Professional Documents

Culture Documents

RISK ASSES-106-Erection of Steel Structure Buildin

Uploaded by

Rochdi Bahiri50%(2)50% found this document useful (2 votes)

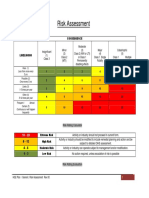

996 views4 pagesHazard Identification and Risk Analysis Procedure (Risk Management) to be undertaken by OCIA and all Subcontractors in order to initi ate, act on, review and effectively manage project-related risks. Table below provides simplified representation of the methodology used and the processes involved in this procedure.

Original Description:

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentHazard Identification and Risk Analysis Procedure (Risk Management) to be undertaken by OCIA and all Subcontractors in order to initi ate, act on, review and effectively manage project-related risks. Table below provides simplified representation of the methodology used and the processes involved in this procedure.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

50%(2)50% found this document useful (2 votes)

996 views4 pagesRISK ASSES-106-Erection of Steel Structure Buildin

Uploaded by

Rochdi BahiriHazard Identification and Risk Analysis Procedure (Risk Management) to be undertaken by OCIA and all Subcontractors in order to initi ate, act on, review and effectively manage project-related risks. Table below provides simplified representation of the methodology used and the processes involved in this procedure.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 4

Location: Terga Date of Assessment:

Assessor(s): FRIDI.ALI System/Activity:

P

r

o

b

a

b

i

l

i

t

y

&

F

r

e

q

u

e

n

c

y

Definite 5 5 10 15 20

High 4 4 8 12 16

Moderate 3 3 6 9 12

Low 2 2 4 6 8

Negligible 1 1 2 3 4

1 2 3 4

Minor Serious Major Catastrophic

Severity

Key to Priorities

Medium Priority (5

days)

High Priority (2-3 days) Immediate

INTRODUCTION

The table below provides a simplified representation of the methodology used and the processes

Management) to be undertaken by OCIA and all Subcontractors in order to initi

IDENTIFICATION - Pre planning, Method

statement , Job safety analysis.

ASSESSMENT

Mitigation measure, Residual risk

Identify activities , Identify hazards Assess Impacts, Analyze Risk ,

Establish Mitigation Measures.

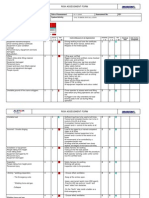

RISK ASSESSMENT FORM

Date of Assessment: 21-07-2010 Assessment No:

System/Activity: Erection of Steel Structure Building (B12)1.2.3

The table below provides a simplified representation of the methodology used and the processes involved in this Hazard Identification & Risk Analysis Procedure (Risk

Management) to be undertaken by OCIA and all Subcontractors in order to initi ate, act on, review and effectively manage project-related risks

ASSESSMENT Impact, Risk factor,

Mitigation measure, Residual risk

IMPLEMENTATION &

COMMUNICATION

REVIEW & UP DATE

Assess Impacts, Analyze Risk ,

Establish Mitigation Measures.

Communication & Training Audit, Inspection & Up dating of Log.

Page 2 sur 5

106

1.2.3

involved in this Hazard Identification & Risk Analysis Procedure (Risk

related risks throughout the Construction Phase.

REVIEW & UP DATE

Audit, Inspection & Up dating of Log.

Tasks Hazards Identified (include

the exposed groups)

Probability

1 - 5

Transfer

equipment

Transfer device collide

with other things;

Oil leakage

4

Locate the crane Hitting injury 4

Transport Traffic risk

Collision with person

Collision device

3

Movement of

traffic Slip/trip/all

3

RISK ASSESSMENT FORM

Severity

1 - 4

Risk

1 - 20

Control Measures to be Implemented

Probability

1 - 5

3 12 Chose a qualified driver before

work

Check the calibration of all tools

Make sure the transport device in

good condition

1

3 12 Solid the ground

Reinforce the pads beneath the

outriggers

Check the around circumstance

before working

1

3 9 The trucks must respect:

The limited speed in the site

The circulation signs

The circulation plan (updated)

2

3 9

All hose/ropes/cables in use shall

be secured to the side of walkways

and handrails

All unnecessary materials and

equipment to be immediately

removed from site

All exits and walkways to be kept

clear for use of personnel

High standard of housekeeping to

be maintained at all times

2

Page 3 sur 5

Probability Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date

Action

Completed

2 2

2 2

3 6

2 4

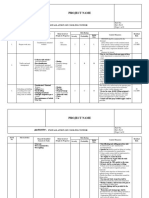

Tasks Hazards Identified (include

the exposed groups)

Probability

1 - 5

Lifting Fall from height and

hurt workers

Component fall down

Component collide

with other things

surrounded

collision with person

collision between

frame and scaffolding

collision between the

crane and equipments

falling materials

Poor visibility for the

driver

4

RISK ASSESSMENT FORM

Severity

1 - 4

Risk

1 - 20

Control Measures to be Implemented

Probability

1 - 5

4 16 Lifting crane, forklift wires should

be regularly calibrated, safe

working loads are announced max

speed at site is respected for all

vehicle

It is not allowed to work under

loads

Handling by qualified riggers worn

the related PPE and under

supervision

Qualified crane operator and

qualified rigger to operate lifting

work

Crane in calibrated period

Barricade the lifting area

Proper lifting tools

Make sure lifting wok operated in

good weather

mark the area of operations of the

crane

officer commanding the ship

maneuver through regulatory

actions to avoid accidents

Control of the safety catch hook

the slings

Ensure the crane on his dashboard

that the load weight does not

exceed the maximum allowed

Ban the person be under a

suspended load

defining the radius of the rotary

crane

prohibit the movement of people

around the handling

stop the lifting operation in strong

winds exceed the 50km /h

2

Page 4 sur 5

Probability Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date Action

Completed

3 6

Tasks Hazards Identified (include

the exposed groups)

Probability

1 - 5

Work at height

(Scaffolding and

Man basket)

falls from height

falling objects

4

Use tools Hand injuries

crushed fingers

smooth head against the

frame

3

Environmental

Pollution the air:

Exhaust gas, The dust

Leaking oil or diesel

machines on soil

3

Assessor Print :

RISK ASSESSMENT FORM

Severity

1 - 4

Risk

1 - 20

Control Measures to be Implemented

Probability

1 - 5

3 12 the scaffolding should be based on

graded soil with good foundation

protect a guard with a height of

1.15 m

Protection of Persons with safety

harnesses

protect with an end-board 10 to 15

cm high

prohibit work at height if the

weather affected the safety of

persons

2

3 9 ensure protection adequate PPE

(gloves, helmet, goggles, harness

2

3 9

Checking the condition of

equipments before beginning the

work

ventilation Workstation

2

Sign: Date:

Page 5 sur 5

Probability Severity

1 - 4

Risk

1 - 20

Residual

Risk

Date

Action

Completed

2 4

2 4

2 4

You might also like

- Risk Asses 65-Piping Fabricated and Assembly - H03Document11 pagesRisk Asses 65-Piping Fabricated and Assembly - H03Rochdi BahiriNo ratings yet

- Column Lifting & Erection JSADocument7 pagesColumn Lifting & Erection JSAAli Mohsin100% (3)

- RISK ASSES-105-Erection of Steel Structure BuildinDocument4 pagesRISK ASSES-105-Erection of Steel Structure BuildinRochdi Bahiri75% (8)

- Risk Assesment 16 - Pre - Assembly and Erection ofDocument7 pagesRisk Assesment 16 - Pre - Assembly and Erection ofRochdi BahiriNo ratings yet

- HSE PLAN Generic RA PDFDocument5 pagesHSE PLAN Generic RA PDFテレブリコ ジェファーソン100% (1)

- Assessment No 47 Demolition Basin E40Document4 pagesAssessment No 47 Demolition Basin E40Rochdi Bahiri0% (1)

- RISK ASSE 110 - Fire Fighting System - F03Document8 pagesRISK ASSE 110 - Fire Fighting System - F03Rochdi BahiriNo ratings yet

- Water Tank Base Construction Hazard Identification and Risk ControlDocument5 pagesWater Tank Base Construction Hazard Identification and Risk Controlramod100% (2)

- Risk Assessment For Working in Confined SpaceDocument1 pageRisk Assessment For Working in Confined SpaceRicardo Dalisay100% (1)

- Risk Assessment for Scaffolding OperationsDocument5 pagesRisk Assessment for Scaffolding OperationsAnonymous iI88Lt0% (1)

- Grinding Equipment Risk AssessmentDocument3 pagesGrinding Equipment Risk Assessmentdroffilcz270% (1)

- Electric Hand Drill Risk AssessmentDocument4 pagesElectric Hand Drill Risk AssessmentTariq AkhtarNo ratings yet

- Working at Heights RiskDocument3 pagesWorking at Heights Riskmyo lwin75% (4)

- Example Risk Assessment For Excavations Updated 21-11-12Document3 pagesExample Risk Assessment For Excavations Updated 21-11-12rishi100% (3)

- Assignment Nos. 3 - Scaffolding Risk AssessmentDocument11 pagesAssignment Nos. 3 - Scaffolding Risk AssessmentFrancis Enriquez Tan100% (1)

- JSA Template 5 - Plumbing and Wastewater System InspectionsDocument13 pagesJSA Template 5 - Plumbing and Wastewater System InspectionsSayed Darwish100% (2)

- Hot Work TRA Workshop NightDocument3 pagesHot Work TRA Workshop Nightmarvin100% (1)

- Risk Assessment LoaderDocument3 pagesRisk Assessment Loadermohamed ghalyNo ratings yet

- Risk Assessment For Hot WorksDocument4 pagesRisk Assessment For Hot Workseldho100% (1)

- DewateringDocument1 pageDewateringChandruNo ratings yet

- Gas Cutting Work: Hazard Identification and Risk AssessmentDocument3 pagesGas Cutting Work: Hazard Identification and Risk AssessmentAchalere Shekhar Kashinath100% (2)

- 6-Steel Work Risk Assessment ReportDocument7 pages6-Steel Work Risk Assessment ReportSyed Ali Hassan67% (3)

- Risk Assessment Form Gaz Turbine InstallationDocument6 pagesRisk Assessment Form Gaz Turbine InstallationRochdi Bahiri100% (1)

- DLF PCC HiraDocument6 pagesDLF PCC HiraskfahimuddinNo ratings yet

- 2.risk Assessment of Working at HeightDocument7 pages2.risk Assessment of Working at HeightRisal Sinu50% (2)

- Risk Assessment of Scaffolding Works - Rev. 1Document20 pagesRisk Assessment of Scaffolding Works - Rev. 1Jayson Escamillan67% (3)

- EHS RISK ASSESSMENT FOR MATERIAL HANDLINGDocument4 pagesEHS RISK ASSESSMENT FOR MATERIAL HANDLINGshamshu123100% (1)

- Use of Hand ToolsDocument2 pagesUse of Hand Toolsvictor100% (1)

- HIRA FOR SLICING DEMOLITION WORKS IN UG STATIONS - CMRL Rev 01Document21 pagesHIRA FOR SLICING DEMOLITION WORKS IN UG STATIONS - CMRL Rev 01mahesh naik100% (1)

- Risk Assessment - Lifting OperationsDocument3 pagesRisk Assessment - Lifting Operationsdnmule100% (1)

- 007 - Risk Ass. - CE-0994-MEP WorksDocument9 pages007 - Risk Ass. - CE-0994-MEP Worksnsadnan50% (2)

- Forklift Risk AssessmentDocument5 pagesForklift Risk AssessmentNii Ashiii100% (1)

- Risk Assessment - Concrete CastingDocument3 pagesRisk Assessment - Concrete Castingdnmule50% (2)

- Lifting Bridge JSADocument8 pagesLifting Bridge JSAeslamNo ratings yet

- (SWMS-01) Loading, Unloading and ShiftingDocument5 pages(SWMS-01) Loading, Unloading and ShiftingPRATEEK SINGH100% (2)

- Risk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEDocument12 pagesRisk Ass - CE - 0994 - GAS CUTTING, WELDING, GRINDING, LOADING AND UNLOADING OF ANODE PALETTEnsadnan100% (4)

- RA For Man Lift OperationDocument6 pagesRA For Man Lift Operationalla malikNo ratings yet

- Cooling tower installation risk assessmentDocument9 pagesCooling tower installation risk assessmentGirithar M Sundaram100% (2)

- Ehs Risk AssessmentDocument2 pagesEhs Risk AssessmentRohit Singh100% (1)

- #15 Activity Based Risk Assessment For Painting of The Terror Club Compound and Roof Washing of T.C. BuildingsDocument14 pages#15 Activity Based Risk Assessment For Painting of The Terror Club Compound and Roof Washing of T.C. BuildingsSathish Insmile100% (1)

- 01 HIRA Lifting & RiggingDocument3 pages01 HIRA Lifting & RiggingMudhyn MI75% (4)

- 20) Pumping of WaterDocument7 pages20) Pumping of WaterMobin Thomas Abraham75% (12)

- Risk Assessment For Repair of ManholeDocument5 pagesRisk Assessment For Repair of Manholeflmm09No ratings yet

- Job Safety Analysis For Highmast ErectionDocument8 pagesJob Safety Analysis For Highmast ErectionSantoshkumar Gupta100% (3)

- JHA Example Installation of Underfloor Plumbing and DrainsDocument15 pagesJHA Example Installation of Underfloor Plumbing and DrainsShamel Jen FacundoNo ratings yet

- Backfilling Risk AssessmentDocument3 pagesBackfilling Risk Assessmentgulryz84100% (1)

- Risk Assessment For General ActivitiesDocument25 pagesRisk Assessment For General Activitiesabou bakar67% (3)

- Risk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)Document3 pagesRisk Assessment - 4500018082-Testing of Slab To Earth Resistance (Potrooms)nsadnan0% (1)

- TRA of Lifting of EquipmentsDocument3 pagesTRA of Lifting of EquipmentsandreNo ratings yet

- RA Equipment MobilizationDocument1 pageRA Equipment MobilizationSn Ahsan100% (1)

- Risk assessment for erection of boiler steam drumDocument4 pagesRisk assessment for erection of boiler steam drumQuynh Tao100% (1)

- RA, COSHH, MSDS Screed & Waterproofing PDFDocument27 pagesRA, COSHH, MSDS Screed & Waterproofing PDFテレブリコ ジェファーソン60% (5)

- Job Hazard AssessmentDocument26 pagesJob Hazard AssessmentGeherson AbustanNo ratings yet

- JSA-Construction Right of WayDocument3 pagesJSA-Construction Right of Wayfrancis_e_tan100% (5)

- HIRA Boiler Pressure Part Risk AssessmentDocument15 pagesHIRA Boiler Pressure Part Risk AssessmentHARSHAL100% (2)

- Excavation Risk AssessmentDocument3 pagesExcavation Risk Assessmentrashid zaman57% (7)

- Rmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)Document2 pagesRmdjv-pj74-Hiradc-subc 08l (Steel Structure Erection)myn maliQueNo ratings yet

- GROUP RISK ASSESSMENTDocument3 pagesGROUP RISK ASSESSMENTJacob ChirayilNo ratings yet

- Risk Assess - 98-Installation Fuel Oil ConditioniDocument4 pagesRisk Assess - 98-Installation Fuel Oil ConditioniRochdi BahiriNo ratings yet

- RISK ASSES-97-Erection of Steel Structure BuildingDocument8 pagesRISK ASSES-97-Erection of Steel Structure BuildingRochdi BahiriNo ratings yet

- A Case Study of 3-MW Scale Grid-Connected Solar Photovoltaic Power Plant at Kolar, KarnatakaDocument38 pagesA Case Study of 3-MW Scale Grid-Connected Solar Photovoltaic Power Plant at Kolar, KarnatakaAnant Joshi67% (3)

- Project Finance and Merchant PowerDocument76 pagesProject Finance and Merchant Powersimplyanks_5100% (2)

- Risk Asses 118-Transformers Oil TreatmentDocument5 pagesRisk Asses 118-Transformers Oil TreatmentRochdi BahiriNo ratings yet

- Readme 1 STDocument1 pageReadme 1 STRochdi BahiriNo ratings yet

- Evaluate economic feasibility of power plant projectsDocument7 pagesEvaluate economic feasibility of power plant projectsfundu123No ratings yet

- Power Electronics For Modern Wind Turbines-Frede Blaabjerg Zhe ChenDocument68 pagesPower Electronics For Modern Wind Turbines-Frede Blaabjerg Zhe Chennelber_xNo ratings yet

- What Is Quadrature Axis Reactance PDFDocument11 pagesWhat Is Quadrature Axis Reactance PDFRochdi BahiriNo ratings yet

- Audit of Power Purchase AgreementsDocument6 pagesAudit of Power Purchase AgreementsRochdi BahiriNo ratings yet

- Epc Contracts in The Power SectorDocument30 pagesEpc Contracts in The Power SectorIwan Anggara100% (2)

- Risk Asses 116 - Boiler Hydro Test LP3Document5 pagesRisk Asses 116 - Boiler Hydro Test LP3Rochdi BahiriNo ratings yet

- Pump Efficiency For Single Stage Centrifugal PumpsDocument8 pagesPump Efficiency For Single Stage Centrifugal PumpsPerrobast100% (1)

- Risk Asses23 - Generator RotorDocument3 pagesRisk Asses23 - Generator RotorRochdi BahiriNo ratings yet

- Primavera: Contract Manager Functional OverviewDocument22 pagesPrimavera: Contract Manager Functional OverviewIgor ČučekNo ratings yet

- TSA Appendices State - 16 09 2014 - WPDocument24,221 pagesTSA Appendices State - 16 09 2014 - WPRochdi BahiriNo ratings yet

- Lettre Recommandation Orascom ConstructionDocument1 pageLettre Recommandation Orascom ConstructionRochdi BahiriNo ratings yet

- Financial Analysis of Projects I - OutlineDocument2 pagesFinancial Analysis of Projects I - OutlineRochdi BahiriNo ratings yet

- 308 BeheraDocument6 pages308 BeheraRajneesh VachaspatiNo ratings yet

- Financing and Performance Contracting For EE Projects OutlineDocument1 pageFinancing and Performance Contracting For EE Projects OutlineRochdi BahiriNo ratings yet

- Install NotesDocument1 pageInstall NotesRochdi BahiriNo ratings yet

- BRD - Lean Manufacturing CaseDocument62 pagesBRD - Lean Manufacturing CaseRochdi BahiriNo ratings yet

- Hawk 4000 Controls: HAWK 4000 Boiler Control System Sample SpecificationsDocument4 pagesHawk 4000 Controls: HAWK 4000 Boiler Control System Sample SpecificationsRochdi BahiriNo ratings yet

- Primavera Project Planner p3Document300 pagesPrimavera Project Planner p3MARIANO100% (19)

- Dampers ExplanationDocument7 pagesDampers ExplanationRochdi BahiriNo ratings yet

- P6 Reference ManualDocument550 pagesP6 Reference Manualsaluthomas100% (22)

- Project and O&M CostDocument2 pagesProject and O&M CostRochdi BahiriNo ratings yet

- 750-326 OM Blowdown Separator 04-10Document8 pages750-326 OM Blowdown Separator 04-10Rochdi BahiriNo ratings yet

- Boiler Design StepDocument3 pagesBoiler Design StepRochdi BahiriNo ratings yet

- Wmu 2013 - PPT - FinalDocument103 pagesWmu 2013 - PPT - FinalRochdi BahiriNo ratings yet

- Risk Asses23 - Generator RotorDocument3 pagesRisk Asses23 - Generator RotorRochdi BahiriNo ratings yet

- Liebherr LHM 550 Mobile Harbour Crane Data Sheet en 9980-0Document8 pagesLiebherr LHM 550 Mobile Harbour Crane Data Sheet en 9980-0candra trisilawati100% (1)

- Design Specification For Loads PDFDocument19 pagesDesign Specification For Loads PDFAJAY SHINDENo ratings yet

- Standardsand Specificationsfor KspanprojectsDocument45 pagesStandardsand Specificationsfor KspanprojectsDonnabel CaleNo ratings yet

- Product Sheet Damen Transshipment Crane Barge 6324 Yn522002 Stock 12 2017Document2 pagesProduct Sheet Damen Transshipment Crane Barge 6324 Yn522002 Stock 12 2017Tiago TeixeiraNo ratings yet

- FPS 013 - Use of Boatswain chairREV1Document4 pagesFPS 013 - Use of Boatswain chairREV1grantNo ratings yet

- Sheave Manual SMDocument8 pagesSheave Manual SMLutfi IsmailNo ratings yet

- Manual-P1250 9510 PDFDocument82 pagesManual-P1250 9510 PDFThiện Nguyễn Bá50% (2)

- Katalog - Downs Crane HoistDocument6 pagesKatalog - Downs Crane HoistDemy Iman TaufikNo ratings yet

- 15419Document29 pages15419tushar11singhNo ratings yet

- Product Design SpecificationDocument7 pagesProduct Design Specificationspellbinder50No ratings yet

- InjectorDocument64 pagesInjectorMuhammad rizki100% (1)

- STEEL FABRICATION METHOD STATEMENTDocument14 pagesSTEEL FABRICATION METHOD STATEMENTKhyle Laurenz Duro100% (4)

- Brochure Bonfiglioli MotoriDocument56 pagesBrochure Bonfiglioli MotoriMattia CanutiNo ratings yet

- Manual Palletizer 825pa001Document58 pagesManual Palletizer 825pa001audonscribd100% (1)

- Resume Format Diploma Mechanical MahindraDocument3 pagesResume Format Diploma Mechanical MahindraDeepak Gupta0% (1)

- New Mechanical ProjectDocument10 pagesNew Mechanical Projectवैज्ञानिक बाबाNo ratings yet

- Design an overhead crane beamDocument95 pagesDesign an overhead crane beamEnrique Santiago BenavidesNo ratings yet

- AV UM AV Outriggers EN 7845448-03 A5 2017-12Document33 pagesAV UM AV Outriggers EN 7845448-03 A5 2017-12JunaedyNo ratings yet

- Chevron Lifting Rigging StandardDocument76 pagesChevron Lifting Rigging StandardBigBaby Julian93% (15)

- ABUS GM wire rope hoists for industrial cranesDocument1 pageABUS GM wire rope hoists for industrial cranesAhmed ShawkyNo ratings yet

- Komatsu Hydraulic Excavator Pc228 Us 3 Shop ManualDocument20 pagesKomatsu Hydraulic Excavator Pc228 Us 3 Shop Manualhelen100% (50)

- 3 5 15 TPI Inspection Properly Maintained Regularly Maintained InspectionDocument5 pages3 5 15 TPI Inspection Properly Maintained Regularly Maintained InspectionMDR PRAPHUNo ratings yet

- Nigeria Factories Act, 1987Document56 pagesNigeria Factories Act, 1987Ethelbert AkwuruahaNo ratings yet

- Machine Handling and Installation 4.0Document10 pagesMachine Handling and Installation 4.0Reza KühnNo ratings yet

- Topaz Tangaroa Tiamat Vessel SpecsDocument5 pagesTopaz Tangaroa Tiamat Vessel SpecsDhil SanNo ratings yet

- Compro Exxa Hire Web CompressDocument24 pagesCompro Exxa Hire Web CompressJoshuaNo ratings yet

- BlokCam & BlokAlert - BrochureDocument20 pagesBlokCam & BlokAlert - BrochureCKNo ratings yet

- TRIO Brochure HQ enDocument50 pagesTRIO Brochure HQ enKrm ChariNo ratings yet

- NES 113 Part 7 Requirements For Mechanical Handling - Lever Hoists Category 2Document20 pagesNES 113 Part 7 Requirements For Mechanical Handling - Lever Hoists Category 2JEORJENo ratings yet

- Pip-001 Rev. A6Document8 pagesPip-001 Rev. A6anisaanNo ratings yet