Professional Documents

Culture Documents

A 599

Uploaded by

Gustavo Suarez0 ratings0% found this document useful (0 votes)

78 views3 pagesThis standard covers cold-rolled steel sheet in coils or in cut lengths, tin-coated by electrodeposition. Tin coating is available as unmelted or melted. This standard is issued under the fixed designation a 599 / a 599M.

Original Description:

Original Title

A-599

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis standard covers cold-rolled steel sheet in coils or in cut lengths, tin-coated by electrodeposition. Tin coating is available as unmelted or melted. This standard is issued under the fixed designation a 599 / a 599M.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

78 views3 pagesA 599

Uploaded by

Gustavo SuarezThis standard covers cold-rolled steel sheet in coils or in cut lengths, tin-coated by electrodeposition. Tin coating is available as unmelted or melted. This standard is issued under the fixed designation a 599 / a 599M.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

Designation: A 599/A 599M 99

Standard Specication for

Tin Mill Products, Electrolytic Tin-Coated, Cold-Rolled

Sheet

1

This standard is issued under the xed designation A 599/A 599M; the number immediately following the designation indicates the year

of original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval.

A superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This specication covers cold-rolled steel sheet in coils

or in cut lengths, tin-coated by electrodeposition. The product

is commonly known as electrolytic tin-coated sheet, and is for

applications that need good solderability, good surface appear-

ance, and a degree of corrosion resistance. Tin-coated sheet is

produced to various designations of tin coating, as outlined in

Table 1.

1.1.1 Electrolytic tin-coated sheet is customarily available

as commercial steel (CS); drawing steel (DS); deep drawing

steel (DDS); extra deep drawing steel (EDDS), and structural

steel (SS). The tin coating is available as unmelted or melted.

1.2 LimitationsThis specication is applicable to orders

in either inch-pound units (as A 599), which is supplied in

thicknesses from 0.015 in. to 0.033 in., or SI units [as A599M],

which is supplied in thicknesses from 0.38 mm to 0.84 mm.

For thicknesses lighter than 0.015 in. [0.38 mm], refer to A624

[A 624M].

1.3 Unless the order shows the M designation [SI units],

the product shall be furnished to inch-pound units. The values

stated in either inch-pound or SI units are to be regarded as

standard. Within the text, the SI units are shown in brackets.

The values stated in each system are not exact equivalents;

therefore, each system must be used independently of the other.

Combining values from the two systems may result in noncon-

formance with this specication.

2. Referenced Documents

2.1 ASTM Standards:

A 366/A 366M Specication for Commercial Steel (CS)

Sheet, Carbon (0.15 Maximum Percent) Cold-Rolled

2

A 568/A 568M Specication for Steel, Sheet, Carbon, and

High-Strength, Low-Alloy, Hot-Rolled and Cold-Rolled,

General Requirements for

2

A 611 Specication for Structural Steel (SS), Sheet, Car-

bon, Cold-Rolled

2

A 620/A 620M Specication for Drawing Steel (DS),

Sheet, Carbon, Cold-Rolled

2

A 623 Specication for Tin Mill Products, General Require-

ments

3

A 623M Specication for Tin Mill Products, General Re-

quirements (Metric)

3

A 624/A 624M Specication for Tin Mill Products, Electro-

lytic Tinplate, Single-Reduced

3

A 630 Test Methods for Determination of Tin Coating

Weights for Hot-Dip and Electrolytic Tin Plate

3

A 700 Practices for Packaging, Marking, and Loading

Methods for Steel Products for Domestic Shipment

4

A 963/A 963M Specication for Deep Drawing Steel

(DDS), Sheet, Carbon, Cold-Rolled

2

A 969/A 969M Specication for Extra Deep Drawing Steel

(EDDS) Sheet, Carbon, Cold-Rolled

2

3. Terminology

3.1 Denitions of Terms Specic to This Standard:

3.1.1 chemical treatmenta passivating chemical treat-

ment, normally applied to the tinned surface to stabilize the

surface to control tin oxide formation and growth. Sodium

dichromate is most commonly used. Without such treatment,

1

This specication is under the jurisdiction of ASTM Committee A-1 on Steel,

Stainless Steel, and Related Alloys and is the direct responsibility of Subcommittee

A01.20 on Tin Mill Products.

Current edition approved Sept. 10, 1999. Published December 1999. Originally

published as A 599 69. Last previous edition A 599 92 (1998).

2

Annual Book of ASTM Standards, Vol 01.03.

3

Annual Book of ASTM Standards, Vol 01.06.

4

Annual Book of ASTM Standards, Vol 01.05.

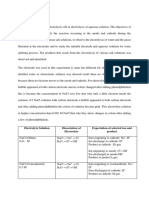

TABLE 1 Electrolytic Tin-Coated Sheets Coating Weight [Mass]

NOTE 1Listed below are the commonly produced coating weights

[mass] upon agreement between the producer and the purchaser. Other

combinations of coatings may be specied and the appropriate minimum

average test values

A

apply.

Designation No.

Nominal Tin Coating

Weight [Mass]

(Each Surface)

lb/base box (g/m

2

)

B

Minimum Average Coating

Weight [Mass]

(Each Surface Test Value)

lb/base box (g/m

2

)

B,C

5 (0.6/0.6) 0.025/0.025 (0.6/0.6) 0.02/0.02 (0.5/0.5)

10 (1.1/1.1) 0.05/0.05 (1.1/1.1) 0.04/0.04 (0.9/0.9)

15 (1.7/1.7) 0.075/0.075 (1.7/1.7) 0.06/0.06 (1.4/1.4)

20 (2.2/2.2) 0.10/0.10 (2.2/2.2) 0.08/0.08 (1.8/1.8)

25 (2.8/2.8) 0.125/0.125 (2.8/2.8) 0.11/0.11 (2.5/2.5)

50 (5.6/5.6) 0.25/0.25 (5.6/5.6) 0.23/0.23 (5.2/5.2)

75 (8.4/8.4) 0.375/0.375 (8.4/8.4) 0.35/0.35 (7.8/7.8)

100 (11.2/11.2) 0.50/0.50 (11.2/11.2) 0.45/0.45 (10.1/10.1)

A

Refer to Specications A 623 and A 623M.

B

A base box is dened as a unit of area equivalent to 112 sheets 14 in. by 20 in.

or 31 360 in.

2

(refer to Specication A 623).

C

The minimum single spot value shall not be less than 80 % of the minimum

average tin coating weight [mass] (see 8.1 and 8.2).

1

Copyright ASTM, 100 Barr Harbor Drive, West Conshohocken, PA 19428-2959, United States.

severe tin oxide growth, and its resultant discoloration, is a

hazard. Excessive oxide growth may also cause poor solder-

ability and poor adhesion of organic coatings. If a special

surface treatment is required, it should be negotiated with the

supplier.

3.2 Finishes:

3.2.1 No. 5 Finisha shot-blasted roll base metal nish

usually employed on unmelted tin-coated sheet.

3.2.2 No. 7 Finisha ground-roll base metal nish usually

employed on melted tin-coated sheet.

3.2.2.1 DiscussionIt is possible to produce either No. 5 or

No. 7 Finish as unmelted or melted; however, end application

is important and should be negotiated with the producer.

3.3 melted tin coatingtin coated by electrodeposition on a

base steel normally having a ground-roll nish (see 3.2), and

then melted to reow the tin. The resultant coating has a

brighter appearance than unmelted tin. An iron-tin alloy layer

is developed during the melting operation, thus reducing the

amount of free tin available. Due to the limitations of the

reow section of the plating lines, certain thicknesses may not

be available with a melted nish.

3.4 oilan extremely thin oil lm furnished on both sur-

faces of tinned sheet to minimize abrasion in shearing, coiling

or uncoiling, shipping, and handling. Usually dioctyl sebecate

(DOS) or acetyl tributyl citrate (ATBC) is used. Surface active

agents such as glycerol mono-oleate may be incorporated into

the lubricant for application on tinned sheet. Oil lm other than

normal should be negotiated with the producer. The oil lm is

not a drawing lubricant.

3.5 unmelted tin coatingtin-coated by electrodeposition

on a base steel normally having a dull, blasted-roll surface

texture (see 3.2). The deposited tin also has a dull gray

appearance.

4. Ordering Information

4.1 Orders for material under this specication shall include

the following, as required, to adequately describe the required

material.

4.1.1 Name of material (electrolytic tin-coated sheet) and

quality.

4.1.2 Coating designation (melted or unmelted).

4.1.3 Base Metal FinishSpecify either No. 5 (blasted roll)

or No. 7 (ground roll) base metal nish. If a special nish is

required, it should be negotiated with the supplier.

4.1.4 Dimensions (show thickness, width, and length, if cut

lengths).

4.1.5 Coil Size RequirementsSpecify maximum outside

diameter (OD), acceptable inside diameter (ID), and max-

imum coil weight [mass]; specify whether welds are acceptable

or not.

4.1.6 Application (show part identication and description).

4.1.7 ASTM designation number and year of issue.

4.1.8 Special requirements, if required.

NOTE 1A typical ordering description is as follows: Electrolytic

Tin-Coated SheetDeep Drawing Steel (DDS), Coating Designation 25,

Unmelted, No. 5 Finish, 0.018 by 26

3

16 in. by coil, 60 in. max OD, 16 in.

ID, 18 000 lb max, coil for oil-lter shells. ASTM A 599____ .

[Tin-Coated SheetDeep Drawing Steel (DDS), Coating Designation

2.8/2.8, Unmelted, No. 5 Finish, 0.50 mm by 668 mm by coil, 1530 mm

max OD, 408 mm ID, 8.2 metric tons max, coil for oil-lter shells. ASTM

A 599M____ .]

5. Manufacture

5.1 Base MetalThe base metal is produced in conform-

ance to that described for cold-rolled sheet in Specication

A 568/A 568M.

5.2 Coil PreparationNormal coil inside diameter is 16 in.

[400 mm]; any other should be negotiated. Requirements as to

the maximum outside diameter and to the maximum weight

should be indicated. The leading ends of lap welds shall not

exceed 1 in. [25 mm].

6. Chemical Requirements

6.1 The chemical composition of base metal furnished in

accordance with this specication shall conform to the require-

ments of the applicable quality designations of Specications

A 366/A 366M, A 611, A 620/A 620M, A 963/A 963M, and

A 969/A 969M.

7. Mechanical Requirements

7.1 Structural steel (SS) sheet is approved to tensile prop-

erty values as specied in Specication A 611.

7.2 Drawing steel (DS) sheet, deep drawing steel (DDS)

sheet, and extra deep drawing steel (EDDS) sheet are produced

to typical nonmandatory mechanical properties found in Table

2 of Specication A 620/A 620M, A 963/A 963M, and A 969/

A 969M, respectively.

8. Weight [Mass] of Coating

8.1 The weight [mass] of coating shall conform to the

requirements prescribed in Table 1 for the coating designation.

The weight of coating is the total amount on both sides of a

sheet, expressed in pounds per base box [or in grams per square

metre].

8.2 Determination of Tin Coating WeightsTypical meth-

ods for determination of tin coating weights are described in

Test Methods A 630. In cases of dispute, Method D, referee

method, shall be used.

9. Weight [Mass] of Coating Tests

9.1 When the purchaser wishes to make tests to ascertain

compliance of this specication for tin coating weight on a lot

of any specic item of electrolytic tin-coated sheet, the

procedure to be employed shall be that described in Test

Methods A 630.

10. Dimensions and Tolerances

10.1 Except for thickness and width tolerances shown in

TABLE 2 Thickness Tolerances for Electrolytic Tin-Coated

Steel Sheet

NOTE 1Thickness is measured at any point across the width not less

than |n# in. (9.5 mm) from a side edge.

Specied Width, in. [mm]

Thickness Tolerance, Over and Under, in.

[mm]

Specied Thickness, in. [mm]

Over 0.020 to 0.036

[0.51 to 0.91]

Over 0.015 to 0.020

[0.38 to 0.51], incl

Over 12 to 36 [300 to 900], incl 0.003 [0.08] 0.002 [0.05]

A 599/A 599M

2

Tables 2 and 3, material furnished to this specication shall

conform to the applicable requirements of the latest edition of

Specication A 568/A 568M. It is noted that tin-coated sheet

does not carry the width overrun associated with lighter gage

tin mill products.

11. Workmanship and Quality Level Requirements

11.1 The production of coils does not afford the same

opportunity for inspection, grading, and sorting as does the

production of cut lengths. Accordingly, appropriate processing

and quality control procedures are required by the purchaser to

obtain optimum utilization of the product. The hazard of

abrasion on coils is greater than on cut lengths and may occur

during coiling, shipping, or uncoiling.

12. General Requirements for Delivery

12.1 Material furnished under this specication shall con-

form to the applicable requirements of the latest edition of

Specication A 568/A 568M unless otherwise specied herein.

12.2 Tin-coated steel sheet shall be ordered to a base metal

decimal thickness for both coils and cut lengths, exclusive of

the coating thickness.

13. Rejection and Rehearing

13.1 Rejection and rehearing are subject to the same proce-

dure as described in Specication A 568/A 568M.

14. Marking

14.1 Marking shall be in accordance with the requirements

of Specication A 568/A 568M.

15. Packaging and Loading

15.1 It is normal to ship coils with the eye vertical.

Experience has shown that transit abrasion is minimized by

shipping with the eye of the coil vertical.

15.2 It is common practice to use the methods shown in the

latest edition of Practices A 700.

The American Society for Testing and Materials takes no position respecting the validity of any patent rights asserted in connection

with any item mentioned in this standard. Users of this standard are expressly advised that determination of the validity of any such

patent rights, and the risk of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM Headquarters. Your comments will receive careful consideration at a meeting of the responsible

technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should make your

views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA19428-2959, United States.

Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above address or at

610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website (www.astm.org).

TABLE 3 Width Tolerance for Electrolytic Tin-Coated Sheet

Specied Width, in. [mm]

Tolerance over Specied Width,

in. [mm] (No Tolerance Under)

Over 12 to 30 [300 to 600]

Over 30 to 48 [600 to 1200]

1

8 [3]

3

16 [5]

A 599/A 599M

3

You might also like

- A 782Document3 pagesA 782Gustavo SuarezNo ratings yet

- A 134Document4 pagesA 134Gustavo SuarezNo ratings yet

- Astm A 352a 352mDocument6 pagesAstm A 352a 352mGustavo SuarezNo ratings yet

- F1327Document2 pagesF1327Gustavo SuarezNo ratings yet

- Astm Rdi1mtcDocument6 pagesAstm Rdi1mtcGustavo SuarezNo ratings yet

- F1440Document6 pagesF1440Gustavo SuarezNo ratings yet

- F2180Document4 pagesF2180Gustavo SuarezNo ratings yet

- F2183Document4 pagesF2183Gustavo SuarezNo ratings yet

- F1089Document3 pagesF1089Gustavo SuarezNo ratings yet

- Wrought Cobalt-20Chromium-15Tungsten-10Nickel Alloy Surgical Fixation Wire (UNS R30605)Document3 pagesWrought Cobalt-20Chromium-15Tungsten-10Nickel Alloy Surgical Fixation Wire (UNS R30605)Gustavo SuarezNo ratings yet

- Astm F899Document6 pagesAstm F899Gustavo SuarezNo ratings yet

- D6124Document4 pagesD6124Gustavo Suarez67% (3)

- Composition of Anorganic Bone For Surgical ImplantsDocument4 pagesComposition of Anorganic Bone For Surgical ImplantsGustavo SuarezNo ratings yet

- F2079Document3 pagesF2079Gustavo SuarezNo ratings yet

- F138Document4 pagesF138Gustavo SuarezNo ratings yet

- F1079Document2 pagesF1079Gustavo Suarez100% (1)

- F366Document5 pagesF366Gustavo SuarezNo ratings yet

- F138Document4 pagesF138Gustavo SuarezNo ratings yet

- F1377Document2 pagesF1377Gustavo SuarezNo ratings yet

- Astm - F960Document8 pagesAstm - F960Gustavo SuarezNo ratings yet

- D6124Document4 pagesD6124Gustavo Suarez67% (3)

- Metallic Medical Bone Screws: Standard Specification and Test Methods ForDocument17 pagesMetallic Medical Bone Screws: Standard Specification and Test Methods ForGustavo SuarezNo ratings yet

- F640Document4 pagesF640Gustavo SuarezNo ratings yet

- F2146Document4 pagesF2146Gustavo SuarezNo ratings yet

- F623Document8 pagesF623Gustavo Suarez100% (1)

- Metallic Medical Bone Screws: Standard Specification and Test Methods ForDocument17 pagesMetallic Medical Bone Screws: Standard Specification and Test Methods ForGustavo SuarezNo ratings yet

- F136Document4 pagesF136Gustavo SuarezNo ratings yet

- F560Document3 pagesF560Gustavo SuarezNo ratings yet

- F366Document5 pagesF366Gustavo SuarezNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Powerful Production Pumps for Deep Geothermal ProjectsDocument4 pagesPowerful Production Pumps for Deep Geothermal ProjectsAchraf AkidNo ratings yet

- 34 DuPont MECS Startup Shutdown Procedure For MET Plants Sulfuric AcidDocument4 pages34 DuPont MECS Startup Shutdown Procedure For MET Plants Sulfuric AcidLouis Andree Bujanda RufattNo ratings yet

- Operations Management and Decision MakingDocument55 pagesOperations Management and Decision MakingAnkit SinghNo ratings yet

- Science Clinic Gr10 Chemistry Questions 2016Document44 pagesScience Clinic Gr10 Chemistry Questions 2016BhekiNo ratings yet

- STATS Shortcut FormulaDocument3 pagesSTATS Shortcut Formulajeet sighNo ratings yet

- Week 2Document11 pagesWeek 2KISHANo ratings yet

- Deep Learning: Huawei AI Academy Training MaterialsDocument47 pagesDeep Learning: Huawei AI Academy Training Materialsfadhil muhammad hanafiNo ratings yet

- Chapter 5: Work, Energy and PowerDocument4 pagesChapter 5: Work, Energy and PowerPriyaa JayasankarNo ratings yet

- Profit Signals How Evidence Based Decisions Power Six Sigma BreakthroughsDocument262 pagesProfit Signals How Evidence Based Decisions Power Six Sigma BreakthroughsM. Daniel SloanNo ratings yet

- Discussion Exp 2 Chm674Document4 pagesDiscussion Exp 2 Chm674Eva Lizwina MatinNo ratings yet

- Endothermic Reactions Absorb HeatDocument2 pagesEndothermic Reactions Absorb HeatRista WaniNo ratings yet

- Artikel Materi Skripsi - Qurrotu Aini-2Document13 pagesArtikel Materi Skripsi - Qurrotu Aini-2Qurrotu AiniNo ratings yet

- Lectures Chpter#4 MOSFET of Sedra Semith (Micro Electronic Circuits)Document170 pagesLectures Chpter#4 MOSFET of Sedra Semith (Micro Electronic Circuits)Ahmar NiaziNo ratings yet

- EDOC-Benefits & Advantages of Applying Externally Gapped Line ArrestersDocument20 pagesEDOC-Benefits & Advantages of Applying Externally Gapped Line ArrestersEl Comedor BenedictNo ratings yet

- More About Generating FunctionDocument11 pagesMore About Generating FunctionThiên LamNo ratings yet

- R Fulltext01Document136 pagesR Fulltext01vhj gbhjNo ratings yet

- P18 Probability in The CourtroomDocument14 pagesP18 Probability in The CourtroomYehiaNo ratings yet

- SKM and OKM User ManualDocument36 pagesSKM and OKM User ManualOutlawRNo ratings yet

- M.SC - Physics 3rd Sem FinalDocument12 pagesM.SC - Physics 3rd Sem FinalKhileswar ChandiNo ratings yet

- Electrical Plant Load AnalysisDocument36 pagesElectrical Plant Load AnalysisJesus EspinozaNo ratings yet

- Eclipse RCPDocument281 pagesEclipse RCPjpradeebanNo ratings yet

- 25 Most Frequently Asked DSA Questions in MAANGDocument17 pages25 Most Frequently Asked DSA Questions in MAANGPranjalNo ratings yet

- CBIP draft meter standardsDocument22 pagesCBIP draft meter standardslalit123indiaNo ratings yet

- Primary Reformer TubesDocument10 pagesPrimary Reformer TubesAhmed ELmlahyNo ratings yet

- Clinical Microscopy ReviewerDocument31 pagesClinical Microscopy ReviewerbokbokbokNo ratings yet

- Web Intelligence XI 3.0 Parameter GuideDocument10 pagesWeb Intelligence XI 3.0 Parameter GuideJaime Andrés Triviño Sánchez0% (1)

- Parts of The NailDocument22 pagesParts of The NailMariel Balmes Hernandez100% (1)

- Complex Numbers: Problem-SolvingDocument2 pagesComplex Numbers: Problem-SolvingK TariNo ratings yet

- Westfalia Separator Installation DiagramDocument68 pagesWestfalia Separator Installation DiagramOno Jr Araza100% (3)

- Subsurface Remote Sensing of Kelp ForestsDocument20 pagesSubsurface Remote Sensing of Kelp Forestsjpeterson1No ratings yet