Professional Documents

Culture Documents

J208V25 en

Uploaded by

Martin Kratky0 ratings0% found this document useful (0 votes)

21 views4 pagesJenbacher

Original Title

J208V25_en

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentJenbacher

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

21 views4 pagesJ208V25 en

Uploaded by

Martin KratkyJenbacher

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

GE Jenbacher GmbH & Co OHG

A-6200 Jenbach, Austria

JMS 208 GS-B.L

Biogas 330kW el.

http://information.jenbacher.com

jenbacher.info@ge.com

Tel. +43 5244 600-0

Fax +43 5244 63255

Jenbacher gas engines

Technical Specification

JMS 208 GS-B.L

Biogas 330kW el.

CO-GEN Module data: Additional information:

Electrical output kW el. 330 Sound pressure level (engine, average value 1m) dB(A) 92

Recoverable thermal output (180 C) kW 400 Sound pressure level exhaust gas (1m, 30 off engin dB(A) 108

Energy input kW 852 Exhaust gas mass flow rate, wet kg/h 1.878

Fuel Consumption based on a LHV of Exhaust gas volume, wet Nm/h 1.460

5 kWh/Nm Nm/h 170 Max.admissible exhaust back pressure after engine mbar 60

Electrical efficiency % 38,7% Exhaust gas temperature at full load C [8] 500

Thermal efficiency % 46,9% Combustion air mass flow rate kg/h 1.726

Total efficiency % 85,7% Combustion air volume Nm/h 1.335

Heat to be dissipated (LT-Circuit) kW ~ Max. inlet cooling water temp. (intercooler) C 70

Emission values: Max. pressure drop in front of intake-air filter mbar 10

NOx < 500 mg/Nm (5% O2) Return temperature C 70

Forward temperature C 90

Hot water flow rate m/h 17,2

Engine data: Alternator:

Engine type J 208 GS-C25 Manufacturer STAMFORD

Configuration In - Line Type HCI 534 E2

No. of cylinders 8 Type rating kVA 600

Bore mm 135

Stroke mm 145

Piston displacement lit 16,60 Efficiency at p.f. = 1,0 % 96,5%

Nominal speed rpm 1.500 Efficiency at p.f. = 0,8 % 95,5%

Mean piston speed m/s 7,25 Ratings at p.f. = 1,0 kW 330

Mean effe. press. at stand. power and nom. spe bar 16,50 Ratings at p.f. = 0,8 kW 327

Compression ratio Epsilon 12,0 Frequency Hz 50

ISO standard fuel stop power ICFN kW 342 Voltage V 400

Spec. fuel consumption of engine kWh/kWh 2,49 Protection Class IP 23

Specific lube oil consumption g/kWh 0,30 Insulation class H

Weight dry kg 1.800 Speed rpm 1.500

Filling capacity lube oil lit 133 Mass kg 1.535

Based on methane number MZ 100

Technical parameters:

Applicable standards: Based on DIN-ISO 3046

Based on VDE 0530 REM with specified tolerance

Standard conditions: Air pressure: 1000 mbar or 100 m above sea level

Air temperature: 25C or 298 K

Relative Humidity: 30%

Engine output derating:

Gas quality: according to TA 1000-0300

Gas flow pressure: 80 - 200 mbar

(Lower gas pressures upon inquiry)

Max. variation in gas pressure: 10%

All data are based on engine full load at specified media temperatures and are subject to change.

The technical Instruction TA 1100-0110 "PARAMETER FOR GE Jenbacher GAS ENGINES" must be strictly observed.

for plants installed at > 500m above see level and/or intake temperature > 30C, the reduction of engine power is

determined for each project.

Jenbacher gas engines

Technical Specification

Basic engine equipment: Module equipment:

*Exhaust gas turbocharger, Intercooler *Base frame for gas engine,

*Motorized carburator for LEANOX control alternator and heat exchangers

*Electronic contactless high performance ignition system *Internal pole alternator with excitation alternator and

*Lubricating oil pump (gear driven) with automatic voltage regulator; p.f. 0,8 lagging to 1,0

*Lubricating oil filters in main circuit *Flexible coupling, bell housing

*Lubricating oil sump; Lubricating oil heat exchanger *Anti-vibration mounts

*Jacket water pump *Air filter

*Fuel-, lubricating oil and jacket water pipe work on engine *Automatic lube oil replenishing with level control

*Flywheel for alternator operation; Exhaust gas manifold *Wiring of components to module control panel

*Viscous damper *Crankcase breather

*Knock sensors *Jacket water electric preheating

Engine accessories:

*Electric starter motor

*Electronic speed governor

*Electronic speed monitoring device including starting and Module control panel:

overspeed control *Totally enclosed , single door cubicle, mounted on module,

*Transducers and switches for oil pressure, jacket water temp., fully interconnected and completed

jacket water pressure, charge pressure and mixture temperature

Control equipment:

*COMPACT CONTROLLER with the following functions:

Supplied loose: LEANOX control, knock control, power and speed control,

Gas train according to DIN-DVGW consisting of: automatic synchronizing, loss of mains protection,

*Manual stop valve, fuel gas filter, two solenoid valves, Operating hour counter, start counter,

Leakage control device, gas pressure regulator Operation mode selector switch: "OFF", "MANUAL", "AUTOMATIC"

*Generator switchgear (generator circuit breaker)

Documentation:

*Operating and maintenance manual

*Spare parts manual

*Drawings

Assembly, painting, testing in Jenbach/Austria

Identical to Genset except that heat recovery is included.

*jacket water heat exchanger mounted on module frame

*exhaust gas heat exchanger mounted on module frame;

*all heat exchangers with complete pipework

*Heat exchangers and all inherent auxiliaries

*Identical to module/genset but installed in 40' ISO container (65 dB(A) @ 10m); complete with all pipework and fittings

*Twin circuit radation cooler for dissipation of intercooler jacket water and lube oil thermal output; ventilation equipment

*Gas & smoke detectors; exhaust silencer; lube oil equipment; starting system; flexible connections

*Seperate control room complete with generator switchgear and all internal power and monitoring cables

Scope of Supply & Design Subject to Local Regulations and product development

>>> Scope of supply container - JG(M)C 208 GS-B.L

>>> Scope of supply genset - JGS 208 GS-B.L

>>> Scope of supply module - JMS 208 GS-B.L

Jenbacher gas engines

Technical Specification

Genset

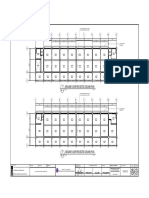

Main dimensions and weights (approximate value) Connections (at genset)

Length L mm 4.900 Jacket water inlet and outlet DN/PN 50/10

Width B mm 1.700 Exhaust gas outlet DN/PN 200/10

Height H mm 2.000 Fuel gas (at gas train) DN/PN 65/16

Weight empty kg 5.100 Intercooler water connection:

Weight filled kg 5.300 Low Temperature Circuit DN/PN 50/10

Module

Main dimensions and weights (approximate value) Connections (at module)

Length L mm 4.900 Hot water inlet and outlet DN/PN 50/10

Width B mm 1.700 Exhaust gas outlet DN/PN 200/10

Height H mm 2.000 Fuel gas (at gas train) DN/PN 65/16

Weight empty kg 5.800 Intercooler water connection:

Weight filled kg 6.000 Intercooler water-Inlet/Outlet 2nd stage DN/PN 50/10

Container

Main dimensions and weights (approximate value) Connections (container)

Length L mm 12.200

Width B mm 2.500 Jacket water inlet and outlet DN/PN 50/10

Height H mm 2.600 Exhaust gas outlet DN/PN 200/10

Container weight (dry) kg 17.200 Fuel gas connection (container) mm 100/16

Container weight (filled) kg 18.000 Fresh oil connection G 28x2''

GE Jenbacher GmbH & Co OHG Tel. +43 5244 600-0

A-6200 Jenbach, Austria Fax +43 5244 63255

0

4

.

J

u

l

2

0

0

6

http://information.jenbacher.com

jenbacher.info@ge.com

Jenbacher gas engines

Technical Specification

You might also like

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (894)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Fairbanks MorseDocument32 pagesFairbanks MorseMartin Kratky100% (1)

- Weber ManualDocument28 pagesWeber ManualMedardo SilvaNo ratings yet

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- EMD 645 Marine Emissions Kits A4Document2 pagesEMD 645 Marine Emissions Kits A4Martin KratkyNo ratings yet

- HIMSEN Catalog 2010 PDFDocument46 pagesHIMSEN Catalog 2010 PDFGabriela SanchezNo ratings yet

- Katalog Weldotherm 10 - 2013 GB Email PDFDocument40 pagesKatalog Weldotherm 10 - 2013 GB Email PDFcarlosNo ratings yet

- Nordwest Service Manual PDFDocument136 pagesNordwest Service Manual PDFMartin KratkyNo ratings yet

- Nordwest Service Manual PDFDocument136 pagesNordwest Service Manual PDFMartin KratkyNo ratings yet

- PST Personal Survival Technique CourseDocument143 pagesPST Personal Survival Technique CourseAlhaj Massoud100% (1)

- Baudouin 12M33 SpecSheetDocument2 pagesBaudouin 12M33 SpecSheetMartin KratkyNo ratings yet

- Baudouin 12M33 SpecSheetDocument2 pagesBaudouin 12M33 SpecSheetMartin KratkyNo ratings yet

- Baudouin 12M33 SpecSheetDocument2 pagesBaudouin 12M33 SpecSheetMartin KratkyNo ratings yet

- Rolls-Royce Allen 5000 Engine For Liquid FuelDocument2 pagesRolls-Royce Allen 5000 Engine For Liquid FuelMartin KratkyNo ratings yet

- Rolls-Royce Allen 5000 Engine For Liquid FuelDocument2 pagesRolls-Royce Allen 5000 Engine For Liquid FuelMartin KratkyNo ratings yet

- HIMSEN Catalog 2011Document100 pagesHIMSEN Catalog 2011airtupasNo ratings yet

- Daihatsu de SeriesDocument32 pagesDaihatsu de Seriesfernando_cassol100% (1)

- Underwater Hull Cleaning and Diving Survey in Vietnam AsiaDocument54 pagesUnderwater Hull Cleaning and Diving Survey in Vietnam AsiaInspectionNo ratings yet

- Manoeuvre The Ship-38pDocument38 pagesManoeuvre The Ship-38pWosf TanagraNo ratings yet

- 23T Truck Mounted Crane with Maximum Reach of 16.6mDocument2 pages23T Truck Mounted Crane with Maximum Reach of 16.6mAnonymous e3yfLHTBv100% (1)

- P2 Beckton STW SIPDocument16 pagesP2 Beckton STW SIPthamestunnelNo ratings yet

- Book PDFDocument24 pagesBook PDFJon SnowNo ratings yet

- Synchronous Generator ManualDocument56 pagesSynchronous Generator ManualMartin Kratky100% (3)

- GE's New L250 Inline Diesel Engine Offers Compact Power and Emissions ComplianceDocument6 pagesGE's New L250 Inline Diesel Engine Offers Compact Power and Emissions ComplianceMartin KratkyNo ratings yet

- Wartsila 'Combined Heat and Power' LeafletDocument16 pagesWartsila 'Combined Heat and Power' LeafletMartin Kratky100% (1)

- INNIO Jenbacher Type 2 - 2019 - enDocument2 pagesINNIO Jenbacher Type 2 - 2019 - enMartin KratkyNo ratings yet

- High-Efficiency Diesel EngineDocument4 pagesHigh-Efficiency Diesel EngineMartin KratkyNo ratings yet

- Lexe0422 04Document2 pagesLexe0422 04Connor SailorNo ratings yet

- Himsen Engines: Hyundai Heavy Industries Annual Report 2012Document2 pagesHimsen Engines: Hyundai Heavy Industries Annual Report 2012Martin KratkyNo ratings yet

- Daihatsu Diesel Dual-Fuel Engines: Precise Control for High Environmental PerformanceDocument8 pagesDaihatsu Diesel Dual-Fuel Engines: Precise Control for High Environmental PerformancePrince ChaudharyNo ratings yet

- Baudouin Company ProfileDocument16 pagesBaudouin Company ProfileMartin KratkyNo ratings yet

- Lexe0422 04Document2 pagesLexe0422 04Connor SailorNo ratings yet

- Kohler Sdmo Kd2250-EDocument6 pagesKohler Sdmo Kd2250-EMartin KratkyNo ratings yet

- Power: SolutionsDocument12 pagesPower: Solutionsmargarita margaNo ratings yet

- Flexicycle Power Plants 2015 PDFDocument6 pagesFlexicycle Power Plants 2015 PDFVictor Macedo AchancarayNo ratings yet

- FME OP BrochureDocument2 pagesFME OP BrochureMartin KratkyNo ratings yet

- Wartsila W32 Brochure 2016Document2 pagesWartsila W32 Brochure 2016Martin KratkyNo ratings yet

- The New Prechamber Improves Efficiency of W34SGDocument1 pageThe New Prechamber Improves Efficiency of W34SGMartin KratkyNo ratings yet

- MTU 4000 PPU1500NG 50 HZ ENDocument15 pagesMTU 4000 PPU1500NG 50 HZ ENMartin KratkyNo ratings yet

- 1985-Y-02 Route ChangesDocument15 pages1985-Y-02 Route ChangesNoelia Peirats AymerichNo ratings yet

- Ticket SunilDocument2 pagesTicket SunilDURGA PRASAD TRIPATHYNo ratings yet

- DelhimasseiaDocument261 pagesDelhimasseiaPranika MahajanNo ratings yet

- Sulu PNP Armoured VehicleDocument2 pagesSulu PNP Armoured VehiclePauloHenriqueRibeiroNo ratings yet

- Curriculum Vitae of Jakir Mohammad: Accademic QualificationDocument2 pagesCurriculum Vitae of Jakir Mohammad: Accademic QualificationNoman HossainNo ratings yet

- Study of Multimodal Transport Facilities in Construction Project Management at JNPTDocument8 pagesStudy of Multimodal Transport Facilities in Construction Project Management at JNPTRohit DigraNo ratings yet

- Airport Runway DesignDocument3 pagesAirport Runway DesignAnem PoojaNo ratings yet

- Clark ST Station NYCT 19Document9 pagesClark ST Station NYCT 19Susannah PasquantonioNo ratings yet

- EOQ Inventory Control Models Chapter SummaryDocument33 pagesEOQ Inventory Control Models Chapter SummaryJay PatelNo ratings yet

- Dokumen - Tips - 2009 FLNG FLNG Safe Tandem Offloading of LNG SeoulpptDocument27 pagesDokumen - Tips - 2009 FLNG FLNG Safe Tandem Offloading of LNG SeoulpptOlusegun OyebanjiNo ratings yet

- Social Cost Benefit AnalysisDocument23 pagesSocial Cost Benefit AnalysisMukesh Kumar SharmaNo ratings yet

- Ground Floor Reflected Ceiling Plan: Pertconsult International Schema Engineers and AssociatesDocument1 pageGround Floor Reflected Ceiling Plan: Pertconsult International Schema Engineers and AssociatesMalson GutierrezNo ratings yet

- Diagnostic Codes 4 Cyl CompleteDocument18 pagesDiagnostic Codes 4 Cyl CompleteKruno ŽunecNo ratings yet

- Houston To Mobile Passage PlanDocument4 pagesHouston To Mobile Passage Planconcordiafamily100% (1)

- Laney AH50Document2 pagesLaney AH50Zoeloe_2No ratings yet

- TCP Ip MultimediaDocument87 pagesTCP Ip MultimediadeqahmedNo ratings yet

- Chapter 9 AP WilmingtonDocument6 pagesChapter 9 AP Wilmingtonspeedks78No ratings yet

- Reading Measured Value Block: Readout Specifications For Unit InjectorsDocument2 pagesReading Measured Value Block: Readout Specifications For Unit InjectorsaritmeticsNo ratings yet

- What Are Car Insurance Points and How Do They Differ From DMV Points?Document2 pagesWhat Are Car Insurance Points and How Do They Differ From DMV Points?lykaNo ratings yet

- 20 Reasons To Reject The Elephant & Castle Shopping Center ApplicationDocument210 pages20 Reasons To Reject The Elephant & Castle Shopping Center Applicationchris56aNo ratings yet

- Admiral Insurance: Insurance Product Information DocumentDocument2 pagesAdmiral Insurance: Insurance Product Information DocumentMarkNo ratings yet

- Sample Bibliography Cards: Book Internet SiteDocument2 pagesSample Bibliography Cards: Book Internet Siteapi-30192479No ratings yet

- Amendments To List of Codes, Recommendations, Guidelines and Other Safety-And Security-Related Non-Mandatory InstrumentsDocument13 pagesAmendments To List of Codes, Recommendations, Guidelines and Other Safety-And Security-Related Non-Mandatory InstrumentsEmanuel HuardNo ratings yet