Professional Documents

Culture Documents

Saep 322

Uploaded by

brecht1980100%(1)100% found this document useful (1 vote)

567 views18 pagesOriginal Title

SAEP-322

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(1)100% found this document useful (1 vote)

567 views18 pagesSaep 322

Uploaded by

brecht1980Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 18

Engineering Procedure

SAEP-322 1 J uly 2008

Performance Qualification Testing

And Certification of Saudi Aramco Brazers

Document Responsibility: Inspection Department

Saudi Aramco DeskTop Standards

Table of Contents

1 Scope............................................................. 2

2 Conflicts and Deviations................................ 2

3 Applicable Documents................................... 2

4 Definitions and Acronyms.............................. 2

5 Responsibilities.............................................. 5

6 Instructions..................................................... 7

Appendix 1 Flow Chart for Testing

and Certifying Brazers.......................... 14

Appendix 2 Flow Chart for Maintaining

Brazer Certification............................... 15

Appendix 3 List of Approved Brazing

Test Supplements................................. 16

Appendix 4 Minimum Retraining Times

for Welders Taking the

Performance Qualification Retest......... 17

Appendix 5 Brazer Experience Record........... 18

Previous Issue: 30 J une 2003 Next Planned Update: 1 J uly 2013

Page 1 of 18

Primary contact: Supervisor, IEU on 874-6604

CopyrightSaudi Aramco 2008. All rights reserved.

Document Responsibility: Inspection Dept. SAEP-322

Issue Date: 1 J uly 2008 Performance Qualification Testing

Next Planned Update: 1 J uly 2013 And Certification of Saudi Aramco Brazers

Page 2 of 18

1 Scope

This Engineering Procedure specifies the minimum requirements for the testing,

certification and registration of Saudi Aramco brazers working for Maintenance. For

the purpose of this Engineering Procedure Maintenance shall also include to mean other

proponent organizations performing fabrication and maintenance welding activities

such as Operations Field Services, Pump Shops, Drilling & Workover, etc.

2 Conflicts and Deviations

Conflicts between this Engineering Procedure and any other Saudi Aramco Standard

shall be resolved by the Operations Inspection Division of the Inspection Department in

writing.

3 Applicable Documents

Unless stated otherwise, all codes and standards referenced shall be the latest issue

(including Revisions and Addenda). Sections of industry codes and standards

referenced herein shall be considered as part of this Engineering Procedure.

3.1 Saudi Aramco References

Saudi Aramco Engineering Procedure

SAEP-1125 Test Supplement S25 for Brazer Performance

Qualification

Saudi Aramco Forms

SA 2318-ENG Welder and Welding Operator Qualification

Record

SA 3331-ENG Welder Qualification Card

SA 4758-ENG Job Clearance Card

3.2 Industry Codes and Standards

American Society of Mechanical Engineers/Boiler & Pressure Vessel Code

ASME SEC IIC Welding Rods, Electrodes and Filler Metals

ASME B31.3 Process Piping

4 Definitions and Acronyms

Ability Test: An ad hoc test used to determine if a brazer has the ability to produce

work in accordance with a valid certification. The Ability Test shall be performed on

Document Responsibility: Inspection Dept. SAEP-322

Issue Date: 1 J uly 2008 Performance Qualification Testing

Next Planned Update: 1 J uly 2013 And Certification of Saudi Aramco Brazers

Page 3 of 18

either a production braze or test coupon that falls within the limits of the certification.

To be valid, the test shall be witnessed and documented by the OIU inspector. Test

acceptance is based on sectioning, polishing and visual examination of cross sections.

Anniversary Recertification: The mandatory retesting of all brazers every three (3)

years on the anniversary date of the issue of their first performance qualification

certification (all welding and brazing certifications become invalid on that date).

Brazers shall be recertified to each Supplement in the month prior to the anniversary

date if brazing to that Supplement is to be permitted after that date. Anniversary

recertification testing is conducted by the WTC in accordance with approved Test

Supplements.

ART: Anniversary Recertification Test

ASME B&PVC Code: American Society of Mechanical Engineers, Boiler and

Pressure Vessel Code.

Braze: A joint between two metals produced by brazing.

Brazer: One who performs a brazing operation.

Brazer Certification: Certification in writing (i.e., Form SA 2318-ENG) that a brazer

has produced a test braze meeting a defined standard.

Brazer Performance Qualification: The demonstration of a brazers ability to produce

a test braze meeting a defined standard.

Brazing: A group of metal joining processes which produce coalescence of materials

by heating them to a suitable temperature, and by using a filler metal having a liquidus

above 840 Fahrenheit and below the solidus of the base materials. The filler is

distributed between the closely fitted surfaces of the joint by capillary action.

Brazing Flux: Material applied to the braze and used to prevent, dissolve, or facilitate

removal of oxides and other undesirable surface substances during brazing.

Brazing Temperature: The temperature to which the base materials are heated to

enable the filler metal to wet the base materials and form a brazed joint.

Certification: See preferred term Brazer Certification.

Certified Brazer: A brazer that has a valid certification for one or more brazing

processes. A certified brazer is only qualified to braze with those brazing processes,

and within the essential variables, of the valid certification(s).

Cu: Copper.

Document Responsibility: Inspection Dept. SAEP-322

Issue Date: 1 J uly 2008 Performance Qualification Testing

Next Planned Update: 1 J uly 2013 And Certification of Saudi Aramco Brazers

Page 4 of 18

ID: Inspection Department.

Initial Field Testing: Examination of the first production work produced by a brazer

immediately after WTC certification testing and OIU registration.

OID: Operations Inspection Division.

OIU: Operations Inspection Unit.

PT: Penetrant Test.

Qualification: See preferred terms Brazer Performance Qualification.

Qualification Card (Form SA 3331-ENG): A photo identity card issued by the WTC

to a brazer that lists all brazing certifications. Qualification Cards shall be carried at all

times by the brazer, and must be presented for review upon request.

Qualification Record (Form SA 2318-ENG): See preferred term brazer certification.

Qualified Brazer: See preferred term Certified Brazer.

Recertification Test: The performance qualification test conducted by the WTC to

reinstate a revoked certification.

Registered Brazer: A brazer whose certifications have been reviewed, found to be

acceptable, and are on file with the Operations Inspection Unit.

Registration: The act of registering a brazer certification, or a photostatic copy

thereof. Registration is performed by the responsible Inspection Authority.

Retest: The repeat test that is permitted to be taken when a brazer fails the initial

certification test to a Test Supplement, or the recertification test to reinstate a revoked

certification. Only one retest is permitted.

Revoked Brazer Certification: A certification with a brazing process that is no longer

valid as a result of a brazer (1) not brazing with a brazing process for six (6) or more

consecutive months, or (2) not passing an Ability Test. A brazer whose certification(s)

with a process become REVOKED is required to pass a recertification test (Test

Supplement) conducted by the WTC prior to resuming production brazing.

TB: Torch Brazing.

Test Supplement: Contains the performance qualification test requirements needed to

perform a brazing certification test, and the limitations of that certification.

Torch Brazing (TB): A brazing process in which the heat required is supplied by a

fuel gas flame.

Document Responsibility: Inspection Dept. SAEP-322

Issue Date: 1 J uly 2008 Performance Qualification Testing

Next Planned Update: 1 J uly 2013 And Certification of Saudi Aramco Brazers

Page 5 of 18

Uncertified Brazer: A brazer that does not have a valid brazing certification.

Unqualified Brazer: See preferred term Uncertified Brazer.

WTC: Welder Test Center.

WTS: Welder Tracking System.

5 Responsibilities

5.1 Inspection Department

5.1.1 The Operations Inspection Division (OID) is responsible for:

(a) Preparing revisions to this Engineering Procedure;

(b) Auditing records of the NDE & Welder Testing Unit;

(c) Auditing records of the Operations Inspection Units.

5.1.2 The NDE & Welder Testing Unit of the Operations Inspection Division

is responsible for:

(a) Administering all brazer performance qualification tests;

(b) Keeping track of the status of all Saudi Aramco brazers.

5.1.3 The Welder Test Center (WTC) of the NDE & Welder Testing Unit is

responsible for:

(a) Conducting performance qualification testing of brazers in

accordance with approved Test Supplements;

(b) Conducting recertification testing of brazers with revoked

certifications;

(c) Preparing certifications (Form SA 2318-ENG) for brazers who pass

performance qualification or recertification tests;

(d) Inputting certification results in the WTS for welders that take

performance qualification or recertification;

(e) Obtaining welder symbols (assigned automatically) from WTS for

all welders who take the performance qualification tests;

(f) Preparing new or updating old Qualification Cards for brazers

passing certification tests;

Document Responsibility: Inspection Dept. SAEP-322

Issue Date: 1 J uly 2008 Performance Qualification Testing

Next Planned Update: 1 J uly 2013 And Certification of Saudi Aramco Brazers

Page 6 of 18

(g) Conducting Anniversary Recertification testing of brazers every

three years;

(h) Sending brazers certification information to the WTS

Administrator;

(i) Generating new or updating welder records/data in WTS.

5.1.4 The WTC Welding Inspector is responsible for:

(a) Witnessing and evaluating brazer performance qualification tests;

(b) Witnessing and evaluating recertification tests of brazers with

revoked certifications.

5.1.5 The WTS Administrator is responsible for:

(a) Maintaining the WTS database on the mainframe computer current

by inputting performance qualification and recertification test

information (Form SA 2318-ENG) into the WTS database;

(b) Maintaining the WTS database on the mainframe computer current

by terminating revoked brazer certification information from the

WTS database;

(c) Assigning WTS access to new users and updating their access

information;

(d) creating/updating proponent Maintenance Organization or

Operations Inspection Unit in WTS.

5.2 Business Line Maintenance Organizations

The Maintenance Superintendent/Foreman is responsible for:

(a) Ensuring all brazers are properly certified prior to the start of work;

(b) Ensuring all brazers maintain valid certifications for every process

certified through continuous brazing;

(c) Ensuring all brazers undergo the additional training prior to taking a retest;

(d) Maintaining a log of brazers working in the Unit.

5.3 Business Line Engineering Organizations

5.3.1 The Operations Inspection Unit (OIU) is responsible for:

Document Responsibility: Inspection Dept. SAEP-322

Issue Date: 1 J uly 2008 Performance Qualification Testing

Next Planned Update: 1 J uly 2013 And Certification of Saudi Aramco Brazers

Page 7 of 18

(a) Ensuring all brazer performance certifications are current and up to

date through documentation of brazing activity;

(b) Ensuring all newly certified brazers are capable of making sound

welds by conducting Initial Field Testing;

(c) Conducting Ability Testing of brazers whose skills may be in

doubt;

(d) Registering properly certified Maintenance brazers;

(e) Reporting Initial Field and Ability Testing results to Maintenance

Organizations;

(f) Conducting Ability Testing of brazers if no production activity is

performed within three months to avoid revoked certification.

(Revise Appendix II Flow Chart).

5.3.2 The Operations Inspection Unit Inspector is responsible for: witnessing

and evaluating Initial Field Tests and Ability Tests.

6 Instructions

6.1 Brazer Performance Qualification Test

6.1.1 General Information

6.1.1.1 Performance Qualification Testing shall be conducted at a

Welder Test Center (WTC) and be witnessed by a WTC

welding inspector. A flow chart showing the steps involved in

testing and certifying brazers is shown in Appendix 1.

6.1.1.2 When it is impractical to bring brazers from remote locations to

the WTC for testing, the Inspection Department shall assign the

testing to a local inspection organization.

6.1.1.3 Performance Qualification testing shall be conducted in

accordance with an approved Saudi Aramco Engineering

Procedure Test Supplement. A list and description of all of the

approved brazing Test Supplements is given in Appendix 3.

6.1.1.4 If it becomes apparent to the WTC welding inspector at any

time that a brazer does not have the necessary skill to complete

the performance qualification test, the test shall be terminated

and the brazer sent back to the proponent organization for

retraining and/or reassignment.

Document Responsibility: Inspection Dept. SAEP-322

Issue Date: 1 J uly 2008 Performance Qualification Testing

Next Planned Update: 1 J uly 2013 And Certification of Saudi Aramco Brazers

Page 8 of 18

6.1.2 Coupon Preparation and Brazing

6.1.2.1 The brazer shall mechanically clean the test coupons and mark

the brazers name (or welder symbol if currently certified) on

both ends of the test coupon.

6.1.2.2 After the WTC welding inspector has inspected and approved

the cleaning and marking, the test coupons shall be secured in

the required test positions at a height of eighteen (18") inches

above the floor of the test booth. They shall remain fixed

throughout the test until after the final inspection of the

completed coupons by the WTC welding inspector.

6.1.2.3 Grinding, filing, or mechanical dressing of the completed braze

is not permitted. Evidence of such shall be cause for rejection

of the test coupon (test failure).

6.1.3 Visual Examination of the Test Coupon

6.1.3.1 After completion of brazing the WTC welding inspector shall

perform a visual examination of the external and internal (after

sectioning) surfaces of the test coupons. The ends of the

mating surfaces shall be completely filled with braze metal.

The appearance of voids at the lap ends shall be cause for

rejection of the test coupon.

6.1.3.2 The test coupons shall be sectioned longitudinally (cut with a

hacksaw) through the braze into quarters. The cross sections

(all) shall be polished using either sand paper or emery cloth

and examined with a four power (4X) magnifying glass. The

sum of the lengths of the unbrazed areas on any side,

considered individually, shall not exceed twenty percent (20%)

of the joint overlap in any one section.

6.1.4 Retest

6.1.4.1 Brazers are permitted one (1) retest per Test Supplement

provided they receive additional training in accordance with

the schedule given in Appendix 4. Brazers that fail the

performance qualification test for multiple causes shall

undergo a total minimum retraining time equal to the sum of

the minimum retraining times for each cause.

6.1.4.2 Prior to taking the retest the Maintenance Superintendent shall

certify in writing that the brazer has undergone the required

Document Responsibility: Inspection Dept. SAEP-322

Issue Date: 1 J uly 2008 Performance Qualification Testing

Next Planned Update: 1 J uly 2013 And Certification of Saudi Aramco Brazers

Page 9 of 18

additional training and is fully prepared to take the retest. A

copy shall be attached to the request for retest submitted by the

OIU to the WTC.

6.1.4.3 All retests shall be conducted by the WTC.

6.1.4.4 Brazers that fail the retest shall not be permitted to take a

second retest. They shall also be prohibited from retaking that

brazing performance qualification test sooner than one (1)

month from the date of the failed retest. During the waiting

period the brazer shall be given additional training by the Unit.

If the Unit sends the brazer to retake the test at the end of one

(1) month the Maintenance Superintendent shall certify in

writing that the brazer has received sufficient training and is

capable of passing the Supplement Test (attached to the request

submitted by OIU to the WTC).

6.2 Certification of Brazers

6.2.1 Upon successful completion of the performance qualification test, the

WTC shall certify the results by:

(a) Obtaining the brazer a welder symbol (if required) from WTS.

When a brazer leaves the employ of the company that welder

symbol shall be retired and a letter of notification should be sent to

the WTS Administrator to terminate that symbol from WTS

database;

(b) Completing Form SA 2318-ENG. The original shall be kept on file

with the WTC. Copies shall be sent to the WTS Administrator and

the OIU; and

(c) Issuing the brazer with a new/revised Qualification Card (Form SA

3331-ENG). The Qualification Card shall list all valid

certifications held by the brazer. It shall also include a photograph

of the brazer and be carried by the brazer at all times. A copy shall

be kept on file at the WTC, and also be sent to the OIU and the

WTS Administrator.

6.2.2 Immediately after the successful completion of the performance

qualification test newly certified brazers shall report to the OIU to be

registered. Brazers shall not be permitted to start production brazing

without first being registered by the OIU.

6.3 Maintaining Brazer Certifications

Document Responsibility: Inspection Dept. SAEP-322

Issue Date: 1 J uly 2008 Performance Qualification Testing

Next Planned Update: 1 J uly 2013 And Certification of Saudi Aramco Brazers

Page 10 of 18

6.3.1 Initial Field Testing

6.3.1.1 After certification and registration, but prior to the start of

production brazing, each brazer shall braze a test coupon in the

field for each test position qualified. The test shall be

witnessed by an inspector of the OIU.

6.3.1.2 Each test braze shall be visually examined in accordance with

the requirements of section 6.1.3 of this Engineering

Procedure.

6.3.1.3 If the test brazes are satisfactory the brazer shall be permitted

to start production brazing.

6.3.1.4 If any of the test brazes are unsatisfactory the brazers

certification shall be revoked. The brazers Qualification Card

shall be sent by the OIU to the WTC for updating along with a

letter of notification. The WTC shall return the revised

Qualification Card to the brazer through the OIU. A copy of

the revised Qualification Card (and the letter of notification)

shall be sent to the WTS Administrator.

6.3.1.5 Brazers that have a certification revoked during the Initial Field

Test shall not be allowed to take another certification test to

that Supplement for at least one (1) month. During that time

the brazer shall be given additional training. When the brazer

is ready to retake the Supplement Test the Maintenance

Superintendent shall certify in writing that the brazer has been

given the required additional training and is fully capable of

passing the Supplement Test. The test shall be scheduled in

writing by OIU with the WTC.

6.3.2 General Requirements

6.3.2.1 A flow chart showing the steps involved in maintaining brazer

certifications is shown in Appendix 2.

6.3.2.2 If a brazer does not braze for a period of at least six (6)

consecutive months, all brazing certifications shall become

revoked. The brazer shall not be permitted to perform any

production brazing prior to being recertified by the WTC in

accordance with section 6.1 of this Engineering Procedure. All

brazes made by a brazer after a certification is revoked shall be

cut out.

Document Responsibility: Inspection Dept. SAEP-322

Issue Date: 1 J uly 2008 Performance Qualification Testing

Next Planned Update: 1 J uly 2013 And Certification of Saudi Aramco Brazers

Page 11 of 18

Commentary Note:

A welder will be placed in the Inactive welders list if he did not

appear for Anniversary Exam (ARD) within 90 days. The

welder will be in the Separated welders list if he did not

appear for ARD after the 90 days period; subsequently to

reinstate him in the WTS, a letter from his perspective

Maintenance Division head explaining the welder's case shall

be sent to the Operations Inspection Division head of the

Inspection Department.

6.3.2.3 If there is a specific reason to question a brazers ability to

produce sound braze joints, OIU inspector can require that the

brazer perform an Ability Test on a test coupon (the brazing

shall be witnessed by the inspector). The test coupon can be

any size qualified by the certification. The test shall be

conducted in the vertical upflow position. The completed test

braze shall be visually examined externally, sectioned and

polished (through the cross section). If the coupon does not

meet the visual acceptance criteria of paragraph 6.1.3 the

brazers certification shall be revoked.

6.3.2.4 Brazers with revoked certifications shall be retested and

recertified in accordance with the requirements described in

section 6.4 prior to resuming production brazing.

6.3.2.5 When a brazers certification becomes revoked the OIU shall

send the brazers Qualification Card to the WTC along with a

letter of notification. The WTC shall delete the revoked

certifications from the Qualification Card and return the card to

the brazer through the OIU. The WTC shall send a copy of the

letter and revised Qualification Card to the WTS

Administrator.

6.3.2.6 A brazers certifications shall expire (cease to be valid) every

three (3) years on the anniversary date of the issue of the

brazers first performance certification (welding or brazing).

During the month prior to the anniversary date brazers shall

recertify to every brazing Test Supplement previously held

and/or required. This blanket recertification shall be called the

Anniversary Recertification and shall be conducted by the

WTC. Those certifications obtained in the year prior to the

anniversary date are exempt from retesting until the following

anniversary date. The soon to be expired Qualification Card

shall be surrendered to the WTC by the brazer prior to the test.

Document Responsibility: Inspection Dept. SAEP-322

Issue Date: 1 J uly 2008 Performance Qualification Testing

Next Planned Update: 1 J uly 2013 And Certification of Saudi Aramco Brazers

Page 12 of 18

A new Qualification Card shall be issued after completion of

testing.

6.3.2.7 The OIU shall maintain a Brazer Experience Record for each

certified brazer. Verification of brazing experience can be by

reference to a braze inspection report, braze number or any

similar type of documentation. Records shall be reviewed

during Inspection Department audits of OIU. A suggested

Brazer Experience Record Form is given in Appendix 5.

6.3.2.8 The Maintenance Foreman shall maintain an up to date log of

brazers working in the Unit. The brazers log shall include a

listing of valid certifications, anniversary date and any other

pertinent information.

6.4 Recertification of Brazers with Revoked Certifications

6.4.1 Brazers with a revoked certification shall not be permitted to braze on

production work using the certification until they have been recertified.

The Recertification Test shall be conducted by the WTC in accordance

with the requirements of section 6.1 of this Engineering Procedure.

6.4.2 The OIU shall schedule the brazers Recertification Test with the WTC in

writing. The test shall not be scheduled sooner than one (1) month from

the date the certification was revoked. The Maintenance Superintendent

shall certify in writing that the brazer has been given the required

additional training and is fully capable of passing the Recertification

Test. The test shall then be scheduled in writing by the OIU with the

WTC.

6.4.3 Brazers that fail the Recertification Test may take only one retest as

permitted in paragraph 6.1.4.

6.4.4 Brazers that pass the Recertification Test or retest shall be certified and

registered in accordance with the requirements of section 6.2 of this

Engineering Procedure. Subsequent production work shall meet the

requirements of section 6.3.1 (Initial Field Testing).

6.4.5 Brazers that fail the Recertification Test retest shall have all

certifications with the process tested revoked if the certification was

originally revoked as a result brazing inactivity. If the certification was

revoked as a result of a failed Ability Test only the particular

certification tested shall be revoked.

Document Responsibility: Inspection Dept. SAEP-322

Issue Date: 1 J uly 2008 Performance Qualification Testing

Next Planned Update: 1 J uly 2013 And Certification of Saudi Aramco Brazers

Page 13 of 18

6.4.6 Brazers that fail the retest shall not be permitted to retake the

Supplement Test for a period of at least one (1) month from the date of

the test failure. The WTC shall inform the OIU and WTS Administrator

of the test results in writing.

Revision Summary

1 J uly 2008 Revised the "Next Planned Update". Reaffirmed the contents of the document, and reissued

with no other changes.

Document Responsibility: Inspection Dept. SAEP-322

Issue Date: 1 J uly 2008 Performance Qualification Testing

Next Planned Update: 1 J uly 2013 And Certification of Saudi Aramco Brazers

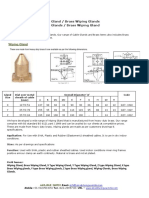

Appendix 1 Flow Chart for Testing and Certifying Brazers

ACCEPTABLE

OK OK OK

WTC TO ISSUE CERTIFICATION

OK

evaluate testing

(WTC) START

TESTING

PROCESS

HERE

visual inspection of

completed braze

(WTC inspector)

braze test

coupon (brazer)

SCHEDULE

RETEST

(Inspection

Unit)

retraining

completed

(certified by the

Maintenance

Superintendent)

RETRAINING

(refer to APPENDIX 4

for minimum

requirements)

2nd retest

(not permitted)

1rst retest

(permitted)

1 month waiting periodrequired (brazer to

undergo additional training) before another test

can be scheduled with the WTC by the

Operations InspectionUnit (retraining certified by

the Maintenance Superintendent)

verification of test

position

(WTC inspector)

visual inspection of

coupon preparation

(WTC inspector)

UNACCEPTABLE

testing required

by Supplement

(WTC)

schedule Initial or

Recertification

tests with the WTC

(Inspection Unit)

secure coupon

in test position

(brazer)

clean and mark

test coupon

(brazer)

S

T

O

P

S

T

O

P

S

T

O

P

S

T

O

P

Page 14 of 18

Document Responsibility: Inspection Dept. SAEP-322

Issue Date: 1 J uly 2008 Performance Qualification Testing

Next Planned Update: 1 J uly 2013 And Certification of Saudi Aramco Brazers

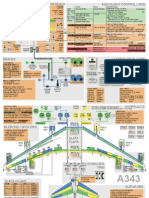

Appendix 2 Flow Chart for Maintaining Brazer Certification

Page 15 of 18

Document Responsibility: Inspection Dept. SAEP-322

Issue Date: 1 J uly 2008 Performance Qualification Testing

Next Planned Update: 1 J uly 2013 And Certification of Saudi Aramco Brazers

Page 16 of 18

Appendix 3 List of Approved Brazing Test Supplements

SAEP Num Type Proc Base Mat'l Filler Metal Limitations

1125 S25 Tube Torch Cu Alloys Bag-3, Bag-7 Vertical up

1126 ============RESERVED FOR FUTURE TEST SUPPLEMENTS=============

1127 ============RESERVED FOR FUTURE TEST SUPPLEMENTS=============

1128 ============RESERVED FOR FUTURE TEST SUPPLEMENTS=============

1129 ============RESERVED FOR FUTURE TEST SUPPLEMENTS=============

1130 ============RESERVED FOR FUTURE TEST SUPPLEMENTS=============

NOTE: The X's in the filler metal classifications indicate that multiple ASME SEC IIC Filler Metal Specifications

are applicable. For example, EXX18 represents E7018, E8018-B1, E8018-C2, E9018, etc.

Al = Aluminum

Cat-"D" = Category "D" Service as defined in ASME B31.3

CS = Carbon steel

Cu = Copper

LAS = Low alloy steel

Ni = Nickel

SS = Stainless steel

Document Responsibility: Inspection Dept. SAEP-322

Issue Date: 1 J uly 2008 Performance Qualification Testing

Next Planned Update: 1 J uly 2013 And Certification of Saudi Aramco Brazers

Page 17 of 18

Appendix 4 Minimum Retraining Times

For Welders Taking the Performance Qualification Retest

Cause of Test Failure Minimum Retraining Time

Excessive grinding filling or mechanical dressing (6.1.2.3) 7 days

Visual inspection - external appearance (6.1.3.1) 7 days

Visual inspection - cross section (6.1.3.2) 7 days

Rejection for cause (6.1.1.4) 14 days

NOTE: Prior to taking the retest the Maintenance Superintendent must certify in writing that the brazer has

undergone additional training and is fully prepared to take a second retest, and are also prohibited

from retaking that brazing performance qualification test sooner than one (1) months from that date.

Document Responsibility: Inspection Dept. SAEP-322

Issue Date: 1 J uly 2008 Performance Qualification Testing

Next Planned Update: 1 J uly 2013 And Certification of Saudi Aramco Brazers

Page 18 of 18

Appendix 5 Brazer Experience Record

Name ___________________ Employee Number ___________ Welder Symbol ___________

Org Code ____________ Anniversary Recertification Date _________

Supplement Number Qualified To

Month _____ _____ _____ _____ _____ _____

1 _____ _____ _____ _____ _____ _____

2 _____ _____ _____ _____ _____ _____

3 _____ _____ _____ _____ _____ _____

4 _____ _____ _____ _____ _____ _____

5 _____ _____ _____ _____ _____ _____

6 _____ _____ _____ _____ _____ _____

7 _____ _____ _____ _____ _____ _____

8 _____ _____ _____ _____ _____ _____

9 _____ _____ _____ _____ _____ _____

10 _____ _____ _____ _____ _____ _____

11 _____ _____ _____ _____ _____ _____

12 _____ _____ _____ _____ _____ _____

(A) Reference inspection report, RT report, weld/braze number, etc.

You might also like

- Saep 324 PDFDocument13 pagesSaep 324 PDFArvind ShakyaNo ratings yet

- Saep 1150Document50 pagesSaep 1150ishaq_khanNo ratings yet

- Saep 321Document28 pagesSaep 321brecht1980No ratings yet

- Saep 323Document8 pagesSaep 323brecht1980100% (1)

- Saep 1142Document11 pagesSaep 1142shaban100% (2)

- Saep 351Document24 pagesSaep 351Raj KumarNo ratings yet

- 175 091300Document2 pages175 091300Abu Anas M.SalaheldinNo ratings yet

- Saep 1160Document13 pagesSaep 1160Durga Jagan Puppala100% (1)

- Saes H 201Document9 pagesSaes H 201heartbreakkid132No ratings yet

- 01 Samss 031Document3 pages01 Samss 031Awais CheemaNo ratings yet

- SAUDIPIPINGMATTRACEDocument9 pagesSAUDIPIPINGMATTRACEMAZHARULNo ratings yet

- Saudi Aramco Test Report Pre-Pressure Test Checklist (Form)Document2 pagesSaudi Aramco Test Report Pre-Pressure Test Checklist (Form)Rijwan MohammadNo ratings yet

- Saudi Aramco Inspection ChecklistDocument3 pagesSaudi Aramco Inspection ChecklistAbdul HannanNo ratings yet

- AEP1152Document10 pagesAEP1152walitedisonNo ratings yet

- Ad 036821 001Document1 pageAd 036821 001AmolNo ratings yet

- 01 Samss 010 PDFDocument11 pages01 Samss 010 PDFAnonymous ZxJZoU0% (1)

- Saep 1145Document20 pagesSaep 1145Amit shah100% (1)

- SAIC-W-2015 Rev 7 (NDE Selection)Document17 pagesSAIC-W-2015 Rev 7 (NDE Selection)vijayachiduNo ratings yet

- Saudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatDocument3 pagesSaudi Aramco Test Report: In-Process Inspection of Field Coating SATR-H-2006 27-Jan-19 CoatMoghal AliNo ratings yet

- Saic W 2003Document14 pagesSaic W 2003Mohammed IlliasuddinNo ratings yet

- 32 Samss 020Document18 pages32 Samss 020naruto256No ratings yet

- Materials System SpecificationDocument21 pagesMaterials System Specificationnadeem shaikhNo ratings yet

- Saudi Aramco Inspection ChecklistDocument15 pagesSaudi Aramco Inspection ChecklistManoj Kumar100% (1)

- Inspection Procedure EDRDocument8 pagesInspection Procedure EDRaamirtec301No ratings yet

- Saep 1140Document15 pagesSaep 1140shaban100% (1)

- Manual Ultrasonic Thickness Testing ProcedureDocument8 pagesManual Ultrasonic Thickness Testing ProcedureAmit shahNo ratings yet

- Saic L 2008 PDFDocument4 pagesSaic L 2008 PDFHesham HelalNo ratings yet

- Saep 352 PDFDocument15 pagesSaep 352 PDFRami ElloumiNo ratings yet

- Saudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliDocument5 pagesSaudi Aramco Typical Inspection Plan Cross Country Above Ground PipeliShahbaz AhmadNo ratings yet

- Saudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureDocument2 pagesSaudi Aramco Inspection Checklist: Review of Flange Joint-Gasket Verification and Bolt Tightening ProcedureMAZHARULNo ratings yet

- SAER1972Document9 pagesSAER1972zamil2008No ratings yet

- 175 000003 PDFDocument1 page175 000003 PDFSohail TisekarNo ratings yet

- Saudi Aramco Air Cooled Heat Exchanger Inspection PlanDocument2 pagesSaudi Aramco Air Cooled Heat Exchanger Inspection PlanAnonymous S9qBDVkyNo ratings yet

- SAIC-A-2015 Saudi Aramco Inspection ChecklistDocument8 pagesSAIC-A-2015 Saudi Aramco Inspection Checklistkarthi51289No ratings yet

- Saep 380 PDFDocument10 pagesSaep 380 PDFbassamNo ratings yet

- QMISDocument14 pagesQMISLopez Gardo0% (1)

- Saudi Aramco Test ReportDocument4 pagesSaudi Aramco Test Reportkarthi51289No ratings yet

- SAIC-L-2136 Rev 0Document3 pagesSAIC-L-2136 Rev 0philipyapNo ratings yet

- 175 043000Document1 page175 043000Fahad AhmadNo ratings yet

- 34-Samss-010 2018Document9 pages34-Samss-010 2018asimazami69No ratings yet

- Saes H 204Document34 pagesSaes H 204heartbreakkid132No ratings yet

- Saudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 MechDocument2 pagesSaudi Aramco Inspection Checklist: Storage and Preservation of Valves SAIC-L-2041 30-Apr-17 Mechsuresh100% (1)

- Materials System SpecificationDocument7 pagesMaterials System Specificationaanouar77No ratings yet

- Saudi Aramco PMI checklist ensures alloy purityDocument5 pagesSaudi Aramco PMI checklist ensures alloy puritykarioke mohaNo ratings yet

- Saep 316 2016 PDFDocument25 pagesSaep 316 2016 PDFAllan LindoNo ratings yet

- SAIC-H-2014 Rev 7Document3 pagesSAIC-H-2014 Rev 7mohammed siddiqNo ratings yet

- SAES-W-012 - Google Search3Document1 pageSAES-W-012 - Google Search3fayceal0% (1)

- Saudi Aramco Inspection ChecklistDocument4 pagesSaudi Aramco Inspection ChecklistRijwan MohammadNo ratings yet

- SAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingDocument5 pagesSAEP-1106 - Welding Test Supplement S06 For GTAW, Aluminum With BackingFiras AlbaweiNo ratings yet

- 34 Samss 711 PDFDocument26 pages34 Samss 711 PDFFlorin Daniel AnghelNo ratings yet

- Saudi Aramco piping inspection planDocument2 pagesSaudi Aramco piping inspection planMuhammad Farukh ManzoorNo ratings yet

- Satip - S-050-01Document4 pagesSatip - S-050-01LIJINNo ratings yet

- 01 Samss 044 PDFDocument11 pages01 Samss 044 PDFAbdul Rahim ShaikhNo ratings yet

- Saep 324Document8 pagesSaep 324brecht1980100% (3)

- Saep 323Document8 pagesSaep 323paul cafeNo ratings yet

- Saep 323 PDFDocument8 pagesSaep 323 PDFthanga balanNo ratings yet

- 100-YER-PM-PPM-0550 (Welders & Brazers)Document11 pages100-YER-PM-PPM-0550 (Welders & Brazers)Armando AballeNo ratings yet

- Saep 324Document13 pagesSaep 324Hansel Francis100% (4)

- Saep 323Document12 pagesSaep 323rafatNo ratings yet

- Purchasing Process in Prep For ISODocument4 pagesPurchasing Process in Prep For ISObrecht1980No ratings yet

- AirLine Respirator MSA PDFDocument8 pagesAirLine Respirator MSA PDFbrecht1980No ratings yet

- Saep 333Document39 pagesSaep 333brecht1980100% (1)

- Saep 316Document20 pagesSaep 316brecht1980100% (17)

- Saep 332Document15 pagesSaep 332abidch143100% (1)

- Saep 329Document20 pagesSaep 329brecht1980100% (2)

- Saep 327Document11 pagesSaep 327brecht1980100% (2)

- Saep 324Document8 pagesSaep 324brecht1980100% (3)

- Saep 317Document22 pagesSaep 317brecht1980100% (1)

- Saep 318Document28 pagesSaep 318brecht1980No ratings yet

- Saep 303Document60 pagesSaep 303brecht1980100% (2)

- Saep 309Document22 pagesSaep 309brecht1980No ratings yet

- Saep 311Document31 pagesSaep 311brecht1980No ratings yet

- Saep 133Document10 pagesSaep 133abidch143100% (1)

- Engineering Procedure: SAEP-310 13 January 2008 Piping and Pipeline Repair Piping Standards Committee MembersDocument39 pagesEngineering Procedure: SAEP-310 13 January 2008 Piping and Pipeline Repair Piping Standards Committee Membersbrecht1980100% (4)

- Saep 308Document19 pagesSaep 308brecht1980No ratings yet

- Saep 135Document47 pagesSaep 135brecht1980No ratings yet

- Saep 305Document5 pagesSaep 305brecht1980No ratings yet

- Saep 250Document32 pagesSaep 250brecht198075% (4)

- Saep 306Document13 pagesSaep 306brecht1980No ratings yet

- Saep 201Document5 pagesSaep 201brecht1980No ratings yet

- Saep 134Document5 pagesSaep 134brecht1980100% (1)

- Saep 140Document10 pagesSaep 140brecht1980No ratings yet

- Saep 127Document9 pagesSaep 127brecht1980No ratings yet

- Saep 136Document20 pagesSaep 136brecht1980No ratings yet

- Saep 125Document9 pagesSaep 125brecht1980No ratings yet

- Engineering Procedure: SAEP-122 31 July, 2005 Project Records Document Responsibility: Project Support and Controls DeptDocument11 pagesEngineering Procedure: SAEP-122 31 July, 2005 Project Records Document Responsibility: Project Support and Controls Deptbrecht1980100% (3)

- De Havilland CaseDocument10 pagesDe Havilland CaseKayley FultonNo ratings yet

- EPDP Overview Training For TeamsDocument186 pagesEPDP Overview Training For Teamsp.c abhishek50% (2)

- Overview of Plug-In Electric Vehicle Technologies: K.Ramalingam and C.S.IndulkarDocument21 pagesOverview of Plug-In Electric Vehicle Technologies: K.Ramalingam and C.S.Indulkarpratap68No ratings yet

- Vehicle History Report: 2008 Honda Accord Ex-LDocument10 pagesVehicle History Report: 2008 Honda Accord Ex-LCole WalshNo ratings yet

- Production Supervisor/ Dairy Companies /milk, Cheese, YougourtDocument2 pagesProduction Supervisor/ Dairy Companies /milk, Cheese, YougourtkaramzahiNo ratings yet

- Vision and Scope Document Final by M UmairDocument6 pagesVision and Scope Document Final by M UmairDilini Dakshika HerathNo ratings yet

- Synopsis of T24 Java DocumentationsDocument1 pageSynopsis of T24 Java DocumentationsAbdelmadjid BouamamaNo ratings yet

- Buro Happold Customer Story PDFDocument2 pagesBuro Happold Customer Story PDFkyleNo ratings yet

- CIV003 Technical Approval of DesignDocument62 pagesCIV003 Technical Approval of DesignAlex ChanNo ratings yet

- Terms of Reference TemplateDocument3 pagesTerms of Reference Templatechinkapook100% (8)

- Kanya Venkatappa ResumeDocument1 pageKanya Venkatappa ResumekansanNo ratings yet

- Straightness and ParallelismDocument18 pagesStraightness and Parallelismnikle_DNo ratings yet

- Digital Weighing Indicator XK3190-A12 (E) : User ManualDocument17 pagesDigital Weighing Indicator XK3190-A12 (E) : User Manualiyol1No ratings yet

- Wiping Gland Brass Wiping Glands ManufacturerDocument3 pagesWiping Gland Brass Wiping Glands ManufacturerUjjwal ShahNo ratings yet

- E TechDocument10 pagesE Techrachel joanne arceoNo ratings yet

- Supplier Manual en 2021-9-6Document11 pagesSupplier Manual en 2021-9-6alexNo ratings yet

- Landing Gear / Nws Brakes: X F/CTL Altn Law (Prot Lost)Document1 pageLanding Gear / Nws Brakes: X F/CTL Altn Law (Prot Lost)Elias IruelaNo ratings yet

- Risk Management Strategies for Global ExpansionDocument18 pagesRisk Management Strategies for Global ExpansionAlolika DattaNo ratings yet

- Workforce Management Roles & ResponsibilitiesDocument12 pagesWorkforce Management Roles & ResponsibilitiesmsamviNo ratings yet

- Donnelly Erp SuccessDocument4 pagesDonnelly Erp SuccessvishalNo ratings yet

- Advantages of JSPDocument4 pagesAdvantages of JSPanon_599765031No ratings yet

- UCIL Company ProfileDocument4 pagesUCIL Company ProfileDipti Ranjan SwainNo ratings yet

- 2016 CPRA Log - Grand TerraceDocument3 pages2016 CPRA Log - Grand TerraceBeau YarbroughNo ratings yet

- Telescopic CylinderDocument4 pagesTelescopic Cylindergapc210% (1)

- TOCBooksDocument15 pagesTOCBooksinfaredmailmanNo ratings yet

- Chris Dauw ResumeDocument3 pagesChris Dauw ResumeChris DauwNo ratings yet

- SQL Section 1 Quiz ResultsDocument4 pagesSQL Section 1 Quiz ResultsPanda DamanikNo ratings yet

- Fbabf JNBJFNNN NkinDocument56 pagesFbabf JNBJFNNN NkinMajor ShobhitNo ratings yet

- Omnitracs IVG - CER DVIR Driver OverviewDocument22 pagesOmnitracs IVG - CER DVIR Driver OverviewBradNo ratings yet

- 2001ICT - Project Management: Building ScheduleDocument22 pages2001ICT - Project Management: Building ScheduleĐdũng_3No ratings yet