Professional Documents

Culture Documents

Turn Signal and Hazard Warning Systems

Uploaded by

Dalton WiseOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Turn Signal and Hazard Warning Systems

Uploaded by

Dalton WiseCopyright:

Available Formats

TURN SIGNAL AND HAZARD WARNING SYSTEMS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 1

DESCRIPTION AND OPERATION

COMBINATION FLASHER . . . . . . . . . . . . . . . . . . 1

HAZARD WARNING SYSTEM . . . . . . . . . . . . . . . 1

TURN SIGNAL INDICATOR LAMP . . . . . . . . . . . 3

TURN SIGNAL LAMP . . . . . . . . . . . . . . . . . . . . . 3

TURN SIGNAL SWITCH AND HAZARD

WARNING SWITCH . . . . . . . . . . . . . . . . . . . . . 2

TURN SIGNAL SYSTEM . . . . . . . . . . . . . . . . . . . 1

VEHICLE INFORMATION CENTER . . . . . . . . . . . 3

DIAGNOSIS AND TESTING

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . 3

MULTI-FUNCTION SWITCH . . . . . . . . . . . . . . . . 4

TURN SIGNAL AND HAZARD WARNING

SYSTEMS . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

REMOVAL AND INSTALLATION

COMBINATION FLASHER . . . . . . . . . . . . . . . . . . 5

MULTI-FUNCTION SWITCH . . . . . . . . . . . . . . . . 6

GENERAL INFORMATION

INTRODUCTION

Fol l owi ng are general descri pti ons of the major

components i n the turn si gnal and hazard warni ng

systems. Refer to 8W-52 - Turn Si gnal s i n Group 8W

- Wi ri ng Di agrams for compl ete ci rcui t descri pti ons

and di agrams.

DESCRIPTION AND OPERATION

TURN SIGNAL SYSTEM

Wi th the i gni ti on swi tch i n the On posi ti on, and

the mul ti -functi on swi tch control l ever moved up

(ri ght turn) or down (l eft turn), the turn si gnal sys-

tem i s acti vated. The swi tch has a detent posi ti on i n

each di recti on that provi des turn si gnal s wi th auto-

mati c cancel l ati on, and an i ntermedi ate momentary

posi ti on i n each di recti on that provi des turn si gnal s

onl y unti l the mul ti -functi on swi tch l ever i s rel eased.

When the turn si gnal swi tch i s i n a detent posi -

ti on, i t i s turned off by one of two cancel l i ng cam

l obes mol ded i nto the hub of the cl ockspri ng mecha-

ni sm. When turni ng the steeri ng wheel causes one of

the cam l obes to contact a cancel actuator i n the

mul ti -functi on swi tch, the turn si gnal swi tch auto-

mati cal l y returns to the off posi ti on.

When the turn si gnal system i s acti vated, the

sel ected (ri ght or l eft) turn si gnal i ndi cator l amp,

front park/turn si gnal l amp, front si de marker l amp,

and rear tai l /stop/turn si gnal l amp bul bs wi l l fl ash.

Wi th the headl amp swi tch i n the Off posi ti on, the

front turn si gnal and front si de marker l amps fl ash

i n uni son. Wi th the headl amp swi tch i n the On posi -

ti on, the front turn si gnal and front si de marker

l amps fl ash al ternatel y.

HAZARD WARNING SYSTEM

The hazard warni ng system i s acti vated by a

swi tch button i n the mul ti -functi on swi tch. The but-

ton i s l ocated on the top of the steeri ng col umn

between the steeri ng wheel and the i nstrument

panel . The hazard warni ng swi tch button i s i denti -

fi ed wi th a doubl e tri angl e.

The hazard warni ng system i s connected to a non-

swi tched battery feed so that the system remai ns

functi onal , regardl ess of the i gni ti on swi tch posi ti on.

Push the swi tch button i n to acti vate the hazard

warni ng system, and push i n on the button agai n to

turn the system off.

When the hazard warni ng system i s acti vated, the

ri ght and l eft turn si gnal i ndi cators, front park/turn

si gnal l amps, front si de marker l amps, and rear tai l /

stop/turn si gnal l amps wi l l fl ash.

COMBINATION FLASHER

The combi nati on fl asher i s a smart rel ay that func-

ti ons as both the turn si gnal system and hazard

warni ng system fl asher. The combi nati on fl asher con-

tai ns acti ve el ectroni c I ntegrated Ci rcui try (I C) el e-

ments. Thi s fl asher i s desi gned to handl e the current

fl ow requi rements of the factory-i nstal l ed l i ghti ng. I f

suppl emental l i ghti ng i s added to the turn si gnal

l amp ci rcui ts, such as when towi ng a trai l er wi th

l i ghts, the combi nati on fl asher wi l l automati cal l y try

to compensate to keep the fl ash rate the same.

Whi l e the combi nati on fl asher has a I nternati onal

Standards Organi zati on (I SO)-type rel ay termi nal

confi gurati on or footpri nt, the i nternal ci rcui try i s

much di fferent. The combi nati on fl asher does not use

standard I SO-rel ay i nputs or provi de I SO-rel ay type

outputs or functi ons. The combi nati on fl asher shoul d

never be substi tuted for an I SO-rel ay or repl aced

ZJ TURN SIGNAL AND HAZARD WARNING SYSTEMS 8J - 1

wi th an I SO-rel ay, or el se component and vehi cl e

damage may occur.

The combi nati on fl asher has fi ve bl ade-type termi -

nal s i ntended for the fol l owi ng i nputs and outputs:

Battery B+, I gni ti on B+, Ground, Turn Si gnal ci rcui t,

and Hazard Warni ng ci rcui t. Constant battery vol t-

age and ground are suppl i ed to the fl asher so that i t

can perform the hazard warni ng functi on, and i gni -

ti on swi tched battery vol tage i s suppl i ed for the turn

si gnal functi on. Refer to 8W-52 - Turn Si gnal s i n

Group 8W - Wi ri ng Di agrams for compl ete ci rcui t

descri pti ons, di agrams and termi nal functi on i denti -

fi cati on.

The I C wi thi n the combi nati on fl asher (Fi g. 1) con-

tai ns the l ogi c that control s the fl asher operati on and

the fl ash rate. Pi n 6 of the I C recei ves a sense vol t-

age from the hazard warni ng porti on of the mul ti -

functi on swi tch. When the hazard swi tch i s turned

on, the hazard on sense vol tage wi l l become l ow due

to the ci rcui t bei ng grounded through the turn si gnal

bul bs. Thi s l ow vol tage sense si gnal s the I C to ener-

gi ze the fl ash control Posi ti ve-Negati ve-Posi ti ve

(PNP) transi stor at a pre-cal i brated fl ash rate or fre-

quency. Each ti me the PNP transi stor energi zes the

hazard warni ng ci rcui t, the pi n 6 hazard on sense

vol tage wi l l become hi gh and the I C si gnal s the PNP

transi stor to de-energi ze the ci rcui t. Thi s cycl i ng wi l l

conti nue unti l the hazard warni ng swi tch i s turned

off.

Li kewi se, pi n 8 of the I C recei ves a sense vol tage

from the turn si gnal porti on of the mul ti -functi on

swi tch. When the l eft or ri ght turn si gnal i s turned

on, the turn si gnal on sense vol tage wi l l become l ow

due to the ci rcui t bei ng grounded through the turn

si gnal bul bs. Thi s l ow vol tage sense si gnal s the I C to

energi ze the fl ash control PNP transi stor at a pre-

cal i brated fl ash rate or frequency. Each ti me the PNP

transi stor energi zes the turn si gnal ci rcui t, the pi n 8

turn si gnal on sense vol tage wi l l become hi gh and

the I C si gnal s the PNP transi stor to de-energi ze the

ci rcui t. Thi s cycl i ng wi l l conti nue unti l the ri ght or

l eft turn si gnal i s turned off.

A speci al desi gn feature of the combi nati on fl asher

al l ows i t to sense that a turn si gnal ci rcui t or bul b

i s not operati ng, and provi de the dri ver an i ndi cati on

of the condi ti on by fl ashi ng the remai ni ng bul bs i n

the affected ci rcui t at a hi gher rate (120 fl ashes-per-

mi nute or hi gher). Conventi onal fl ashers ei ther con-

ti nue fl ashi ng at thei r typi cal rate (heavy-duty type),

or di sconti nue fl ashi ng the affected ci rcui t enti rel y

(standard-duty type). Duri ng turn si gnal operati on,

the combi nati on fl asher I C compares normal battery

vol tage i nput on pi n 2 wi th the shunt resi stor vol tage

i nput on pi n 7. I f the I C senses that the vol tage di f-

ference between pi n 2 and pi n 7 i s di fferent than the

pre-cal i brated val ue of the I C, i t wi l l i ncrease the

rate at whi ch i t si gnal s the PNP transi stor to ener-

gi ze the pi n 1 output. Thus, the i noperati ve hal f (l eft

or ri ght si de) of the turn si gnal ci rcui t wi l l fl ash

faster.

Because of the acti ve el ectroni c el ements wi thi n

the combi nati on fl asher, i t cannot be tested wi th con-

venti onal automoti ve el ectri cal test equi pment. I f the

combi nati on fl asher i s bel i eved to be faul ty, test the

turn si gnal and hazard warni ng system ci rcui ts as

descri bed i n thi s group. Then repl ace the combi na-

ti on fl asher wi th a known good uni t to confi rm sys-

tem operati on.

The combi nati on fl asher cannot be repai red and, i f

faul ty or damaged, i t must be repl aced.

TURN SIGNAL SWITCH AND HAZARD WARNING

SWITCH

The turn si gnal and hazard warni ng swi tches are

i ntegral to the mul ti -functi on swi tch assembl y. The

mul ti -functi on swi tch assembl y i s mounted to the l eft

si de of the steeri ng col umn (Fi g. 2). Thi s swi tch con-

tai ns ci rcui try for the fol l owi ng functi ons:

Turn si gnal s

Hazard warni ng

Headl amp beam sel ecti on

Headl amp opti cal horn

Wi ndshi el d wi pers

Wi ndshi el d washers.

The i nformati on contai ned i n thi s group addresses

onl y the mul ti -functi on swi tch functi ons for the turn

si gnal and hazard warni ng ci rcui ts. For i nformati on

rel ati ve to the other swi tch functi ons, refer to the

proper group. However, the mul ti -functi on swi tch

cannot be repai red. I f any functi on of the mul ti -func-

ti on swi tch i s faul ty, or i f the swi tch i s damaged, the

enti re swi tch assembl y must be repl aced.

Fig. 1 Combination Flasher - Typical

8J - 2 TURN SIGNAL AND HAZARD WARNING SYSTEMS ZJ

DESCRIPTION AND OPERATION (Continued)

TURN SIGNAL INDICATOR LAMP

The turn si gnal i ndi cator l amps are l ocated i n the

i nstrument cl uster. They fl ash wi th the exteri or turn

si gnal l amps to gi ve the dri ver a vi sual i ndi cati on

that a turn si gnal or the hazard warni ng system i s

operati ng. For di agnosi s and servi ce of these l amps,

refer to Group 8E - I nstrument Panel Systems.

VEHICLE INFORMATION CENTER

Model s equi pped wi th the opti onal Vehi cl e I nfor-

mati on Center (VI C) have a turn si gnal on warni ng

feature. The VI C modul e moni tors the turn si gnal

ci rcui t through the combi nati on fl asher. The VI C

modul e wi l l di spl ay a Turn Si gnal On message and

send a request to the Body Control Modul e (BCM) on

the Chrysl er Col l i si on Detecti on (CCD) data bus net-

work for si x chi me tones, i f a turn si gnal remai ns

acti vated for more than approxi matel y one-hal f mi l e

of dri vi ng.

Refer to Group 8E - I nstrument Panel Systems for

more i nformati on on the VI C modul e. For di agnosi s

of the VI C, the BCM or the CCD data bus, the use of

a DRB scan tool and the proper Di agnosti c Proce-

dures manual are recommended.

TURN SIGNAL LAMP

The exteri or l amps i n the turn si gnal and hazard

warni ng ci rcui ts i ncl ude the front park/turn si gnal ,

the front si de marker, and the rear tai l /stop/turn si g-

nal . For di agnosi s and servi ce of these l amps, refer to

Group 8L - Lamps.

DIAGNOSIS AND TESTING

INTRODUCTION

When di agnosi ng the turn si gnal or hazard warn-

i ng ci rcui ts, remember that hi gh generator output

can burn out bul bs rapi dl y and repeatedl y. I f thi s i s a

probl em on the vehi cl e bei ng di agnosed, refer to

Group 8C - Chargi ng System for further di agnosi s of

a possi bl e generator overchargi ng condi ti on.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

TURN SIGNAL AND HAZARD WARNING SYSTEMS

For ci rcui t descri pti ons and di agrams, refer to

8W-52 - Turn Si gnal s i n Group 8W - Wi ri ng Di a-

grams.

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Turn the i gni ti on swi tch to the On posi ti on.

Actuate the turn si gnal l ever or the hazard warni ng

button. Observe the turn si gnal i ndi cator l amp(s) i n

the i nstrument cl uster. I f the fl ash rate i s very hi gh,

check for a turn si gnal bul b that i s not l i t or i s very

di ml y l i t. Repai r the ci rcui ts to that l amp or repl ace

the faul ty bul b, as requi red. Test the operati on of the

turn si gnal and hazard warni ng systems agai n. I f the

turn si gnal i ndi cator(s) fai l to l i ght, go to Step 2.

(2) Turn the i gni ti on swi tch to the Off posi ti on.

Check the turn si gnal fuse i n the juncti on bl ock

and/or the hazard warni ng fuse i n the Power Di stri -

buti on Center (PDC). I f OK, go to Step 3. I f not OK,

repai r the shorted ci rcui t or component as requi red

and repl ace the faul ty fuse(s).

Fig. 2 Multi-Function Switch

ZJ TURN SIGNAL AND HAZARD WARNING SYSTEMS 8J - 3

DESCRIPTION AND OPERATION (Continued)

(3) Turn the i gni ti on swi tch to the On posi ti on to

check for battery vol tage at the turn si gnal fuse i n

the juncti on bl ock; or, l eave the i gni ti on swi tch i n the

Off posi ti on to check for battery vol tage at the haz-

ard warni ng fuse i n the PDC. I f OK, go to Step 4. I f

not OK, repai r the open ci rcui t as requi red.

(4) Turn the i gni ti on swi tch to the Off posi ti on.

Di sconnect and i sol ate the battery negati ve cabl e.

Unpl ug the combi nati on fl asher from the juncti on

bl ock and repl ace i t wi th a known good uni t. Connect

the battery negati ve cabl e. Test the operati on of the

turn si gnal and hazard warni ng systems. I f OK, di s-

card the faul ty combi nati on fl asher. I f not OK,

remove the test fl asher and go to Step 5.

(5) Turn the i gni ti on swi tch to the On posi ti on.

Check for battery vol tage at the fused i gni ti on swi tch

output ci rcui t cavi ty for the combi nati on fl asher i n the

juncti on bl ock. I f OK, go to Step 6. I f not OK, repai r the

open ci rcui t to the turn si gnal fuse as requi red.

(6) Turn the i gni ti on swi tch to the Off posi ti on.

Check for battery vol tage at the fused B(+) ci rcui t

cavi ty for the combi nati on fl asher i n the juncti on

bl ock. I f OK, go to Step 7. I f not OK, repai r the open

ci rcui t to the hazard warni ng fuse as requi red.

(7) Di sconnect and i sol ate the battery negati ve

cabl e. Check for conti nui ty between the ground ci r-

cui t cavi ty for the combi nati on fl asher i n the juncti on

bl ock and a good ground. There shoul d be conti nui ty.

I f OK, go to Step 8. I f not OK, repai r the ci rcui t to

ground as requi red.

(8) Unpl ug the mul ti -functi on swi tch wi re harness

connector as descri bed i n thi s group. Check for con-

ti nui ty between the combi nati on fl asher hazard si g-

nal ci rcui t cavi ti es i n the juncti on bl ock and i n the

mul ti -functi on swi tch wi re harness connector. There

shoul d be conti nui ty. I f OK, go to Step 9. I f not OK,

repai r the open ci rcui t as requi red.

(9) Check for conti nui ty between the combi nati on

fl asher turn si gnal ci rcui t cavi ti es i n the juncti on

bl ock and i n the mul ti -functi on swi tch wi re harness

connector. There shoul d be conti nui ty. I f OK, test the

mul ti -functi on swi tch as descri bed i n thi s group. I f

not OK, repai r the open ci rcui t as requi red.

MULTI-FUNCTION SWITCH

Perform the di agnosi s of the hazard warni ng

and/or turn si gnal systems as descri bed i n thi s group

before testi ng the mul ti -functi on swi tch. For ci rcui t

descri pti ons and di agrams, refer to 8W-52 - Turn Si g-

nal s i n Group 8W - Wi ri ng Di agrams.

WARNING: ON VEHICLES EQUIPPED WITH AIRBAGS,

REFER TO GROUP 8M - PASSIVE RESTRAINT SYS-

TEMS BEFORE ATTEMPTING ANY STEERING WHEEL,

STEERING COLUMN, OR INSTRUMENT PANEL COM-

PONENT DIAGNOSIS OR SERVICE. FAILURE TO TAKE

THE PROPER PRECAUTIONS COULD RESULT IN

ACCIDENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

(1) Di sconnect and i sol ate the battery negati ve

cabl e. Unpl ug the mul ti -functi on swi tch wi re harness

connector.

(2) Usi ng an ohmmeter, perform the swi tch conti -

nui ty checks at the swi tch termi nal s as shown i n the

Mul ti -Functi on Swi tch Conti nui ty chart (Fi g. 3).

(3) I f the swi tch fai l s any of the conti nui ty checks,

repl ace the faul ty swi tch. I f the swi tch i s OK, repai r

the l i ghti ng ci rcui ts as requi red.

8J - 4 TURN SIGNAL AND HAZARD WARNING SYSTEMS ZJ

DIAGNOSIS AND TESTING (Continued)

REMOVAL AND INSTALLATION

COMBINATION FLASHER

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Di sconnect and i sol ate the battery negati ve

cabl e.

(2) Remove the fuse access panel by unsnappi ng i t

from the ri ght cowl si de tri m panel .

(3) Remove the push nut that secures the ri ght

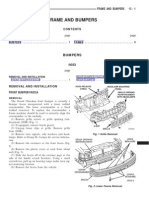

cowl si de tri m panel to the juncti on bl ock stud (Fi g.

4).

(4) Remove the two screws that secure the ri ght

cowl si de tri m panel to the ri ght front door openi ng

tri m.

(5) Remove the ri ght cowl si de tri m panel from the

ri ght cowl si de i nner panel .

(6) Unpl ug the combi nati on fl asher from the junc-

ti on bl ock.

(7) I nstal l the combi nati on fl asher by al i gni ng the

fl asher termi nal s wi th the cavi ti es i n the juncti on

bl ock and pushi ng the fl asher fi rml y i nto pl ace.

(8) Connect the battery negati ve cabl e.

(9) Test the fl asher operati on.

Fig. 3 Multi-Function Switch Continuity

Fig. 4 Right Cowl Side Trim Panel Remove/Install

ZJ TURN SIGNAL AND HAZARD WARNING SYSTEMS 8J - 5

(10) Rei nstal l the ri ght cowl si de tri m panel and

the fuse access panel .

MULTI-FUNCTION SWITCH

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

(1) Di sconnect and i sol ate the battery negati ve

cabl e.

(2) I f the vehi cl e i s so equi pped, remove the ti l t

steeri ng col umn l ever.

(3) Usi ng a tri m sti ck or another sui tabl e wi de

fl at-bl aded tool , pry gentl y around the peri meter

edges of both i nstrument panel swi tch pod bezel s to

rel ease the snap cl i p retai ners. Remove both bezel s

from the i nstrument panel .

(4) Remove the one screw on each si de of the steer-

i ng col umn that secures the upper edge of the steer-

i ng col umn openi ng cover/knee bl ocker to the

i nstrument panel (Fi g. 5).

(5) Remove the one screw that secures the steeri ng

col umn openi ng cover/knee bl ocker to the outboard

end of the i nstrument panel .

(6) Remove the four screws that secure the l ower

edge of the steeri ng col umn openi ng cover/knee

bl ocker to the l ower i nstrument panel rei nforcement.

(7) Usi ng a tri m sti ck or another sui tabl e wi de

fl at-bl aded tool , gentl y pry the edges of the steeri ng

col umn openi ng cover/knee bl ocker away from the

i nstrument panel at the snap cl i p retai ner l ocati ons

(Fi g. 5).

(8) Remove the steeri ng col umn openi ng cover/

knee bl ocker from the i nstrument panel .

(9) Remove both the upper and l ower shrouds from

the steeri ng col umn (Fi g. 6).

(10) Remove the l ower fi xed col umn shroud.

(11) Loosen the nuts that secure the steeri ng col -

umn upper mounti ng bracket to the dash panel steer-

i ng col umn support bracket studs. Lower the col umn

far enough to move the upper fi xed col umn shroud.

(12) Move the upper fi xed col umn shroud far

enough to access the rear of the mul ti -functi on

swi tch (Fi g. 7).

Fig. 5 Steering Column Opening Cover/Knee

Blocker Remove/Install

Fig. 6 Steering Column Shrouds Remove/Install -

Typical

Fig. 7 Multi-Function Switch Connector - Typical

8J - 6 TURN SIGNAL AND HAZARD WARNING SYSTEMS ZJ

REMOVAL AND INSTALLATION (Continued)

(13) Remove the tamper proof mounti ng screws (a

Snap On tamper proof torx bi t TTXR20B2 or equi va-

l ent i s requi red) that secure the mul ti -functi on

swi tch to the steeri ng col umn.

(14) Gentl y pul l the swi tch away from the steeri ng

col umn far enough to access and l oosen the mul ti -

functi on swi tch wi re harness connector screw. The

screw wi l l remai n i n the wi re harness connector.

(15) Unpl ug the wi re harness connector from the

mul ti -functi on swi tch.

(16) Reverse the removal procedures to i nstal l .

Ti ghten the fasteners as fol l ows:

Mul ti -functi on swi tch wi re harness connector

screw - 2 Nm (17 i n. l bs.)

Mul ti -functi on swi tch mounti ng screws - 2 Nm

(17 i n. l bs.)

Steeri ng col umn mounti ng nuts - 12 Nm (110

i n. l bs.).

ZJ TURN SIGNAL AND HAZARD WARNING SYSTEMS 8J - 7

REMOVAL AND INSTALLATION (Continued)

You might also like

- Reference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2From EverandReference Guide To Useful Electronic Circuits And Circuit Design Techniques - Part 2No ratings yet

- ZJ Starting Systems 8B - 1Document10 pagesZJ Starting Systems 8B - 1Dalton WiseNo ratings yet

- Guide to Turn Signal and Hazard Warning SystemsDocument8 pagesGuide to Turn Signal and Hazard Warning SystemsEinar OftebroNo ratings yet

- Electrical Correcting Elements in Automatic Control and Regulation CircuitsFrom EverandElectrical Correcting Elements in Automatic Control and Regulation CircuitsNo ratings yet

- ZJ Chime/Buzzer Warning Systems 8U - 1Document4 pagesZJ Chime/Buzzer Warning Systems 8U - 1Dalton WiseNo ratings yet

- Marine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersFrom EverandMarine Gyro-Compasses and Automatic Pilots: A Handbook for Merchant Navy OfficersRating: 5 out of 5 stars5/5 (2)

- ZJ Wiper and Washer Systems 8K - 1Document16 pagesZJ Wiper and Washer Systems 8K - 1Dalton WiseNo ratings yet

- Electrically Heated Systems: Defogger SystemDocument10 pagesElectrically Heated Systems: Defogger SystemDalton WiseNo ratings yet

- Automotive Electronic Diagnostics (Course 2)From EverandAutomotive Electronic Diagnostics (Course 2)Rating: 4 out of 5 stars4/5 (2)

- Jeep XJ 2000 08j Tunr Signal and Hazard Warning SystemsDocument8 pagesJeep XJ 2000 08j Tunr Signal and Hazard Warning SystemsStanislav AnastassovNo ratings yet

- Horn System Diagnosis and Testing GuideDocument4 pagesHorn System Diagnosis and Testing GuideDalton WiseNo ratings yet

- Rolls-Royce Engine De-Icing GuideDocument10 pagesRolls-Royce Engine De-Icing GuideJimyToasaNo ratings yet

- Grand Cherokee WJ 2000Document14 pagesGrand Cherokee WJ 2000العقار امين عيسىNo ratings yet

- Speed Control SystemDocument8 pagesSpeed Control SystemDalton WiseNo ratings yet

- Chime Buzzer Warning SystemsDocument4 pagesChime Buzzer Warning SystemsArt DoeNo ratings yet

- Chime Warning/Reminder System: Description and Operation Headlamps Left OnDocument2 pagesChime Warning/Reminder System: Description and Operation Headlamps Left OnRoberto VazquezNo ratings yet

- ProtectionDocument79 pagesProtectionNishant Anthwal100% (1)

- Testing and AdjustingDocument55 pagesTesting and Adjustingahmad sulaimanNo ratings yet

- Passsive Restraint Systems Guide with Airbag Component DescriptionsDocument12 pagesPasssive Restraint Systems Guide with Airbag Component DescriptionsDalton WiseNo ratings yet

- ZG Turn Signal and Hazard Warning Systems 8J - 1Document6 pagesZG Turn Signal and Hazard Warning Systems 8J - 1ensmartisNo ratings yet

- Nikon Nikkormat Ft2 ColorDocument0 pagesNikon Nikkormat Ft2 ColorpnimannNo ratings yet

- MAGNAVALVE Mod ACDocument25 pagesMAGNAVALVE Mod ACdahora13No ratings yet

- Electrical Input ComponentsDocument13 pagesElectrical Input ComponentshassanNo ratings yet

- Mine Hoist Control Systems Safety FeaturesDocument14 pagesMine Hoist Control Systems Safety FeaturesMarco A. Lara CarocaNo ratings yet

- PSDocument19 pagesPStomallor101No ratings yet

- Design and Construction of 20 K VA Automatic Voltage Stabilizer Control SystemDocument11 pagesDesign and Construction of 20 K VA Automatic Voltage Stabilizer Control SystemNimeshNo ratings yet

- TCU (DC5 - A/T) : 1) Start Motor, Tgs Lever, Can LineDocument22 pagesTCU (DC5 - A/T) : 1) Start Motor, Tgs Lever, Can LineВячеслав ГлушакNo ratings yet

- Chrysler Dakota Part14Document4 pagesChrysler Dakota Part14Sašo Brunšek-BrunoNo ratings yet

- ZJ Ignition System 8D - 1Document26 pagesZJ Ignition System 8D - 1Dalton WiseNo ratings yet

- 98DN - 8B Starting SystemsDocument8 pages98DN - 8B Starting SystemsylescorNo ratings yet

- TJ Starting Systems 8B - 1Document10 pagesTJ Starting Systems 8B - 1Art DoeNo ratings yet

- Transmission 950gDocument17 pagesTransmission 950gAbi JithNo ratings yet

- 93ZJ Secc 8J Turn Signals and Hazard Warning FlashesDocument4 pages93ZJ Secc 8J Turn Signals and Hazard Warning Flasheshelgith74No ratings yet

- Haas AlarmsDocument46 pagesHaas AlarmsKar GayeeNo ratings yet

- WJ - 00 - 08B - Starting SystemDocument12 pagesWJ - 00 - 08B - Starting SystemCesar BartzNo ratings yet

- PID Controller - WikipediaDocument41 pagesPID Controller - WikipediaHaroon Mohamed MorshedNo ratings yet

- ZG Starting Systems 8B - 1Document14 pagesZG Starting Systems 8B - 1ensmartisNo ratings yet

- Toyota p1222Document5 pagesToyota p1222esquisof71% (7)

- Student'S Corner (/Blog/Studentscorner) E-NewslettersubscriptionDocument11 pagesStudent'S Corner (/Blog/Studentscorner) E-NewslettersubscriptionThirumalNo ratings yet

- Install Cruise Control T4Document9 pagesInstall Cruise Control T4daveyp2001100% (1)

- Starting System Guide for Complete Diagnosis and RepairDocument14 pagesStarting System Guide for Complete Diagnosis and RepairLiliana Rebeca Santos santosNo ratings yet

- 1999 Jeep TJ Wrangler Service Manual - 08. Electrical SystemsDocument434 pages1999 Jeep TJ Wrangler Service Manual - 08. Electrical Systemsbfranklin3390% (10)

- General Technical Information on Chrysler TorqueFlite TransmissionsDocument80 pagesGeneral Technical Information on Chrysler TorqueFlite TransmissionsTodd Palmer80% (5)

- Turn Signals and Hazard Warning FlasherDocument8 pagesTurn Signals and Hazard Warning FlasherChristian MartinezNo ratings yet

- Clarke Mechanical Engine Controller Alarm Verification ProcedureDocument4 pagesClarke Mechanical Engine Controller Alarm Verification ProcedureChanat MeonsiNo ratings yet

- Operation Manual for Mode 4/Mode S Test SystemDocument4 pagesOperation Manual for Mode 4/Mode S Test SystemLuca BianchiNo ratings yet

- Protection and Interlocking Scheme of MV Switchgear: Murtaza Hussain Dy, MGR, Switchgear Engineering DivDocument103 pagesProtection and Interlocking Scheme of MV Switchgear: Murtaza Hussain Dy, MGR, Switchgear Engineering DivgopisettyNo ratings yet

- Beko Dfs1500 Dishwasher - Functional Test & Eeprom ResetDocument2 pagesBeko Dfs1500 Dishwasher - Functional Test & Eeprom ResetGoran Pantic100% (1)

- Printercarriage ArduinoDocument7 pagesPrintercarriage ArduinoMoineau011No ratings yet

- Ace WriteupDocument32 pagesAce WriteupVatsal GalaNo ratings yet

- Advanced Kit Upgrade FC New Version Manul-EnglishDocument31 pagesAdvanced Kit Upgrade FC New Version Manul-EnglishGabriel De GregorioNo ratings yet

- Lab Psim SCRDocument3 pagesLab Psim SCRNoah Tiago De GutierrezNo ratings yet

- Transmission Pressures - Test and AdjustDocument8 pagesTransmission Pressures - Test and Adjustjuankielec100% (3)

- AT2000PCS User GuideDocument18 pagesAT2000PCS User GuideShadi MuhammedNo ratings yet

- Safety Relay Series UE 45-3 S 1: 6 Maintenance 5 CommissioningDocument4 pagesSafety Relay Series UE 45-3 S 1: 6 Maintenance 5 Commissioningleomar_bNo ratings yet

- Eq CKT Power System PlantDocument32 pagesEq CKT Power System PlantBalan PalaniappanNo ratings yet

- 846Document18 pages846cleberNo ratings yet

- TEXT Information Energy Control SystemsDocument6 pagesTEXT Information Energy Control SystemsNick CraddockNo ratings yet

- Chrysler Corporation: Service Manual Supplement 1998 Grand CherokeeDocument4 pagesChrysler Corporation: Service Manual Supplement 1998 Grand CherokeeDalton WiseNo ratings yet

- Ezg 14Document66 pagesEzg 14Dalton WiseNo ratings yet

- Ezg InaDocument2 pagesEzg InaDalton WiseNo ratings yet

- Ezg inDocument8 pagesEzg inDalton WiseNo ratings yet

- Ezg 13Document12 pagesEzg 13Dalton WiseNo ratings yet

- Ezg 21aDocument14 pagesEzg 21aDalton WiseNo ratings yet

- Ezg 24aDocument12 pagesEzg 24aDalton WiseNo ratings yet

- Ezg 25aDocument8 pagesEzg 25aDalton WiseNo ratings yet

- Ezg 25Document20 pagesEzg 25Dalton WiseNo ratings yet

- Transmission and Transfer Case Guide for 42/44RE Automatic and NV242/249 Transfer CasesDocument296 pagesTransmission and Transfer Case Guide for 42/44RE Automatic and NV242/249 Transfer CasesDalton WiseNo ratings yet

- Ezg 23Document54 pagesEzg 23Dalton WiseNo ratings yet

- ZG Exhaust System and Intake Manifold 11 - 1Document4 pagesZG Exhaust System and Intake Manifold 11 - 1Dalton WiseNo ratings yet

- Ezg 24Document54 pagesEzg 24Dalton WiseNo ratings yet

- Ezg 22Document10 pagesEzg 22Dalton WiseNo ratings yet

- Speed Proportional Steering System GuideDocument6 pagesSpeed Proportional Steering System GuideDalton WiseNo ratings yet

- Ezg 19Document26 pagesEzg 19Dalton WiseNo ratings yet

- Ezg 8wDocument488 pagesEzg 8wDalton WiseNo ratings yet

- Ezg 14aDocument40 pagesEzg 14aDalton WiseNo ratings yet

- Ezg 8vDocument10 pagesEzg 8vDalton WiseNo ratings yet

- Ezg 9aDocument48 pagesEzg 9aDalton WiseNo ratings yet

- ZJ Exhaust System and Intake Manifold 11 - 1Document10 pagesZJ Exhaust System and Intake Manifold 11 - 1Dalton WiseNo ratings yet

- Ezg 9Document120 pagesEzg 9Dalton WiseNo ratings yet

- Power Mirror SystemsDocument8 pagesPower Mirror SystemsDalton WiseNo ratings yet

- ZJ Power Seat Systems 8R - 1Document8 pagesZJ Power Seat Systems 8R - 1Dalton WiseNo ratings yet

- ZJ Power Window Systems 8S - 1Document8 pagesZJ Power Window Systems 8S - 1Dalton WiseNo ratings yet

- Ezg 8qaDocument12 pagesEzg 8qaDalton WiseNo ratings yet

- ZJ Power Lock Systems 8P - 1Document8 pagesZJ Power Lock Systems 8P - 1Dalton WiseNo ratings yet

- ZJ Vehicle Theft/Security Systems 8Q - 1Document10 pagesZJ Vehicle Theft/Security Systems 8Q - 1Dalton WiseNo ratings yet

- MS C A Roofed Skeleton BOQDocument2 pagesMS C A Roofed Skeleton BOQBrighton MUZAHURANo ratings yet

- Liquefaction of Silty SoilsDocument2 pagesLiquefaction of Silty SoilsvishwanathzNo ratings yet

- Get mailbox quotas and usageDocument4 pagesGet mailbox quotas and usagecopoz_copozNo ratings yet

- Structural Behaviour of Cold-Formed Thin-Walled Short Steel Channel Columns at Elevated Temperatures. Part 2 Design Calculations and Numerical AnDocument2 pagesStructural Behaviour of Cold-Formed Thin-Walled Short Steel Channel Columns at Elevated Temperatures. Part 2 Design Calculations and Numerical AnReaditReaditNo ratings yet

- BCA - Concrete Carpark RefurbishmentDocument104 pagesBCA - Concrete Carpark RefurbishmenthemendraengNo ratings yet

- PostProcessor Reference Help enDocument270 pagesPostProcessor Reference Help enHisham Hanafy100% (2)

- Three Storey Commercial BuildingDocument2 pagesThree Storey Commercial Buildingrichard romasantaNo ratings yet

- BLD-ELEC Standard Data For Electrical Items In BuildingsDocument115 pagesBLD-ELEC Standard Data For Electrical Items In BuildingsrokiahhassanNo ratings yet

- The Process and TheoryDocument3 pagesThe Process and TheoryAnand.5No ratings yet

- CC Marine 2013-14 Catalogue - SailingDocument8 pagesCC Marine 2013-14 Catalogue - SailingGregGGHNo ratings yet

- Certificate of Product Approval: TRIMO D.O.ODocument2 pagesCertificate of Product Approval: TRIMO D.O.Oprimoz1No ratings yet

- Enter 400 Bad Request Nginx/1.2.9Document9 pagesEnter 400 Bad Request Nginx/1.2.9Hadi BarakNo ratings yet

- Structural Pruning Guide for Strong, Safe TreesDocument8 pagesStructural Pruning Guide for Strong, Safe TreeswdarreNo ratings yet

- Bootstrapping Scrum and XP Under Crisis: Crisp AB, Sweden Henrik - Kniberg@crisp - Se, Reza - Farhang@crisp - SeDocument9 pagesBootstrapping Scrum and XP Under Crisis: Crisp AB, Sweden Henrik - Kniberg@crisp - Se, Reza - Farhang@crisp - SeateifNo ratings yet

- ISCOM2900 Series Product Description (Rel - 07) PDFDocument77 pagesISCOM2900 Series Product Description (Rel - 07) PDFJhovanny PasaranNo ratings yet

- Resume - Jeremy DeLaBruereDocument1 pageResume - Jeremy DeLaBruerejeremyd82No ratings yet

- BoQ GRP Pipe Contructor 20180918Document8 pagesBoQ GRP Pipe Contructor 20180918Mohammad SyeduzzamanNo ratings yet

- Operation Manual Telairity SD HD Encoder Setup Manual-EDocument65 pagesOperation Manual Telairity SD HD Encoder Setup Manual-ETechne Phobos100% (2)

- Install Oracle 10g R2 in CentOS 6.2Document4 pagesInstall Oracle 10g R2 in CentOS 6.2sajal_0171No ratings yet

- Exercise No. 5Document7 pagesExercise No. 5Stanly Mark SantosNo ratings yet

- HTTPD Docs 2.0.63.enDocument691 pagesHTTPD Docs 2.0.63.enlbonilla30890% (1)

- RBD-17 09 2020Document137 pagesRBD-17 09 2020hishamndtNo ratings yet

- Sem 3okDocument31 pagesSem 3okVishakha PatelNo ratings yet

- 05 Ancient Indian Town Planning SystemDocument9 pages05 Ancient Indian Town Planning SystemMirunaalini SekarNo ratings yet

- BDD Bubble Diagram Analisa Organisasi RuangDocument1 pageBDD Bubble Diagram Analisa Organisasi Ruanganon_545295732No ratings yet

- Plucka 1450909082Document83 pagesPlucka 1450909082AymeeenNo ratings yet

- Proposed Studio: 11 Reno RD, Sandringham, Vic 3191Document11 pagesProposed Studio: 11 Reno RD, Sandringham, Vic 3191Engineer 1122No ratings yet

- Common Batch Job FailuresDocument6 pagesCommon Batch Job FailuresSiji SurendranNo ratings yet

- Adaptive cross-layer algorithms for multimedia transmission and energy management in wireless networksDocument92 pagesAdaptive cross-layer algorithms for multimedia transmission and energy management in wireless networksSamaWhiteNo ratings yet

- Issue14final PDFDocument51 pagesIssue14final PDFPOWER NewsNo ratings yet

- 100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiFrom Everand100 Micro Amigurumi: Crochet patterns and charts for tiny amigurumiRating: 5 out of 5 stars5/5 (2)

- Irene Strange's Curious Crochet Creatures: Amazing amigurumi patterns for wonderfully weird animalsFrom EverandIrene Strange's Curious Crochet Creatures: Amazing amigurumi patterns for wonderfully weird animalsRating: 5 out of 5 stars5/5 (2)

- Faster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestFrom EverandFaster: How a Jewish Driver, an American Heiress, and a Legendary Car Beat Hitler's BestRating: 4 out of 5 stars4/5 (28)

- The Martha Manual: How to Do (Almost) EverythingFrom EverandThe Martha Manual: How to Do (Almost) EverythingRating: 4 out of 5 stars4/5 (11)

- Coloring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesFrom EverandColoring Book for Adults & Grown Ups : An Easy & Quick Guide to Mastering Coloring for Stress Relieving Relaxation & Health Today!: The Stress Relieving Adult Coloring PagesRating: 2 out of 5 stars2/5 (12)

- Too Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreFrom EverandToo Cute Amigurumi: 30 Crochet Patterns for Adorable Animals, Playful Plants, Sweet Treats and MoreRating: 5 out of 5 stars5/5 (2)

- Crafts For Adults Basics - The Ultimate Starting Guide For All Craft Beginners To Master The Knowledge & Basics Of Different CraftsFrom EverandCrafts For Adults Basics - The Ultimate Starting Guide For All Craft Beginners To Master The Knowledge & Basics Of Different CraftsRating: 1.5 out of 5 stars1.5/5 (3)

- Across the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsFrom EverandAcross the Airless Wilds: The Lunar Rover and the Triumph of the Final Moon LandingsNo ratings yet

- Crochet Impkins: Over a million possible combinations! Yes, really!From EverandCrochet Impkins: Over a million possible combinations! Yes, really!Rating: 4.5 out of 5 stars4.5/5 (9)

- Handmade: Creative Focus in the Age of DistractionFrom EverandHandmade: Creative Focus in the Age of DistractionRating: 4.5 out of 5 stars4.5/5 (25)

- Martha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeFrom EverandMartha Stewart's Very Good Things: Clever Tips & Genius Ideas for an Easier, More Enjoyable LifeNo ratings yet

- Crochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastFrom EverandCrochet Pattern Books: The Ultimate Complete Guide to Learning How to Crochet FastRating: 5 out of 5 stars5/5 (1)

- A Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionFrom EverandA Life in Stitches: Knitting My Way Through Love, Loss, and Laughter - Tenth Anniversary EditionRating: 4.5 out of 5 stars4.5/5 (23)

- 100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesFrom Everand100 Crochet Tiles: Charts and patterns for crochet motifs inspired by decorative tilesNo ratings yet

- Knit a Box of Socks: 24 sock knitting patterns for your dream box of socksFrom EverandKnit a Box of Socks: 24 sock knitting patterns for your dream box of socksNo ratings yet

- Edward's Menagerie: The New Collection: 50 animal patterns to learn to crochetFrom EverandEdward's Menagerie: The New Collection: 50 animal patterns to learn to crochetRating: 3.5 out of 5 stars3.5/5 (4)

- Sri Yantra with Golden Ratio Triangle and InscriptionsFrom EverandSri Yantra with Golden Ratio Triangle and InscriptionsRating: 5 out of 5 stars5/5 (1)

- Crochet: Fun & Easy Patterns For BeginnersFrom EverandCrochet: Fun & Easy Patterns For BeginnersRating: 5 out of 5 stars5/5 (3)

- Sew Bags: The Practical Guide to Making Purses, Totes, Clutches & More; 13 Skill-Building ProjectsFrom EverandSew Bags: The Practical Guide to Making Purses, Totes, Clutches & More; 13 Skill-Building ProjectsRating: 5 out of 5 stars5/5 (3)

- Crochet Collage Garden: 100 patterns for crochet flowers, plants and petalsFrom EverandCrochet Collage Garden: 100 patterns for crochet flowers, plants and petalsRating: 5 out of 5 stars5/5 (1)

- The Basics of Corset Building: A Handbook for BeginnersFrom EverandThe Basics of Corset Building: A Handbook for BeginnersRating: 4.5 out of 5 stars4.5/5 (17)

- Knitting for Anarchists: The What, Why and How of KnittingFrom EverandKnitting for Anarchists: The What, Why and How of KnittingRating: 4 out of 5 stars4/5 (51)

- Crochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiFrom EverandCrochet Zodiac Dolls: Stitch the horoscope with astrological amigurumiRating: 4 out of 5 stars4/5 (3)

- Creative Stitches for Contemporary Embroidery: Visual Guide to 120 Essential Stitches for Stunning DesignsFrom EverandCreative Stitches for Contemporary Embroidery: Visual Guide to 120 Essential Stitches for Stunning DesignsRating: 4.5 out of 5 stars4.5/5 (2)

- Celestial Watercolor: Learn to Paint the Zodiac Constellations and Seasonal Night SkiesFrom EverandCelestial Watercolor: Learn to Paint the Zodiac Constellations and Seasonal Night SkiesRating: 3.5 out of 5 stars3.5/5 (6)

- Edward's Menagerie: Dogs: 50 canine crochet patternsFrom EverandEdward's Menagerie: Dogs: 50 canine crochet patternsRating: 3 out of 5 stars3/5 (5)

- Fabric Manipulation: 150 Creative Sewing TechniquesFrom EverandFabric Manipulation: 150 Creative Sewing TechniquesRating: 4.5 out of 5 stars4.5/5 (13)

- Sharpie Art Workshop: Techniques & Ideas for Transforming Your WorldFrom EverandSharpie Art Workshop: Techniques & Ideas for Transforming Your WorldRating: 3 out of 5 stars3/5 (16)

- Friends: The One with the Crochet: The Official Crochet Pattern BookFrom EverandFriends: The One with the Crochet: The Official Crochet Pattern BookRating: 5 out of 5 stars5/5 (1)