Professional Documents

Culture Documents

Cable Ladder Leaflet

Uploaded by

Mohsan AbbasOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Cable Ladder Leaflet

Uploaded by

Mohsan AbbasCopyright:

Available Formats

for Building & Construction Materials

METALLIC CABLE

MANAGEMENT SYSTEMS

CABLE LADDER TRAYS

Specialized Factory for Steel Products

Sigma Factory for Steel Products

S

A

0

9

/211

5

8

8

for Building & Constructon Materials

CABLE LADDER TRAYS

2

METALLIC CABLE MANAGEMENT SYSTEMS

CABLE LADDER SYSTEMS

Specialized Factory for Steel Products (Jeddah/KSA)

Sigma Factory for Steel Products (Ajman & Umm Al Quwain /UAE)

Specialized Factory for Steel Products (6th of October/Egypt)

Unimetal Cable Tray Systems, ftngs and accessories from SFSP are manufactured in compliance with :

- IEC 61537 Internatonal Electrotechnical Commission (Cable management Cable tray systems and

cable ladder systems)

- SASO IEC (61537/2007) Saudi Standard (Cable management Cable tray systems and cable ladder systems)

- NEMA VE 1 - 2009 Natonal Electrical Manufacturers Associaton. (Metal Cable Tray Systems)

- NEMA VE 2 - 2006 Natonal Electrical Manufacturers Associaton. (Metal Cable Tray Installaton Guide Lines)

- NEC (ANSI / NFPA 70) Natonal Electric Code (Metal Cable Tray Guide Lines)

Unimetal Cable Ladder Tray Systems are designed to meet most requirements of cable and electrical wire installatons

and comply to local and internatonal standards of fabricaton and fnishing.

ISO CERTIFICATES

Products

Unimetal Cable Trays - Ladder type, ftngs and accessories from SFSP are

manufactured in compliance with internatonal standards.

Unimetal provides a wide range of products capable of providing the

characteristcs which respond to the proposed applicaton, along with quality of

assembly, speed of installaton and cost-saving cable Trays.

MATERIALS & FINISHES

Hot rolled steel S235JR as per EN 10025 / ASTM A-1011 CS Type B (formerly ASTM A569 or ASTM A570)

Cold rolled steel DC01 as per EN 10130 / ASTM A1008 CS Type B ( formerly ASTM A-366)

and then:

Hot- dip galvanized as per BS EN 1461 (formerly BS 729 ) / ASTM A123 or

Electro plated as per EN 12329 / ASTM B633 (Electrodeposited coatngs of zinc on iron and steel)

Pre- galvanized steel DX51 D +Z as per EN 10346 ( G180 and G275 is available upon special request) which supersedes EN 10327

which is a replacement of EN 10142 which in turn supersedes.

- BS 2989 / ASTM A653M zinc coated ( hot-dip galvanized ) iron and steel CS( commercial ) or SS ( structural ) quality G60 and G90 is

available upon special request ( formerly ASTM A527M ) / ASTM A924 (coatng ) ( formerly A525 ) .

Stainless steel 1.4301 as per EN 10088-2( formerly BS 1449 Part 2 / ASTM A240M, Grade AISI 304 )

Aluminum 6063-T6 or 5052-H32 alloy as per ASTM B209

REFERNCES (Cable Management Systems) :

ANSI /NFPA 70 - Natonal Electrical Code

NEMA VE 1-2009 - Metal Cable Trays Systems

NEMA VE 2-2006 - Cable Tray Installaton Guidelines

IEC 61537 Internatonal Electrotechnical Commission

SASO IEC (61537/2007) Saudi Standard

CSA C22.2 No. 126. 1-02 -Metal Cable Tray Systems

CABLE TRAY SYSTEMS OVERVIEW

Swaged Ladder Cable Trays (Aluminum & Steel)

SFSPs Swaged Ladder Cable Trays consist of 2 outside rails are connected by round tubular rung of 25 mm outside diameter.

- SFSPs Swaged Ladder Cable Trays, are manufacturred in widths (w): 100 mm, 150 mm, 200 mm, 300 mm, 400 mm, 500 mm,

600 mm, 750 mm and 900 mm.

Tubular Rungs

The available distance spacing (S) between the rungs is 229 mm. Length (L): 2440/3000 mm. Side height of the side rail is 110 mm, 136

mm, 162 mm and 188 mm. Swaged Ladder Cable Trays are available in:

Aluminum 6063 T6 Hot-Dip galvanized afer fabricaton S 235. Mil galvanized

CABLE LADDER TRAYS

C

A

B

L

E

L

A

D

D

E

R

T

R

A

Y

S

3

RUNG TYPES

CABLE TRAY SYSTEMS OVERVIEW

w

h

L

o

a

d

d

e

p

t

h

20 20

R

a

il

T

u

b

u

la

r R

u

n

g

L

Rung Dimensions

25

w

h

F F

L

o

a

d

D

e

p

t

h

Swaged connectons make the

most rigid tray system in the

industry.

The swaging process does not

afect the temper and strength of

surrounding metal the way that

traditonal welds do.

Rung Types and Dimensions

Rung Thicknesses:

1,5 mm, 2.0 mm and 2.5mm

Height of rail

50mm - 150mm

Downwards

Upwards

50 mm

upon r (slots only equest )

13 X 25 mm

21

41

Side Rails Types

Z-Type

Top outside

Bottom inside

20

20

h

20

20

C-Type

outside

h

20

Inside return

flange

R - Type

h

Length and Rung Spacing

h

h

9 x 20 mm

9 x 20 mm

300 mm

3000 mm

Tubular Rounded Rung

w

h

F F

25

Rung Dimensions

L

o

a

d

D

e

p

th

L

Rung Spacing on center

S S

Rounded Tubular

Rung

W

Swaged Rounded Tubular

(Aluminum & Steel)

Plain Channel

(Steel)

Z-Type C-Type R-type

CABLE LADDER TRAYS

4

Aluminum 6063 T6 - Side Rails

LAddER TypE RuNS (SwAGEd TubuLAR RuNG)

Design Data

Side Height Load Depth Thickness f W I

Rail H (mm) fd (mm) (mm) (mm) cm

3

cm

4

A1 110 80 2.0 19.5 8.12 46.06

A2 136 106 2.0 19.5 11.24 78.95

A3 162 132 2.0 19.5 14.78 123.85

A4 188 158 2.5 19.5 23.14 224.70

Load Classes

Side Load Span Classes

Rail kg/m (m) NEMA

A1 52 3.0 A

A2 97 3.0 C

A3 74 3.70 12A

A4 134 3.70 12B

Swaged Rounded Tubular

- Class A (52 kg/m by 3,0m)

and 8A (95 kg/m by 2,40m)

- Class C (97.0 kg/m by 3.0 m)

- Class 12 A (74 kg/m by 3.70 m)

- Class 12 B (134 kg/m by 3.70 m)

f

Hf

d

Steel - Side Rails

LAddER TypE RuNS (SwAGEd TubuLAR ANd C-ChANNEL RuNGS)

Design Data

Classes

Side Height Load Depth Thickness f W I NEMA

Rail H (mm) fd (mm) (mm) (mm) cm

3

cm

4

Span Class

s1 105 75 1.5 22 5.24 27.53 2.40 8C

S2 130 100 1.5 22 7.30 47.45 3.70 12A

S3 155 125 1.5 22 9.65 74.81 3.70 12B

S4 105 75 2.0 22 6.83 35.87 3.70 12A

S5 130 100 2.0 22 9.55 62.08 3.70 12B

S6 155 125 2.0 22 12.67 98.17 4.90 16A

S7 105 75 2.5 22 8.34 43.81 3.70 12A

S8 130 100 2.5 22 11.71 76.15 3.70 12C

S9 155 125 2.5 22 15.58 120.75 6.0 D

Cable Ladder Tray

- Class 8C (149 kg/m by 2,40m)

- Class 12A (74 kg/m by 3.70m)

- Class 12B (194 kg/m by 3.70m)

- Class 12A (74 kg/m by 3.70m)

- Class 12B (123 kg/m by 3.70m)

- Class 16A (82 kg/m by 4.90m)

- Class 12A (87 kg/m by 3.70m)

- Class 12C (150 kg/m by 3.70m)

- Class Steel S9

Load Classes

Side Load Span Classes

Rail kg/m (m) NEMA

s1 149 2.40 8C

S2 74 3.70 12A

S3 119 3.70 12B

S4 74 3.70 12A

S5 123 3.70 12B

S6 82 4.90 16A

S7 87 3.70 12A

S8 150 3.70 12C

S9 67 6.00 D

f

H

t

f

d

C - Channel

CABLE LADDER TRAYS

C

A

B

L

E

L

A

D

D

E

R

T

R

A

Y

S

5

LADDER TYPE FITTINGS

Ladder Cable Tray ftngs are those components which provide changes in directon or

elevaton of the Ladder Cable Tray systems.

SFSP ftngs are available in diferent bending radii to accommodate a wide range of cable

sizes and types.

The horizontal and vertcal elbows are available in 450, and 900 degrees of arc.

All illustratons shown herein depict our standard ladder rung.

The rung spacing of ladder ftngs is generally maintained at the ftng centerline.

Ladder Cable Tray ftngs are usually manufactured in two types; cornered and curved.

BEND 45

0

BEND 90

0

TEE BRANCH hoRIzoNTAL CRoSS (INTERSECTIoN)

INSIDE VERTICAL ELBOW (Inside Riser) OUTSIDE VERTICAL ELBOW (Outside Riser)

STRAIGHT CENTRAL REDUCERS RIGHT HAND REDUCERS LEFT HAND REDUCERS

2110 2410

2110A T

Aluminum

2710

3310

3910 4210 4510

3610

3010

2710A T

Aluminum

3310A T

Aluminum

3610A T

Aluminum

3010A T

Aluminum

2410A T

Aluminum

CABLE LADDER TRAYS

6

175

h

20

175

h

ACCESSORIES

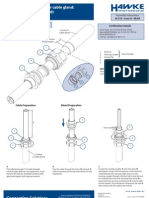

Connectors

STRAIGHT CONNECTOR ANGLE CONNECTOR

ADJUSTABLE VERTICAL

CONNECTOR

ADJUSTABLE HORIZONTAL

CONNECTOR

1000

1010

1030

1040

175

h

20

1120

BARRIER STRIP dRop-ouT pLATE CABLE TIE

h

25

1070

Available Lengths: 2440 / 3000 mm

W

=

w

m

inus

7

m

m

1110 1120

Cable Trays Cover

Functons

Covers shall be considered for any of the following purposes:

Protecton from falling objects or debris, as may occur beneath personnel walkways.

Shielding from ultra-violet rays of the sun and guarding against other weathering elements.

Minimizing accumulaton of foreign contaminants such as ash or other industrial deposits.

Protecton of cables and personnel where a riser tray penetrates a foor or gratng.

SFSP covers are supplied with or without a 15 mm downturned fange.

Straight secton covers are furnished 3000 mm long. All ftng covers are furnished in solid design only.

SOLID COVER VENTILATED COVER

COVER WITH LOCKING

CLAMP

2000 2010

2100

CABLE LADDER TRAYS

C

A

B

L

E

L

A

D

D

E

R

T

R

A

Y

S

7

G

E D C

H B

Cable Trays Cover

Functons

Covers shall be considered for any of the following purposes:

Protecton from falling objects or debris, as may occur beneath personnel walkways.

Shielding from ultra-violet rays of the sun and guarding against other weathering elements.

Minimizing accumulaton of foreign contaminants such as ash or other industrial deposits.

Protecton of cables and personnel where a riser tray penetrates a foor or gratng.

SFSP covers are supplied with or without a 15 mm downturned fange.

Straight secton covers are furnished 3000 mm long. All ftng covers are furnished in solid design only.

SOLID COVER VENTILATED COVER

COVER WITH LOCKING

CLAMP

2000 2010

2100

Part No Channel dimensions Thickness

height h width w

CCH - 220/221 21.0 mm 41.0 mm 1.5 mm

CCH - 240/241 41.0 mm 41.0 mm 1.5 mm

CCH - 320/321 21.0 mm 41.0 mm 2.0 mm

CCH - 340/341 41.0 mm 41.0 mm 2.0 mm

CCH - 420/421 21.0 mm 41.0 mm 2.5 mm

CCH - 440/441 41.0 mm 41.0 mm 2.5 mm

Standard Length: 3000 mm (Custom lengths are available upon

request)

Materials: Mild Steel (Hot & Cold Rolled) and Stainless Steel.

Finishes: Pre-Galvanized and Hot-Dip Galvanized.

ACCESSORIES ACCESSORIES

Round washers DIN 440,

DIN 9021

Tinner Copper Flexible Braids

Crimped with Connectors / Terminals - 1300

Crimping Type Copper

Tubular Cable Terminal Ends - 1200

Round head Machine

Screws

Fully Threaded Rods

Grade 4.6 DIN 975

METAL FRAMING CHANNELS

Selecton Chart

Z

Z

Y Y

Z

Z

Y Y

Z

Z

Y Y

Z

Z

Y Y

21.0

7.0

41.0

21.0

41.0

22.0

42.0

7.0

41.0

22.0

41.0

7.0

41.0

41.0

41.0

22.0

82.0

7.0

41.0

22.0

5

0

3

0

1

3

Z

Z

Y Y

Z

Z

Y Y

Z

Z

Y Y

Z

Z

Y Y

21.0

7.0

41.0

21.0

41.0

22.0

42.0

7.0

41.0

22.0

41.0

7.0

41.0

41.0

41.0

22.0

82.0

7.0

41.0

22.0

5

0

3

0

1

3

Z

Z

Y Y

Z

Z

Y Y

Z

Z

Y Y

Z

Z

Y Y

21.0

7.0

41.0

21.0

41.0

22.0

42.0

7.0

41.0

22.0

41.0

7.0

41.0

41.0

41.0

22.0

82.0

7.0

41.0

22.0

5

0

3

0

1

3

Z

Z

Y Y

Z

Z

Y Y

Z

Z

Y Y

Z

Z

Y Y

21.0

7.0

41.0

21.0

41.0

22.0

42.0

7.0

41.0

22.0

41.0

7.0

41.0

41.0

41.0

22.0

82.0

7.0

41.0

22.0

5

0

3

0

1

3

Z

Z

Y Y

Z

Z

Y Y

Z

Z

Y

Y

Z

Z

Y Y

21.0

7.0

41.0

21.0

41.0

22.0

42.0

7.0

41.0

22.0

41.0

7.0

41.0

41.0

41.0

22.0

82.0

7.0

41.0

22.0

5

0

3

0

1

3

Toothed Channel

Cantlever Arm bracket b2b Cantlever Arm bracket

CABLE TRAYS SUPPORT SYSTEMS

Round washers

DIN 125

S

m

S

d

D

S

d

D

Zinc Plated

Thread - ZP

Zinc Plated

for bolt - ZP

Zinc Plated

Dimension- ZP

D

[mm]

D

[mm]

S/m

DIN

[mm]

S

DIN

[mm]

S/m

ISO

[mm]

S

EN

[mm]

e

[mm]

d

[mm]

d

[mm]

s

[mm]

s

[mm]

Length

[mm]

Load

cap.

[kN]

Threaded Rods, Hexagon Head Bol ts, Nuts, Washers

FR AMI NG SY STEM S ACCESSORI ES

Order Example : TR - ZP - M 12 1000

Order Example : HB - ZP - M 12 1000

Order Example: WA - ZP - M 12 - DIN 9021

Order Example: WA - ZP - M 12 - DIN 125

DIN

22

24

30

45

37

50

12

16

21

24

30

10/ 5

13/6,5

17/ 8

19/10

24/13

10

13

17

19

24

18

24

10

13

16

10/ 6

13/7,5

16/ 9,5

18/12

24/15,5

11,5

15,0

19,6

21,9

27,7

6,6

8,4

10,5

13,5

13

17

6,4

8,4

10,5

13

17

2

2

2,5

4

3

3

1,6

1,6

2

2,5

3

1000

1000

1000

1000

1000

2,2

4,0

6,4

12,9

17,3

M 6

M 8

M 10

M 12

M 16

M 6 x 12

M 6 x 25

M 8 x 25

M 8 x 40

M 10 x 20

M 10 x 30

M 10 x 45

M 10 x 60

M 10 x 70

M 12 x 22

M 12 x 25

M 12 x 30

M 12 x 40

M 12 x 50

M 12 x 60

M 12 x 80

M 12 x 90

M 16 x 40

M 16 x 60

M 16 x 90

M 8 x 25

M 10 x 30

M 10 x 45

M 12 x 25

M 12 x 30

M 12 x 40

M 12 x 60

M 12 x 80

M 16 x 40

M 16 x 60

M 16 x 90

M 6

M 8

M 10

M 12

M 16

M 6

M 8

M 10

M 12

M 16

440

9021

9021

440

9021

9021

M 6

M 8

M 10

M 12

M 12

M 16

M 6

M 8

M 10

M 12

M 16

M 8

M 10

M 12

M 16

M 6

M 8

M 10

M 12

M 16

M 6

M 8

M 10

M 12

M 16

Stainless Steel

Thread

Zinc Plated

Thread - ZP

Stainless Steel

Thread

Stainless Steel

for bolt

Zinc Plated

for bolt - ZP

Stainless Steel

for bolt

Stainless Steel

Dimension

Material & Finishes Codes

( S. 53)

= h.d. galvanised, strength grade 4.6

= electroplated, 4.6

= , 8.8

= Stainless steel grade A4-50

strength grade

h.d. galvanised strength grade

= electroplated, strength grade 8.8

= Stainless steel grade A4-70

= Stainless steel grade A2-50

= Stainless steel grade A2-70

= Stainless steel W1.4529 HCR-50

fv

gv

fv 8.8

A4-50

gv 8.8

A4-70

A2-50

A2-70

HCR

e

S

Square washers SSw

SSW 40/40

for all channels

41/21 Series

FR AMI NG SY STEM S ACCESSORI ES

s

L

D

L

Load

cap.

[kN]

Order example:

Order example:

Load

cap.

[kN]

S

[mm]

L

[mm]

D

[mm]

L

[mm]

10/10

12/14

13/16

16/20

21/25

26/32

13

17

22

15

20

25

30

40

50

40

40

50

2,2

4,0

6,4

9,3

17,3

27,0

6,4

9,3

17,3

M 6

M 8

M 10

M 12

M 16

M 20

M 10

M 12

M 16

M 6

M 8

M 10

M 12

M 16

M 20

M 10

M 12

M 16

CS - GV - M 16

HRC - GV - M 12

Coupl er Sl eeves, Square washers ,Sleeve Anchor ,Throught Anchor .......

Throught Anchor

Sleeve Anchor

b

d

a

b

d

a

Order Example: SW 41/41 - HDG - M 12

40 x 40 x 5

40 x 40 x 5

40 x 40 x 5

40 x 40 x 6

40 x 40 x 6

40 x 40 x 6

a x b x d

[mm]

M 10

M 12

M 16

M 6

M 10

M 12

M 6

M 10

M 12

M 10

M 12

M 16

Electroplated

Thread - GV

Electroplated

Thread - GV

Stainless Steel

Thread

Stainless Steel

Thread

H.D. Galvanised

for Bolts - HDG

Stainless Steel

for Bolts

Yellow zinc

plated Steel

Thread (Zn)

L

(mm)

Order example:

M 6

M 8

M 10

M 12

45

50

60

74

M 6

M 8

M 10

STM - Zn - M 12

Stainless

Steel

Thread

Drill

(mm)

10

12

15

18

Min.

Drill hole

(mm)

55

60

75

90

M 6

M 8

M 10

Stainless

Steel

Thread

Yellow zinc

plated Steel

Thread (Zn)

Screw

x Length

(mm)

Order example:

M 6

M 8

M 10

M 12

6x50

8x60

10x80

12x90

STMH - Zn - M 12

S max

fixing

(mm)

5

10

20

25

Yellow zinc plated

Steel Thread (Zn)

10

25

45

75

10.3

12.2

17.1

25.3

9.6

17.5

27.8

40.5

M 6

M 8

M 10

M 12

Type

Max Torque

(mm)

Pull

Out

Shear

8

19

38

9.5

14

19

8.4

15.4

24.4

Max Torque

(mm)

Pull

Out

Shear

Stainless Steel

Thread

Pull-out values in KN -concrete R 250kg/cm

2

its is advisable to apply safty factor in consideration of the various

ways of employment

(1KN=100kg)

SSW 41/41

for all channels

41/41 Series

FR AMI NG SY STEM S ACCESSORI ES

s

L

D

L

Load

cap.

[kN]

Order example:

Order example:

Load

cap.

[kN]

S

[mm]

L

[mm]

D

[mm]

L

[mm]

10/10

12/14

13/16

16/20

21/25

26/32

13

17

22

15

20

25

30

40

50

40

40

50

2,2

4,0

6,4

9,3

17,3

27,0

6,4

9,3

17,3

M 6

M 8

M 10

M 12

M 16

M 20

M 10

M 12

M 16

M 6

M 8

M 10

M 12

M 16

M 20

M 10

M 12

M 16

CS - GV - M 16

HRC - GV - M 12

Coupl er Sl eeves, Square washers ,Sleeve Anchor ,Throught Anchor .......

Throught Anchor

Sleeve Anchor

b

d

a

b

d

a

Order Example: SW 41/41 - HDG - M 12

40 x 40 x 5

40 x 40 x 5

40 x 40 x 5

40 x 40 x 6

40 x 40 x 6

40 x 40 x 6

a x b x d

[mm]

M 10

M 12

M 16

M 6

M 10

M 12

M 6

M 10

M 12

M 10

M 12

M 16

Electroplated

Thread - GV

Electroplated

Thread - GV

Stainless Steel

Thread

Stainless Steel

Thread

H.D. Galvanised

for Bolts - HDG

Stainless Steel

for Bolts

Yellow zinc

plated Steel

Thread (Zn)

L

(mm)

Order example:

M 6

M 8

M 10

M 12

45

50

60

74

M 6

M 8

M 10

STM - Zn - M 12

Stainless

Steel

Thread

Drill

(mm)

10

12

15

18

Min.

Drill hole

(mm)

55

60

75

90

M 6

M 8

M 10

Stainless

Steel

Thread

Yellow zinc

plated Steel

Thread (Zn)

Screw

x Length

(mm)

Order example:

M 6

M 8

M 10

M 12

6x50

8x60

10x80

12x90

STMH - Zn - M 12

S max

fixing

(mm)

5

10

20

25

Yellow zinc plated

Steel Thread (Zn)

10

25

45

75

10.3

12.2

17.1

25.3

9.6

17.5

27.8

40.5

M 6

M 8

M 10

M 12

Type

Max Torque

(mm)

Pull

Out

Shear

8

19

38

9.5

14

19

8.4

15.4

24.4

Max Torque

(mm)

Pull

Out

Shear

Stainless Steel

Thread

Pull-out values in KN -concrete R 250kg/cm

2

its is advisable to apply safty factor in consideration of the various

ways of employment

(1KN=100kg)

S

m

S

d

D

S

d

D

Z

i

n

c

P

l

a

t

e

d

T

h

r

e

a

d

-

Z

P

Z

i

n

c

P

l

a

t

e

d

f

o

r

b

o

l

t

-

Z

P

Z

i

n

c

P

l

a

t

e

d

D

i

m

e

n

s

i

o

n

-

Z

P

D

[

m

m

]

D

[

m

m

]

S

/

m

D

IN

[

m

m

]

S

D

IN

[

m

m

]

S

/

m

IS

O

[

m

m

]

S

E

N

[

m

m

]

e

[

m

m

]

d

[

m

m

]

d

[

m

m

]

s

[

m

m

]

s

[

m

m

]

L

e

n

g

t

h

[

m

m

]

L

o

a

d c

a

p

. [

k

N

]

T

h

r

e

a

d

e

d

R

o

d

s

,

H

e

x

a

g

o

n

H

e

a

d

B

o

l

t

s

,

N

u

t

s

,

W

a

s

h

e

r

s

F

R

A

M

I

N

G

S

Y

S

T

E

M

S

A

C

C

E

S

S

O

R

I

E

S

O

r

d

e

r

E

x

a

m

p

l

e

: T

R

-

Z

P

-

M

1

2

1

0

0

0

O

r

d

e

r

E

x

a

m

p

l

e

: H

B

-

Z

P

-

M

1

2

1

0

0

0

O

r

d

e

r

E

x

a

m

p

le

: W

A

-

Z

P

-

M

1

2

-

D

I

N

9

0

2

1

O

r

d

e

r

E

x

a

m

p

le

: W

A

-

Z

P

-

M

1

2

-

D

I

N

1

2

5

D

IN

2

2

2

4

3

0

4

5

3

7

5

0

1

2

1

6

2

1

2

4

3

0

1

0

/

5 1

3

/

6

,5 1

7

/

8 1

9

/

1

0

2

4

/

1

3

1

0

1

3

1

7

1

9

2

4

1

8

2

4

1

0

1

3

1

6

1

0

/

6 1

3

/

7

,5

1

6

/

9

,5

1

8

/

1

2

2

4

/

1

5

,5

1

1

,5

1

5

,0

1

9

,6

2

1

,9

2

7

,7

6

,6

8

,4

1

0

,5

1

3

,5

1

3

1

7

6

,4

8

,4

1

0

,5

1

3

1

7

2

2

2

,5

4

3

3

1

,6

1

,6

2

2

,5

3

1

0

0

0 1

0

0

0 1

0

0

0 1

0

0

0 1

0

0

0

2

,2

4

,0

6

,4

1

2

,9

1

7

,3

M

6 M

8 M

1

0 M

1

2 M

1

6

M

6

x

1

2

M

6

x

2

5

M

8

x

2

5

M

8

x

4

0

M

1

0

x

2

0

M

1

0

x

3

0

M

1

0

x

4

5

M

1

0

x

6

0

M

1

0

x

7

0

M

1

2

x

2

2

M

1

2

x

2

5

M

1

2

x

3

0

M

1

2

x

4

0

M

1

2

x

5

0

M

1

2

x

6

0

M

1

2

x

8

0

M

1

2

x

9

0

M

1

6

x

4

0

M

1

6

x

6

0

M

1

6

x

9

0

M

8

x

2

5

M

1

0

x

3

0

M

1

0

x

4

5

M

1

2

x

2

5

M

1

2

x

3

0

M

1

2

x

4

0 M

1

2

x

6

0

M

1

2

x

8

0 M

1

6

x

4

0

M

1

6

x

6

0

M

1

6

x

9

0

M

6 M

8 M

1

0 M

1

2 M

1

6 M

6 M

8 M

1

0 M

1

2 M

1

6

4

4

0

9

0

2

1 9

0

2

1

4

4

0

9

0

2

1 9

0

2

1

M

6

M

8

M

1

0 M

1

2 M

1

2 M

1

6

M

6

M

8 M

1

0 M

1

2 M

1

6

M

8 M

1

0

M

1

2 M

1

6

M

6

M

8 M

1

0 M

1

2 M

1

6

M

6 M

8 M

1

0 M

1

2 M

1

6

S

t

a

i

n

l

e

s

s

S

t

e

e

l

T

h

r

e

a

d

Z

i

n

c

P

l

a

t

e

d

T

h

r

e

a

d

-

Z

P

S

t

a

i

n

l

e

s

s

S

t

e

e

l

T

h

r

e

a

d

S

t

a

i

n

l

e

s

s

S

t

e

e

l

f

o

r

b

o

l

t

Z

i

n

c

P

l

a

t

e

d

f

o

r

b

o

l

t

-

Z

P

S

t

a

i

n

l

e

s

s

S

t

e

e

l

f

o

r

b

o

l

t

S

t

a

i

n

l

e

s

s

S

t

e

e

l

D

i

m

e

n

s

i

o

n

M

a

t

e

r

i

a

l

&

F

i

n

i

s

h

e

s

C

o

d

e

s

(

S

.

5

3

)

=

h

.d

.

g

a

lv

a

n

is

e

d

,

s

t

r

e

n

g

t

h

g

r

a

d

e

4

.6

=

e

le

c

tr

o

p

la

t

e

d

,

4

.6

=

,

8

.8

=

S

t

a

in

le

ss

s

t

e

e

l

g

r

a

d

e

A

4

-

5

0

s

t

r

e

n

g

t

h

g

r

a

d

e

h

.d

.

g

a

lv

a

n

is

e

d

s

t

r

e

n

g

t

h

g

r

a

d

e

=

e

le

c

tr

o

p

la

t

e

d

,

s

t

r

e

n

g

t

h

g

r

a

d

e

8

.8

=

S

t

a

in

le

ss

s

t

e

e

l

g

r

a

d

e

A

4

-

7

0

=

S

t

a

in

le

ss

s

t

e

e

l

g

r

a

d

e

A

2

-

5

0

=

S

t

a

in

le

ss

s

t

e

e

l

g

r

a

d

e

A

2

-

7

0

=

S

t

a

in

le

ss

s

t

e

e

l

W

1

.4

5

2

9

H

C

R

-

5

0

f

v

g

v

f

v

8

.8

A

4

-

5

0

g

v

8

.8

A

4

-

7

0 A

2

-

5

0 A

2

-

7

0 H

C

R

e

S

Roofng bolts

Hexagon Nuts DIN 934,

DIN EN 24032

S

m

S

d

D

S

d

D

Zinc Plated

Thread - ZP

Zinc Plated

for bolt - ZP

Zinc Plated

Dimension- ZP

D

[mm]

D

[mm]

S/m

DIN

[mm]

S

DIN

[mm]

S/m

ISO

[mm]

S

EN

[mm]

e

[mm]

d

[mm]

d

[mm]

s

[mm]

s

[mm]

Length

[mm]

Load

cap.

[kN]

Threaded Rods, Hexagon Head Bol ts, Nuts, Washers

FR AMI NG SY STEM S ACCESSORI ES

Order Example : TR - ZP - M 12 1000

Order Example : HB - ZP - M 12 1000

Order Example: WA - ZP - M 12 - DIN 9021

Order Example: WA - ZP - M 12 - DIN 125

DIN

22

24

30

45

37

50

12

16

21

24

30

10/ 5

13/6,5

17/ 8

19/10

24/13

10

13

17

19

24

18

24

10

13

16

10/ 6

13/7,5

16/ 9,5

18/12

24/15,5

11,5

15,0

19,6

21,9

27,7

6,6

8,4

10,5

13,5

13

17

6,4

8,4

10,5

13

17

2

2

2,5

4

3

3

1,6

1,6

2

2,5

3

1000

1000

1000

1000

1000

2,2

4,0

6,4

12,9

17,3

M 6

M 8

M 10

M 12

M 16

M 6 x 12

M 6 x 25

M 8 x 25

M 8 x 40

M 10 x 20

M 10 x 30

M 10 x 45

M 10 x 60

M 10 x 70

M 12 x 22

M 12 x 25

M 12 x 30

M 12 x 40

M 12 x 50

M 12 x 60

M 12 x 80

M 12 x 90

M 16 x 40

M 16 x 60

M 16 x 90

M 8 x 25

M 10 x 30

M 10 x 45

M 12 x 25

M 12 x 30

M 12 x 40

M 12 x 60

M 12 x 80

M 16 x 40

M 16 x 60

M 16 x 90

M 6

M 8

M 10

M 12

M 16

M 6

M 8

M 10

M 12

M 16

440

9021

9021

440

9021

9021

M 6

M 8

M 10

M 12

M 12

M 16

M 6

M 8

M 10

M 12

M 16

M 8

M 10

M 12

M 16

M 6

M 8

M 10

M 12

M 16

M 6

M 8

M 10

M 12

M 16

Stainless Steel

Thread

Zinc Plated

Thread - ZP

Stainless Steel

Thread

Stainless Steel

for bolt

Zinc Plated

for bolt - ZP

Stainless Steel

for bolt

Stainless Steel

Dimension

Material & Finishes Codes

( S. 53)

= h.d. galvanised, strength grade 4.6

= electroplated, 4.6

= , 8.8

= Stainless steel grade A4-50

strength grade

h.d. galvanised strength grade

= electroplated, strength grade 8.8

= Stainless steel grade A4-70

= Stainless steel grade A2-50

= Stainless steel grade A2-70

= Stainless steel W1.4529 HCR-50

fv

gv

fv 8.8

A4-50

gv 8.8

A4-70

A2-50

A2-70

HCR

e

S

S

m

S

d

D

S

d

D

Zinc Plated

Thread - ZP

Zinc Plated

for bolt - ZP

Zinc Plated

Dimension- ZP

D

[mm]

D

[mm]

S/m

DIN

[mm]

S

DIN

[mm]

S/m

ISO

[mm]

S

EN

[mm]

e

[mm]

d

[mm]

d

[mm]

s

[mm]

s

[mm]

Length

[mm]

Load

cap.

[kN]

Threaded Rods, Hexagon Head Bol ts, Nuts, Washers

FR AMI NG SY STEM S ACCESSORI ES

Order Example : TR - ZP - M 12 1000

Order Example : HB - ZP - M 12 1000

Order Example: WA - ZP - M 12 - DIN 9021

Order Example: WA - ZP - M 12 - DIN 125

DIN

22

24

30

45

37

50

12

16

21

24

30

10/ 5

13/6,5

17/ 8

19/10

24/13

10

13

17

19

24

18

24

10

13

16

10/ 6

13/7,5

16/ 9,5

18/12

24/15,5

11,5

15,0

19,6

21,9

27,7

6,6

8,4

10,5

13,5

13

17

6,4

8,4

10,5

13

17

2

2

2,5

4

3

3

1,6

1,6

2

2,5

3

1000

1000

1000

1000

1000

2,2

4,0

6,4

12,9

17,3

M 6

M 8

M 10

M 12

M 16

M 6 x 12

M 6 x 25

M 8 x 25

M 8 x 40

M 10 x 20

M 10 x 30

M 10 x 45

M 10 x 60

M 10 x 70

M 12 x 22

M 12 x 25

M 12 x 30

M 12 x 40

M 12 x 50

M 12 x 60

M 12 x 80

M 12 x 90

M 16 x 40

M 16 x 60

M 16 x 90

M 8 x 25

M 10 x 30

M 10 x 45

M 12 x 25

M 12 x 30

M 12 x 40

M 12 x 60

M 12 x 80

M 16 x 40

M 16 x 60

M 16 x 90

M 6

M 8

M 10

M 12

M 16

M 6

M 8

M 10

M 12

M 16

440

9021

9021

440

9021

9021

M 6

M 8

M 10

M 12

M 12

M 16

M 6

M 8

M 10

M 12

M 16

M 8

M 10

M 12

M 16

M 6

M 8

M 10

M 12

M 16

M 6

M 8

M 10

M 12

M 16

Stainless Steel

Thread

Zinc Plated

Thread - ZP

Stainless Steel

Thread

Stainless Steel

for bolt

Zinc Plated

for bolt - ZP

Stainless Steel

for bolt

Stainless Steel

Dimension

Material & Finishes Codes

( S. 53)

= h.d. galvanised, strength grade 4.6

= electroplated, 4.6

= , 8.8

= Stainless steel grade A4-50

strength grade

h.d. galvanised strength grade

= electroplated, strength grade 8.8

= Stainless steel grade A4-70

= Stainless steel grade A2-50

= Stainless steel grade A2-70

= Stainless steel W1.4529 HCR-50

fv

gv

fv 8.8

A4-50

gv 8.8

A4-70

A2-50

A2-70

HCR

e

S

S

m

S

d

D

S

d

D

Zinc Plated

Thread - ZP

Zinc Plated

for bolt - ZP

Zinc Plated

Dimension- ZP

D

[mm]

D

[mm]

S/m

DIN

[mm]

S

DIN

[mm]

S/m

ISO

[mm]

S

EN

[mm]

e

[mm]

d

[mm]

d

[mm]

s

[mm]

s

[mm]

Length

[mm]

Load

cap.

[kN]

Threaded Rods, Hexagon Head Bol ts, Nuts, Washers

FR AMI NG SY STEM S ACCESSORI ES

Order Example : TR - ZP - M 12 1000

Order Example : HB - ZP - M 12 1000

Order Example: WA - ZP - M 12 - DIN 9021

Order Example: WA - ZP - M 12 - DIN 125

DIN

22

24

30

45

37

50

12

16

21

24

30

10/ 5

13/6,5

17/ 8

19/10

24/13

10

13

17

19

24

18

24

10

13

16

10/ 6

13/7,5

16/ 9,5

18/12

24/15,5

11,5

15,0

19,6

21,9

27,7

6,6

8,4

10,5

13,5

13

17

6,4

8,4

10,5

13

17

2

2

2,5

4

3

3

1,6

1,6

2

2,5

3

1000

1000

1000

1000

1000

2,2

4,0

6,4

12,9

17,3

M 6

M 8

M 10

M 12

M 16

M 6 x 12

M 6 x 25

M 8 x 25

M 8 x 40

M 10 x 20

M 10 x 30

M 10 x 45

M 10 x 60

M 10 x 70

M 12 x 22

M 12 x 25

M 12 x 30

M 12 x 40

M 12 x 50

M 12 x 60

M 12 x 80

M 12 x 90

M 16 x 40

M 16 x 60

M 16 x 90

M 8 x 25

M 10 x 30

M 10 x 45

M 12 x 25

M 12 x 30

M 12 x 40

M 12 x 60

M 12 x 80

M 16 x 40

M 16 x 60

M 16 x 90

M 6

M 8

M 10

M 12

M 16

M 6

M 8

M 10

M 12

M 16

440

9021

9021

440

9021

9021

M 6

M 8

M 10

M 12

M 12

M 16

M 6

M 8

M 10

M 12

M 16

M 8

M 10

M 12

M 16

M 6

M 8

M 10

M 12

M 16

M 6

M 8

M 10

M 12

M 16

Stainless Steel

Thread

Zinc Plated

Thread - ZP

Stainless Steel

Thread

Stainless Steel

for bolt

Zinc Plated

for bolt - ZP

Stainless Steel

for bolt

Stainless Steel

Dimension

Material & Finishes Codes

( S. 53)

= h.d. galvanised, strength grade 4.6

= electroplated, 4.6

= , 8.8

= Stainless steel grade A4-50

strength grade

h.d. galvanised strength grade

= electroplated, strength grade 8.8

= Stainless steel grade A4-70

= Stainless steel grade A2-50

= Stainless steel grade A2-70

= Stainless steel W1.4529 HCR-50

fv

gv

fv 8.8

A4-50

gv 8.8

A4-70

A2-50

A2-70

HCR

e

S

Machine hex head bolts

DIN 933, DIN 24017

S

m

S

dD

S

dD

Z

i

n

c

P

l

a

t

e

d

T

h

r

e

a

d

-

Z

P

Z

i

n

c

P

l

a

t

e

d

f

o

r

b

o

l

t

-

Z

P

Z

i

n

c

P

l

a

t

e

d

D

i

m

e

n

s

i

o

n

-

Z

P

D

[

m

m

]

D

[

m

m

]

S

/

m

D

I

N

[

m

m

]

S

D

I

N

[

m

m

]

S

/

m

I

S

O

[

m

m

]

S

E

N

[

m

m

]

e

[

m

m

]

d

[

m

m

]

d

[

m

m

]

s

[

m

m

]

s

[

m

m

]

L

e

n

g

t

h

[

m

m

]

L

o

a

d

c

a

p

.

[

k

N

]

T

h

r

e

a

d

e

d

R

o

d

s

,

H

e

x

a

g

o

n

H

e

a

d

B

o

l

t

s

,

N

u

t

s

,

W

a

s

h

e

r

s

F

R

A

M

I

N

G

S

Y

S

T

E

M

S

A

C

C

E

S

S

O

R

I

E

S

O

r

d

e

r

E

x

a

m

p

l

e

:

T

R

-

Z

P

-

M

1

2

1

0

0

0

O

r

d

e

r

E

x

a

m

p

l

e

:

H

B

-

Z

P

-

M

1

2

1

0

0

0

O

r

d

e

r

E

x

a

m

p

l

e

:

W

A

-

Z

P

-

M

1

2

-

D

I

N

9

0

2

1

O

r

d

e

r

E

x

a

m

p

l

e

:

W

A

-

Z

P

-

M

1

2

-

D

I

N

1

2

5

D

I

N

2

2

2

4

3

0

4

5

3

7

5

0

1

2

1

6

2

1

2

4

3

0

1

0

/

5

1

3

/

6

,

5

1

7

/

8

1

9

/

1

0

2

4

/

1

3

1

0

1

3

1

7

1

9

2

4

1

8

2

4

1

0

1

3

1

6

1

0

/

6

1

3

/

7

,

5

1

6

/

9

,

5

1

8

/

1

2

2

4

/

1

5

,

5

1

1

,

5

1

5

,

0

1

9

,

6

2

1

,

9

2

7

,

7

6

,

6

8

,

4

1

0

,

5

1

3

,

5

1

3

1

7

6

,

4

8

,

4

1

0

,

5

1

3

1

7

22

2

,

5

433

1

,

6

1

,

6

2

2

,

5

3

1

0

0

0

1

0

0

0

1

0

0

0

1

0

0

0

1

0

0

0

2

,

2

4

,

0

6

,

4

1

2

,

9

1

7

,

3

M

6

M

8

M

1

0

M

1

2

M

1

6

M

6

x

1

2

M

6

x

2

5

M

8

x

2

5

M

8

x

4

0

M

1

0

x

2

0

M

1

0

x

3

0

M

1

0

x

4

5

M

1

0

x

6

0

M

1

0

x

7

0

M

1

2

x

2

2

M

1

2

x

2

5

M

1

2

x

3

0

M

1

2

x

4

0

M

1

2

x

5

0

M

1

2

x

6

0

M

1

2

x

8

0

M

1

2

x

9

0

M

1

6

x

4

0

M

1

6

x

6

0

M

1

6

x

9

0

M

8

x

2

5

M

1

0

x

3

0

M

1

0

x

4

5

M

1

2

x

2

5

M

1

2

x

3

0

M

1

2

x

4

0

M

1

2

x

6

0

M

1

2

x

8

0

M

1

6

x

4

0

M

1

6

x

6

0

M

1

6

x

9

0

M

6

M

8

M

1

0

M

1

2

M

1

6

M

6

M

8

M

1

0

M

1

2

M

1

6

4

4

0

9

0

2

1

9

0

2

1

4

4

0

9

0

2

1

9

0

2

1

M

6

M

8

M

1

0

M

1

2

M

1

2

M

1

6

M

6

M

8

M

1

0

M

1

2

M

1

6

M

8

M

1

0

M

1

2

M

1

6

M

6

M

8

M

1

0

M

1

2

M

1

6

M

6

M

8

M

1

0

M

1

2

M

1

6

S

t

a

i

n

l

e

s

s

S

t

e

e

l

T

h

r

e

a

d

Z

i

n

c

P

l

a

t

e

d

T

h

r

e

a

d

-

Z

P

S

t

a

i

n

l

e

s

s

S

t

e

e

l

T

h

r

e

a

d

S

t

a

i

n

l

e

s

s

S

t

e

e

l

f

o

r

b

o

l

t

Z

i

n

c

P

l

a

t

e

d

f

o

r

b

o

l

t

-

Z

P

S

t

a

i

n

l

e

s

s

S

t

e

e

l

f

o

r

b

o

l

t

S

t

a

i

n

l

e

s

s

S

t

e

e

l

D

i

m

e

n

s

i

o

n

M

a

t

e

r

i

a

l

&

F

i

n

i

s

h

e

s

C

o

d

e

s

(

S

.

5

3

)

=

h

.

d

.

g

a

l

v

a

n

i

s

e

d

,

s

t

r

e

n

g

t

h

g

r

a

d

e

4

.

6

=

e

l

e

c

t

r

o

p

l

a

t

e

d

,

4

.

6

=

,

8

.

8

=

S

t

a

i

n

l

e

s

s

s

t

e

e

l

g

r

a

d

e

A

4

-

5

0

s

t

r

e

n

g

t

h

g

r

a

d

e

h

.

d

.

g

a

l

v

a

n

i

s

e

d

s

t

r

e

n

g

t

h

g

r

a

d

e

=

e

l

e

c

t

r

o

p

l

a

t

e

d

,

s

t

r

e

n

g

t

h

g

r

a

d

e

8

.

8

=

S

t

a

i

n

l

e

s

s

s

t

e

e

l

g

r

a

d

e

A

4

-

7

0

=

S

t

a

i

n

l

e

s

s

s

t

e

e

l

g

r

a

d

e

A

2

-

5

0

=

S

t

a

i

n

l

e

s

s

s

t

e

e

l

g

r

a

d

e

A

2

-

7

0

=

S

t

a

i

n

l

e

s

s

s

t

e

e

l

W

1

.

4

5

2

9

H

C

R

-

5

0

f

v

g

v

f

v

8

.

8

A

4

-

5

0

g

v

8

.

8

A

4

-

7

0

A

2

-

5

0

A

2

-

7

0

H

C

R

e

S

S

m

S

dD

S

dD

Z

i

n

c

P

l

a

t

e

d

T

h

r

e

a

d

-

Z

P

Z

i

n

c

P

l

a

t

e

d

f

o

r

b

o

l

t

-

Z

P

Z

i

n

c

P

l

a

t

e

d

D

i

m

e

n

s

i

o

n

-

Z

P

D

[

m

m

]

D

[

m

m

]

S

/

m

D

I

N

[

m

m

]

S

D

I

N

[

m

m

]

S

/

m

I

S

O

[

m

m

]

S

E

N

[

m

m

]

e

[

m

m

]

d

[

m

m

]

d

[

m

m

]

s

[

m

m

]

s

[

m

m

]

L

e

n

g

t

h

[

m

m

]

L

o

a

d

c

a

p

.

[

k

N

]

T

h

r

e

a

d

e

d

R

o

d

s

,

H

e

x

a

g

o

n

H

e

a

d

B

o

l

t

s

,

N

u

t

s

,

W

a

s

h

e

r

s

F

R

A

M

I

N

G

S

Y

S

T

E

M

S

A

C

C

E

S

S

O

R

I

E

S

O

r

d

e

r

E

x

a

m

p

l

e

:

T

R

-

Z

P

-

M

1

2

1

0

0

0

O

r

d

e

r

E

x

a

m

p

l

e

:

H

B

-

Z

P

-

M

1

2

1

0

0

0

O

r

d

e

r

E

x

a

m

p

l

e

:

W

A

-

Z

P

-

M

1

2

-

D

I

N

9

0

2

1

O

r

d

e

r

E

x

a

m

p

l

e

:

W

A

-

Z

P

-

M

1

2

-

D

I

N

1

2

5

D

I

N

2

2

2

4

3

0

4

5

3

7

5

0

1

2

1

6

2

1

2

4

3

0

1

0

/

5

1

3

/

6

,

5

1

7

/

8

1

9

/

1

0

2

4

/

1

3

1

0

1

3

1

7

1

9

2

4

1

8

2

4

1

0

1

3

1

6

1

0

/

6

1

3

/

7

,

5

1

6

/

9

,

5

1

8

/

1

2

2

4

/

1

5

,

5

1

1

,

5

1

5

,

0

1

9

,

6

2

1

,

9

2

7

,

7

6

,

6

8

,

4

1

0

,

5

1

3

,

5

1

3

1

7

6

,

4

8

,

4

1

0

,

5

1

3

1

7

22

2

,

5

433

1

,

6

1

,

6

2

2

,

5

3

1

0

0

0

1

0

0

0

1

0

0

0

1

0

0

0

1

0

0

0

2

,

2

4

,

0

6

,

4

1

2

,

9

1

7

,

3

M

6

M

8

M

1

0

M

1

2

M

1

6

M

6

x

1

2

M

6

x

2

5

M

8

x

2

5

M

8

x

4

0

M

1

0

x

2

0

M

1

0

x

3

0

M

1

0

x

4

5

M

1

0

x

6

0

M

1

0

x

7

0

M

1

2

x

2

2

M

1

2

x

2

5

M

1

2

x

3

0

M

1

2

x

4

0

M

1

2

x

5

0

M

1

2

x

6

0

M

1

2

x

8

0

M

1

2

x

9

0

M

1

6

x

4

0

M

1

6

x

6

0

M

1

6

x

9

0

M

8

x

2

5

M

1

0

x

3

0

M

1

0

x

4

5

M

1

2

x

2

5

M

1

2

x

3

0

M

1

2

x

4

0

M

1

2

x

6

0

M

1

2

x

8

0

M

1

6

x

4

0

M

1

6

x

6

0

M

1

6

x

9

0

M

6

M

8

M

1

0

M

1

2

M

1

6

M

6

M

8

M

1

0

M

1

2

M

1

6

4

4

0

9

0

2

1

9

0

2

1

4

4

0

9

0

2

1

9

0

2

1

M

6

M

8

M

1

0

M

1

2

M

1

2

M

1

6

M

6

M

8

M

1

0

M

1

2

M

1

6

M

8

M

1

0

M

1

2

M

1

6

M

6

M

8

M

1

0

M

1

2

M

1

6

M

6

M

8

M

1

0

M

1

2

M

1

6

S

t

a

i

n

l

e

s

s

S

t

e

e

l

T

h

r

e

a

d

Z

i

n

c

P

l

a

t

e

d

T

h

r

e

a

d

-

Z

P

S

t

a

i

n

l

e

s

s

S

t

e

e

l

T

h

r

e

a

d

S

t

a

i

n

l

e

s

s

S

t

e

e

l

f

o

r

b

o

l

t

Z

i

n

c

P

l

a

t

e

d

f

o

r

b

o

l

t

-

Z

P

S

t

a

i

n

l

e

s

s

S

t

e

e

l

f

o

r

b

o

l

t

S

t

a

i

n

l

e

s

s

S

t

e

e

l

D

i

m

e

n

s

i

o

n

M

a

t

e

r

i

a

l

&

F

i

n

i

s

h

e

s

C

o

d

e

s

(

S

.

5

3

)

=

h

.

d

.

g

a

l

v

a

n

i

s

e

d

,

s

t

r

e

n

g

t

h

g

r

a

d

e

4

.

6

=

e

l

e

c

t

r

o

p

l

a

t

e

d

,

4

.

6

=

,

8

.

8

=

S

t

a

i

n

l

e

s

s

s

t

e

e

l

g

r

a

d

e

A

4

-

5

0

s

t

r

e

n

g

t

h

g

r

a

d

e

h

.

d

.

g

a

l

v

a

n

i

s

e

d

s

t

r

e

n

g

t

h

g

r

a

d

e

=

e

l

e

c

t

r

o

p

l

a

t

e

d

,

s

t

r

e

n

g

t

h

g

r

a

d

e

8

.

8

=

S

t

a

i

n

l

e

s

s

s

t

e

e

l

g

r

a

d

e

A

4

-

7

0

=

S

t

a

i

n

l

e

s

s

s

t

e

e

l

g

r

a

d

e

A

2

-

5

0

=

S

t

a

i

n

l

e

s

s

s

t

e

e

l

g

r

a

d

e

A

2

-

7

0

=

S

t

a

i

n

l

e

s

s

s

t

e

e

l

W

1

.

4

5

2

9

H

C

R

-

5

0

f

v

g

v

f

v

8

.

8

A

4

-

5

0

g

v

8

.

8

A

4

-

7

0

A

2

-

5

0

A

2

-

7

0

H

C

R

e

S

Coupler Sleeves Rounded Rod Coupler Hexagonal

Carriage bolts with Nut

Below Head DIN 603

H

P

E

O

A

S

m

S

d

D

S

d

D

Zinc Plated

Thread - ZP

Zinc Plated

for bolt - ZP

Zinc Plated

Dimension- ZP

D

[mm]

D

[mm]

S/m

DIN

[mm]

S

DIN

[mm]

S/m

ISO

[mm]

S

EN

[mm]

e

[mm]

d

[mm]

d

[mm]

s

[mm]

s

[mm]

Length

[mm]

Load

cap.

[kN]

Threaded Rods, Hexagon Head Bol ts, Nuts, Washers

FR AMI NG SY STEM S ACCESSORI ES

Order Example : TR - ZP - M 12 1000

Order Example : HB - ZP - M 12 1000

Order Example: WA - ZP - M 12 - DIN 9021

Order Example: WA - ZP - M 12 - DIN 125

DIN

22

24

30

45

37

50

12

16

21

24

30

10/ 5

13/6,5

17/ 8

19/10

24/13

10

13

17

19

24

18

24

10

13

16

10/ 6

13/7,5

16/ 9,5

18/12

24/15,5

11,5

15,0

19,6

21,9

27,7

6,6

8,4

10,5

13,5

13

17

6,4

8,4

10,5

13

17

2

2

2,5

4

3

3

1,6

1,6

2

2,5

3

1000

1000

1000

1000

1000

2,2

4,0

6,4

12,9

17,3

M 6

M 8

M 10

M 12

M 16

M 6 x 12

M 6 x 25

M 8 x 25

M 8 x 40

M 10 x 20

M 10 x 30

M 10 x 45

M 10 x 60

M 10 x 70

M 12 x 22

M 12 x 25

M 12 x 30

M 12 x 40

M 12 x 50

M 12 x 60

M 12 x 80

M 12 x 90

M 16 x 40

M 16 x 60

M 16 x 90

M 8 x 25

M 10 x 30

M 10 x 45

M 12 x 25

M 12 x 30

M 12 x 40

M 12 x 60

M 12 x 80

M 16 x 40

M 16 x 60

M 16 x 90

M 6

M 8

M 10

M 12

M 16

M 6

M 8

M 10

M 12

M 16

440

9021

9021

440

9021

9021

M 6

M 8

M 10

M 12

M 12

M 16

M 6

M 8

M 10

M 12

M 16

M 8

M 10

M 12

M 16

M 6

M 8

M 10

M 12

M 16

M 6

M 8

M 10

M 12

M 16

Stainless Steel

Thread

Zinc Plated

Thread - ZP

Stainless Steel

Thread

Stainless Steel

for bolt

Zinc Plated

for bolt - ZP

Stainless Steel

for bolt

Stainless Steel

Dimension

Material & Finishes Codes

( S. 53)

= h.d. galvanised, strength grade 4.6

= electroplated, 4.6

= , 8.8

= Stainless steel grade A4-50

strength grade

h.d. galvanised strength grade

= electroplated, strength grade 8.8

= Stainless steel grade A4-70

= Stainless steel grade A2-50

= Stainless steel grade A2-70

= Stainless steel W1.4529 HCR-50

fv

gv

fv 8.8

A4-50

gv 8.8

A4-70

A2-50

A2-70

HCR

e

S

www.unitech-ikk.com

www.unimetal-ikk.com

www.sfsp-ikk.com

Jeddah

Tel: +966 2 627 8222

Fax: +966 2 627 8722

unitech.ksa@ikkgroup.com

Jeddah - Ghurab Showroom

Tel: +966 2 667 2000

Fax: +966 2 661 4306

unitech.ksa@ikkgroup.com

Mak kah, Taif

Tel: +966 2 597 2675

Fax: +966 2 597 0588

unitech.ksa@ikkgroup.com

Mad inah

Tel: +966 4 864 9111

Fax: +966 4 864 9222

unitech.ksa@ikkgroup.com

Yanbu

Tel: +966 4 390 1499

Fax: +966 4 322 7101

unitech.ksa@ikkgroup.com

Khamis Mushayt

Tel: +966 7 237 5929

Fax: +966 7 237 8783

unitech.ksa@ikkgroup.com

baha

Tel: +966 7 237 5929

Fax: +966 7 237 8783

unitech.ksa@ikkgroup.com

Najran

Tel: +966 7 321 4038

Fax: +966 7 321 4035

unitech.ksa@ikkgroup.com

Gizan

Tel: +966 7 321 6660

Fax: +966 7 321 0665

unitech.ksa@ikkgroup.com

Riyadh

Tel: +966 1 454 9282

Fax: +966 1 456 6627

unitech.ksa@ikkgroup.com

Riyadh - Rail St.ofce

Tel: +966 1 810 5926

Fax: +966 1 456 6627

unitech.ksa@ikkgroup.com

Qassim

Tel: +966 6 382 3946

Fax: +966 6 385 2186

unitech.ksa@ikkgroup.com

Qassim Showroom

Tel: +966 6 385 2598

Fax: +966 6 382 6684

unitech.ksa@ikkgroup.com

Tabuk

Tel: +966 4 424 3386

Fax: +966 4 423 5203

unitech.ksa@ikkgroup.com

Skakah, Qurayyat

Tel: +966 4 626 3904

Fax: +966 4 626 3905

unitech.ksa@ikkgroup.com

Hail

Tel: +966 6 543 3931

Fax: +966 6 543 3935

unitech.ksa@ikkgroup.com

hafar Al batn

Tel: +966 3 721 5915

Fax: +966 3 721 5915

unitech.ksa@ikkgroup.com

Dammam

Tel: +966 3 859 0097

Fax: +966 3 857 8177

unitech.ksa@ikkgroup.com

dammam - Showroom

Tel: +966 3 834 9300

Fax: +966 3 834 9457

unitech.ksa@ikkgroup.com

Hufuf

Tel: +966 3 586 9732

Fax: +966 3 584 5966

unitech.ksa@ikkgroup.com

Jubail

Tel: +966 3 361 4390

Fax: +966 3 361 4499

unitech.ksa@ikkgroup.com

UNITED ARAB EMIRATES

Dubai - DIP

Tel : +971 4 884 7275

Fax: +971 4 884 7278

unitech.uae@ikkgroup.com

dubai - Al Rashidiyah

Tel: +971 4 285 6031

Fax: +971 4 286 2941

unitech.uae@ikkgroup.com

Sharjah

Tel: +971 6 534 4092

Fax: +971 6 534 8949

unitech.uae@ikkgroup.com

Abu dhabi - Musafah

Tel: +971 2 551 2334

Fax: +971 2 551 2335

unitech.uae@ikkgroup.com

EGYPT

Cairo

Tel: +20 2 3346 8566

Fax: +20 2 3346 8567

unitech.egypt@ikkgroup.com

Cairo - Gamhouriyah St.

Tel: +20 2 2787 2152

Fax: +20 2 2593 1053

unitech.egypt@ikkgroup.com

Cairo - Tagammu Al-Khamis

Tel: +20 2 2616 1650

Fax: +20 2 2616 1651

unitech.egypt@ikkgroup.com

BAHRAIN

Manamah

Tel: +973 1 756 4386

Fax: +973 1 756 4315

unitech.bahrain@ikkgroup.com

QATAR

doha

Tel: +974 4451 3301/2/3

Fax: +974 4451 3305

unitech.qatar@ikkgroup.com

LEBANON

Beirut

Tel: +961 1 858 277

Fax: +961 1 858 276

unitech.lebanon@ikkgroup.com

JORDAN

Amman

Tel: +962 6 556 3030

Fax: +962 6 554 7911

unitech.jordan@ikkgroup.com

LIBYA

Tripoli

Tel: +218 21 717 0264

Fax: +218 21 477 1612

unitech.libya@ikkgroup.com

OMAN

Muscat

Tel: + 968 24 591 006

Fax: + 968 24 597 006

unitech.oman@ikkgroup.com

KUWAIT

Kuwait City

Tel : +965 22 459 984

Fax: +965 22 459 985

unitech.kuwait@ikkgroup.com

YEMEN

Sanaa

Tel: +967 1 473 542

Fax: +967 1 473 542

unitech.yemen@ikkgroup.com

SUDAN

Khartoum

Tel: +249 183 528 065

Fax: +249 183 248 065

unitech.sudan@ikkgroup.com

UK

birmingham

Tel: +44 121 698 21 85

Fax: +44 121 698 21 47

unitech.uk@ikkgroup.com

DESIGN OFFICE

Germany

Stutgart

Tel: +49 711 6868 7222

Fax: +49 711 6868 7223

unitech.germany@ikkgroup.com

SFSP / KINGDOM OF SAUDI ARABIA

Specialized Factory for Steel Products - Jeddah

Tel: +966 2 637 4482

Fax: +966 2 636 1963

sfsp.jeddah@ikkgroup.com

SFSP / UNITED ARAB EMIRATES

SIGMA Factory for Steel Products - Ajman

Tel: +971 6 743 9907

Fax: +971 6 743 9908

sfsp.ajman@ikkgroup.com

SFSP / EGYPT

Specialized Factory for Steel Products - 6th of October, Cairo

Tel: +20 2 3831 2477

Fax: +20 2 3831 1036

sfsp.cairo@ikkgroup.com

SIGMA Factory for Steel Products - Umm Al Quwain

Tel: +971 6 767 0514

Fax: +971 6 767 0515

sfsp.uaq@ikkgroup.com

KINGDOM OF SAUDI ARABIA

You might also like

- Kubota V Manual U20!3!25 31Document508 pagesKubota V Manual U20!3!25 31brunosamaeian82% (11)

- I - Rectangular Ducts: II - Rectangular Ducts WeldedDocument32 pagesI - Rectangular Ducts: II - Rectangular Ducts WeldedRoy Anthone Layson100% (11)

- DW144 Smacna 2005Document32 pagesDW144 Smacna 2005Angel Daniel GarciajoyaNo ratings yet

- Connections For Hydraulic Fluid Power and General Use - Hose FittingsDocument20 pagesConnections For Hydraulic Fluid Power and General Use - Hose FittingsОлег СоловьевNo ratings yet

- VSL Threadbar SystemsDocument16 pagesVSL Threadbar SystemsNguyen Chau LanNo ratings yet

- Protection Guide enDocument74 pagesProtection Guide enEmad100% (28)

- CatalogDocument48 pagesCatalogAhmad AshrafNo ratings yet

- Bolted and Welded ConnectionsDocument12 pagesBolted and Welded ConnectionsTemesgenAbiy100% (2)

- Calculations For HV and LVDocument40 pagesCalculations For HV and LVAerwin BautistaNo ratings yet

- Calculations For HV and LVDocument40 pagesCalculations For HV and LVAerwin BautistaNo ratings yet

- Cable GlandsDocument20 pagesCable GlandsBalaji VenkatesanNo ratings yet

- Cable Ladder CatalogueDocument18 pagesCable Ladder Catalogue123peniscolaNo ratings yet

- XLPE Insulated Low Voltage Cables 2012Document40 pagesXLPE Insulated Low Voltage Cables 2012Jeremy McfaddenNo ratings yet

- XLPE Insulated Low Voltage Cables 2012Document40 pagesXLPE Insulated Low Voltage Cables 2012Jeremy McfaddenNo ratings yet

- XLPE Insulated Low Voltage Cables 2012Document40 pagesXLPE Insulated Low Voltage Cables 2012Jeremy McfaddenNo ratings yet

- 1st Floor DrawingsDocument1 page1st Floor DrawingsBedan KivuvaNo ratings yet

- Top 10 Rules 2014NECDocument45 pagesTop 10 Rules 2014NECerubengoNo ratings yet

- Cable Ladder TrayDocument80 pagesCable Ladder TrayrocketvtNo ratings yet

- Junction BoxDocument1 pageJunction BoxIkhsan ArifNo ratings yet

- Catalogue J.BDocument17 pagesCatalogue J.Bdip461No ratings yet

- Telecommunications Building Cabling Systems Planning and DesignDocument45 pagesTelecommunications Building Cabling Systems Planning and Designศิษย์เก่า ทีเจพี100% (1)