Professional Documents

Culture Documents

Greiner Extrusion Plant Engineering Eng

Uploaded by

Paras JainCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Greiner Extrusion Plant Engineering Eng

Uploaded by

Paras JainCopyright:

Available Formats

PARTNERS FOR

SUCCESS.

CONTACT

GREINER EXTRUSION GMBH.

Friedrich-Schiedel-Strasse 1, 4542 Nussbach, Austria, www.greiner-extrusion.at

T +43 (0)505 41 -0 F +43 (0)505 41 -41 631 Mail ofce@greiner-extrusion.at

The right to make technical changes is reserved and no responsibility is accepted for misprints.

Copyright by Greiner Extrusion GmbH

PARTNERS FOR

SUCCESS.

COMPLETE SOLUTIONS FOR PVC PROFILE PRODUCTION

The right to make technical changes is reserved and no responsibility is accepted for misprints.

Copyright by Greiner Extrusion GmbH

PLANT ENGINEERING.

2

COMPLETE SOLUTIONS FOR PVC PROFILE PRODUCTION

PLANT ENGINEERING.

PRODUCT AND PRODUCTION PLANT DESIGN FOR PVC WINDOWS AND DOORS.

Customer production success is our goal. With over 30 years of experience, Greiner Extrusion is the world leader in the extruded

plastic prole tooling and machinery market. Our competence lead in the key area of prole extrusion and a comprehensive range

of services make us the no.1 partner for the creation of product design and turn-key plants for PVC windows and doors. Reliability,

punctuality of delivery and a large number of successfully completed projects are all evidence of Greiner expertise in the plant

engineering eld.

P

L

A

N

T

E

N

G

I

N

E

E

R

I

N

G

. 3

GROUND BREAKING CONSTRUCTION WORKS THE PLANT

GREINER PLANT ENGINEERING CAPABILITIES.

ADVICE & CONSULTING

Feasibility studies

Market analyses

Protability studies

Cost planning

Financial consulting

PLANNING & DEVELOPMENT

Window and door system development

Development of technical proles

PVC formulation proposals

Extrusion line layouts

Plant layouts

REALISATION & SERVICES

Turn-key project management

Complete plant and machine installations

System and machine documentation

Employee training (Greiner extrusion college)

Life cycle services

LEADERSHIP.

COMPLETE SOLUTIONS FOR PVC PROFILE PRODUCTION

PLANT ENGINEERING.

4

AN IDEAL BLEND OF KNOW-HOW AND EXPERIENCE.

Greiner Extrusion offers a complete package of services for the production of PVC window proles and doors.

Tailor-made solutions are prepared for every customer in a process that involves close teamwork and takes into

account the characteristic market needs and conditions prevailing in individual countries. Systems which meet

all individual stipulations and requirements are the result. Thousands of proles and a large number of complete

Greiner Extrusion systems are in operation in both Europe and the worlds growth markets.

A SYSTEM RICH IN ADVANTAGES.

Cooperation in any desired form, from complete system development to the preparation of individual static

and thermal calculations.

Comprehensive documentation for customers with complete facts and gures regarding sealings,

reinforcement and glazing guidelines, up to production and installation directives.

3D model drawings for injection moulded parts or stereo-lithographic samples.

Complete system developments for PVC window proles, PVC doors, PVC foam interior doors, table and

panelling sheets, rigid PVC technical proles.

PROFILE SYSTEM

CONSULTING.

COMPLETE SOLUTIONS FOR PVC PROFILE PRODUCTION

PLANT ENGINEERING.

P

L

A

N

T

E

N

G

I

N

E

E

R

I

N

G

. 5

INJECTION MOULDING

DRAWINGS

CROSS-

SECTIONS

CALCULATION

OF U-VALUES

STATIC

CALCULATION

1 2 3 4

A4

2009 by G

R

E

IN

E

R

E

X

T

R

U

S

IO

N

G

M

B

H

Material Scale

Drawn

Profile weight

PCE (Coex) weight

Customer

Internal walls

Wall thickness

Name System

Drawing Nr:

-

31.03.09

-

section

Profile

Tilt & turn window

Drehkipp-Fenster

HAND SKETCH

INDIVIDUAL SOLUTIONS

2D-CAD DRAWING

READY-TO-MANUFACTURE

WINDOW SYSTEMS

3D-CAD DRAWING

6

COMPLETE SOLUTIONS FOR PVC PROFILE PRODUCTION

PLANT ENGINEERING.

SERVICES SAFE, SPEEDY AND UNIVERSAL.

Everything from on-the-spot, start-up services with customer personnel training, maintenance and servicing, to a fast spare part

service mean that Greiner services start early and never stop. Life cycle security creates leadership and supports production

success.

P

L

A

N

T

E

N

G

I

N

E

E

R

I

N

G

. 7

PLANNING, REALISATION, SERVICE AND TRAINING.

PLANNING FOR HIGHER PRODUCTIVITY

The proven interplay derived from Greiner specialists in various disciplines combining in constructive teamwork

guarantees ideal, overall solutions.

Plant layouts that precisely meet production requirements and local conditions, including the optimum

positioning of the electricity, water and compressed air supply, as well as the complete cooling

water treatment.

Extrusion line layouts for complete production from extrusion, to nal processing and stacking systems.

Documentation of plant and line layouts with all plans and supplemented by lists of connection and

consumption values for electricity, water and compressed air.

Training. Greiner extrusion college (Geco) offers individual training and educational programmes for

customers personnel, either on-the-spot or at Greiner training facilities.

REALISATION WITH OPTIMUM TOOLING AND MACHINE SELECTION

The heart of any plant is the extrusion process. Here, Greiner relies entirely on tooling and machines manufactured

in-house. Moreover, those parts not produced within the company are purchased exclusively from respected

suppliers, who have demonstrated their quality and reliability in the course of long-term cooperation. Greiner

specialists assume responsibility for the project management, provide technical support and ensure punctual

installation.

PLANT.

MACHINERY TOOLING TRAINING

REALISATION

with time planning and project management

ON-THE-SPOT SERVICES

You might also like

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- Improvised Sabotage DevicesDocument72 pagesImprovised Sabotage Deviceskqthomson88% (48)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- 5th Oman Plast 2018. List of ParticipantsDocument5 pages5th Oman Plast 2018. List of ParticipantsPallavi JagtapNo ratings yet

- Geogrid Prices For Uniaxail Grid, PVC CoatedDocument1 pageGeogrid Prices For Uniaxail Grid, PVC CoatedParas JainNo ratings yet

- Brysbuzz BrochureDocument29 pagesBrysbuzz BrochureParas JainNo ratings yet

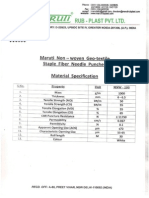

- Material SpecificationDocument1 pageMaterial SpecificationParas JainNo ratings yet

- Panasonic TDA 100D, Mr. Paras JainDocument4 pagesPanasonic TDA 100D, Mr. Paras JainParas JainNo ratings yet

- ACE Advantages DieselDocument1 pageACE Advantages DieselParas JainNo ratings yet

- Chapter 6Document10 pagesChapter 6Paras JainNo ratings yet

- Ten CateDocument12 pagesTen CatetodoransNo ratings yet

- NM228 Quatation For Battery Operated Fork LiftDocument5 pagesNM228 Quatation For Battery Operated Fork LiftParas JainNo ratings yet

- Kisan Baburao HazareDocument7 pagesKisan Baburao HazareParas JainNo ratings yet

- Chapter 1Document10 pagesChapter 1Paras JainNo ratings yet

- One Way Slab - NptelDocument25 pagesOne Way Slab - Npteljindal_bharatNo ratings yet

- Word 2003 TutorialDocument32 pagesWord 2003 TutorialParas JainNo ratings yet

- Uni Max CatalogueDocument32 pagesUni Max CataloguedpbblNo ratings yet

- Mega Project Profiles PVC Manufacturing KSIDC IPDocument6 pagesMega Project Profiles PVC Manufacturing KSIDC IPAgasthya BNo ratings yet

- Entegris Quick Connect System 3560-2438-0113Document8 pagesEntegris Quick Connect System 3560-2438-0113TBNo ratings yet

- DoymaDocument28 pagesDoymaMariusNo ratings yet

- Aote Aviation BrochureDocument4 pagesAote Aviation BrochureSaurabh UttamNo ratings yet

- Mould BaseDocument8 pagesMould BaseMould Base ManufacturerNo ratings yet

- U.S. Paint & Coatings Industry Study 2015-2020: Green & Sustainable Coatings LeadDocument8 pagesU.S. Paint & Coatings Industry Study 2015-2020: Green & Sustainable Coatings LeadAndres FernándezNo ratings yet

- 4 Pipes 2015Document134 pages4 Pipes 2015kk Philips SmartNo ratings yet

- Australian Standard: Butterfly Valves For Waterworks Purposes Part 1: Wafer and LuggedDocument7 pagesAustralian Standard: Butterfly Valves For Waterworks Purposes Part 1: Wafer and LuggedMuthukumar VeerappanNo ratings yet

- GP Fund Advance FormDocument2 pagesGP Fund Advance FormNauman LiaqatNo ratings yet

- B2B Strategy- MRF TyresDocument20 pagesB2B Strategy- MRF TyresShivamSoniNo ratings yet

- Wika LMB Eng Ik CCB Hvac 01Document22 pagesWika LMB Eng Ik CCB Hvac 01riyadigeng19gmailcomNo ratings yet

- Typical Roof Detail Duct Thru Roof Detail Vent Thru Roof Detail Concrete Pad On Roof DetailDocument1 pageTypical Roof Detail Duct Thru Roof Detail Vent Thru Roof Detail Concrete Pad On Roof DetailAdel KhalilNo ratings yet

- Rockford Company Case StudyDocument1 pageRockford Company Case StudyYohanes Fernando50% (2)

- PetrochemicalDocument3 pagesPetrochemicalVidhi DaveNo ratings yet

- Lavina KatalogDocument64 pagesLavina KatalogMilan CvorovicNo ratings yet

- Belting & Rubber Repair: Devcon Flexane 80 Liquid Devcon Flexane 94 Liquid Devcon Flexane PrimerDocument1 pageBelting & Rubber Repair: Devcon Flexane 80 Liquid Devcon Flexane 94 Liquid Devcon Flexane PrimerjohnNo ratings yet

- Cgo12 2002aDocument227 pagesCgo12 2002aahmadansari6601588100% (1)

- Naylor: DenlokDocument15 pagesNaylor: DenlokhutuguoNo ratings yet

- Thermoplastic Polyurethanes Bridge The Gap Between Rubber and PlasticsDocument4 pagesThermoplastic Polyurethanes Bridge The Gap Between Rubber and PlasticsA MahmoodNo ratings yet

- TDS Gate Valve Range OverviewDocument14 pagesTDS Gate Valve Range OverviewShaheen S. RatnaniNo ratings yet

- Construction Materials Wholesale Price Index Primer - 6Document2 pagesConstruction Materials Wholesale Price Index Primer - 6Charilyn EcheverreNo ratings yet

- CSE Catalog - IndiaDocument67 pagesCSE Catalog - IndiaDheeraj SivadasNo ratings yet

- Tyre BasicsDocument54 pagesTyre BasicsDani WijayaNo ratings yet

- Flood Barrier BrochureDocument44 pagesFlood Barrier BrochureWolfnkom NkomNo ratings yet

- Melco Corporate Brochure - MarchDocument11 pagesMelco Corporate Brochure - MarchArobella HaleNo ratings yet

- Adwea Standard Quality Control Plan (SQCP) : Butterfly Valves (For Water Pipeline Works)Document20 pagesAdwea Standard Quality Control Plan (SQCP) : Butterfly Valves (For Water Pipeline Works)Amro HarasisNo ratings yet

- Indian CompaniesDocument309 pagesIndian Companiesanand4286No ratings yet