Professional Documents

Culture Documents

Dl550 Doosan

Uploaded by

Elvis Eberth Huanca MachacaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Dl550 Doosan

Uploaded by

Elvis Eberth Huanca MachacaCopyright:

Available Formats

DL550

Engine Power : SAE J1995, gross 294 kW (394 HP)@ 2,100 rpm

Operational Weight : 31,125 kg (68,619 lb) - STD.

Bucket capacity(SAE) : 5.4 ~ 5.7 m

3

( 7.1 ~ 7.5 cu.yd)

The new DL550 wheel loader has all the advantages of the

previous loaders. This logical new step provides real added

value to the operator.

The new DL550 was developed with the concept of providing

optimum value to the end user. In concrete terms, this

translates, into :

Increased production due to the use of a new generation "Direct Injection"engine and the excellent synchronisation

of the drive train with the hydraulics system.

Improved ergonomics, increased comfort and excellent all round visibility ensuring safe and pleasant working conditions.

Improved reliability through the use of higher performance new materials, the development of new computer-assisted structural

design techniques and by intensive and systematic test programs. All of these combine to increase the life of vital components and

reduce operating costs.

Reduced maintenance increases the availability of the loader and reduces operating costs.

Wheel loader : DOOSAN DL550

A Powerful Wheel loader with

Novel Features

PERFORMANCE

DL550 features an intelligent, load-sensing hydraulic system. Two variable piston pumps provide the exact

flow and pressure required and deliver a powerful, highly effective force, offering superior penetration of the

hardest materials. The exceptional drawbar pull at the wheels, is reinforced further by providing Hydraulic

differential Lock as standard equipment. The engine offers high power and torque characteristics. As a

result, the hydraulic system is able to multi-function with power and speed.

Scania DC13 engine

Scania DC13 engine is based on electronically controlled unit injectors that gives high

torque with good fuel economy and low exhaust emissions

Full Auto Transmission

The electronic powershift transmission is particularly smooth and gear ratios perfectly

spaced to give optimal speed.That gives comfort at the same time that it delivers

excellent traction in every working conditions. Built-in electronic controls enhance

productivity and durability. The free wheel stator torque converter improves power

train efficiency in load and carry operations which contributes to the improved fuel

efficiency.

Hydraulic Power Steering

Works with a flow amplifier and priority valve. And the emergency steering system is equipped as an option to secure

a safety against a malfunction of steering system during traveling.

High Lift (Option)

As High Lift is equipped besides Standard Lift, customers

have further options.

The differential can be automatically engaged,

depending on transmission torque,

in the first and second gears.

Hydraulic differential locks (Standard)

Available standard for DL550. Two modes are available.

In manual mode, the operator can use a foot switch to

lock the differential completely.

Rear view camera & LCD (Option)

A camera provides a clear view of whats happening behind the machine for added

safety and peace of mind. The monitor is aligned with the rear mirrors.

COMFORT

Air Conditioning & Defroster System

Double filtered air cab, air ducts are properly placed all

around the cab with proportional sensitive controls and

air re-circulation facility. we offer the same comfort as a

passenger car.

Sunvisor & Roommirror(Std.)

From the beginning, Doosan has had great concern for machine operators. People need to work in a well-

designed and comfortable environment. The work area is spacious, with several places for storage. The

checking and monitoring devices are comprehensive. There is an open view of the work area. For night

work, operators are provided with powerful front and rear lighting.

Outside mirrors with built-in hot wires

The hot wires built in the outside mirrors get rid of

moisture and frost caused by rain or snow to secure rear

fields of vision even in bad weather.

The steering Column

The steering column features both tilting and telescopic

functions.

Wrist rest

The tilting and telescopic wrist rest allows the operator

to work more comfortably.

Easy-to-reach control panel

All controls are placed to the right, top and front of the operator. They are clearly positioned for comfortable access

and grouped by function, enabling safe, confident operation.

a. Gauges

b. ECO bar

c. Auto-idle

Colour LCD monitor panel

The 5.5 TFT LCD panel is suitable for day and night work. The monitor is user-friendly

and gives full access to machine settings and maintenance data. Any abnormality is

clearly displayed on the screen, allowing you to work safely and confidently with an

accurate overview of all conditions.

Engine coolant and transmission oil temperatures, fuel levels.

Informs the operator about the fuel efficiency of the current

driving profile.

Automatically decreases engine rpm when the controls are

not operated.

(Opt.)

3" Safety belt

- Retractable seat belt

Air-Suspension & Heating Seat (Opt.)

Now available Air-suspension seats provide more

comfort and support for the operator. The built-in hot

wires help to rapidly adjust the temperatures to an

optimal level to give comfort in the cold winter.

Tailored performance for maximumefficiency

The DL550 allows you to select from 3 different working modes: ECO, Normal and

Power. It also features a Power-up function which lets the operator switch the machine

into a higher working mode with lower transmission shift intervals by fully applying

the acceleration pedal.

Auto-idle

User menu Anti-theft protection

Filter/oil information

Torque converter lock-up switch (Opt.)

The torque converter lock-up function automatically links the impeller (input side) with

the turbine (output side). This provides a mechanical connection between the engine

and transmission for direct drive. With no power loss, fuel consumption is reduced and

traction force is increased. Unlike most other systems, the Doosan torque converter

lock-up is automatically engaged from 2nd to 4th gear, depending on transmission

torque.

Automatic lift armkick-out switch

The boom raise kick-down positions create faster cycle times and can be adjusted from

within the cab. An optional return to dig position is available.

Joystick or fingertip control

The bucket can be moved using a convenient joystick

with an FNR switch and kick-down function. The

operator can also choose the option of fingertip control.

Transmission cut-off

The transmission cut-off function disconnects the

driveline from the engine if the brake pedal is engaged.

This delivers the full engine power to the hydraulics,

speeding up cycle times and boosting fuel efficiency. The

brake pressure needed for activation is automatically

controlled, depending on speed, pedal angle and

transmission resistance.

a

b

c

1

1 2

3

2

3

Monitoring

MAINTENANCE

Improved Air Condenser

Optimized air condenser position for cooling & maintenance.

Remote Engine oil & Coolant Drain

Remote drain valves have been installed in an easily

accessible location for convenient draining of fluids.

(Coolant - Right, Engine oil - Left)

Central Remote Hydraulic Pressure Check Port

The centralized remote hydraulic check ports allow

main, steering, brake charge, pilot,load-sensing signal

and transmission clutch pressures to be checked at a

convenient central location.

Propeller Shaft

A protective cover has been installed to protect the oil

seal from dust, foreign objects and premature wear.

Swing Out Cooling Fan

Our fan assembly has been designed with the one touch swing out mechanism and

cleaning the radiator core is very easy.

Air-Cleaner Filter

The high capacity air cleaner eliminates harmful

particles from the air and extends the life of the engine

and replacement intervals.

Sight Gauges

Well-located, yet easily visible sight gauges for the

hydraulic oil and radiator coolant allow easy daily

checks while reducing the risk of contaminants entering

the systems.

Remote Greasing Lubrication Ports

The front pins can be lubricated from the outside of the

machine without crawling under the machine or in awkward

positions through the lubrication ports.

Convenient Transmission Oil Filling

The oil filler pipe is located near the articulation joint for

easy access.

Transmission Filter

The transmission filters are within easy reach and like

the rest of the machines service components, can be

checked from ground level.

Central Joints

A good accessibility at the articulation joint is essential for an easy maintenance.

Transmission & Engine Diagonosis

The transmission and engine can be diagnosed using a laptop computer to interface

with the diagnostic system.

A liquid crystal display conveys information to the operator relative to the machine. At the same time, it

reports the nature of a problem (of one exists). When servicing the loader, a specialised apparatus can be

used to adjust the clutch disks to compensate for their wear. Additionally, by connecting a lap top

computer, a complete transmission diagnostic can be performed.

Brake & Pilot Filter

The brake & pilot filter is easy to replace and a clogged

filter warning system has been added for extra

protection.

RELIABILITY

Engine

Three stage air cleaner with Turbo-3

pre-cleaner, inner filter, and external plugging

indicator as at the dashboard

Water separator with fuel filter

Crankcase Ventilation oiltrap system

Two fuel filters

Hydraulically driven fan

External drains for engine oil and coolant

Electric driven fuel feeding pump

Mode selector switch for the engine power

(Standard / Economy mode)

Self-diagnosis function

Lifting and Hydraulic system

Robust Z bar lifting system

General purpose bucket 5.4m

3

(SAE,heaped)

FNR Lever(Finger tip lever is option)

Hydraulic control valve with two sections

Automatic boom kick out

Automatic bucket return to dig

Fast couplers for hydraulic check

Variable displacement piston pump and

load sensing hydraulic system

Steering system

Load sensing steering system

External equipments

Lower protection plates

Lifting hooks

Articulation lock in the transport position

Towing hitch

Tools compartment

Fender

Mud guard

Electric System

Alternator 100A / 28 V

Working lights : 2 at the front and 4 at the rear

(6 x 70W)

Driving lights: low and high beams

Tail indicators, stop, reversing lights

Reversing alarm

Loader Linkage

Z-bar loader linkage

Drive line and Brake system

Intelligent transmission clutch cut-off via the

brake pedal

Gear box with diagnosis and monitoring

indicator, and electronic plug for a fast

adjustment

Mode selector switch for the transmission

(Manual / Auto 1 4 / Auto 2 4)

Starting safety system

Kickdown and travelling direction

selection: lever at left of the steering wheel or

on the joystick

DHL on front axle.

Dual brake circuits with accumulator

Tire 29.5R25 (L3)

Dual service brake pedals

Secondary brake system

Parking brake on the transmission,

electric-hydraulic

Cab

Air-conditioning / heating with recirculation

function

Double Filtered air cab

Mechanical suspension seat with safety

belt(2")

Adjustable steering column

Compartment for cans

Floor mat

Tinted glasses

Left sliding window

Front and rear wiper

Front and rear washers

Sun visor

Interior cab light

Interior room mirror (2)

Exterior rear view mirrors (2)

Machine monitoring (condition, control &

maintenance indicators in front of the driver

by dials, gauges and lamps)

Main switches in front of the driver

(Starter & hazard switchs)

Switches for the general functions in the right

console

Electrical horn

Cigarette lighter

MP3 CD Player

12 Volt socket

Cup holder

Compartment for Shoes

Glass antenna

Heatwire in side mirror

ROPS Cabin(Rollover Protective Structure):

ROPS Meets The Following Criteria

- SAE 1040 , ISO 3471

FOPS Cabin(Falling Objects Protective

Structure): FORS Meets The Following

Criteria - SAE J 231, ISO 3449

Digital clock

Coat hook

Some of these optional equipments may be standard in

some markets. Some of these optional equipments

cannot be available on some markets. You must check

with the local Doosan dealer to know about the

availability or to release the adaptation following the

needs of the application.

Ground Engaging Tools

Various types of buckets, Pallet fork, timber

grapples and accessories

Drive line and Brake System

5 Gear with Lock-up clutch

Tires

L3, L4, L5 following various types of

manufacturers

Hydraulic

Hydraulic 3rd function control valve

FNR lever with 3rd function lever

for third section

Two hydraulic levers for 2 sections function

Three hydraulic levers for 3 sections function

Load isolation system (LIS)

Emergency steering pump driven by electric

motor(ESS)

Electric Steering Lever

Electric system

Rotating beacon

Additional lighting

Cab

Rear Camera (CCTV) and monitor

Air suspension seat with 3" belt

Various

Additional counterweight

External equipments

Full fender with rubber protector

Loader Linkage

Z-bar high lift loader linkage

Bucket and Attachments

Adapter tooth

5.4m

3

(7.1 cu.yd.)

Bolt-on edge

5.7m

3

(7.5 cu.yd.)

Mono tooth

5.0m

3

(6.5 cu.yd.)

Adapter tooth

5.0m

3

(6.5 cu.yd.)

Teeth & segments

5.2m

3

(6.8 cu.yd.)

Bolt-on edge

5.2m

3

(6.8 cu.yd.)

Rock bucket Adapter tooth

4.5m

3

(5.9 cu.yd.)

STANDARD AND OPTIONAL EQUIPMENT

STANDARD EQUIPMENT OPTIONAL EQUIPMENT

Every morning, when the operators commence work, they know that things will go smoothly- because

Doosan has taken care of it. The product is soild. Operators know that they have significant reserves at

hand and that they wont have to push the machine to its limit. The Doosan DL550 wheel loader is

designed and built to last. For Doosan, reliable means availability, accessibility and simplicity.

*

The standard delivery package and options may vary by region.

Fender-Edge(Opt.)

Hydraulic Oil Return Filter

The high-efficiency, large-capacity return filter

manufactured with the glass-fiber media can eliminate

foreign substances up to 99.5 percent to protect the

costly hydraulic equipment and substantially extend the

replacement cycle.

ORFS(O-Ring faced Seal)-All Ports(Even in Pilot line and Low pressure

line)

2-Piece Type Tooth(Pin-on+Bolt-on adapter)

Radiator Grill (Steel structure) Rubber-Mounting (for Radiator: Lateral 2EA /

Vertical 2EA)

Front Combination Lamp

With the application of high-grade Hella products, the

lamp life has extended much more.

Rear Combination Lamp

A semi-permanent lamp life has been secured with the

application of LED-type stop and position lamps.

The front and rear axles with planetary hub

reductions are built on the base of very reputed

components.

Fitted as standard, the front hydraulic differential

locks, ensure the traction is optimal in all

circumstances.

Maker and model :

MT-L3125II / MT-L3115II

Differential :

Front DHL (100%) / Rear (Open)

Oscillation angle :

+/- 10

Brake :

Dual circuit multi-plate wet discs.

Hydraulic actuation with pump and

accumulator.

A spring applied and hydraulically released

parking brake is mounted on the transmission

shaft.

General description

The high performance Engine Scania DC13

combined a 6 cylinder in-line,

high-pressure unit injector fuel injection system

with electronically controlled direct injection and

turbo charged air to air intercooler offers low fuel

consumption and emission.

-GROSS SAE J1995

Rated Power :

294 kW @2,100rpm

394 HP @2,100rpm

Max. Power :

394 HP (294 kW) @2,100 rpm

Max. Torque :

2,157 Nm @1,200rpm

1,591 lbf.ft @1,200rpm

Displacement :

12,700cc (775 cu.in)

Bore x stroke :

130 x 160 (5.1"x 6.3")mm

Wet replaceable cylinder liner

3 stages Air cleaner including a very efficent pre-

cleaner, main and safety elements.

Hydraulically driven puller type fan with

possibility of adjustment.

Battery :

System voltage : 24V

Quantity : 12V x 2

Capacity (AMP) : 150Ah

Starter power :

24V x 6.0kW

Alternator output :

100A

TECHNICAL SPECIFICATIONS

ENGINE AXLES TRANSMISSION HYDRAULIC SYSTEM OPERATOR CAB LIFTING SYSTEM

Full Power Shift transmission. It can be used in

manual or automatic modes.

This transmission is based on components having

excellent worldwide reputations. It is equipped

with a modulation system allowing soft gear

shifting and inversion of travel direction. Safety

devices also protect the transmission of bad

operations.

The gear and direction shifting is operated by a

single lever to the left of the steering wheel. A

travel direction control is also mounted on the

hydraulic joystick.

With a special electronic device, the transmission

can be tested and adjusted easily for optimum

performance and efficiently.

The transmission can be de-clutched by the

operation of brake pedal to increase the power

available to the hydraulic pumps.

A safety device prevents the starting of the

engine when not in neutral.

Torque converter :

Type : 4 speed, Full auto power-shift,

Countershaft, Engine remote

mounted with propeller shaft and

damper

Stall ratio : 2.598

Gear box :

Maker and model : ZF 4 WG 310

Speed Forward/Rearward :

1 6.5 / 6.5 km/h

(4.0 /4.0 mph)

2 12.4 / 12.1 km/h

(7.5 / 7.5 mph)

3 19.7 / 19 km/h

(12.2 / 11.8 mph)

* 28.0 km/h

(17.4 mph)

4/5 36 km/h

(22.4 mph)

Two load-sensing axial piston pumps with

variable displacement.

Main control valve of double acting 2-spool is

controlled by standard single lever.

Automatic boom kick out and bucket return to

dig. Is standard.

All of hydraulic lines are equipped with special

seals (ORFS)

Max flow main:

480 / min (Main 210 + Steering 270)

Working Pressure:

275 bars

Pressure of the pilot circuit:

30 bars

Filtration capacity on the return line:

10 microns

Loading cycles time:

Lifting speed (loaded) :

6.1 sec

Dumping speed (loaded) :

1.1 sec

Lowering speed (empty) :

4.2 sec

The modular cab allows excellent visibility in all

directions. The optimal ventilation is obtained by

numerous ventilation outlets. Touch buttons

control the air re-circulation air conditioning and

heating systems. The air of the cab is filtered.

All necessary information for the operator are

centralized in front of him.

The main functions are actuated via switches

located on a console at the right of the operator.

Generous storage places are well located. The

cab, mounted on viscous element and equiped

with an air suspended seat, offers a better

comfort for the operator.

Access door: 1

Emergency exits: 2

The cab conforms ROPS ISO 3471 and

FOPS : ISO 3449

Guaranteed external noise level Lwa:

(following ISO 6395, 2000 / 14 / EC) 113 dB(A)

The lifting system with two cylinders and Z

configuration is designed for the toughest jobs.

The breakout force (26.5 ton with a 5.4m

3

bucket)

is optimized for work and the bucket movements

are fast.

The Z formlifting geometry is extremely robust

and especially tailored for demanding jobs.

Particularly effective in penetrating piles of hard

material, it delivers superior breakout force and

loader stability. This is achieved with fewer moving

parts and reduced stress on components.

Performance improves with rapid bucket

movements and correct angle positioning in every

situation. With greater dumping and lifting speed

for the bucket and lift arm, faster cycle times and

increased productivity are ensured.

Lifting cylinders (2)

bore x stroke : 190 x 890 mm (7.5" x 2'11")

Bucket cylinders (1)

bore x stroke : 220 x 610 mm (8.7" x 2'0")

The steering system is a load sensing type with a

flow amplifier and a priority valve.

Steering angle :

40

Oil flow :

270 /min

Working pressure :

185 bars

Steering cylinders (2) :

bore x stroke : 110 x 465 mm (4.3" x 1' 6")

Emergency steering system with hydraulic

pump driven by electric motor.

STEERING

Maintenance is easy due to excellent access.

The transmission is electronically controlled. An

error coding system allows easy diagnosis of the

systems and proper intervention.

Engine (oil) : 45 (11.8 gal)

Radiator (cooling liquid) : 60 (15.8 gal)

Fuel : 564 (148.9gal)

Hydraulic oil : 247 (65.2 gal)

Gear box and

torque converter : 54 (14.2 gal)

Front axle : 50 (13.2 gal)

Rear axle : 50 (13.2 gal)

MAINTENANCE

**

: 5 speed w/lock up (option)

: 4th,5th T/M max speed is 36 km/h

*

**

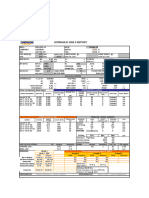

OPERATIONAL DATA DIMENSIONS

General purpose Loader type

1) Measured to the tip of the bucket teeth or bolt on edge with tires 29.5R25VSNT(L4)

Capacity heaped ISO/SAE

Bucket width

Breakout force

Static tipping load (straight)

Static tipping load (at full turn)

Dump height (at 45)

(at fully raised)

1)

Dump reach (at 45)

(at fully raised)

1)

Dump height (at max. dump)

(at max. reach)

1)

Dump reach (at max. dump)

(at max. reach)

1)

Digging depth

Height at bucket pivot point

Max. tilt angle at carry position

Max. tilt angle at fully raised

Max. tilt angle on ground

Max. tilt angle at max. reach

Max. dump angle at max. reach

Max. dump angle on ground

Max. dump angle at fully raised

External radius at bucket edge

Overall length

Operating weight

B

H

I

J

K

M

Q

A

m

3

yd

3

mm

ft in

kN

lbf

kg

lb

kg

lb

mm

ft in

mm

ft in

mm

ft in

mm

ft in

mm

ft in

mm

ft in

deg

deg

deg

deg

deg

deg

deg

mm

ft in

mm

ft in

kg

lb

5.4

7.1

3,405

11'2''

260

58,450

24,680

54,410

21,790

48,039

3,285

10'9''

1,535

5'0''

685

2'3''

1,830

6'0''

80

3''

4,795

15'9''

48

67

43

68

68

79

47

7,565

24'10''

9,870

32'5''

31,125

68,619

5.7

7.5

3,405

11'2''

260

58,450

24,290

53,550

21,445

47,278

3,405

11'2''

1,400

4'7''

855

2'10''

1,750

5'9''

80

3''

4,795

15'9''

48

67

43

68

68

79

47

7,515

24'8''

9,680

31'9''

31,250

68,894

5.0

6.5

3,405

11'2''

283

63,621

24,845

54,774

21,935

48,358

3,355

11'0''

1,460

4'10''

785

2'7''

1,790

5'10''

80

3''

4,795

15'9''

48

67

43

68

68

79

47

7,525

24'8"

9,760

32'0''

30,950

68,233

5.2

6.8

3,405

11'2''

282

63,396

24,345

53,671

21,495

47,388

3,480

11'5''

1,325

4'4''

955

3'2''

1,710

5'7''

80

3''

4,795

15'9''

48

67

43

68

68

79

47

7,485

24'7''

9,575

31'5''

31,195

68,773

5.2

6.8

3,405

11'2''

282

63,396

24,480

53,969

21,615

47,653

3,355

11'0''

1,460

4'9''

785

2'7''

1,790

5'10''

80

3''

4,795

15'9''

48

67

43

68

68

79

47

7,485

24'7''

9,760

32'0''

31,120

68,608

Configuration

Bucket mount

Adapter

tooth

Unit

Teeth &

segments

Adapter

tooth

Mono

tooth

PIN ON PIN ON

Bolt-on

edge

Bolt-on

edge

Bolt-on

edge

PIN ON

Adapter

tooth

PIN ON

5.0

6.5

3,405

11'2''

283

63,621

24,865

54,818

21,955

48,402

3,380

11'1''

1,435

4'9''

820

2'8''

1,770

5'10''

80

3''

4,795

15'9''

48

67

43

68

68

79

47

7,535

24'9''

9,725

31'11''

30,995

68,332

Rock

4.5

5.9

3,440

11'3''

266

59,799

24,025

52,966

21,210

46,760

3,330

10'11''

1,545

5'1''

730

2'5''

1,855

6'1''

45

2''

4,795

15'9''

48

67

43

68

68

79

47

7,555

24'9''

9,805

32'2''

31,280

68,961

PIN ON

High lift

5.7

7.5

3,405

11'2''

253

56,877

19,490

42,968

17,210

37,942

3,830

12'7''

1,620

5'4''

870

2'10''

2,295

7'6''

205

8''

5,220

17'2''

50

62

43

62

65

79

47

7,790

25'7''

10,255

33'8''

31,705

69,897

PIN ON PIN ON PIN ON

D

e

l ta

-

T

e

m

p

e

r

a

tu

r

e

s

Running Time (min)

Differential

Hub

100

80

60

40

20

0 50 100 150 200 250 300 350

k

g

/

m

3

S

n

o

w

C

o

k

e

C

o

a

l

C

la

y

E

a

t

t

h

G

r

a

v

e

l

S

a

n

d

R

o

c

k

c

r

u

s

h

e

d

G

r

a

n

it

e

(

lo

o

s

e

d

)

B

a

s

a

lt

L

im

e

s

t

o

n

e

S

a

n

d

s

t

o

n

e

2000

1800

1600

1400

1200

1000

800

600

400

Specific Weight (kg/m

3

)

m

3

SAE

Bucket filling factor

4.5

4.3

4.1

3.9

2 1.9 1.8 1.7 1.6 1.5 tonnes/m

3

Bucket Capacity

Material specific weight

95% 100% 115%

The specific weight of material largely depends on moisture rate, compacting value,

percentage of various components etc... This chart is given only for information.

The Bucket filling factor depends also of the nature of material, the working conditions

and the operator ability.

D

e

l ta

-T

e

m

p

e

ra

tu

re

s

Running Time (min)

Differential

Hub

100

80

60

40

20

0 50 100 150 200 250 300 350

k

g

/m

3

S

n

o

w

C

o

k

e

C

o

a

l

C

la

y

E

a

tth

G

r

a

v

e

l

S

a

n

d

R

o

c

k

c

r

u

s

h

e

d

G

r

a

n

ite

(

lo

o

s

e

d

)

B

a

s

a

lt

L

im

e

s

to

n

e

S

a

n

d

s

to

n

e

2000

1800

1600

1400

1200

1000

800

600

400

Specific Weight (kg/m

3

)

m3SAE

(Adapter tooth)

(Cutting edge

tooth)

Bucket filling factor

2.4 2.2 2 1.8 1.6 1.4 1.2

tonnes/m

3

Bucket Capacity

Material specific weight

(V-type Rock

Bucket)

4.5

5.4

95% 100% 115%

High lift arm

(Adapter tooth)

5.4

5.7

B

Q

A

H

J

K

M

H

"

I

I"

Belgium

(Frameries)

France

(Pontchateau)

USA

(Statesville)

Czech Republic

(Dobris)

China

(Suzhou)

Korea

(Incheon & Gunsan)

UK

(Slane)

Brazil

(So Paulo)

China

(Shanghai)

China

(Yantai)

USA

(Litchfield)

USA

(Gwinner)

France

(Lyon)

USA

(Bismarck)

USA

(Lake City)

Doosan worldwide factories

Heavy Equipment Factory

Compact Equipment Factory

Attachment Factory

www.doosaninfracore.com/ce/

Doosan Infracore Korea Office (HQ)

27/F, Doosan Tower 18-12, Euljiro-6Ga, Jung-Gu

Seoul 100-730 Korea

Tel : 82 2 3398 8114

ILDESIGN_EN_201303

You might also like

- PW160 7Document24 pagesPW160 7Baciu SorinNo ratings yet

- Thomson Electrac HD Linear Actuator Motion Control per CAN BusFrom EverandThomson Electrac HD Linear Actuator Motion Control per CAN BusNo ratings yet

- Ec700b Eu EngDocument24 pagesEc700b Eu Engdalibor_bogdanNo ratings yet

- PC700-8 Uess15301 1208Document24 pagesPC700-8 Uess15301 1208LTATECNICONo ratings yet

- Doosan DL450Document16 pagesDoosan DL450Foromaquinas100% (3)

- Volvo Tier 4 Interim EngineDocument8 pagesVolvo Tier 4 Interim Enginehelp3r100% (1)

- R922Document24 pagesR922equipment9278No ratings yet

- Litronic Performance Liebherr Wheel Excavators Have Been DesignedDocument20 pagesLitronic Performance Liebherr Wheel Excavators Have Been DesignedLiebherr100% (1)

- A35DContainerHauler EnglishDocument6 pagesA35DContainerHauler Englishandreika1970No ratings yet

- Komatsu Excavadora PC850 - 850se-8 - PDFDocument8 pagesKomatsu Excavadora PC850 - 850se-8 - PDFCrecencio Sanches100% (1)

- Komatsu D375A-5 PDFDocument12 pagesKomatsu D375A-5 PDFtechnical trainer 011cNo ratings yet

- Operación y MantenimientoDocument299 pagesOperación y MantenimientoJose A. Basanta H.No ratings yet

- V Ec460 212 1621 0009Document10 pagesV Ec460 212 1621 0009Maria Da Graça RomãoNo ratings yet

- Technical Specifications: Hydraulic ExcavatorDocument10 pagesTechnical Specifications: Hydraulic ExcavatorJonathan KaleNo ratings yet

- DX700LC PDFDocument20 pagesDX700LC PDFA Ramos GabyNo ratings yet

- DX 340 Operational ManualDocument288 pagesDX 340 Operational ManualJoakimindarno100% (1)

- JAMA Seminar 2019 LCM WG - Final PDFDocument37 pagesJAMA Seminar 2019 LCM WG - Final PDFgilar herliana putraNo ratings yet

- Service Guide L350FDocument4 pagesService Guide L350FInjeletro DieselNo ratings yet

- AP 240 enDocument6 pagesAP 240 enJoão GuardadoNo ratings yet

- Blue Line Hydraulic Breakers: Product RangeDocument6 pagesBlue Line Hydraulic Breakers: Product RangeChandra prakash Jangid0% (1)

- PC490 PC490LC: EU Stage V EngineDocument20 pagesPC490 PC490LC: EU Stage V EnginevitaliyNo ratings yet

- PC350 PC350LCDocument24 pagesPC350 PC350LCEdu LimayNo ratings yet

- HM400 3M0 PDFDocument20 pagesHM400 3M0 PDFFakhrur RizkyNo ratings yet

- FX 1000 User S Manual 2Document328 pagesFX 1000 User S Manual 2jacobbritto100% (1)

- Om K1024898e (dx140w)Document309 pagesOm K1024898e (dx140w)Diego Mauricio Zapata Garcia50% (2)

- Attachment Ref Book - Ver1.3Document89 pagesAttachment Ref Book - Ver1.3mikeNo ratings yet

- SDLG RS8140 Road Roller For SaleDocument4 pagesSDLG RS8140 Road Roller For SaleMartin Lee100% (2)

- 1021F-1121F 20050GB PDFDocument24 pages1021F-1121F 20050GB PDFnksiavash0% (1)

- Doosan 340Document16 pagesDoosan 340Victor VillarrealNo ratings yet

- KS En013eup PDFDocument24 pagesKS En013eup PDFElvis Justo Choquegonza GomezNo ratings yet

- D155a 6 PDFDocument16 pagesD155a 6 PDFJulio A CamposNo ratings yet

- Ficha Tecnica Excavadora Hyundai r500lc-7Document9 pagesFicha Tecnica Excavadora Hyundai r500lc-7Ervin MayorcaNo ratings yet

- VOLVO EC160e Product BrochureDocument28 pagesVOLVO EC160e Product BrochurePHÁT NGUYỄN THẾ100% (1)

- PC1250Document106 pagesPC1250yonathan yonathan100% (1)

- Kamatsu PC270 - 270LC-8 - 2Document7 pagesKamatsu PC270 - 270LC-8 - 2Piotr Gabryś Hi-this100% (1)

- Kenr5125kenr5125-02 SisDocument13 pagesKenr5125kenr5125-02 Sisygor valdezNo ratings yet

- DX300LCDocument20 pagesDX300LCjohnmichph_95611836No ratings yet

- Wa380 5Document12 pagesWa380 5alsief1951100% (3)

- S220LC-V Om enDocument173 pagesS220LC-V Om ensergio mata100% (1)

- D155ax 8Document16 pagesD155ax 8eliasNo ratings yet

- Volvo EC380D EC480D BrochureDocument17 pagesVolvo EC380D EC480D BrochureKhaled BounecerNo ratings yet

- D8R Lubricant Viscosity PDFDocument37 pagesD8R Lubricant Viscosity PDFarfa ujiantoNo ratings yet

- Hyundai R290LC 7 Crawler Excavator Service Repair ManualDocument648 pagesHyundai R290LC 7 Crawler Excavator Service Repair ManualcodeyNo ratings yet

- Doosan DL550 - OMMDocument392 pagesDoosan DL550 - OMMkeron trotz100% (1)

- Especificações TecnicasDocument20 pagesEspecificações TecnicasDanubio Rocha de LimaNo ratings yet

- AT12101 PC2000 BOOM RepairDocument16 pagesAT12101 PC2000 BOOM Repairluy nguyen100% (1)

- ZX160-3 Techni̇cal Manual Tt1t1-E-00 (20071112)Document622 pagesZX160-3 Techni̇cal Manual Tt1t1-E-00 (20071112)Baris TuranNo ratings yet

- Service Training Malaga 345C/365C/385C Hydraulic Excavators: Francis Apr 05Document5 pagesService Training Malaga 345C/365C/385C Hydraulic Excavators: Francis Apr 05Milorad Zelenovic100% (1)

- Catalog 2021: With Always at Your ServiceDocument27 pagesCatalog 2021: With Always at Your ServiceYaman mNo ratings yet

- A25F, A30F: Volvo Articulated HaulersDocument24 pagesA25F, A30F: Volvo Articulated HaulersSanNo ratings yet

- OmegaDocument2 pagesOmegaATHOLSCHWARZNo ratings yet

- 2009 10 20 PDF KOMTRAX Troubleshoot Guide 68411 PDFDocument35 pages2009 10 20 PDF KOMTRAX Troubleshoot Guide 68411 PDFphankhoa83-1No ratings yet

- Komatsu Technical Operator Training v6Document7 pagesKomatsu Technical Operator Training v6Hamid Essarbouti100% (2)

- Volvo Wheel LoaderDocument20 pagesVolvo Wheel LoaderDanival Guðjón StefánssonNo ratings yet

- Komatsu VHMS PC SoftwareDocument1 pageKomatsu VHMS PC SoftwareNguyễn Thanh NhànNo ratings yet

- BrochureEC460C 21A1005396 2009-02 SerNo115011Document24 pagesBrochureEC460C 21A1005396 2009-02 SerNo115011Faisal RosidNo ratings yet

- EC290B LC Ec290B NLC: Volvo ExcavatorDocument12 pagesEC290B LC Ec290B NLC: Volvo Excavatorمحمد عابدينNo ratings yet

- New Holland - Grader 156-7Document16 pagesNew Holland - Grader 156-7Cristian Cernega100% (1)

- Liebherr A904C HD BrochureDocument14 pagesLiebherr A904C HD Brochureibilge100% (1)

- D11TDocument24 pagesD11TFelix Juan Valentin Paucar MamaniNo ratings yet

- El Mundo de ScaniaDocument20 pagesEl Mundo de ScaniaElvis Eberth Huanca MachacaNo ratings yet

- Scoop TrampsDocument4 pagesScoop TrampsElvis Eberth Huanca MachacaNo ratings yet

- Productbrochure - L150G - L180G - L220G - VOE22A1006521 - 2011-02Document32 pagesProductbrochure - L150G - L180G - L220G - VOE22A1006521 - 2011-02Pradeep Raj100% (1)

- Catalogo General LiebherDocument4 pagesCatalogo General LiebherElvis Eberth Huanca MachacaNo ratings yet

- Catalogo JCBDocument28 pagesCatalogo JCBElvis Eberth Huanca MachacaNo ratings yet

- Skid-Steer Safety: Agriculture and Natural ResourcesDocument2 pagesSkid-Steer Safety: Agriculture and Natural ResourcesElvis Eberth Huanca MachacaNo ratings yet

- EX 2500 Especificaciones TecnicasDocument16 pagesEX 2500 Especificaciones TecnicasElvis Eberth Huanca Machaca100% (2)

- 2013 - Skid Steer Loader - Parts Catalog PDFDocument27 pages2013 - Skid Steer Loader - Parts Catalog PDFElvis Eberth Huanca MachacaNo ratings yet

- See More. Lift More. Do MoreDocument6 pagesSee More. Lift More. Do MoreElvis Eberth Huanca Machaca0% (1)

- Wa 800 Catalogo Komatsu CargadorDocument12 pagesWa 800 Catalogo Komatsu CargadorElvis Eberth Huanca MachacaNo ratings yet

- Skid Steer & CTL Attachments: Consistently Leading The WayDocument16 pagesSkid Steer & CTL Attachments: Consistently Leading The WayElvis Eberth Huanca MachacaNo ratings yet

- Preventing Injuries and Deaths From Skid-Steer LoadersDocument20 pagesPreventing Injuries and Deaths From Skid-Steer LoadersElvis Eberth Huanca MachacaNo ratings yet

- L30G L35G VolvoDocument20 pagesL30G L35G VolvoElvis Eberth Huanca MachacaNo ratings yet

- 2012 UKonly MS130Document2 pages2012 UKonly MS130Elvis Eberth Huanca MachacaNo ratings yet

- Bobcat 463Document4 pagesBobcat 463Elvis Eberth Huanca MachacaNo ratings yet

- Treeliminator: Ts55 Skid Steer Tree SawDocument20 pagesTreeliminator: Ts55 Skid Steer Tree SawElvis Eberth Huanca MachacaNo ratings yet

- Fresadoras Atlas 2013Document26 pagesFresadoras Atlas 2013Elvis Eberth Huanca MachacaNo ratings yet

- PTH Crusher GBDocument16 pagesPTH Crusher GBElvis Eberth Huanca MachacaNo ratings yet

- WA200 6 InglesDocument12 pagesWA200 6 InglesElvis Eberth Huanca MachacaNo ratings yet

- Operating and Maintenance Manual For Launching-And Retrieval System of Freefall Lifeboat Type: FFADocument22 pagesOperating and Maintenance Manual For Launching-And Retrieval System of Freefall Lifeboat Type: FFAGoga100% (2)

- 7000 Series Field Operations Manual PDFDocument45 pages7000 Series Field Operations Manual PDFmanzanaNo ratings yet

- Hydraulic Report Mudlogging ExampleDocument1 pageHydraulic Report Mudlogging ExampleCarmen Ibeth Olivos PradaNo ratings yet

- Cityfix Operating Instructions - 09-2004Document34 pagesCityfix Operating Instructions - 09-2004ismail emre canbolatNo ratings yet

- Projectreport ExcavatorArmDocument41 pagesProjectreport ExcavatorArmVinod Yb0% (1)

- Yawei Pressbrake ManualDocument54 pagesYawei Pressbrake ManualWayne Hoppe100% (1)

- BopDocument66 pagesBopArif budi CahyonoNo ratings yet

- Landing Gear R 01Document56 pagesLanding Gear R 01kimkurniawanNo ratings yet

- Nimco Monoblock Control ValvesDocument66 pagesNimco Monoblock Control ValvesHui ChenNo ratings yet

- Ren-Tek DC Catalogue - 2007Document40 pagesRen-Tek DC Catalogue - 2007rlnjay2003No ratings yet

- Blitz OperatorsDocument44 pagesBlitz OperatorsjchumpitazfNo ratings yet

- 374DL SpecalogDocument28 pages374DL SpecalogDiego Osorio AguirreNo ratings yet

- TDS Alpha 20 (EN) V5Document2 pagesTDS Alpha 20 (EN) V5Carlos Francisco F'ArNo ratings yet

- Hudraulic FliudsDocument19 pagesHudraulic Fliudsmohamed elejmiNo ratings yet

- Service Manual Kramer 680Document252 pagesService Manual Kramer 680Rafał Dworak100% (12)

- MECS - SyllabusDocument3 pagesMECS - SyllabusRagunath PalanichamyNo ratings yet

- Hydraulic Oil Iso VG 46Document1 pageHydraulic Oil Iso VG 46KarthikeyanNo ratings yet

- NPK Auto Lube SystemDocument59 pagesNPK Auto Lube SystemLuka Borna100% (1)

- Piston Pump (Hydrostatic) : Systems OperationDocument9 pagesPiston Pump (Hydrostatic) : Systems OperationRajan MullappillyNo ratings yet

- SK485LC: Acera Mark 8Document16 pagesSK485LC: Acera Mark 8Ruben Perez MuñozNo ratings yet

- 330Kv Cable System For The Metrogrid Project in Sydney AustraliaDocument8 pages330Kv Cable System For The Metrogrid Project in Sydney AustraliaramsesiNo ratings yet

- R999000375 Medien Web EN 2016-01-28Document104 pagesR999000375 Medien Web EN 2016-01-28Dragan LazicNo ratings yet

- Carver Hydraulic Press ManualDocument38 pagesCarver Hydraulic Press Manualgotboost777No ratings yet

- Service and Maintenance Manual: ModelDocument116 pagesService and Maintenance Manual: ModelAdriano Alves SilvaNo ratings yet

- Our Program: An ABEL Pump Helps You Work With Difficult MediaDocument10 pagesOur Program: An ABEL Pump Helps You Work With Difficult Mediaha liNo ratings yet

- Hydraulic Systems: Hydraulic Mechanism of Acme Cutting MachineDocument21 pagesHydraulic Systems: Hydraulic Mechanism of Acme Cutting MachineSantha PriyaNo ratings yet

- Manual de Operación y Mantenimiento JumboDocument266 pagesManual de Operación y Mantenimiento JumboarmandoNo ratings yet

- Takeuchi TB180FRDocument2 pagesTakeuchi TB180FRForomaquinas100% (1)

- Subsea Control System For All-Electric TreesDocument74 pagesSubsea Control System For All-Electric TreesZadeh Norman100% (2)