contained in

this technical data sheet is to be used as a guide and is subject to change without notice. This technical data sheet supersedes all previous data sheets on this product.

Local Distributor / Representative:

For contact details of local Distributors / Representatives

Please visit www.berrycpg.com.

Franklin, MA, USA

Tel: +1 508 918 1714

US Toll Free: +1 800 248 0149

Fax: +1 508 918 1910

CPG@berryplastics.com

Tijuana, Mexico

Tel US: +1 866 9 CORROSION

Fax US: +1 619 424 4258

Tel Mexico: +52 664 607 0926

Fax Mexico: +52 664 623 6463

CPGTJ@berryplastics.com

Houston, TX, USA

Tel: +1 713 676 0085

US Toll Free: 01 888 676 7202

Fax:+1 713 676 0086

CPGH@berryplastics.com

Aarschot, Belgium

Tel: +32 16 55 36 00

Fax: +32 16 55 36 74

CPGE@berryplastics.com

Baroda, India

Tel: +91 2667 264721

Fax: +91 2667 264724

CPGIN@berryplastics.com

www.berrycpg.com

Headquarters: BerryPlasticsTapes&CoatingsDivision, FranklinMA, USA

CORROSION PROTECTION GROUP

You might also like

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- DS-980-955 Especificacion Tecnica PolykenDocument2 pagesDS-980-955 Especificacion Tecnica PolykenManolo MontalvanNo ratings yet

- DS Flex Rev7 0309 PDFDocument2 pagesDS Flex Rev7 0309 PDFDavid GonzaloNo ratings yet

- Polyken 2000 High TempDocument2 pagesPolyken 2000 High TempKyaw Kyaw AungNo ratings yet

- Gasket Catalog - James WalkerDocument52 pagesGasket Catalog - James WalkerJaime Lozano GonzálezNo ratings yet

- Spec 3m 375Document2 pagesSpec 3m 375Thích Rong ChơiNo ratings yet

- HBR XL - Crosslink Closed Cell PDSDocument2 pagesHBR XL - Crosslink Closed Cell PDSHuy ThaiNo ratings yet

- Polyflex UltrachemDocument2 pagesPolyflex UltrachemBraulio Candela NoriegaNo ratings yet

- Polyclad 975 H PDSDocument2 pagesPolyclad 975 H PDSLinnie McleodNo ratings yet

- V68 DataumumDocument2 pagesV68 DataumumRohmat SesNo ratings yet

- Polyethylene: For Blow Moulding & Blown Film GradeDocument1 pagePolyethylene: For Blow Moulding & Blown Film GradeRikinNo ratings yet

- Polyken 980,955 Multi-Layer Pipe Coating SystemDocument2 pagesPolyken 980,955 Multi-Layer Pipe Coating Systemraditia2205No ratings yet

- RN 3038Document0 pagesRN 3038Anish KumarNo ratings yet

- Damp Proof Membrane To PIFA Standard Datasheet 12-08-2011Document3 pagesDamp Proof Membrane To PIFA Standard Datasheet 12-08-2011Mrcoke SeieNo ratings yet

- Gasket Jointing FullDocument48 pagesGasket Jointing FullManishBoyNo ratings yet

- 3M 9731RWDocument4 pages3M 9731RWcbol91311No ratings yet

- Polyguard 600 CoatingsDocument2 pagesPolyguard 600 CoatingstechdocuNo ratings yet

- Proofex Torchseal (PE)Document2 pagesProofex Torchseal (PE)kalidindivenkatarajuNo ratings yet

- 659H Chockfast OrangeDocument2 pages659H Chockfast OrangeManodaya ShirodkarNo ratings yet

- Avalon 90ABDocument2 pagesAvalon 90ABborlixNo ratings yet

- Cellflex TDS Oct 09Document2 pagesCellflex TDS Oct 09pete0980No ratings yet

- Sika WP Shield-104 P: APP Modified Plain Finished Bituminous MembraneDocument3 pagesSika WP Shield-104 P: APP Modified Plain Finished Bituminous MembraneSouvik DasNo ratings yet

- Hydroseal P: Hydrophilic Rubber Based On PolyurethaneDocument2 pagesHydroseal P: Hydrophilic Rubber Based On PolyurethaneVaibhav GoyalNo ratings yet

- BR Polyken Rev11 Sep10Document8 pagesBR Polyken Rev11 Sep10diaccessltd_17172961No ratings yet

- Properties Foster Duct-Fas® Adhesive (Non-Flammable) : Product Data SheetDocument2 pagesProperties Foster Duct-Fas® Adhesive (Non-Flammable) : Product Data SheetOscar ZelayaNo ratings yet

- Bitumastic 300MDocument2 pagesBitumastic 300Mtharman749781No ratings yet

- IMPAXX700Document2 pagesIMPAXX700MuditSingh100% (1)

- 830431Document3 pages830431number_25No ratings yet

- Cold Applied Bituminous Waterproofing MembraneDocument2 pagesCold Applied Bituminous Waterproofing MembranekalidindivenkatarajuNo ratings yet

- Faced Duct Wrap Insulation Technical Data SheetDocument4 pagesFaced Duct Wrap Insulation Technical Data Sheethello1230No ratings yet

- Epirez 733 Ultra High Build Epoxy CoatingDocument3 pagesEpirez 733 Ultra High Build Epoxy CoatingRai Hasnain Ahmad DahaNo ratings yet

- 3M Optically Clear AdhesivesDocument5 pages3M Optically Clear AdhesivesPanagiotis ArgyropoulosNo ratings yet

- Tyfo SCH AnchorsDocument2 pagesTyfo SCH AnchorsLindy KhoNo ratings yet

- Polyken 954 TapeDocument2 pagesPolyken 954 TapeKyaw Kyaw AungNo ratings yet

- FLORPRUFE120Document2 pagesFLORPRUFE120Walter PattiNo ratings yet

- Ficha Tecnica - Microseal - DSDocument2 pagesFicha Tecnica - Microseal - DSedocducNo ratings yet

- Powercrete R150Document2 pagesPowercrete R150welbert001No ratings yet

- 186 Soldering Flux: Mildly Activated Rosin Liquid FluxDocument4 pages186 Soldering Flux: Mildly Activated Rosin Liquid FluxAmirNo ratings yet

- Polyken 1600 High TempDocument2 pagesPolyken 1600 High TempKyaw Kyaw AungNo ratings yet

- Proofex ORG: Loose Laid Reinforced TPO Waterproofing MembraneDocument2 pagesProofex ORG: Loose Laid Reinforced TPO Waterproofing MembranekalidindivenkatarajuNo ratings yet

- Bray Butterfly Valves Catalog JECDocument23 pagesBray Butterfly Valves Catalog JECRawadabdoNo ratings yet

- 3M Scotch-Weld Polyurethane Reactive PUR Easy 250 Plastic Adhesive EZ250030.EZ250150Document5 pages3M Scotch-Weld Polyurethane Reactive PUR Easy 250 Plastic Adhesive EZ250030.EZ250150Paul TushausNo ratings yet

- Mastic CarbowrapDocument2 pagesMastic CarbowrapGlishna Peushan WidanapathiranaNo ratings yet

- D9 SB ZINC SILICATE Inorganic Zinc Primer Data SheetDocument2 pagesD9 SB ZINC SILICATE Inorganic Zinc Primer Data SheetPrashant MalveNo ratings yet

- 10-D1-VHightech (Very High Density Foam)Document1 page10-D1-VHightech (Very High Density Foam)GPNo ratings yet

- Dr. Fixit Bathseal Range 169 1 PDFDocument3 pagesDr. Fixit Bathseal Range 169 1 PDF41464147No ratings yet

- Dymax GA-142 UV Curable Gasket Data SheetDocument3 pagesDymax GA-142 UV Curable Gasket Data SheetJoshua WallesNo ratings yet

- 00-Master Catalog PDFDocument96 pages00-Master Catalog PDFAatikh RasheedNo ratings yet

- VpCI-368 DDocument2 pagesVpCI-368 DSpoonful BurnsideNo ratings yet

- High-performance epoxy coating data sheetDocument2 pagesHigh-performance epoxy coating data sheetamadan64No ratings yet

- K-FLEX Tapes GuideDocument16 pagesK-FLEX Tapes GuidegetashishvaidNo ratings yet

- Cold Applied Waterproofing MembraneDocument2 pagesCold Applied Waterproofing MembraneSyed ShahbazNo ratings yet

- Polyken Utility Tape 900 910 908 911 920Document2 pagesPolyken Utility Tape 900 910 908 911 920Tracy EvansNo ratings yet

- Cinta 365 ElectricaDocument2 pagesCinta 365 ElectricamiguelNo ratings yet

- Amercoat 3279 DatasheetDocument0 pagesAmercoat 3279 Datasheetmekag94No ratings yet

- WPC120 PDFDocument2 pagesWPC120 PDFHamzaHashimNo ratings yet

- DR Fixit Pidiseal PS 41G and 42P 112 1Document4 pagesDR Fixit Pidiseal PS 41G and 42P 112 1Avinash GuptaNo ratings yet

- Family Handyman Do-It-Yourself Basics Volume 2From EverandFamily Handyman Do-It-Yourself Basics Volume 2Family HandymanRating: 5 out of 5 stars5/5 (2)

- +pipe Fittings PDFDocument12 pages+pipe Fittings PDFCarlos TarquinoNo ratings yet

- Swagelok-Thread and End Connection Identification Guide-MS-13-77 PDFDocument56 pagesSwagelok-Thread and End Connection Identification Guide-MS-13-77 PDFmac9papNo ratings yet

- ChemRestChart PDFDocument12 pagesChemRestChart PDFCarlos TarquinoNo ratings yet

- Asme B40Document2 pagesAsme B40Durgarao Vasa100% (1)

- IATD April 2015 Packaging - Solutions - LoRes PDFDocument48 pagesIATD April 2015 Packaging - Solutions - LoRes PDFCarlos TarquinoNo ratings yet

- Measuring Petroleum StandardsDocument101 pagesMeasuring Petroleum StandardsJonathan Narh-DometeyNo ratings yet

- PDFDocument2 pagesPDFCarlos TarquinoNo ratings yet

- Sil Quick Guide 1528 PDFDocument4 pagesSil Quick Guide 1528 PDFCarlos TarquinoNo ratings yet

- SIL Explained: Fluid Power Actuators and Control SystemsDocument8 pagesSIL Explained: Fluid Power Actuators and Control Systemsprihartono_diasNo ratings yet

- Bostik NeverseezDocument8 pagesBostik NeverseezginuxNo ratings yet

- Chem ResistanceDocument18 pagesChem Resistancepeng88apNo ratings yet

- Fundamental Principles of Gas Turbine Meters Robert Bennett American Meter CompanyDocument6 pagesFundamental Principles of Gas Turbine Meters Robert Bennett American Meter CompanyCarlos TarquinoNo ratings yet

- Introduccion A La AutomatizacionDocument23 pagesIntroduccion A La AutomatizacionCarlos TarquinoNo ratings yet

- Eam BR2100 4 PDFDocument24 pagesEam BR2100 4 PDFCarlos TarquinoNo ratings yet

- EFM Family Brochure PDFDocument4 pagesEFM Family Brochure PDFCarlos TarquinoNo ratings yet

- CONFPAPERS ALTOSONICV12 Installation Effects en 120524 PDFDocument20 pagesCONFPAPERS ALTOSONICV12 Installation Effects en 120524 PDFCarlos TarquinoNo ratings yet

- GPC 2100 PDFDocument24 pagesGPC 2100 PDFCarlos TarquinoNo ratings yet

- 23 11 13 - Gas Meter StationDocument8 pages23 11 13 - Gas Meter StationCarlos TarquinoNo ratings yet

- Normas de RefDocument4 pagesNormas de Refrolulbadel16No ratings yet

- Optimum Pipe Diameter Calculation SheetDocument81 pagesOptimum Pipe Diameter Calculation Sheetpandu_prabowo_jati100% (2)

- Systems Handbook M&R Station InstrometDocument31 pagesSystems Handbook M&R Station Instrometandy131078No ratings yet

- Masoneilan Control Valve Sizing PDFDocument32 pagesMasoneilan Control Valve Sizing PDFOwen Hennessy100% (1)

- Fundamental Principles of Gas Turbine Meters Robert Bennett American Meter CompanyDocument6 pagesFundamental Principles of Gas Turbine Meters Robert Bennett American Meter CompanyCarlos TarquinoNo ratings yet

- Control Valve SizingDocument36 pagesControl Valve SizingOmar Samir100% (2)

- Emerson-Valve Sizing Calculations (Traditional Method)Document21 pagesEmerson-Valve Sizing Calculations (Traditional Method)iqtorresNo ratings yet

- Ben Gliwa - Network Pressure Regulation in Natural Gas Distribution PDFDocument22 pagesBen Gliwa - Network Pressure Regulation in Natural Gas Distribution PDFCarlos TarquinoNo ratings yet

- Catalogo Medidor Gt3Document12 pagesCatalogo Medidor Gt3luis_d_mNo ratings yet

- Valve Sizing Application NotesDocument12 pagesValve Sizing Application Notestxagus100% (1)

- Gas Flow Calculation Using Cv ValuesDocument1 pageGas Flow Calculation Using Cv ValuesCarlos TarquinoNo ratings yet

- Under Floor Insulation System: CompliesDocument4 pagesUnder Floor Insulation System: CompliesJohn LiebermanNo ratings yet

- Basics of Pipe Stress Analysis A Presentation-Part 2 of 2Document6 pagesBasics of Pipe Stress Analysis A Presentation-Part 2 of 2iaftNo ratings yet

- 32crmov12-10 : Steel GradeDocument5 pages32crmov12-10 : Steel Gradereza haghjooNo ratings yet

- Construction Progress ReportDocument11 pagesConstruction Progress ReportAnthny Alfrt GsprNo ratings yet

- Quality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.ŞDocument3 pagesQuality Control Report: Üntel Kablolari Sanayi Ve Ticaret A.Şomar100% (1)

- (TM) Nissan Manual de Taller Nissan Versa 2007Document4 pages(TM) Nissan Manual de Taller Nissan Versa 2007Jheral Manzanedo cruzNo ratings yet

- 55 Southey Street - WD-2 - Updated Layout - Tender Issue 2Document30 pages55 Southey Street - WD-2 - Updated Layout - Tender Issue 2RashmiNo ratings yet

- User Manual Version 4.0!10!12 2022 WBMBRDocument111 pagesUser Manual Version 4.0!10!12 2022 WBMBRarunava.singha1994No ratings yet

- Antony Wood CTBUH GreenLecture 05Document105 pagesAntony Wood CTBUH GreenLecture 05bansaldhruvNo ratings yet

- Lattice Towers and Masts IntroductionDocument17 pagesLattice Towers and Masts IntroductionPankaj_Taneja_9684No ratings yet

- PDF High Performance Diaphragm Liquid End HPD Low Flow Installation Operation and Maintenance Manual - CompressDocument40 pagesPDF High Performance Diaphragm Liquid End HPD Low Flow Installation Operation and Maintenance Manual - CompressVũ Văn QuangNo ratings yet

- Aramco Hot Tap Welding Procedure Rev 1Document3 pagesAramco Hot Tap Welding Procedure Rev 1BWQNo ratings yet

- Assignment Road Constuction IIDocument6 pagesAssignment Road Constuction IIKry ThanakNo ratings yet

- Service Manual Goodman GPH16MDocument63 pagesService Manual Goodman GPH16MMitchell BaileyNo ratings yet

- The Finite Element Analysis For Fork Based On ANSYSDocument3 pagesThe Finite Element Analysis For Fork Based On ANSYSPacy MugishoNo ratings yet

- WMS For Pipe Supports ErectionDocument17 pagesWMS For Pipe Supports ErectionRamaraju RNo ratings yet

- Burj Vista Floor Plans T1 T2 PDFDocument20 pagesBurj Vista Floor Plans T1 T2 PDFkasugagNo ratings yet

- Method Statement For Mineral Fiber Tiles: Sandvik PVT LTD, Dapodi, PuneDocument3 pagesMethod Statement For Mineral Fiber Tiles: Sandvik PVT LTD, Dapodi, PuneParasNo ratings yet

- Home Tiles Selection SheetDocument6 pagesHome Tiles Selection SheetstyliishmainNo ratings yet

- DA220738 Stormwater Design Calculations - (A8387425)Document7 pagesDA220738 Stormwater Design Calculations - (A8387425)umeimasohail.engNo ratings yet

- Kitchen Equipment SpecificationDocument10 pagesKitchen Equipment SpecificationPalak BatraNo ratings yet

- Intro Well FoundationDocument23 pagesIntro Well FoundationgoutammandNo ratings yet

- Polymers 13 03480 v2Document13 pagesPolymers 13 03480 v2SEBASDAZACNo ratings yet

- ICS - Group ProfileDocument60 pagesICS - Group ProfileShaikh Abdulsaboor SapruNo ratings yet

- Scrutiny Report of Building PlanDocument7 pagesScrutiny Report of Building PlanSubirBhowmikNo ratings yet

- 1.03 - High-Rise Buildings PDFDocument19 pages1.03 - High-Rise Buildings PDFNicolas De NadaiNo ratings yet

- Liebherr Fridge ManualDocument18 pagesLiebherr Fridge ManualJames RavensdaleNo ratings yet

- Building Economics Group AssignmentDocument12 pagesBuilding Economics Group Assignmentapi-323157773No ratings yet

- 56r 08Document21 pages56r 08manojsingh4allNo ratings yet

- High Temperature Tensile Strength TestingDocument4 pagesHigh Temperature Tensile Strength TestingWalter RuedaNo ratings yet