Professional Documents

Culture Documents

Equipo Hot Tap de 42 in

Uploaded by

Serch VillaOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Equipo Hot Tap de 42 in

Uploaded by

Serch VillaCopyright:

Available Formats

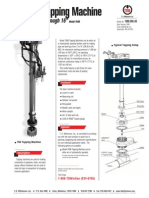

Model 660B Tapping Machines can be either

air or hydraulically operated and are used for

making pipe and tank taps from 3" to 12" (DN 80

to DN 300). Its maximum working pressure is

1,480 psi (100 bar) at 100F (38C). Its operating

temperature is -20F (-29C) to 700F (371C)

at 700 psi (48 bar) for intermittent service. Its

maximum continuous rating is 350F (177C) at

1,025 psi (70 bar).

This model features a split frame for lower

maintenance costs and ease of packing

replacement.

The basic machine includes:

Lower-in crank

Measuring rod

Retainer rod pusher

Ring gasket

Bleeder valve and nipple

Motor adapter

Set of bolts and nuts

LOCK-O-RING

bypass gauge

T. D. Williamson, Inc., is committed to providing

you with the exact product to assist you in

planning, budgeting and meeting the specifications

for your individual application needs. The

following options are available:

Model 660B Tapping Machine can be

either air or hydraulically operated with

optional dual drive.

* For design code options not listed and additional sizes,

consult your sales representative.

Description

Features

Options*

Boring Bar

Adapter

Cutter Holder

Cutter

Gasket

Pilot

SANDWICH

Valve

Gasket

Pipeline

STOPPLE

Fitting

or Tapping Fitting

Split Frame

Tapping machines are used for making

connections to pipelines, tanks, and plant

piping without shutdown and are used to

make hot taps in preparation for plugging

machine application.

Typical Tapping Setup

Toll Free

1-888-TDWmSon (839-6766)

Patented in the United States and in foreign countries.

ISO 9001 Certified

660 Tapping Machine

Bulletin No: 1000.005.03

Date: April 2011

Cross Indexing No: n/a

Supersedes: 1000.005.02 (02/10)

660 Tapping Machine

Sizes: 3- through 12-inch Model 660b

T.D. Williamson, Inc. P.O. Box 3409 Tulsa, Oklahoma 74101-3409 918-447-5100 Fax: 918-446-6327 www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / Copyright 2011. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

Hydraulic Operation Model

Boring Bar Travel 42" (1,067 mm)

Tank Taps* 3" through 12" (80-300 mm)

Pipe Taps* 3" through 12" (80-300 mm)

Max. Operating Pressure 1,480 psi (100 bar) at 100F (38C)

Max. Operating Temperature 700F (371C) at 700 psi (48 bar)**

Power Hydraulic or Air Motor

Feed Rate Standard .005" (.127 mm) per revolution/optional .003" (.076 mm) per revolution

Lower-In Crank 4-1/2 turns per inch (5.6 mm per turn)

Length without measuring rod 64-1/2" (1,638 mm)

Length with measuring rod 110-1/2" (2,087 mm)

Meets NACE specification MR0175-93

* See note 5 in "Recommended Power Options" Chart.

** For intermittent service only. Maximum continuous rating is 350F (177C) at 1,025 psi (70 bar).

Standard Feed (.005"/Revolution) Slow Feed (.003"/Revolution)

Lbs. Kg. Part Number Part Number

Tapping Machine 405 184 05-2179-0000 05-2177-0000

Air Motor Drive Assembly 40 18 05-2326-0000 05-2326-0000

Skid* 179 81 05-0019-0000 05-0019-0000

TOTAL WEIGHT 624 283

* If skid is not purchased with the tapping machine, there will be a special crating charge; consult factory.

Standard Feed (.005"/Revolution) Slow Feed (.003"/Revolution)

Lbs. Kg. Part Number Part Number

Tapping Machine 405 184 05-2179-0000 05-2177-0000

Single Drive Unit & Control Valve 45 20 05-2508-0000 05-2508-0000

Dual Drive Unit & Control Valve 100 45 05-2503-0000 05-2503-0000

Skid* 179 81 05-0019-0000 05-0019-0000

Power Unit

Hydraulic Power Unit and 50' Hose w/Oil

Manual Start/Diesel 585 266 05-2017-0000 05-2017-0000

Electric Start/Diesel 600 272 05-2330-0000 05-2330-0000

Manual Start/Gas 533 242 05-2351-0000 05-2351-0000

Electric Start/Gas 550 250 05-2354-0000 05-2354-0000

* If skid is not purchased with the tapping machine, there will be a special crating charge; consult factory

Operating Specifications

Air Operation Model

Gasoline Power Unit

Diesel Power Unit

660 Tapping Machine Model 660b

T.D. Williamson, Inc. P.O. Box 3409 Tulsa, Oklahoma 74101-3409 918-447-5100 Fax: 918-446-6327 www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / Copyright 2011. All rights reserved T.D. Williamson, Inc. / Printed in USA

1000.005.03 - p2

Standard Adapters for Gate Valves

ASME Class 150 RF Flange ASME Class 300 RF Flange ASME Class 600 RF Flange

Inches mm Lbs. Kg. Part Number Lbs. Kg. Part Number Lbs. Kg. Part Number

3 80 54 24 06-6102-0003 55 25 06-6103-0003 57 26 06-6105-0003

4 100 57 26 06-6102-0004* 65 29 06-6103-0004 80 36 06-5091-0004

6 150 70 32 06-5088-0006* 95 43 06-6103-0006 146 66 06-5091-0006

8 200 85 39 06-6102-0008* 100 45 06-6103-0008 150 68 06-6105-0008

10 250 115 42 06-6102-0010* 155 70 06-6103-0010 200 91 06-6105-0010

12 300 170 77 06-6102-0012* 215 98 06-6103-0012 315 143 06-6105-0012

* Will work on SHORTCUTT

Valves, Bulletin 2010.000.00

Adapters for SANDWICH

Valves and Ball Valves

ASME Class 300 RF Flange ASME Class 600 RF Flange

Inches mm Lbs. Kg. Part Number Lbs. Kg. Part Number

4 100 65 29 06-6103-0004 76 34 06-5091-0004

6 150 95 43 06-6103-0006 130 59 06-5091-0006

8 200 100 45 06-5089-0008 265 91 06-5091-0008

10 250 155 70 06-5089-0010 265 120 06-5091-0010

12 250 215 97 06-5089-0012 384 174 06-5091-0012

Split Frame Feature

The frame assembly is split at the lower end,

so that the lower section can be unbolted and

removed over the drive tube and boring bar

and the packing replaced.

T.D. Williamson, Inc. P.O. Box 3409 Tulsa, Oklahoma 74101-3409 918-447-5100 Fax: 918-446-6327 www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / Copyright 2011. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

660 Tapping Machine Model 660b

1000.005.03 - p3

Tap Size Cutter Holders LOCK-O-RING

Plug Holders

Inches mm Lbs. Kg. Part Number Lbs. Kg. Part Number

3 & 4 80 & 100 2.5 1 05-0054-0001 -- -- --

6-12 150-300 8 4 05-0054-0002 -- -- --

4-16 100-400 -- -- -- 3.5 2 05-0075-0000

Cutter Holders & LOCK-O-RING

Plug Holders

STOPPLE

Cutters & Pilot Drills

SHORTSTOPP

Cutters & Pilot Drills

Standard Cutters & Pilot Drills

T.D. Williamson, Inc. P.O. Box 3409 Tulsa, Oklahoma 74101-3409 918-447-5100 Fax: 918-446-6327 www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / Copyright 2011. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

660 Tapping Machine Model 660b

Inches mm Inches mm Wt./Lbs. Wt./Kg. Part Number Wt./Lbs. Wt./Kg. Part Number Part Number

3 80 2-7/16 67 1 0.5 05-0001-0001 1/2 0.2 05-0293-0001 00-1424-0012

4 100 3-7/16 87.3 2 0.9 05-0328-0004 1/2 0.2 05-0293-0008 00-1424-0012

6 150 5-15/32 138.9 5-3/4 3 05-0328-0006 2 0.9 05-0293-0002 00-1424-0003

8 200 7-5/16 185.8 14-1/2 7 05-0328-0008 2 0.9 05-0293-0003 00-1424-0003

10 250 9-1/2 241.3 22-1/2 10 05-0328-0010 2 0.9 05-0293-0004 00-1424-0003

12 300 11-1/2 292.1 36 16 05-0389-0012 2-1/2 1.0 05-0293-0005 00-1424-0008

4 100 3-7/8 98.4 3-1/4 1 05-0330-0004 1/2 0.2 05-0293-0008 00-1424-0012

6 150 5-7/8 149.2 8-3/4 3 05-0330-0006 2 0.9 05-0293-0002 00-1424-0003

8 200 7-3/4 196.9 20 9 05-0330-0008 2 0.9 05-0293-0003 00-1424-0003

10 250 9-3/4 247.7 23 10 05-0330-0010 2 0.9 05-0293-0004 00-1424-0003

12 300 11-3/4 298.5 40 18 05-0330-0012 2-1/2 1.0 05-0293-0005 00-1424-0003

4 100 3-15/16 100 3-1/2 2 05-0329-0004 1/2 0.2 05-0293-0008 00-1424-0012

6 150 5-15/16 150.8 9 4 05-0329-0006 2 0.9 05-0293-0002 00-1424-0003

8 200 7-7/8 200 16 7 05-0329-0008 2 0.9 05-0293-0003 00-1424-0003

10 250 9-7/8 200.8 27 12 05-0329-0010 2 0.9 05-0293-0004 00-1424-0003

12 300 11-13/16 300.1 40-1/2 18 05-0388-0012 2-1/2 1 05-0293-0005 00-1424-0008

1000.005.03 - p4

Recommended Power Options for Tapping Size On Size

Cutter Size

Feed Rate 3" 4" 6" 8" 10" 12"

(0.005"/REV) AIR/HYD A A A A A A

B B B B B

C C C C

D D D D

E E E E

F F F F

(0.005"/REV) DUAL HYD A A A A A A

B B B B B B

C C C C C C

D D D D D D

E E E E E E

F F F F F F

(0.003"/REV) AIR/HYD A A A A A A

B B B B B B

C C C C C

D D D D D

E E E E E

F F F F

(0.003"/REV) DUAL HYD A A A A A A

B B B B B B

C C C C C C

D D D D D D

E E E E E E

F F F F F F

Notes

1. The following letters represent:

A = Carbon steel pipe SMYS (Specified Minimum Yield Strength) 30,000 to 50,000 psi maximum, tensile strength of 70,000 psi.

B = Carbon steel pipe SMYS 50,000 to 70,000 psi maximum, tensile strength of 90,000 psi.

C = Cast iron pipe. Cutting characteristics vary widely; hard to predict.

D = Chrome-moly, high temperature, steel pipe.

E = 300 series stainless steel pipe.

F = Flat plate cuts using special cutters on the materials listed above (refer to Notes 3 and 4). Pilot drill must be through before cutter tooth engages material.

2. The dual hydraulic drive features an ability to shift from high speed/low torque to low speed/high torque when tapping the larger diameter pipes and/or the more difficult cutting steels.

3. The table for selecting power options (above) is based on the latest TDW designs and past experience. The data should be used as a guideline. There have been, and will be, conditions

which will not strictly follow the guidelines.

4. Special cutters are available for flat plates, stainless steel pipe, cast iron pipe and other special conditions.

5. When tapping a larger pipe or tank, the cutter will sometimes go through the flat-plate condition. For example, all teeth are cutting at the same time. This is the most power-consuming

condition possible and special cutters may be required. Considering cutter size, diameter of cylinder, wall thickness, feed rates, different materials of construction, etc., the possibilities

are infinite. The following table gives some examples of flat-plate conditions. Any pipe or tank with wall thicknesses greater than those shown will also be considered flat plate.

Cutter Size Nom. Pipe x Wall Nom. Pipe x Wall Nom. Pipe x Wall

3" 4" x .359" 6" x .232" 8" x .176

4" 6" x .481 8" x .357 10" x .282

6" 10" x .748" 12" x .616" 14" x .556

8" 18" x .776" 20" x .692" 24" x .571

10" 24" x .980" 30" x .772" 48" x .475"

12" 36" x .943" 48" x .699" 60" x .556

14" 48" x .862" 60" x .685" 72" x .569"

16" 56" x .980" 60" x .913 72" x .757"

T.D. Williamson, Inc. P.O. Box 3409 Tulsa, Oklahoma 74101-3409 918-447-5100 Fax: 918-446-6327 www.tdwilliamson.com

Data subject to change without notice. / Dimensions not for construction unless certified. / Registered trademark of T.D. Williamson, Inc. in the United States and foreign countries / TM Trademark of T.D. Williamson, Inc. in the United States and foreign countries / Copyright 2011. All rights reserved T.D. Williamson, Inc. / Printed in USA

Dimensions and Part Numbers

660 Tapping Machine Model 660b

1000.005.03 - p5

You might also like

- 760 Tapping MachineDocument5 pages760 Tapping MachineLuis Frade San MiguelNo ratings yet

- Tee Split TDWDocument4 pagesTee Split TDWmaoreales100% (1)

- Efficient Modular Cooling Towers for Air Conditioning and Industrial ApplicationsDocument12 pagesEfficient Modular Cooling Towers for Air Conditioning and Industrial ApplicationsnkhhhNo ratings yet

- LOCK-O-RING Flanges and PlugsDocument6 pagesLOCK-O-RING Flanges and Plugsrafael_camacho_15No ratings yet

- T101 Drilling MachineDocument4 pagesT101 Drilling MachineRemmy Torres VegaNo ratings yet

- T101 Drilling MachineDocument4 pagesT101 Drilling MachineFranklin Avendaño ArapaNo ratings yet

- T101 Drilling Machine BrochureDocument4 pagesT101 Drilling Machine BrochureRicardo OrtegaNo ratings yet

- Thread - o - Ring - Fittings (TD Williamson) PDFDocument4 pagesThread - o - Ring - Fittings (TD Williamson) PDFRahul RaghukumarNo ratings yet

- Duff-Norton Actuator Product GuideDocument12 pagesDuff-Norton Actuator Product GuideDeepu RockzzNo ratings yet

- Coupling PDFDocument7 pagesCoupling PDFAnkur GaurNo ratings yet

- Steel Shank Turning/Threading Gang Type Tooling SpecificationsDocument23 pagesSteel Shank Turning/Threading Gang Type Tooling SpecificationsCojocaru LucianNo ratings yet

- M Catalogue 2008Document9 pagesM Catalogue 2008stan876No ratings yet

- Compact CBP Motors Powerful OpportunitiesDocument24 pagesCompact CBP Motors Powerful Opportunitiesidontlikeebooks100% (1)

- Zorra Yale MPB 040 AcDocument13 pagesZorra Yale MPB 040 Accolive1No ratings yet

- Maintenance Arpex enDocument39 pagesMaintenance Arpex enPatrick BaridonNo ratings yet

- Shimpo Able EVB BrochureDocument4 pagesShimpo Able EVB BrochureElectromateNo ratings yet

- List of Equipment Available For Disposal 1 / Factory Available For DismantlingDocument58 pagesList of Equipment Available For Disposal 1 / Factory Available For DismantlingRaghu R NaikNo ratings yet

- Series 774DCDA Specification SheetDocument2 pagesSeries 774DCDA Specification SheetWattsNo ratings yet

- SELF FEED Rail DrillDocument20 pagesSELF FEED Rail DrillKarlos 6:No ratings yet

- Catalogo Valvula Compuerta NewcoDocument92 pagesCatalogo Valvula Compuerta NewcoAlfredo Medina100% (1)

- Scule Pentru Abkant Trumpf Trumabend Si Trubend Si Compatibile - SMDocument76 pagesScule Pentru Abkant Trumpf Trumabend Si Trubend Si Compatibile - SMMihaiNo ratings yet

- 8 t2 SC SeriesDocument16 pages8 t2 SC SeriesAntony VeNo ratings yet

- Turbine Blade MachiningDocument36 pagesTurbine Blade Machiningyh1.yuNo ratings yet

- CopperalloybrakeDocument4 pagesCopperalloybrakeReinaldo Side JuniorNo ratings yet

- Kit Cerramiento de Camisa en DiqueDocument4 pagesKit Cerramiento de Camisa en Diqueheldermanuel100No ratings yet

- Anhui Lai Fu CNC Machine Tool Co., Ltd. YL32 Series Four-Column Deep Drawing Hydraulic PressesDocument4 pagesAnhui Lai Fu CNC Machine Tool Co., Ltd. YL32 Series Four-Column Deep Drawing Hydraulic PressesBALANo ratings yet

- Shimpo Able VRS BrochureDocument4 pagesShimpo Able VRS BrochureElectromateNo ratings yet

- Rohm - Spindles and ChucksDocument12 pagesRohm - Spindles and ChucksGatyo GatevNo ratings yet

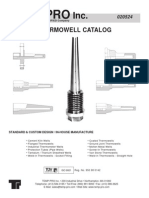

- Thermowell CatalogDocument24 pagesThermowell CatalogMANTCRUZNo ratings yet

- Sandwich Valves: Sizes: 4-Inch and LargerDocument4 pagesSandwich Valves: Sizes: 4-Inch and LargerAndrea Ferrer100% (1)

- 10 SEER air conditioner specsDocument4 pages10 SEER air conditioner specsOscar Sanchez Velasquez0% (1)

- BevelDocument4 pagesBevelDennis OmilaNo ratings yet

- Pernos Huck C50LDocument4 pagesPernos Huck C50LAngelina Santiago JimenezNo ratings yet

- P08-1021-I-MN-1044 Rev 1 Simark - Flanged Turbine ManualDocument12 pagesP08-1021-I-MN-1044 Rev 1 Simark - Flanged Turbine ManualrehanNo ratings yet

- Tooling For Composites and Aerospace Materials: Guhring Coating and Reconditioning Services The Tool CompanyDocument4 pagesTooling For Composites and Aerospace Materials: Guhring Coating and Reconditioning Services The Tool Companyjavier_mor69No ratings yet

- LTG - VSR Ru MS e - 450 60Document18 pagesLTG - VSR Ru MS e - 450 60Ahsan JavedNo ratings yet

- AmeritoolBroch Aug21Document12 pagesAmeritoolBroch Aug21hiscoke69No ratings yet

- Goodwin BFRDocument2 pagesGoodwin BFRHamdzan As'atNo ratings yet

- March Pump Manual 7 Plastic 0155 0046 1000 Rev32Document2 pagesMarch Pump Manual 7 Plastic 0155 0046 1000 Rev32Asima Jaya TamaNo ratings yet

- Model BKR Premium Cement Retainer - Mechanical SetDocument1 pageModel BKR Premium Cement Retainer - Mechanical SetChandra FadhillahNo ratings yet

- Model BKR Premium Cement Retainer Mechanical SetDocument1 pageModel BKR Premium Cement Retainer Mechanical SetCarlos HolguinNo ratings yet

- Aluminium Motors PDFDocument8 pagesAluminium Motors PDFelrajilNo ratings yet

- clfd1292 - 1208Document8 pagesclfd1292 - 1208ggace82No ratings yet

- Torque Systems MDM Stainless Steel Series Product GuideDocument4 pagesTorque Systems MDM Stainless Steel Series Product GuideElectromateNo ratings yet

- Submittal Data Information Model 0013 Cartridge CirculatorDocument1 pageSubmittal Data Information Model 0013 Cartridge Circulatorsas999333No ratings yet

- 02 805Document8 pages02 805Fernando SabinoNo ratings yet

- Launchers & ReceiversDocument7 pagesLaunchers & Receiverssagar1503100% (1)

- T Ces Series PDFDocument12 pagesT Ces Series PDFDaniel InostrozaNo ratings yet

- Elastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsDocument6 pagesElastomer Bellows Seal: Applications Non-Concurrent Operating ConditionsAdhie_ginthinkNo ratings yet

- Sds Eng PDFDocument8 pagesSds Eng PDFdaviko313No ratings yet

- Robotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icDocument8 pagesRobotmount: Specified Internationally For The New Arc Welding Robot ARC Mate 100icAsrul Arashi IrdianaNo ratings yet

- Ventilator Centrifugal de Acoperis Tip Turela CHT CVTDocument6 pagesVentilator Centrifugal de Acoperis Tip Turela CHT CVTIuliana TodoranNo ratings yet

- Ot/Otn/Ots: Class K-5Document3 pagesOt/Otn/Ots: Class K-5Ray SilverioNo ratings yet

- Thread o Ring - Fittings (T O R)Document2 pagesThread o Ring - Fittings (T O R)Jimmy ChanNo ratings yet

- Torque Systems MDM-5000 Product GuideDocument4 pagesTorque Systems MDM-5000 Product GuideElectromateNo ratings yet

- Allison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyFrom EverandAllison Transmissions: How to Rebuild & Modify: How to Rebuild & ModifyRating: 5 out of 5 stars5/5 (1)

- Weld Like a Pro: Beginning to Advanced TechniquesFrom EverandWeld Like a Pro: Beginning to Advanced TechniquesRating: 4.5 out of 5 stars4.5/5 (6)

- GM Automatic Overdrive Transmission Builder's and Swapper's GuideFrom EverandGM Automatic Overdrive Transmission Builder's and Swapper's GuideRating: 4.5 out of 5 stars4.5/5 (8)

- How to Rebuild & Modify Rochester Quadrajet CarburetorsFrom EverandHow to Rebuild & Modify Rochester Quadrajet CarburetorsRating: 5 out of 5 stars5/5 (2)

- Carson Realty Company (A) : The Crimson Press Curriculum Center The Crimson Group, IncDocument1 pageCarson Realty Company (A) : The Crimson Press Curriculum Center The Crimson Group, IncAyaz Ul Haq0% (1)

- G..26160B.tension Carriage.508.512Document3 pagesG..26160B.tension Carriage.508.512Jean ChungNo ratings yet

- RHOWPA Pole Mount: Installation GuideDocument2 pagesRHOWPA Pole Mount: Installation GuideunstrainNo ratings yet

- 046 Death and The Kings HorsemenDocument2 pages046 Death and The Kings HorsemenMisajNo ratings yet

- Copyright FormDocument6 pagesCopyright FormAnonymous xYT3fvQINo ratings yet

- Patent: Law Made Simple Intellectual Property Law Note 3 0f 7 NotesDocument44 pagesPatent: Law Made Simple Intellectual Property Law Note 3 0f 7 Notesmusbri mohamed100% (1)

- Wish Upon A DreamDocument32 pagesWish Upon A DreamPaul100% (1)

- Gopal Swaroop V Krishna Murari 2010Document8 pagesGopal Swaroop V Krishna Murari 2010samiaNo ratings yet

- Chord DecoratingDocument2 pagesChord DecoratingDennis Wong100% (1)

- 0901 B 80380063 Ec 0Document2 pages0901 B 80380063 Ec 0Tuấn Anh ĐinhNo ratings yet

- April ShowersDocument3 pagesApril ShowersGalatea KneathNo ratings yet

- University of Cambridge International Examinations General Certificate of Education Ordinary LevelDocument4 pagesUniversity of Cambridge International Examinations General Certificate of Education Ordinary Levelmstudy123456No ratings yet

- Brand Portfolio ManagementDocument10 pagesBrand Portfolio ManagementMaria GutzNo ratings yet

- ANSYS Polyflow Tutorial GuideDocument416 pagesANSYS Polyflow Tutorial Guidewoongs73No ratings yet

- Who Did It?: Christmas MysteryDocument13 pagesWho Did It?: Christmas MysteryBrittanyNo ratings yet

- Legal Issues For News DatabasesDocument26 pagesLegal Issues For News DatabasesSeerat ChishtiNo ratings yet

- TEDu Card-AppendixDocument14 pagesTEDu Card-AppendixJoemNo ratings yet

- Wendy's Revenge - Plagiarism Charge Against Rajiv Malhotra Is A Red HerringDocument7 pagesWendy's Revenge - Plagiarism Charge Against Rajiv Malhotra Is A Red HerringkhakhrammNo ratings yet

- Beat LicenseDocument3 pagesBeat LicenseCaleb EvansNo ratings yet

- Contents and Scope NEMA TC 6 + 8-2013Document6 pagesContents and Scope NEMA TC 6 + 8-2013cherif yahyaouiNo ratings yet

- 2-Way Wired IntercomDocument56 pages2-Way Wired IntercomVincent Korie100% (4)

- Ramadan Lantern Geo V2Document4 pagesRamadan Lantern Geo V2Little MuslimsNo ratings yet

- Dirtyline Studio-EULADocument1 pageDirtyline Studio-EULAjkjjkjkNo ratings yet

- What's in Her NameDocument11 pagesWhat's in Her NameshittyshitNo ratings yet

- OPC UA Part 3 - Address Space Model Release 1.04 SpecificationDocument112 pagesOPC UA Part 3 - Address Space Model Release 1.04 Specificationpapi charcaNo ratings yet

- AP400 AP400NPC v04 PDFDocument223 pagesAP400 AP400NPC v04 PDFPhotocopy Sửa Máy PhotocopyNo ratings yet

- Thermo Scientific Taq Dna Polymerase With KCL Buffer: DescriptionDocument3 pagesThermo Scientific Taq Dna Polymerase With KCL Buffer: DescriptionCHIRANJEEVINo ratings yet

- Comprehensive Reviewer On Appraiser Examjen PDFDocument110 pagesComprehensive Reviewer On Appraiser Examjen PDFDionico O. Payo Jr.No ratings yet

- Error eksamen blog fixDocument2 pagesError eksamen blog fixCharlotte SkråmestøNo ratings yet

- Pavane For A Dead Princess - RavelDocument1 pagePavane For A Dead Princess - RavelAnna von UrbansNo ratings yet