Professional Documents

Culture Documents

How Do CNC Machines Work Tristar CNC Services GE Fanuc Parts and Repair

Uploaded by

cm_chemical810 ratings0% found this document useful (0 votes)

75 views2 pagesd

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentd

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

75 views2 pagesHow Do CNC Machines Work Tristar CNC Services GE Fanuc Parts and Repair

Uploaded by

cm_chemical81d

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 2

Home About Tri Star Parts Services RMA Warranty Links Contact

FANUC - CNC Machine News and Articles

LCD Upgrades Replacing CRT Monitors in CNC Machines

World's Smallest Self -Contained Wireless CNC Probe

CNC Robotics and Machine Automation Supplier Merger

FANUC Ranks on Forbes Most Innovative List

MACH 2012 Showcases New Products f or the Automation Industry

The Future of CNC Technology

FANUC Robotics Announces Aff ordable Robots at PPMA

FANUC Robots Improve the Food Processing Industry

World's Strongest and Longest Reaching Robot 2011

FANUC Robotics Prof its Soar as Demand Increases

FANUC M-430iA Named Robot of the Year

Fanuc Robots in Green Industries

Robot-Rx - FANUC Robots in Medical Applications

How Do CNC Machines Work?

The Use of FANUC Machines by the U.S.P.S.

Fanuc parts repair and replacement costs verses new Fanuc parts

Fanuc robotics incorporated into blasting machine

Fanuc Ltd. Launches Fanuc CNC America

Buying New FANUC Parts Is Not Always the Best Option

Tri Star Custom FANUC Parts Engineering Saves Clients 70% On CRT Replacement Displays

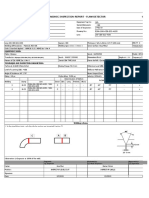

How Do CNC Machines Work?

The f irst question to ask is:

What does CNC stand for?

CNC stands f or Computer Numerically Controlled.

This ref ers to how the computer (instead of people) controls the machines as it manuf actures

complex parts repeatedly. In laymans terms, it means these machines are run by programming

a computer, instead of needing someone to stand there and do it by hand. There are several

types of machines that employ the CNC modif ication: lathes, milling machines, grinding wheels,

drills, and more.

These machines are exceptionally quick and churn out parts at a startlingly swif t pace. This

automation process has helped companies increase their production times exponentially. The

CNC machines utilize CAD data (Computer Aided Design) to move seamlessly f rom the design

process into the production process.

CNC machines have three types of controllers that are commonly f ound on CNC machines.

Desktop controllers are used f rom a remote location a diff erent room or off ice f rom the

machine. Pendant controllers hang f rom an arm attached to the machine, and pedestal

controllers will sit on top of an arm attached to the machine.

CNC machines also make use of one of f our diff erent types of sof tware. Manual G Code

Programming is normally f ound on larger, commercial machines, used f or simple machine

processes. Off line CAM Programming is also f ound on larger machines, but is more diff icult f or

operators to learn.

Conversational Programming is an easy to learn program, making simple and complex parts

easier to manuf acture. Finally, Windows Based Programming is exactly what it sounds like a

Microsof t Windows based program that can understand imported CAM and CAD data, and is

easier f or operators to understand.

When your CNC machine breaks down, dont despair. Contact Tri Star CNC Services LLC

Sear c h

4/29/2014 LCD Upgrades Replacing CRT Monitors

in CNC Machines

3/27/2014 World's Smallest Self-Contained

Wireless CNC Probe

3/20/2014 CNC Robotics and Machine Automation

Supplier Merger

3/17/2014 FANUC Ranks on Forbes Most

Innovative List

4/4/2012 MACH 2012 Showcases NewProducts for

the Automation Industry

Setting Zero Return on Fanuc machines or any

CNC Machine can sometimes be difficult. Each

builder has their own wayto set zero return through

their own side of the control.

today, 262.547.1742 or 815.578.9145, and save money well repair your FANUC or GE

FANUC parts instead of having to replace them! At Tri Star CNC Services, we understand the

importance of keeping these important CNC machines up and running. We will get you a

replacement part right away while we test and repair your old, broken CNC part.

Home About Us Parts Services RMA Warranty Links Contact

Copyright 2014 Tri Star CNC Services LLC Sussex, Wisconsin and McHenry, Illinois

You might also like

- FlexxCNC EbookDocument19 pagesFlexxCNC Ebookgilles bangNo ratings yet

- 13 Parts of CNC Machine Function PDF A Clear GuideDocument10 pages13 Parts of CNC Machine Function PDF A Clear GuideWeirdly GGNo ratings yet

- Course Material On CNC Turning and CNC MillingDocument108 pagesCourse Material On CNC Turning and CNC MillingirinabesliuNo ratings yet

- IJRPR937Document8 pagesIJRPR937Prenank ChandrolNo ratings yet

- Expand Your PROFIT PowerDocument2 pagesExpand Your PROFIT PowerYasser Nour GaafarNo ratings yet

- Tech Ascend CNC Student ManualDocument42 pagesTech Ascend CNC Student ManualabyzenNo ratings yet

- A Project Report On CNC Machine: ComponentsDocument2 pagesA Project Report On CNC Machine: ComponentsksiojiohyuiNo ratings yet

- CNC Stands For Computer Numerical Control, And: G-Code. CNC Was Developed inDocument4 pagesCNC Stands For Computer Numerical Control, And: G-Code. CNC Was Developed inKhateeb Ul Islam QadriNo ratings yet

- CNC Milling ReportDocument15 pagesCNC Milling ReportStarscream Aisyah78% (37)

- I and 0i Mate-: Series 0 Model DDocument16 pagesI and 0i Mate-: Series 0 Model DNorbertoEsparzaNo ratings yet

- CNC Machine Research PaperDocument7 pagesCNC Machine Research Paperafeawldza100% (1)

- Background About CNC MachiningDocument1 pageBackground About CNC MachiningPassmore DubeNo ratings yet

- CNC LatheDocument51 pagesCNC LatheArjun Gowda C SNo ratings yet

- CNC Report DJJ 5032Document46 pagesCNC Report DJJ 5032Shatis kumarNo ratings yet

- AMP ProjectDocument11 pagesAMP Projectomkarkadam50351No ratings yet

- 808 CDocument7 pages808 CDimasNo ratings yet

- CNC MachinesDocument20 pagesCNC MachinesRavi MehtoNo ratings yet

- CNC Milling Machine FYP Final Report V1Document53 pagesCNC Milling Machine FYP Final Report V1Piyush NarkhedeNo ratings yet

- CNC Machining Study FileDocument8 pagesCNC Machining Study FileGurvinder SinghNo ratings yet

- Assignment-1 Computer Aided Manufacturing ME-418Document21 pagesAssignment-1 Computer Aided Manufacturing ME-418Prateek Kharbanda 79No ratings yet

- CNC by AsfiDocument4 pagesCNC by AsfiMuhaimenul SaschoNo ratings yet

- CNC Machines and Programming GuideDocument118 pagesCNC Machines and Programming Guidemadansiyag3No ratings yet

- The CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0From EverandThe CNC Handbook: Digital Manufacturing and Automation from CNC to Industry 4.0Rating: 5 out of 5 stars5/5 (1)

- Post ProcessingDocument12 pagesPost Processingsukhbir24No ratings yet

- Seminar On CNC Machine: Submitted To: Submitted byDocument23 pagesSeminar On CNC Machine: Submitted To: Submitted byFaisal MaqsoodNo ratings yet

- CAMplus Increases Efficiency & ProductivityDocument8 pagesCAMplus Increases Efficiency & ProductivityFagner Moura100% (1)

- Introduction to CAD-CAM Systems and Their EvolutionDocument30 pagesIntroduction to CAD-CAM Systems and Their EvolutionkoalaboiNo ratings yet

- CAM FinalDocument5 pagesCAM FinalYatish TagraNo ratings yet

- Lab 9 PDFDocument5 pagesLab 9 PDFMalik Muhammad IbrahimNo ratings yet

- Research Paper On CNC Machine PDFDocument7 pagesResearch Paper On CNC Machine PDFqdvtairif100% (1)

- Prodcut CCDocument11 pagesProdcut CCKrishna KumarNo ratings yet

- Computer Integrated Manufacturing Lab Manual: Subject Supervisor: Lab InchargeDocument53 pagesComputer Integrated Manufacturing Lab Manual: Subject Supervisor: Lab InchargePuneet G-man KoliNo ratings yet

- Marabti AmarDocument6 pagesMarabti AmarayoubdegvipNo ratings yet

- Definition of Numerical ControlDocument5 pagesDefinition of Numerical ControlRanjan Kumar SinghNo ratings yet

- CenturionDocument11 pagesCenturionGuzzito Rey NU0% (1)

- SolidCAM IMachining 2D A Simulation StudDocument12 pagesSolidCAM IMachining 2D A Simulation StudzzNo ratings yet

- Computer Aided ManufacturingDocument28 pagesComputer Aided ManufacturingSheik AbdullahNo ratings yet

- Complete 850Document140 pagesComplete 850inthemoney8100% (1)

- Notes On CNC PDFDocument27 pagesNotes On CNC PDFAjay Kumar AgarwalNo ratings yet

- Introduction To CAD/CAM: BTEC National Mechanical EngineeringDocument29 pagesIntroduction To CAD/CAM: BTEC National Mechanical EngineeringJames MileyNo ratings yet

- Chapter 1 Introduction 1 1 IntroductionDocument34 pagesChapter 1 Introduction 1 1 IntroductionBeet LalNo ratings yet

- Vericut Brochure 70Document16 pagesVericut Brochure 70sivakumarsambandamNo ratings yet

- CNCDocument36 pagesCNCGokulraju RangasamyNo ratings yet

- CNC Lathe Machine HistoryDocument2 pagesCNC Lathe Machine HistoryKesavan KesaNo ratings yet

- MaterialsDocument14 pagesMaterialsjaiy12No ratings yet

- Computer Aided ManufactureDocument15 pagesComputer Aided ManufactureAnonymous 5lXEgHNo ratings yet

- MachinesDocument16 pagesMachinessit20me028No ratings yet

- Computer 2112Document12 pagesComputer 2112zxcccz100% (2)

- Manufacturing Control and Automation OverviewDocument30 pagesManufacturing Control and Automation OverviewAnurag kumarNo ratings yet

- Introduction to CNC Machines and Computer Numerical ControlDocument12 pagesIntroduction to CNC Machines and Computer Numerical ControlSudeep UpadhyeNo ratings yet

- Engineering Faculty: Department of Mechanical EngineeringDocument3 pagesEngineering Faculty: Department of Mechanical Engineeringmarina890416No ratings yet

- Project Report of CNCDocument9 pagesProject Report of CNCMaqsood WarNo ratings yet

- Module - 4Document71 pagesModule - 4Anand ANo ratings yet

- Notes On CNCDocument27 pagesNotes On CNCKaushalendra Kumar SinghNo ratings yet

- NCDocument7 pagesNCsugiantobarusNo ratings yet

- Increase Efficiency With The NX-to-VERICUT InterfaceDocument4 pagesIncrease Efficiency With The NX-to-VERICUT InterfaceTRUNG QUOC LENo ratings yet

- What Is A CNC Machine and How Does It Aid ManufacturingDocument7 pagesWhat Is A CNC Machine and How Does It Aid ManufacturingjackNo ratings yet

- Literature Review On CNC MachineDocument7 pagesLiterature Review On CNC Machineaflsnbfir100% (1)

- CNC Router Essentials: The Basics for Mastering the Most Innovative Tool in Your WorkshopFrom EverandCNC Router Essentials: The Basics for Mastering the Most Innovative Tool in Your WorkshopRating: 5 out of 5 stars5/5 (3)

- 06-BRIDGE Speci BookletDocument49 pages06-BRIDGE Speci BookletMAULIK RAVALNo ratings yet

- Gujarat Gov WebsiteDocument1 pageGujarat Gov Websitecm_chemical81No ratings yet

- Sl. No. Page NoDocument1 pageSl. No. Page Nocm_chemical81No ratings yet

- 175 1 Language p1 For All Answer KeyDocument5 pages175 1 Language p1 For All Answer Keycm_chemical81No ratings yet

- Details of Entrance Exam and Interviews of Various Courses Offered by Instt of Behavioral ScienceDocument1 pageDetails of Entrance Exam and Interviews of Various Courses Offered by Instt of Behavioral Sciencecm_chemical81No ratings yet

- 175 1 Language p1 For All Answer KeyDocument5 pages175 1 Language p1 For All Answer Keycm_chemical81No ratings yet

- Guj Edu WebsitesDocument1 pageGuj Edu Websitescm_chemical81No ratings yet

- Hindi Phrases Related to Eyes and Their MeaningsDocument1 pageHindi Phrases Related to Eyes and Their Meaningscm_chemical81No ratings yet

- VX 135 - CNC Machines, CNC Turning Centre, CNC Vertical Machining Centre, CNC Machinery India - MacPowerDocument2 pagesVX 135 - CNC Machines, CNC Turning Centre, CNC Vertical Machining Centre, CNC Machinery India - MacPowercm_chemical81No ratings yet

- Ashrkarak VargvyavharDocument56 pagesAshrkarak VargvyavharPrashant PatelNo ratings yet

- Hindi Grammar PDFDocument7 pagesHindi Grammar PDFNitinKumar100% (1)

- MONO 250 - CNC Machines, CNC Turning Centre, CNC Vertical Machining Centre, CNC Machinery India - MacPowerDocument2 pagesMONO 250 - CNC Machines, CNC Turning Centre, CNC Vertical Machining Centre, CNC Machinery India - MacPowercm_chemical81No ratings yet

- Ncte Act 1993Document20 pagesNcte Act 1993cm_chemical81No ratings yet

- Paper 2 E-H Jun 2011Document29 pagesPaper 2 E-H Jun 2011kripa8shankar8pathakNo ratings yet

- Sixan Adhiniyam Sudharo 2010Document5 pagesSixan Adhiniyam Sudharo 2010cm_chemical81No ratings yet

- CNC Class PDFDocument3 pagesCNC Class PDFcm_chemical81No ratings yet

- PTC First Year SyllabusDocument3 pagesPTC First Year Syllabuscm_chemical81100% (2)

- VX 200 - CNC Machines, CNC Turning Centre, CNC Vertical Machining Centre, CNC Machinery India - MacPowerDocument2 pagesVX 200 - CNC Machines, CNC Turning Centre, CNC Vertical Machining Centre, CNC Machinery India - MacPowercm_chemical81100% (1)

- Emulsifier For Base Cutting OilsDocument3 pagesEmulsifier For Base Cutting Oilscm_chemical810% (1)

- Indian machine tools industry: Historical trends and international outlookDocument62 pagesIndian machine tools industry: Historical trends and international outlookdp20111No ratings yet

- CNC Class PDFDocument3 pagesCNC Class PDFcm_chemical81No ratings yet

- What Is The Difference Between A Machine Center and A LatheDocument2 pagesWhat Is The Difference Between A Machine Center and A Lathecm_chemical81No ratings yet

- Current and Reliable Grinder Fluids & Chemicals News StoriesDocument4 pagesCurrent and Reliable Grinder Fluids & Chemicals News Storiescm_chemical81No ratings yet

- Your Search ResultsDocument2 pagesYour Search Resultscm_chemical81No ratings yet

- Cengage Learning India - Author DetailDocument1 pageCengage Learning India - Author Detailcm_chemical81No ratings yet

- Metal Working Fluids - Hydraulic Oil Rust Preventive OilDocument2 pagesMetal Working Fluids - Hydraulic Oil Rust Preventive Oilcm_chemical81No ratings yet

- Cutting Fluid Types and Their Importance in MachiningDocument7 pagesCutting Fluid Types and Their Importance in Machiningcm_chemical81No ratings yet

- What Is The Difference Between A CNC Mill and A CNC LathDocument2 pagesWhat Is The Difference Between A CNC Mill and A CNC Lathcm_chemical81No ratings yet

- Drill and Cutting Coolant Lubricant Keeping Cutters Cool and SharpDocument5 pagesDrill and Cutting Coolant Lubricant Keeping Cutters Cool and Sharpcm_chemical81No ratings yet

- Difference between HMC and VMC CNC machinesDocument2 pagesDifference between HMC and VMC CNC machinescm_chemical81No ratings yet

- Supply Chain Management of VodafoneDocument8 pagesSupply Chain Management of VodafoneAnamika MisraNo ratings yet

- Vortex: Opencl Compatible Risc-V Gpgpu: Fares Elsabbagh Blaise Tine Priyadarshini Roshan Ethan Lyons Euna KimDocument7 pagesVortex: Opencl Compatible Risc-V Gpgpu: Fares Elsabbagh Blaise Tine Priyadarshini Roshan Ethan Lyons Euna KimhiraNo ratings yet

- Barker-Choucalas, Vida PDFDocument176 pagesBarker-Choucalas, Vida PDFAnn GarbinNo ratings yet

- Pakistan Affairs Current Affairs 2016 MCQSDocument3 pagesPakistan Affairs Current Affairs 2016 MCQSMuhammad MudassarNo ratings yet

- Final Reflective Essay by Georgi ShopovDocument7 pagesFinal Reflective Essay by Georgi ShopovMd Siddique UllahNo ratings yet

- Lehman BrothersDocument10 pagesLehman BrothersJaikishin RuprajNo ratings yet

- Chapter 9 Lease DecisionsDocument51 pagesChapter 9 Lease Decisionsceoji25% (4)

- Uvas CaractDocument10 pagesUvas CaractgondeluNo ratings yet

- Data Science From Scratch, 2nd EditionDocument72 pagesData Science From Scratch, 2nd EditionAhmed HusseinNo ratings yet

- A-00 IndexDocument10 pagesA-00 IndexNizarHamrouniNo ratings yet

- Research Chapter 1Document7 pagesResearch Chapter 1Aryando Mocali TampubolonNo ratings yet

- Numerical Solution of Ordinary Differential EquationsDocument31 pagesNumerical Solution of Ordinary Differential Equationschandu3072002100% (1)

- As 91435Document3 pagesAs 91435api-271057641No ratings yet

- Ut ProcedureDocument2 pagesUt ProcedureJJ WeldingNo ratings yet

- Writing Lesson Plan LMDocument6 pagesWriting Lesson Plan LMapi-457032696No ratings yet

- Jt20 ManualDocument201 pagesJt20 Manualweider11No ratings yet

- Nigerian Romance ScamDocument10 pagesNigerian Romance ScamAnonymous Pb39klJNo ratings yet

- Abinitio Interview QuesDocument30 pagesAbinitio Interview QuesVasu ManchikalapudiNo ratings yet

- Reference Letter For Employment AustraliaDocument8 pagesReference Letter For Employment Australiabcqy21t7100% (2)

- Data Structures LightHall ClassDocument43 pagesData Structures LightHall ClassIwuchukwu ChiomaNo ratings yet

- Mediclaim - ChecklistDocument4 pagesMediclaim - ChecklistKarthi KeyanNo ratings yet

- Express VPN Activation CodeDocument5 pagesExpress VPN Activation CodeButler49JuulNo ratings yet

- Ted Hughes's Crow - An Alternative Theological ParadigmDocument16 pagesTed Hughes's Crow - An Alternative Theological Paradigmsa46851No ratings yet

- Unit 4 AE Scan OCRed PDFDocument44 pagesUnit 4 AE Scan OCRed PDFZia AhmedNo ratings yet

- Facebook TemplateDocument2 pagesFacebook Templateapi-352106462No ratings yet

- Download C How To Program An Objects Natural Approach 11E 11Th Edition Paul Deitel full chapter pdf scribdDocument67 pagesDownload C How To Program An Objects Natural Approach 11E 11Th Edition Paul Deitel full chapter pdf scribdjack.bowlin207100% (4)

- Singular and Plural NounsDocument3 pagesSingular and Plural NounsJosé BulquesNo ratings yet

- New Directions Formative TestDocument1 pageNew Directions Formative TestAnonymous xGQcti3qK100% (1)

- Coca Cola Live-ProjectDocument20 pagesCoca Cola Live-ProjectKanchan SharmaNo ratings yet

- PACL Lodha Commette Final NOTICE of SALE With Property DetailsDocument4 pagesPACL Lodha Commette Final NOTICE of SALE With Property DetailsVivek Agrawal100% (2)