Professional Documents

Culture Documents

AL4 Pressure Regulation Fault Diagnosis and Repair

Uploaded by

Jesús Ponce0 ratings0% found this document useful (0 votes)

230 views3 pagesThis document provides information about an intermittent pressure regulation fault in the AL4 automatic transmission found in various Peugeot models from 2003-2005. Symptoms include the snow or sports light flashing or an automatic transmission fault displayed, with the transmission entering a limp home mode. The fault code logged is for a pressure regulation fault caused by a difference between the calculated and actual line pressure. Common causes are internal leaks or a faulty pressure regulation solenoid valve. Diagnosing the problem requires checking transmission fluid and pressure sensor readings, and potentially replacing solenoid valves, seals, magnets, and software before considering replacing the valve body or entire transmission.

Original Description:

Original Title

AL4 Pressure Regulation Fault

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides information about an intermittent pressure regulation fault in the AL4 automatic transmission found in various Peugeot models from 2003-2005. Symptoms include the snow or sports light flashing or an automatic transmission fault displayed, with the transmission entering a limp home mode. The fault code logged is for a pressure regulation fault caused by a difference between the calculated and actual line pressure. Common causes are internal leaks or a faulty pressure regulation solenoid valve. Diagnosing the problem requires checking transmission fluid and pressure sensor readings, and potentially replacing solenoid valves, seals, magnets, and software before considering replacing the valve body or entire transmission.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

230 views3 pagesAL4 Pressure Regulation Fault Diagnosis and Repair

Uploaded by

Jesús PonceThis document provides information about an intermittent pressure regulation fault in the AL4 automatic transmission found in various Peugeot models from 2003-2005. Symptoms include the snow or sports light flashing or an automatic transmission fault displayed, with the transmission entering a limp home mode. The fault code logged is for a pressure regulation fault caused by a difference between the calculated and actual line pressure. Common causes are internal leaks or a faulty pressure regulation solenoid valve. Diagnosing the problem requires checking transmission fluid and pressure sensor readings, and potentially replacing solenoid valves, seals, magnets, and software before considering replacing the valve body or entire transmission.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 3

AL4 Pressure Regulation Fault

Created: 27. 09. 2003

Updated: 20. 09. 2005

Model: 206, 306, 307, 406 with AL4 Automatic Transmission.

Symptoms

Flashing of the snow or sports light or Automatic Transmission Fault on display.

In most cases the transmission will go into the downgraded mode, or limp home. In

this mode the transmission is locked in third speed to enable to continue the operation

of the vehicle. This is reported by some drivers as a loss of power. The downgraded

mode can be preceded by some very harsh up or down shifts. After stopping and

restarting the engine, the transmission will usually return to normal operation.

Most of the time the problem appears at unpredictable intervals. Some owners

experience incidences on a daily basis and others may have weeks of trouble free

operation between incidents. Normally the malfunction lasts only for short periods,

from a few seconds to a minute or two.

The following fault code is logged in the transmission ECU:

"Intermittent fault. Pressure regulation fault, recommendation/variation"

Cause

The pressure regulation fault code is triggered when the ECU senses a difference

between the calculated pressure and the actual line pressure in the transmission. The

pressure difference is caused by internal leakage. Internal leaks can be caused by

mechanical wear, a leak between valve body and transmission casing, incorrect

adjustment of the manual valve index spring. The most common cause however is the

pressure regulation solenoid valve.

Diagnosis.

The diagnosis is not straightforward, several operations are required to eliminate

possibilities.

1. Transmission fluid

a. Check the fluid level in the transmission and rectify if as required. Low or

high fluid levels are equally harmfull.

b. Save some of the drained fluid in a clean container for examination.

The transmission may need to be overhauled or replaced if:

The fluid sample is black and smells burnt, contains metal particles, plastic

particles or friction material.

New fluid is transparent. Fluid drained from a transmission that has been in

operation for some time is usually dark in colour and lacks transparency, this is

acceptable and not necessarily an indication of an internal fault. Caution is to be

exercised with the fluid assessment.

2. Pressure sensor

a. With help of the diagnostic computer check the transmission line

pressure.

The following parameters are expected.

At idle in N: 2,4 - 2,8 bars.

At idle in D: 2,8 - 3,1 bars.

Under full load 2200 rpm: 11,3 - 11,7 bars.

b. If there is no change in pressures, test the sensor and sensor supply.

If a sensor is faulty a constant pressure of 6,5 bars is maintained by the

system. This would also mean that the transmision would be in Limp Home

Mode and that the fault is permanent. Since the problem usually is intermittent

the pressure readings will check out OK most of the time. If no other problems

have been found so far, continue with section 3.

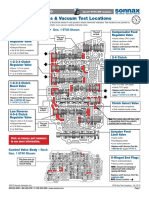

3. Solenoid Valves

a. Replace the pressure regulation valve and the converter lock-up valves.

b. Make sure the 2 seals behind the valve body are correctly fitted. If

necessary replace the seals.

Tension the valve body bolts to 8 NM.

c. After fitting the valve body adjust the selector index spring

d. Adjust the multi-function switch.

e. Before fitting the pan ensure the 2 magnets are present.

f. Fill the transmission with new fluid and adjust the level.

g. Update the transmission ECU software. The older software versions are

not compatible with the new Borg Warner valves.

The operations autlined obove will in most cases resolve the pressure regulation

problem. If the problem can't be resolved follow step 4 or 5.

4. Valve Body

a. Replace the valve body

5. Transmission

. Replace or overhaul the transmission.

Part No. For solenoid: 2574.10 (obsolete)

Part No. For new Borg Warner valves: 2574.16

Part No. For set of magnets: 2221.17

Part No. For transmission fluid. (2 litres): 9736.22

Important reminders

1. Only use genuine Peugeot transmission fluid.

2. The fluid level must be correct.

3. The correct adjustment of the manual valve index spring is very important.

4. Adjust the multi-function switch after the valve adjustment.

5. Cleanliness is absolutely essential when working on the transmission.

You might also like

- AL4 Pressure Regulation FaultDocument3 pagesAL4 Pressure Regulation Faultsirajmy100% (1)

- Audi A1 2013 2022-12-07 - 09-05-55Document3 pagesAudi A1 2013 2022-12-07 - 09-05-55Daniel RamiroNo ratings yet

- New Product Announcement: Zf6Hp19A / Audi 09LDocument1 pageNew Product Announcement: Zf6Hp19A / Audi 09LFSR1407No ratings yet

- Mazda R4-AEL, R4AXEL (929) : Transmission Code: 131Document2 pagesMazda R4-AEL, R4AXEL (929) : Transmission Code: 131Guilherme ZoboliNo ratings yet

- Chevrolet India Owner Manual Cruze 28288086 PDFDocument292 pagesChevrolet India Owner Manual Cruze 28288086 PDFEDIE KANGANo ratings yet

- AW - 55-50SN Valve Body LayoutDocument1 pageAW - 55-50SN Valve Body LayoutRuben RuizNo ratings yet

- ZF 4 HP 16Document6 pagesZF 4 HP 16RIGOBERTO MARTINEZNo ratings yet

- P0740 Torque Converter Circuit DiagnosisDocument2 pagesP0740 Torque Converter Circuit DiagnosishitecNo ratings yet

- AC Product Update November 2014Document1 pageAC Product Update November 2014Raca ZivkovicNo ratings yet

- GM 6T40 Gen1 VBLDocument1 pageGM 6T40 Gen1 VBLAyhan ÜmitNo ratings yet

- Understanding Honda's New 5-Speed Automatic TransmissionDocument4 pagesUnderstanding Honda's New 5-Speed Automatic TransmissionAtanas JanchevNo ratings yet

- Mazda/Ford GF4A-EL Transmission Solenoid and Shift TestDocument2 pagesMazda/Ford GF4A-EL Transmission Solenoid and Shift TestJORFRENo ratings yet

- AF21 UpdatesDocument1 pageAF21 Updatesภูเก็ต เป็นเกาะ100% (1)

- 6L80 Technical TipsDocument6 pages6L80 Technical TipsGina LópezNo ratings yet

- TOY181 Tech InstallDocument2 pagesTOY181 Tech InstallossoskiNo ratings yet

- AW60-41SN Vac Test LocationsDocument5 pagesAW60-41SN Vac Test Locations2791957No ratings yet

- AW55-50SN, AW55-51SN, AF23/33, RE5F22A Zip Kit: Installation DiagramDocument10 pagesAW55-50SN, AW55-51SN, AF23/33, RE5F22A Zip Kit: Installation DiagramKalinin Pineda100% (1)

- MPS6 Wpistons PDFDocument1 pageMPS6 Wpistons PDFCambio Automático do Brasil100% (1)

- Lube Gard AtfDocument249 pagesLube Gard Atfjuan garcia guerraNo ratings yet

- Lube GuardDocument48 pagesLube GuarddavidNo ratings yet

- Tech Sheet VT5-25Document2 pagesTech Sheet VT5-25Haekal ArdyNo ratings yet

- Audi VW 01M Transmission Solenoid Ribbon CodesDocument1 pageAudi VW 01M Transmission Solenoid Ribbon Codesflash_24014910No ratings yet

- Toyota Transmission Code 010 DiagnosticsDocument2 pagesToyota Transmission Code 010 DiagnosticsGuilherme ZoboliNo ratings yet

- Sonnax 77701-076-InDocument2 pagesSonnax 77701-076-InmiguelNo ratings yet

- Gearbox electromagnetic valves and solenoidsDocument3 pagesGearbox electromagnetic valves and solenoidsKarim AbbasNo ratings yet

- Re5f22a PDFDocument297 pagesRe5f22a PDFnetralka.byyandex.ruNo ratings yet

- Catalog A760eDocument4 pagesCatalog A760eautomaticosbrasilNo ratings yet

- Critical Wear Areas & Vacuum Test Locations: Upper Valve BodyDocument4 pagesCritical Wear Areas & Vacuum Test Locations: Upper Valve BodyAlex Maceira GraterolNo ratings yet

- P2716Document4 pagesP2716David RosadoNo ratings yet

- Fallos 02e en InglesDocument15 pagesFallos 02e en Inglesmax powerNo ratings yet

- 2005-2007 5EAT ManualDocument2 pages2005-2007 5EAT ManualGiorgi Avetisov100% (1)

- Transmision Chevrolet Camaro 2010 LT PDFDocument88 pagesTransmision Chevrolet Camaro 2010 LT PDFDick SantiagoNo ratings yet

- Atra GM 6l45!50!80-90 BulletinDocument2 pagesAtra GM 6l45!50!80-90 BulletinAndrés Caleb Blanco GuzmanNo ratings yet

- 722.6, Nag1Document8 pages722.6, Nag1A.M TurboNo ratings yet

- ZF 4HP16 OptraDocument5 pagesZF 4HP16 OptraGERARDO CESSANo ratings yet

- AW55-50N/ AF33-23/RE5F22A:: No 3rd After ServicingDocument4 pagesAW55-50N/ AF33-23/RE5F22A:: No 3rd After ServicingFer LFNo ratings yet

- P1775 OPU Status Line Wiring InspectionDocument3 pagesP1775 OPU Status Line Wiring InspectionLojan Coronel José HumbertoNo ratings yet

- VT3 CVT Transmission BenefitsDocument2 pagesVT3 CVT Transmission BenefitsAli HassanNo ratings yet

- 09G-TF60SN, Tech Info, Inspecting For Manual Valve Bore Wear REV 5-15-13Document1 page09G-TF60SN, Tech Info, Inspecting For Manual Valve Bore Wear REV 5-15-13PedroMecanico0% (1)

- Ford Ranger Bronco II TFI Ignition Diagnostics PDFDocument10 pagesFord Ranger Bronco II TFI Ignition Diagnostics PDFMatthester100% (1)

- Prueba A Selenoides 09GDocument8 pagesPrueba A Selenoides 09Garturo100% (1)

- Boletin Tecnico de MazdaDocument12 pagesBoletin Tecnico de MazdaJulio Bit Ixcamey100% (2)

- 6T40-Vac Test LocationsDocument4 pages6T40-Vac Test LocationsMauricio Exequiel ChavezNo ratings yet

- 8L90 Valvule BodyDocument10 pages8L90 Valvule BodyJose Andres HuertaNo ratings yet

- Technical Bulleti N # 1316: Air ChecksDocument1 pageTechnical Bulleti N # 1316: Air ChecksLojan Coronel José HumbertoNo ratings yet

- AW-6 Linear Solenoid Installation Guide: TF-80 (AF40) and TF-81 (AF21) SeriesDocument2 pagesAW-6 Linear Solenoid Installation Guide: TF-80 (AF40) and TF-81 (AF21) Seriestejonmx100% (1)

- DCT450 - Clutch - Damper - Repair - Copy - Not A PDFDocument1 pageDCT450 - Clutch - Damper - Repair - Copy - Not A PDFSemen AlexandrovNo ratings yet

- Inspect and service hydraulic solenoid control boxDocument6 pagesInspect and service hydraulic solenoid control boxHarry Wart WartNo ratings yet

- Transfer Case MP 3023Document103 pagesTransfer Case MP 3023jackson vivasNo ratings yet

- TF-81SC VBL Interactive PDFDocument1 pageTF-81SC VBL Interactive PDFJULIAN ABRILNo ratings yet

- Ford Fnr5 TCC SlipDocument2 pagesFord Fnr5 TCC SlipAlex Maceira Graterol100% (2)

- Npa12 13 13 ZF8HP45 845reDocument1 pageNpa12 13 13 ZF8HP45 845reFSR1407100% (2)

- OTC Family of Battery Testers: Sabre HPDocument4 pagesOTC Family of Battery Testers: Sabre HPJhon Jairo Mazuera GuzmanNo ratings yet

- Dpo Al4Document1 pageDpo Al4Eloi LeichsenringNo ratings yet

- DP0 AL4 Transmission Repair Manual Renault Peugeot CitroenDocument2 pagesDP0 AL4 Transmission Repair Manual Renault Peugeot Citroenferber107eNo ratings yet

- Atb116 All Honda 4 Speed Info Noise Reverse Bushing Feed PipesDocument4 pagesAtb116 All Honda 4 Speed Info Noise Reverse Bushing Feed PipesAleNo ratings yet

- Wire Gf4aelDocument2 pagesWire Gf4aelLogam LopezNo ratings yet

- WRX FSM 4AT Automatic TransDocument128 pagesWRX FSM 4AT Automatic TransGustavo RivasNo ratings yet

- Al 4 Pressure Regulation FaultDocument4 pagesAl 4 Pressure Regulation Faultcampollano14No ratings yet

- AL4 Pressure Regulation Fault 2Document8 pagesAL4 Pressure Regulation Fault 2Ahmed Fotoh100% (11)

- Cargador Frontal 994FDocument32 pagesCargador Frontal 994FGian Marco PCNo ratings yet

- 182 - Audi A3Document57 pages182 - Audi A3Kaloyan Marinov100% (4)

- Ctc-211 Engine SystemsDocument365 pagesCtc-211 Engine Systemshunganhngoc100% (1)

- Abs 6 StandarDocument46 pagesAbs 6 StandarEdu HdezNo ratings yet

- DSE8610 MKII Configuration Suite PC Software ManualDocument269 pagesDSE8610 MKII Configuration Suite PC Software ManualFaizal Aswari100% (1)

- 303-01b Engine TD4Document166 pages303-01b Engine TD4Juraci Diniz100% (1)

- Codigos de Fallas Harley DavidsonDocument3 pagesCodigos de Fallas Harley DavidsonRuffo Black CustomsNo ratings yet

- History of Cummins Fuel SystemsDocument10 pagesHistory of Cummins Fuel SystemsJESUS100% (1)

- Common Rail Fuel System - CM850 QSC and QSLDocument38 pagesCommon Rail Fuel System - CM850 QSC and QSLEduardo Anselmo100% (2)

- TDB007 ManualDocument39 pagesTDB007 ManualAlejandro Fernández AgudoNo ratings yet

- Vectra A Fault CodesDocument4 pagesVectra A Fault CodesBrujbiiNo ratings yet

- Vecu 5.11 Programming Guide 2018Document190 pagesVecu 5.11 Programming Guide 2018harianaNo ratings yet

- Genius ListDocument8 pagesGenius ListBruno MarianoNo ratings yet

- STAGES IN DESIGNING AND OPTIMIZING MECHATRONIC SYSTEMSDocument12 pagesSTAGES IN DESIGNING AND OPTIMIZING MECHATRONIC SYSTEMSVibin JacobNo ratings yet

- 01 - Engine Control MG4HKED-WE-0871 - 9thDocument392 pages01 - Engine Control MG4HKED-WE-0871 - 9thSyaiful Efendi100% (3)

- Bus b7fb Mwm7a Euro3Document46 pagesBus b7fb Mwm7a Euro3edwinNo ratings yet

- Preparação CabecoteDocument9 pagesPreparação CabecoteDiego Fontenele MunizNo ratings yet

- 11 ECM DiagnosisDocument14 pages11 ECM DiagnosisMas Herawan100% (1)

- AE300 Wizard User GuideDocument103 pagesAE300 Wizard User GuideSergej ZylaNo ratings yet

- Wiring R15 V3Document2 pagesWiring R15 V3arrahmah 2150% (4)

- DT466 530 (2000-2003) Diagnostic Manual (EGES215) PDFDocument358 pagesDT466 530 (2000-2003) Diagnostic Manual (EGES215) PDFDiego LiraNo ratings yet

- T3-4 Lateral Longitudinal DynamicsDocument74 pagesT3-4 Lateral Longitudinal DynamicsGashNo ratings yet

- 8m BaruDocument139 pages8m Barujjoehairy100% (1)

- How To Use Wiring DiagramDocument102 pagesHow To Use Wiring DiagramHECTORNo ratings yet

- Sequential Multipoint Injection 3-4 Cyl: Beltrami MarcoDocument13 pagesSequential Multipoint Injection 3-4 Cyl: Beltrami MarcoDenis Alexander Ibañez GonzalesNo ratings yet

- Cat Engine c23Document15 pagesCat Engine c23wuub wuugfgNo ratings yet

- LHPH 320 330 Electronic Control UnitDocument94 pagesLHPH 320 330 Electronic Control Unitjulio cesar100% (3)

- LITE-CHECK INSPECTOR 920 Operations ManualDocument36 pagesLITE-CHECK INSPECTOR 920 Operations ManualJosé AlcocerNo ratings yet

- Plano Electrico 420E Pra0917Document4 pagesPlano Electrico 420E Pra0917Luis Gustavo Escobar Machado0% (1)

- Fault Codes Overview EMS 2Document4 pagesFault Codes Overview EMS 2Jppi PtkNo ratings yet

- Asset Integrity Management for Offshore and Onshore StructuresFrom EverandAsset Integrity Management for Offshore and Onshore StructuresNo ratings yet

- Machinery Lubrication Technician (MLT) I and II Certification Exam GuideFrom EverandMachinery Lubrication Technician (MLT) I and II Certification Exam GuideRating: 2 out of 5 stars2/5 (1)

- Industrial Piping and Equipment Estimating ManualFrom EverandIndustrial Piping and Equipment Estimating ManualRating: 5 out of 5 stars5/5 (7)

- Oil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionFrom EverandOil and Gas Pipelines and Piping Systems: Design, Construction, Management, and InspectionRating: 4.5 out of 5 stars4.5/5 (16)

- Autodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)From EverandAutodesk Fusion 360: A Power Guide for Beginners and Intermediate Users (3rd Edition)Rating: 5 out of 5 stars5/5 (2)

- Pocket Guide to Flanges, Fittings, and Piping DataFrom EverandPocket Guide to Flanges, Fittings, and Piping DataRating: 3.5 out of 5 stars3.5/5 (22)

- Machine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesFrom EverandMachine Learning and Data Science in the Oil and Gas Industry: Best Practices, Tools, and Case StudiesPatrick BangertRating: 3 out of 5 stars3/5 (2)

- From Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsFrom EverandFrom Vision to Version - Step by step guide for crafting and aligning your product vision, strategy and roadmap: Strategy Framework for Digital Product Management RockstarsNo ratings yet

- Pipeline Integrity: Management and Risk EvaluationFrom EverandPipeline Integrity: Management and Risk EvaluationRating: 4.5 out of 5 stars4.5/5 (6)

- Well Control for Completions and InterventionsFrom EverandWell Control for Completions and InterventionsRating: 4 out of 5 stars4/5 (10)

- Certified Solidworks Professional Advanced Weldments Exam PreparationFrom EverandCertified Solidworks Professional Advanced Weldments Exam PreparationRating: 5 out of 5 stars5/5 (1)

- Practical Reservoir Engineering and CharacterizationFrom EverandPractical Reservoir Engineering and CharacterizationRating: 4.5 out of 5 stars4.5/5 (3)

- Hydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisFrom EverandHydraulic Fracturing in Unconventional Reservoirs: Theories, Operations, and Economic AnalysisNo ratings yet

- Mastering Autodesk Inventor 2014 and Autodesk Inventor LT 2014: Autodesk Official PressFrom EverandMastering Autodesk Inventor 2014 and Autodesk Inventor LT 2014: Autodesk Official PressRating: 5 out of 5 stars5/5 (1)