Professional Documents

Culture Documents

GE introduces new air-cooled H-class gas turbines

Uploaded by

link2u_0070 ratings0% found this document useful (0 votes)

365 views5 pagesGE-H-class

Original Title

GE-H-class

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentGE-H-class

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

365 views5 pagesGE introduces new air-cooled H-class gas turbines

Uploaded by

link2u_007GE-H-class

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 5

GE introduced the first high-

efficiency H-class gas turbines to the

power generation industry in 2002.

The steam-cooled units have logged

200 000 hours of operation and

counting and have proven them-

selves to be stalwarts within GEs

gas turbine lineup. Now, thanks to

advances in technology and shared

knowledge from its myriad business

units, GE is introducing the 7HA and

9HA air-cooled gas turbines.

In a simple-cycle configuration,

the 9HA.01 is rated 397 MW and

the 9HA.02 is rated 470 MW, each

at 3000 r/min, offering greater than

41% efficiency. In a 1x1 combined-

cycle configuration, the 9HA.01 is

rated 592 MW and the 9HA.02 is

rated 701 MW, each at 3000 r/min,

offering greater than 61% efficiency.

In a simple-cycle configuration,

the 7HA.01 is rated 275 MW and

the 7HA.02 is rated 330 MW, each

We are offering our air-cooled

H-class gas turbines in two versions

for the 50 Hz market the 9HA.01

and 9HA.02 and two versions for

the 60 Hz market the 7HA.01 and

7HA.02, said Vic Abate, President and

CEO, Power Generation Products, for

GE Power & Water. The air-cooled

H-class gas turbines are designed

for cyclic and base-load operation

in a simple-cycle and combined-

cycle applications.

New Air-Cooled

H-Class

GE adds air-cooled H-class to its gas turbine lineup

BY BRENT HAIGHT

The first 9HA gas tur-

bine was manufactured

in Belfort, France, and will

be delivered to GEs Green-

ville, South Carolina, U.S.A.,

test facility during the second

quarter of 2014, where it will under-

go full-scale, full-load testing.

DEDICATED TO ENGINE ROOM PRODUCTS, TECHNOLOGIES & NEWS

F

i

r

s

t

L

o

o

k

at 3600 r/min, offering greater than

41% efficiency. In a 1x1 combined-

cycle configuration, the 7HA.01 is

rated 405 MW and the 7HA.02 is

rated 486 MW, each at 3600 r/min,

offering greater than 61% efficiency.

The high-efficiency segment ac-

counts for more than 30% of the

power generation market, Abate

said. That is where the air-cooled

H-class comes in. The 7HA.01 is 275

MW. The 7HA.02 is 330 MW. Those

two machines, in the 60 Hz market,

give you a 400 MW combined-cycle

power plant, a 500 MW combined-

cycle power plant and then you can

bulk into 800 and 1000 MW, or 1200

and 1500. Those sizes fit extremely

well with the retirement of coal that

we see and some of the natural mar-

kets for fixed gears.

Then in the 50 Hz they are a scale

version, the 9HA.01 and 9HA.02,

at 397 MW and 470 MW. So those

then reach 600 MW and 700 MW in

combined-cycle, and can bulk into

1200 and 1400 MW, or 1800 and

2100 MW.

We define H-class as over 2600F

firing temperature. The entire in-

dustry has probably 250 000 hours.

GE has been in the H-class for more

than a decade. We have a tremendous

amount of experience and are confi-

dent in where we are going with this

next step.

According to Abate, air-cooled

H-class gas turbines offer the reli-

ability, flexibility and availability of

GEs popular F-class fleet and lever-

age technology from GEs aviation

business as well as its extensive ex-

perience within the power generation

marketplace.

The air-cooled H-class gas tur-

bine incorporates an aerodynamic

14-stage compressor, leveraged from

GEs proven aircraft engine tech-

nology, and includes an advanced

radial diffuser. Combined with the

Dry Low NO

x

(DLN) 2.6+AFS (Ax-

ial Fuel Staged) combustion system,

this allows improved operation of

the combustion liner and transition

piece cooling, according to GE. The

DLN 2.6+AFS combustion system

provides advanced fuel staging for

enhanced steady state and transient

performance. To modulate airflow, a

variable inlet guide vane (IGV) and

three stages of variable stator vanes

(VSVs) manage compressor operabil-

ity during start-up, control compres-

sor airflow during turndown, and

facilitate variations in ambient tem-

perature and load.

Weve taken the engine compres-

sor design from our aircraft engine

division and implemented it into

our air-cooled H-class gas turbine,

Abate said. What that does, the

compressor has to compress twice

the amount of air that you need be-

cause half of it goes to produce pow-

er and half of it goes to driving the

compressor. If you can get the com-

pressor to be more efficient, that is a

huge opportunity.

With regard to combustion, as

you fire hotter you trade emissions.

Holding emissions at world class lev-

els is paramount for GE as we have

always been an emissions leader.

Weve continued to develop our DLN

emissions technology, which en-

ables us to hold emissions with our

air-cooled H-class gas turbines. The

enhanced DLN 2.6+AFS combus-

tion system supports improved fuel

distribution and operability while re-

ducing thermal loading on the cap,

liner, and transition piece. When

you think about the power turbine

section, we release about 1 million

horsepower in 3 feet. These engines

are operating 400F-plus above the

GEs new 9HA gas turbine rotor on the half shell casing. The

air-cooled H-class gas turbines are designed for cyclic and base-

load operation in simple-cycle and combined-cycle applications.

melting point of met-

al. Its a very high-tech,

challenging environment. Ad-

vanced materials coatings, including

thermal barrier coatings on the air-

foil and single-crystal super alloys on

the airfoil wall, promote durability

and extend parts life by 1.5% versus

comparable technology.

The first 9HA gas turbine was

manufactured in Belfort, France, and

will be delivered to GEs Greenville,

South Carolina, U.S.A., test facility

during the second quarter of 2014,

where it will undergo full-scale, full-

load testing.

The Greenville test facility rep-

licates real-world plant conditions

with the required accessories to run

a fully loaded gas turbine on natu-

ral gas and liquid fuel. To eliminate

limitations of the grid, testing is per-

formed without a generator and grid

connection. The facility is capable of

testing 50 and 60 Hz products. (See

Beyond Real-World Testing, Diesel

& Gas Turbine Worldwide, September

2012, p. 54.)

What is interesting about this

test facility, is that by being inde-

pendent of the grid, we have the

ability to modify speed, we can get

off-design conditions and monitor

the responses of air foils, structural

components, etc., Abate said. We

can see all of ranges of the units

performance. With that we can un-

leash more value through applica-

tion engineering and also mitigate

risk with application.

Natural gas is becoming the fuel

of choice globally and for customers

who operate larger blocks of power.

The desire for increased operating ef-

ficiency and flexibility has never been

greater. Technological advancements

and increasingly stringent environ-

mental regulations are

helping to answer the

call for a new generation of ma-

chines by pushing the power genera-

tion industry to achieve new perfor-

mance standards.

The whole strategy surrounding

GE is technology leadership. The

beauty of a high-tech natural gas

plant is that you dont sell them on

style, you sell them because they have

the best economics, they have the best

technical capability and they provide

our customers the best return. A

A 9HA gas turbine traveling through Belfort, France, from the GE manufacturing facility to the Port

of Strasbourg. More than 3000 people turned out to see the 9HA make its way through Belfort.

A fully assembled 9HA gas turbine being

transferred for packaging and shipping.

Air-Cooled H-Class Specifications

Combined-Cycle Performance

7HA.01 7HA.02

1x1 2x1 1x1 2x1

Plant Output (net) 405 MW 813 MW 486 MW 976 MW

Heat Rate (net)

5580 Btu/kWh

5892 kJ/kWh

5570 Btu/kWh

5877 kJ/kWh

5580 Btu/kWh

5892 kJ/kWh

5570 Btu/kWh

5877 kJ/kWh

Plant Efficiency Greater than 61% Greater than 61% Greater than 61% Greater than 61%

The 7HA Gas Turbines Attributes

Efficiency

Greater than 41% simple-cycle efficiency, greater than 61%

combine-cycle efficiency.

Start Capability Fast start as low as 10 minutes from the start command.

Turndown As low as 30% of base-load.

Ramp Rate The 7HA has one of the best ramp rates in its class at greater than 40 MW/min.

Emissions Less than 25 ppm NOx and CO.

The 9HA Gas Turbines Attributes

Efficiency

Greater than 41% simple-cycle efficiency, greater than 61%

combine-cycle efficiency.

Start Capability

Less than 30 minutes to full plant base-load a 25% improvement

over comparable technologies.

Turndown As low as 30% of base-load.

Ramp Rate The 9HA has one of the best ramp rates in its class at nearly 60 MW/min.

Emissions Less than 25 ppm NOx and CO.

Simple-Cycle Performance

Output (net)

275 MW 7HA.01

330 MW 7HA.02

Heat Rate (net)

8240 Btu/kWh

8694 kj/kWh

Efficiency (net) Greater than 41%

Pressure Ratio 21.5

Exhaust Flow

1269 lb./sec 7HA.01

1522 lb./sec 7HA.02

Turbine Speed 3600 r/min

Exhaust Temperature 1138F

Simple-Cycle Performance

Output (net)

397 MW 9HA.01

470 MW 9HA.02

Heat Rate (net)

8220 Btu/kWh

8673 kj/kWh

Efficiency (net) Greater than 41%

Pressure Ratio 21.8

Exhaust Flow

1822 lb./sec 9HA.01

2157 lb./sec 9HA.02

Turbine Speed 3000 r/min

Exhaust Temperature 1146F

Combined-Cycle Performance

9HA.01 9HA.02

1x1 2x1 1x1 2x1

Plant Output (net) 592 MW 1181 MW 701 MW 1398 MW

Heat Rate (net) 5560 Btu/kWh

5866 kj/kWh

5570 Btu/kWh

5878 kj/kWh

5560 Btu/kWh

5866 kj/kWh

5570 Btu/kWh

5878 kj/kWh

Plant Efficiency Greater than 61% Greater than 61% Greater than 61% Greater than 61%

You might also like

- 9ha 01 - 02Document2 pages9ha 01 - 02Ubair KaziNo ratings yet

- 9FA Enhancement Brochure - GEA17570Document8 pages9FA Enhancement Brochure - GEA17570Peter_Phee_341No ratings yet

- H Class High PerformanceDocument10 pagesH Class High Performancekoohestani_afshin100% (1)

- GE 9HA Gas Turbine PDFDocument4 pagesGE 9HA Gas Turbine PDFAlfian Muhammad RezaNo ratings yet

- 7HA Gas Turbine: World's Largest, Most Efficient Gas Turbine in Its ClassDocument4 pages7HA Gas Turbine: World's Largest, Most Efficient Gas Turbine in Its Classjparmar100% (2)

- GE 9HA Gas TurbineDocument4 pagesGE 9HA Gas TurbinejparmarNo ratings yet

- Technology Experience Innovation: GE Power SystemsDocument20 pagesTechnology Experience Innovation: GE Power SystemsLegwanOPOLE100% (4)

- Proven Solutions GE-EvuletDocument48 pagesProven Solutions GE-EvuletmohamedhasNo ratings yet

- Technical Information Letter: Ge Power TIL 2445 Product ServiceDocument4 pagesTechnical Information Letter: Ge Power TIL 2445 Product ServiceMinhajur Rahman100% (1)

- F646 CompleteSampleDocument36 pagesF646 CompleteSampleraj4523No ratings yet

- Lm2500 DescripDocument2 pagesLm2500 DescripDenis Jimenez100% (1)

- Aero Grid Stability PAPER Sept 2011Document25 pagesAero Grid Stability PAPER Sept 2011igunhakam55No ratings yet

- Lm6000 PF Plus Fact SheetDocument2 pagesLm6000 PF Plus Fact SheetNivaldo GarciaNo ratings yet

- SGT6-5000F PAC - LowRes PDFDocument18 pagesSGT6-5000F PAC - LowRes PDFmyegnrNo ratings yet

- GEA33861 - Fuel Flexible Gas Turbines As Enablers For A Low Carbon Energy EcosystemDocument16 pagesGEA33861 - Fuel Flexible Gas Turbines As Enablers For A Low Carbon Energy EcosystemStephen MwangiNo ratings yet

- Industrial Gas Turbines - Siemens PDFDocument8 pagesIndustrial Gas Turbines - Siemens PDFeankiboNo ratings yet

- Combined Cycle Power Plant FundamentalsDocument110 pagesCombined Cycle Power Plant FundamentalsShamimAhammedNo ratings yet

- MHPS D Class GT UpratesDocument6 pagesMHPS D Class GT Uprateskp pkNo ratings yet

- Gas Turbine in Simple Cycle and Combined Cycle ApplicationsDocument46 pagesGas Turbine in Simple Cycle and Combined Cycle Applicationssevero97100% (2)

- Siemens GTDocument8 pagesSiemens GThbalu007No ratings yet

- Powering the world with innovative gas turbinesDocument22 pagesPowering the world with innovative gas turbinesBony DiazgNo ratings yet

- (ARTICLE) Gas Turbine DegradationDocument36 pages(ARTICLE) Gas Turbine DegradationFrancisco Baptista100% (1)

- Thermal Peaking PDFDocument26 pagesThermal Peaking PDFkhozaqiNo ratings yet

- List of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesDocument4 pagesList of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZNo ratings yet

- Himeji Number 2 Goes CommercialDocument13 pagesHimeji Number 2 Goes CommercialSujeet KumarNo ratings yet

- Gas Turbine CombustionDocument9 pagesGas Turbine Combustionvarun kumarNo ratings yet

- SST-400 Steam Turbine For Economical Production Heat and PowerDocument4 pagesSST-400 Steam Turbine For Economical Production Heat and PowerFaouzi TlemcenNo ratings yet

- Ansaldo Energia AE94.2 Upgrading ProjectDocument20 pagesAnsaldo Energia AE94.2 Upgrading Projectvincent8295547100% (1)

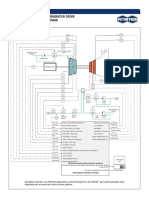

- GE LM6000 Gas Turbine Generator Drive Application Control PackageDocument3 pagesGE LM6000 Gas Turbine Generator Drive Application Control Packageabhaymehta67100% (1)

- Service - Gas Turbine Modernization PDFDocument6 pagesService - Gas Turbine Modernization PDFDiego CarpioNo ratings yet

- GE Aeroderivative Vietnam Sep 22 FinalDocument36 pagesGE Aeroderivative Vietnam Sep 22 Finaltuanpham100% (1)

- 5 Development and Operating Experience PDFDocument10 pages5 Development and Operating Experience PDFVijaya100% (2)

- F Technology StoryDocument16 pagesF Technology StoryTufail Memon100% (1)

- lm2500 Combined Cycle Plant Repowering Whitepaper PDFDocument12 pageslm2500 Combined Cycle Plant Repowering Whitepaper PDF'Izzad AfifNo ratings yet

- 2 Technology EvolutionDocument20 pages2 Technology EvolutionRokan Uddin100% (1)

- CT Inspection IntervalsDocument19 pagesCT Inspection IntervalsSantiago67% (3)

- GEA31503e PGP Product E-Catalog 2015 R10Document47 pagesGEA31503e PGP Product E-Catalog 2015 R10juagamsar100% (1)

- Lm2500 IntroDocument4 pagesLm2500 IntroDenis JimenezNo ratings yet

- Gas Turbine Lm5000 Operations ManualDocument4 pagesGas Turbine Lm5000 Operations ManualMuhammad Ilham RiyadiNo ratings yet

- 9 0 Development and OperatingDocument12 pages9 0 Development and OperatingAnu Partha100% (1)

- GE LM6000 1275-GryDocument1 pageGE LM6000 1275-GryuzairmughalNo ratings yet

- Asia Ha Class Update March 2014Document37 pagesAsia Ha Class Update March 2014Thanaraj SanmughamNo ratings yet

- Siemens Technical Paper Gas Turbine ModernizationDocument14 pagesSiemens Technical Paper Gas Turbine ModernizationAldiarso UtomoNo ratings yet

- Aerosila NPP JSC: Gas Turbine Power PlantsDocument30 pagesAerosila NPP JSC: Gas Turbine Power PlantsSatish Babu Garikapati100% (2)

- Factsheet Industrial Trent 60 Us LowresDocument2 pagesFactsheet Industrial Trent 60 Us LowresAsri GaniNo ratings yet

- Detailed Hot Section Mapping of Siemens SGT 600 PDFDocument19 pagesDetailed Hot Section Mapping of Siemens SGT 600 PDFfrdnNo ratings yet

- LM6000 PC Time Limited ComponentsDocument7 pagesLM6000 PC Time Limited ComponentsmstaszelNo ratings yet

- Oman Energy Conference - World Record Gas Turbine Service ExperiencesDocument16 pagesOman Energy Conference - World Record Gas Turbine Service ExperiencesabelsgNo ratings yet

- Thermal Tests of The 45MW SGT-800 Gas Turbine EquipmentDocument7 pagesThermal Tests of The 45MW SGT-800 Gas Turbine Equipmentbagusu_6No ratings yet

- GE Marine Gas Turbine ManualDocument72 pagesGE Marine Gas Turbine ManualMiguel Francisco Goytia100% (1)

- GE Power Systems 7F Users Conference PresentationsDocument27 pagesGE Power Systems 7F Users Conference Presentationsatfrost4638No ratings yet

- Abradable Seals GEDocument12 pagesAbradable Seals GEdimitrisNo ratings yet

- GTs World Comparison Picture - 1-130 MW - 2015 01 PDFDocument2 pagesGTs World Comparison Picture - 1-130 MW - 2015 01 PDFdvcher78No ratings yet

- 6FA HDGT Product Brochure-GEA17987Document8 pages6FA HDGT Product Brochure-GEA17987mikeNo ratings yet

- SCC5-8000H 1S Irsching 4 On The Way To 60% World Record: Answers For EnergyDocument16 pagesSCC5-8000H 1S Irsching 4 On The Way To 60% World Record: Answers For EnergyUhrin Imre100% (1)

- Aeroderivative Technology PDFDocument10 pagesAeroderivative Technology PDFabhaymehta67No ratings yet

- Ge High TempDocument5 pagesGe High TempkensoiNo ratings yet

- Advancements in H Class Gas Turbines For Combined Cycle Power Plants For High Efficiency Enhanced Operational Capability and Broad Fuel FlexibilityDocument9 pagesAdvancements in H Class Gas Turbines For Combined Cycle Power Plants For High Efficiency Enhanced Operational Capability and Broad Fuel FlexibilityАлександр ТумановNo ratings yet

- Refining Crude Oil: Step 1 - SeparationDocument24 pagesRefining Crude Oil: Step 1 - Separationho-faNo ratings yet

- 7BDocument6 pages7BRahul DalalNo ratings yet

- Emirates Pilot Interview Q&ADocument2 pagesEmirates Pilot Interview Q&Alink2u_007No ratings yet

- Pipe Flow Calculations PDFDocument12 pagesPipe Flow Calculations PDFharrypop418No ratings yet

- Fittings Flanges SpecsDocument8 pagesFittings Flanges SpecsMajed AdamNo ratings yet

- VideoDocument8 pagesVideoDhileepan KumarasamyNo ratings yet

- Simple Guide To Oil RefiningDocument5 pagesSimple Guide To Oil RefiningPatel AshokNo ratings yet

- PipeFittersHand BookDocument108 pagesPipeFittersHand Bookharikrishnanpd3327100% (1)

- TN 5131 TNDocument12 pagesTN 5131 TNlink2u_007No ratings yet

- Lecture 5 (Feb. 6) : Pressure in Liquids and GasesDocument12 pagesLecture 5 (Feb. 6) : Pressure in Liquids and Gaseslink2u_007No ratings yet

- LNG Heavy Duty Truck Case Studies ReportDocument44 pagesLNG Heavy Duty Truck Case Studies Reportlink2u_007No ratings yet

- ThermalDocument5 pagesThermallink2u_007No ratings yet

- Water HeaterDocument2 pagesWater Heaterlink2u_007No ratings yet

- Characteristic Properties of Silicone Rubber CompoundsDocument16 pagesCharacteristic Properties of Silicone Rubber Compoundslink2u_007No ratings yet

- LNGDocument24 pagesLNGlink2u_007100% (3)

- Thermal ExpansionDocument9 pagesThermal ExpansionAce Resurreccion RamirezNo ratings yet

- PH On WheelsDocument1 pagePH On Wheelslink2u_007No ratings yet

- SIEMENS The H Class To Korea BrochureDocument8 pagesSIEMENS The H Class To Korea Brochurelink2u_007No ratings yet

- Rag La ADocument8 pagesRag La ARaghav VahgarNo ratings yet

- Wood Lesson 02Document36 pagesWood Lesson 02link2u_007No ratings yet

- Stone-Age People Knew Nothing of Metal. Colorful: Hematite Iron Ore Were Found, They Would Be GroundDocument2 pagesStone-Age People Knew Nothing of Metal. Colorful: Hematite Iron Ore Were Found, They Would Be Groundlink2u_007No ratings yet

- Energy ConceptsDocument25 pagesEnergy Conceptslink2u_007No ratings yet

- Basic ConceptsDocument14 pagesBasic Conceptslink2u_007No ratings yet

- Surfactants and Their ApplicationsDocument46 pagesSurfactants and Their ApplicationsCecilia Solar100% (4)

- Transformation 02Document10 pagesTransformation 02link2u_007No ratings yet

- Surfactants and Their ApplicationsDocument46 pagesSurfactants and Their ApplicationsCecilia Solar100% (4)

- Stone-Age People Knew Nothing of Metal. Colorful: Hematite Iron Ore Were Found, They Would Be GroundDocument2 pagesStone-Age People Knew Nothing of Metal. Colorful: Hematite Iron Ore Were Found, They Would Be Groundlink2u_007No ratings yet

- Basic Operation and Function of Control ValvesDocument65 pagesBasic Operation and Function of Control ValvesEdgar Huanca0% (1)

- Technology Experience Innovation: GE Power SystemsDocument20 pagesTechnology Experience Innovation: GE Power SystemsLegwanOPOLE100% (4)

- Dytran Reference ManualDocument866 pagesDytran Reference ManualDon100% (2)

- Hydraulic Calculation of Box Culvert: Wlu HC Hu C HLB Blu BLC WLCDocument1 pageHydraulic Calculation of Box Culvert: Wlu HC Hu C HLB Blu BLC WLCIwanTiaraMotorNo ratings yet

- A Literature Review On The Performance Analysis of 4 Stroke Diesel Engines With Ceramic Coating Material-36993 PDFDocument7 pagesA Literature Review On The Performance Analysis of 4 Stroke Diesel Engines With Ceramic Coating Material-36993 PDFShiva ShankarNo ratings yet

- ChE Objective Type Questions Compilation Dean Medina 8 27 10Document177 pagesChE Objective Type Questions Compilation Dean Medina 8 27 10BEA GEDELYN GARCIANo ratings yet

- Unitor Udf 2100 Ultrasonic Cleaner 230VDocument2 pagesUnitor Udf 2100 Ultrasonic Cleaner 230Vankarthik11No ratings yet

- Pressure Vessel HandbookDocument2 pagesPressure Vessel HandbookAriq FauzanNo ratings yet

- Root Cause of Sub-Synchronous Vibration in Multi-stage Centrifugal CompressorDocument20 pagesRoot Cause of Sub-Synchronous Vibration in Multi-stage Centrifugal CompressorAUTVPDPPC1022 Muhammad Safuan Bin Md SallehNo ratings yet

- Ra92060 2006-12 PDFDocument36 pagesRa92060 2006-12 PDFabdelrhmangbr86No ratings yet

- NED Booklet 2015 ENDocument120 pagesNED Booklet 2015 ENElena JursinaNo ratings yet

- Pumps HighPressureDrainage D42AB D53AB DatasheetDocument2 pagesPumps HighPressureDrainage D42AB D53AB DatasheetMohammad ZeeshanNo ratings yet

- DSS Site Visit ReportDocument13 pagesDSS Site Visit Report39 - Deep MandokarNo ratings yet

- 3039exq Week 11 Session 1 Notes Example The Design of Slender RC ColumnsDocument8 pages3039exq Week 11 Session 1 Notes Example The Design of Slender RC ColumnsengkjNo ratings yet

- Boll Duplex Type 2.04.5Document2 pagesBoll Duplex Type 2.04.5Phung Van HiepNo ratings yet

- Technical Data For Fan Model VAX-S-710-6/20-E2: Performance - Required ActualDocument2 pagesTechnical Data For Fan Model VAX-S-710-6/20-E2: Performance - Required Actualkarim tarekNo ratings yet

- Lecture 4 - Particle Under A Net ForceDocument15 pagesLecture 4 - Particle Under A Net ForceJ KimNo ratings yet

- Properties of Fluids ExplainedDocument13 pagesProperties of Fluids ExplainedGie Andal0% (3)

- Zubair Oil Field Development Project: Eni Iraq B.VDocument17 pagesZubair Oil Field Development Project: Eni Iraq B.VMohammed HijaziNo ratings yet

- UTDocument346 pagesUTramdhani100% (1)

- View thousands of Crane Specifications on FreeCraneSpecs.comDocument64 pagesView thousands of Crane Specifications on FreeCraneSpecs.comD Rider Casanova100% (1)

- Morgana Digifold Service ManualDocument55 pagesMorgana Digifold Service Manualpfequip100% (1)

- Astm A352-A352m-06-1Document5 pagesAstm A352-A352m-06-1Kishor JadhavNo ratings yet

- 08.precommissioning Checklist GeneralDocument19 pages08.precommissioning Checklist GeneralAnujGarg100% (1)

- DR650SEL2 Catalogo Partes PDFDocument75 pagesDR650SEL2 Catalogo Partes PDFEderNo ratings yet

- Test 924G, 1. General Testing and AdjustingDocument7 pagesTest 924G, 1. General Testing and Adjustingmijael1393100% (1)

- Syphon For Pressure Measuring Instruments Model 910.15: ApplicationsDocument4 pagesSyphon For Pressure Measuring Instruments Model 910.15: Applicationsluis carlos martin contrerasNo ratings yet

- 728444Document45 pages728444Ed DeMossNo ratings yet

- Full Length Test 1 Paper Civil Ki GoliDocument45 pagesFull Length Test 1 Paper Civil Ki GoliPankaj BadiwalNo ratings yet

- Cup 04 HSP Uk Web PDFDocument2 pagesCup 04 HSP Uk Web PDFcasda73No ratings yet

- Lecture 2Document30 pagesLecture 2hania dogar0% (1)

- Chapter7 PDFDocument34 pagesChapter7 PDFWillian DiazNo ratings yet