Professional Documents

Culture Documents

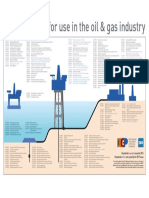

Well Testing Systems: Norsok Standard

Uploaded by

Boris ZaslichkoOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Well Testing Systems: Norsok Standard

Uploaded by

Boris ZaslichkoCopyright:

Available Formats

NORSOK STANDARD

SYSTEM REQUIREMENTS

WELL TESTING SYSTEMS

D-SR-007

Rev.1, J anuary 1996

Please note that whilst every effort has been made to ensure the accuracy of the NORSOK standards

neither OLF nor TBL or any of their members will assume liability for any use thereof.

Well testing systems D-SR-007

Rev. 1, J anuary 1996

NORSOK standard 1 of 38

CONTENTS

1 FOREWORD 2

2 SCOPE 2

3 NORMATIVE REFERENCES 2

4 DEFINITIONS AND ABBREVIATIONS 3

4.1 Definitions 3

4.2 Abbreviations 3

5 FUNCTIONAL REQUIREMENTS 3

5.1 General 3

5.2 Products/services 3

5.3 Equipment/schematic 4

5.4 Performance/output 5

5.5 Regularity 5

5.6 Process/ambient conditions 5

5.7 Operational requirements 5

5.8 Maintenance requirements 7

5.9 Isolation and sectioning 7

5.10 Layout requirements 7

5.11 Interface requirements 7

5.12 Commissioning requirements 7

6 INFORMATIVE REFERENCES 8

ANNEX A SERVICE DATA SHEETS 9

ANNEX B EQUIPMENT DATA SHEET 19

Well testing systems D-SR-007

Rev. 1, J anuary 1996

NORSOK standard 2 of 38

1 FOREWORD

NORSOK (The competitive standing of the Norwegian offshore sector) is the industry initiative to

add value, reduce cost and lead time and remove unnecessary activities in offshore field

developments and operations.

The NORSOK standards are developed by the Norwegian petroleum industry as a part of the

NORSOK initiative and are jointly issued by OLF (The Norwegian Oil Industry Association) and

TBL (The Federation of Norwegian Engineering Industries). NORSOK standards are administered

by NTS (Norwegian Technology Standards Institution).

The purpose of this industry standard is to replace the individual oil company specifications for use

in existing and future petroleum industry developments, subject to the individual company's review

and application.

The NORSOK standards make extensive references to international standards. Where relevant, the

contents of this standard will be used to provide input to the international standardisation process.

Subject to implementation into international standards, this NORSOK standard will be withdrawn.

2 SCOPE

This standard describes functional, performance and operational requirements for well testing

equipment and systems.

3 NORMATIVE REFERENCES

API Spec, 5CT Specification for casing and tubing

API RP 7G Recommended practice for drill stem design and operating limits

API Spec. 6A Specification for valves and wellhead equipment

API Spec. 14A Specification for sub surface safety valve equipment

API RP 14C Recommended practice for analysis, design, installation and

testing of basic surface safety systems on offshore production

platforms

API RP 14E Recommended practice for design and installation of offshore

production platform piping systems

API 17B Recommended practise for flexible pipes

API RP 44 Recommended practice for sampling petroleum reservoir fluids

API RP 520 Recommended practice for sizing, selection and installation of

pressure-relieving devices in refineries

API RP 521 Recommended practice for pressure-relieving and depressuring

systems

DnV Certification Note 2.7-1 Offshore freight containers. Design and certification

ASME Section VIII Div. 1 and 2 Rules for construction of pressure vessels

ANSI/ASME B31.3 Chemical plant and petroleum refinery piping

NACE MR-01-75 Sulphide stress cracking resistant metallic materials for oil field

equipment

Well testing systems D-SR-007

Rev. 1, J anuary 1996

NORSOK standard 3 of 38

4 DEFINITIONS AND ABBREVIATIONS

4.1 Definitions

Normative references Shall mean normative in the application of NORSOK standards.

Informative references Shall mean informative in the application of NORSOK standards.

Shall Shall is an absolute requirement which shall be followed strictly in order

to conform with the standard.

Should Should is a recommendation. Alternative solutions having the same

functionality and quality are acceptable.

May May indicates a course of action that is permissible within the limits of

the standard (a permission).

Can Can requirements are conditional and indicates a possibility open to the

user of the standard.

4.2 Abbreviations

None.

5 FUNCTIONAL REQUIREMENTS

5.1 General

SI units and Imperial units are used in this specification. SI units with imperial units in brackets

shall be used in all documentation.

5.2 Products/services

The well testing equipment is grouped in 5 categories:

5.2.1 Drill stem test tools

The downhole equipment shall be able to control test production of reservoir fluids into the test

tubing, alternatively injection of fluids from tubing into formation. It shall also provide means to

establish a permanent or closeable communication between tubing and annulus.

5.2.2 Landing string equipment

The landing string equipment shall constitute the safety elements in the test string enabling shutting

in the well stream and perform a controlled disconnect at sea floor level. It shall also provide means

to lubricate working tools into the test string.

5.2.3 Surface equipment

The surface equipment shall be able to receive high pressure well fluid, perform 3 phase separation

of the fluid and accurately measure the individual flow stream. Produced water and hydrocarbons

shall be disposed off without spill to sea.

5.2.4 Reservoir information acquisition

Shall perform acquisition of representative and accurate surface and downhole pressure and

temperature measurements during flow production testing of the well. Shall also acquire

representative bottom hole and/or surface samples for detailed analysis.

Well testing systems D-SR-007

Rev. 1, J anuary 1996

NORSOK standard 4 of 38

5.2.5 Test tubing

Shall provide a gastight mean to transport hydrocarbons to surface.

5.3 Equipment/schematic

5.3.1 Drill stem test tools

Packer of permanent or retrievable type.

Tester valve.

Circulating valves.

Slip joint.

Hydraulic jar.

Safety joint.

Auxiliary valves.

Integrated Downhole Data Acquisition Tool.

Subs and x-overs.

5.3.2 Surface equipment

Surface test tree.

Flexible flowline (for floaters).

Rigid flowline (for jack ups).

Flowline manifold/dataheader.

Chemical injection pumps.

Stand-alone safety valve.

Choke manifold.

Heat exchanger.

Three phase separator.

Surge tank.

Transfer pump.

Crude oil burners.

Control cabin/laboratory.

PSD/ESD system.

Interconnecting piping.

Instrumentation.

Auxiliary equipment.

5.3.3 Landing string equipment

Subsea test tree w/fluted hanger and slick joint.

Lubricator valve.

Retainer valve.

BOP safety valve (for jack-ups).

Subs and x-over.

5.3.4 Reservoir information acquisition

Pressure and temperature recorders.

Bottom hole sampling equipment.

Surface sampling equipment.

Well testing systems D-SR-007

Rev. 1, J anuary 1996

NORSOK standard 5 of 38

Trace element and wellsite chemistry analysis.

Data acquisition system.

Sand detection equipment.

5.3.5 Test tubing

Test tubing.

5.4 Performance/output

The provided equipment shall be mobilised, installed, commissioned, operated, maintained and

demobilised by competent personnel provided by the contractor.

5.5 Regularity

N/A

5.6 Process/ambient conditions

Standard eqt. HPHT eqt.

Maximum reservoir pressure 690 Bar 1035 Bar

Maximum annulus downhole pressure 1035 Bar 1379 Bar

Maximum downhole temperature 150C 210C

Maximum wellhead temperature 100C 130C (175C for jack-ups)

Maximum operating temperature -20C -20C

H

2

S Service Yes Yes

CO

2

Service Yes Yes

All equipment shall be designed for offshore environment with corrosive and salt containing

atmosphere. 100 % relative humidity and surface temperature of -20 to 30C.

5.7 Operational requirements

5.7.1 Surface equipment

The pressure relief system from all relief devices shall be routed to relief headers for high or low

pressure relief. It is vendors responsibility to ensure that the relief system is suitably sized to

discharge the maximum gas and/or liquid design flow rate. Discharge shall by preference be

directed to the flareboom. Alternatively can discharge be routed to dedicated safe area minimum 3

meter below lower deck area.

Vessels designed for, or potentially operated as atmospheric vessels shall be equipped with devices

or designed so that return of air causing an explosive mixture or backfire into the vessel is

prevented.

The interconnecting piping system shall by preference be permanently installed with an effort to

minimise elastomers in the connections. Permanently installed piping shall be covered with grating

where appropriate to provide a safe working environment.

Any water dumped overboard shall contain less that 40ppm of hydrocarbons. Discharged water shall

be sampled and quantity measured.

Well testing systems D-SR-007

Rev. 1, J anuary 1996

NORSOK standard 6 of 38

Burning of hydrocarbons shall take place without pollution to sea. An effort shall be made to

minimise smoke and pollution to air where this is not impairing the burning efficiently.

API 14C shall be used as a guideline to safeguard the surface process equipment. SAFE, SAC and

SAT charts shall be presented.

The main process equipment area shall be equipped with coaming to prevent oil spill from

spreading outside the dedicated area.

Heat radiation calculations shall be presented to Company upon request displaying maximum

exposure at maximum production rate in a worst case scenario.

When the piping installation has a change of pressure rating (spec. break), the lower rated pipe shall

be adequately protected against overpressure. Double isolation valves shall be installed where

practical.

All surface pressure containing piping and vessels shall be mounted in such a manner that blow-

down of the equipment is possible form safe area through a manual activation feature provided by

contractor.

Process control shall be through local pneumatic control.

The PSD system shall be electronically operated and monitored form contractors control room.

Permanently installed equipment shall be fitted with ladders, stairways and railing as required for

safe and convenient access for operation and maintenance. The equipment and layout design shall

allow for normal maintenance and service to be carried out between test periods, while hooked up

on the rig.

The equipment necessary for executing the work shall be skid or container mounted to ease

movement and installation.

Equipment permanently installed on deck shall be fastened to deck to withstand a survival state

similar to that of the rig it is installed on. Fastening shall be calculated and documented.

Equipment which is shipped frequently to the offshore installation shall have lifting arrangement

suitably designed to withstand dynamic loads. DnV 2.7-1 is recommended used to comply with the

regulatory requirements.

5.7.2 Downhole test tools

Shall be annulus or tubing pressure operated.

All test string components shall be so designed that all handling on deck and drill floor can be

performed safely and efficiently.

Downhole test tools shall have a safety factor of minimum 1,1 included when quoting maximum

working pressure at working temperature. (I.e. quoting 15000 psi working pressure shall mean a

calculated maximum design pressure of 16500 psi).

Well testing systems D-SR-007

Rev. 1, J anuary 1996

NORSOK standard 7 of 38

Internal profiles shall have no sharp edges or obstructions.

All downhole tools are to be drifted with an API standard drift.

The equipment shall be designed to withstand loads and pressure downhole, including maximum

applied annulus pressure in addition to the specified maximum working pressure for the tool.

Contractor shall make sure that the design load limits of the equipment are known to the operator

and not exceeded during operation. Safety factors for tools employed shall be documented and made

available upon request.

A bleed off function shall be provided wherever pressure may be trapped.

5.8 Maintenance requirements

Contractor shall carry out calibration of all measuring devices before and after each job. Contractor

shall carry with him necessary spare parts to resume operation in case of malfunction. Any

permanently installed equipment shall be put in good storage order after the jobs, prior to the

contractor crew leaving the location.

5.9 Isolation and sectioning

Each and any individual component in the process plant downstream the choke manifold shall have

the ability to be bypassed.

5.10 Layout requirements

Contractor shall compress the equipment layout as much as possible while at the same time ensure

sufficient escape ways.

Contractor shall ensure that the maximum permissible deck load is not exceeded and if required,

supply necessary spreader beams below the equipment.

P&ID drawing with valve numbering and component specifications shall be made available.

General arrangement drawings shall be made available after installation of equipment.

Flow diagrams shall be made available after installation of equipment.

5.11 Interface requirements

Steam.

Electrical power.

Compressed air.

Sea water.

Piping connections.

Requirements will be described in the data sheets.

5.12 Commissioning requirements

Acceptance test programme shall be made and performed with use of air and water as testing

medium. Programme shall include sequence for initial and pre-job pressure testing.

Well testing systems D-SR-007

Rev. 1, J anuary 1996

NORSOK standard 8 of 38

6 INFORMATIVE REFERENCES

N/A

Well testing systems D-SR-007

Annex A Rev. 1, J anuary 1996

NORSOK standard 9 of 38

ANNEX A SERVICE DATA SHEETS

SERVICE DATA SHEET

TITLE:

ANNEX 1 DRILL STEM TEST TOOLS SYSTEM REQUIREMENTS

Retrievable packer:

The packer shall be set by a simple manipulation of the string.

It shall be possible to unseat and reset the packer without any change in performance.

Shall hold pressure form above and below as specified in Data sheet.

Tester Valve:

Shall be operated by annulus pressure.

Unless otherwise specified by the Operator, the tester valve shall close if the annulus pressure is

bled off.

It shall be possible to open the tester valve with a pressure differential of 50% of working

pressure from below.

Circulating valves:

A minimum of two circulating valves shall be run in the test strings.

One of the valves shall have the possibility of being operated an unlimited number of times.

One of the valves shall be single shot. I.e. remain open once activated.

The flow ports shall have sufficient area and resistance to erosion to permit circulation at an

effective rate with a pressure that does not cause operation of other tools.

Slip joints:

Shall have no internal obstructions in which wireline can be stuck due to internal movement.

Shall be of internal balance type.

Jar:

Shall be of a hydraulic type, and it shall be possible to repeat the jarring operation.

Safety joint:

Shall when required cause a mechanical separation of the test string from the packer assembly

when exceeding the tensile strength limit in the joint. The lower half remaining with the fish

shall have a design which enhances fishing of the string.

The safety joint shall not be of a rotation type if this interfere with right hand rotation to

mechanically unlatch the subsea test tree.

Integrated downhole data acquisition tool:

Shall be concentric and have no internal obstructions.

Shall be equipped with means to check for and safely release any internal pressure build-up

caused by downhole use or pressure testing.

Well testing systems D-SR-007

Annex A Rev. 1, J anuary 1996

NORSOK standard 10 of 38

SERVICE DATA SHEET

TITLE:

ANNEX 2 LANDING STRING EQUIPMENT SYSTEM REQUIREMENTS

Subsea test tree:

The fluted hanger shall have an adjustable feature to allow the slick joint to be varied over a

given range.

It shall be possible to position the subsea tree in the rigs BOP stack so that middle piperams can

be closed on the slick joint and it shall be possible to close shear/blindram above the latched

subsea tree assembly.

The subsea tree assembly shall be equipped with a shearable sub located across the rig BOP

shear-ram. Required force to shear shall be documented.

The subsea tree control system shall be equipped with a remote station for emergency closure of

the tree.

The subsea test tree shall be equipped with a chemical injection system with a double non return

valve located in tool assembly. The injection line shall be an integral part of the control hose

bundle.

The control hose bundle shall be one single length without splices or intermediate connections.

The subsea test tree shall be able to cut coiled tubing with internal monoconductor cable and/or

7/16 logging cable.

The subsea tree shall be able to unlatch under tension. It shall however not be possible to

accidentally unlatch the tree while running in hole.

The subsea tree shall be equipped with a mechanical unlatch feature to be operated as a

secondary mean in case of lost hydraulic power.

The subsea tree shall be able to transmit any torque required to operate downhole equipment.

BOP safety valve:

Shall be installed in the test string such that BOP rams can be closed on a slick joint above the

valve.

The safety valve assembly shall be equipped with a shearable sub located across the rig BOP

shear-ram. Required force to shear shall be documented.

The valve shall be of a pump through type.

The valve shall be able to cut coiled tubing with internal monoconductor cable and/or 7/16

logging cable.

The valve shall be equipped with a chemical injection system with a double non return valve

located in tool assembly. The injection line shall be an integral part of the control hose bundle.

Lubricator valve:

The lubricator valve shall be designed to be hydraulically pumped open and closed, without

failing to any position in case of lost control pressure. It shall be possible to pump through the

valve and also to pressure test against the valve from both below and above.

Well testing systems D-SR-007

Annex A Rev. 1, J anuary 1996

NORSOK standard 11 of 38

SERVICE DATA SHEET

TITLE:

ANNEX 2 LANDING STRING EQUIPMENT SYSTEM REQUIREMENTS

Pressure lock between multiple valves run in combination shall not be possible.

Retainer valve:

The valve shall retain landing string fluid under pressure following a disconnect.

The valve shall be multi-shot.

The valve shall when included on the string not impair disconnect time.

The subsea test tree and retainer valve operating mechanism shall be such that both automatically

go to a safe closed position if the shearable sub is severed.

The subsea test tree and retainer valve systems shall include a system to allow pressure testing of

the landing string following reconnection.

Well testing systems D-SR-007

Annex A Rev. 1, J anuary 1996

NORSOK standard 12 of 38

SERVICE DATA SHEET

TITLE:

ANNEX 3 SURFACE EQUIPMENT SYSTEM REQUIREMENTS

Surface test tree:

The surface test tree shall be equipped with swab, master, kill and flow valves. A swivel,

positioned above the master valve, shall also be incorporated to allow rotation of the string.

The surface test tree shall be able to be hung off in a standard drillpipe elevator and shall have

connections for kill and flow lines facing down.

The kill and flow valve on the surface test tree shall be hydraulically operated and fail to closed

position: They shall be able to close in less than 5 seconds at temperature down to minimum

operating temperature. The control system shall be equipped with a remote station for emergency

closure of the tree.

The tree shall be equipped with a frame for protection of valve stems and actuators.

It shall be possible to interface the wing flow valve with the PSD/ESD system.

It is recommended that the tree is equipped for installation of pressure and temperature sensors

upstream of the prod. Wing valve.

Flexible flowline:

The flexible line shall be compatible with the well fluid chemistry.

The end connections shall be equipped with safety slings for attachment to the flowhead and

standpipe/flowline manifold.

The end connections shall be of the hub type.

Flowline manifold:

The manifold shall have sufficient points for analogue pressure and temperature monitoring,

electronic data acquisition sensors, dead weight tester, sand erosion probe, sampling and

injection, each equipped with double block and bleed valves.

The end connections shall be of the hub or flange type.

Chemical injection pumps:

Pumps used to inject chemicals (methanol, glycol, separation enhancement additives) shall have

full redundancy and be equipped with filtration device.

The pumps shall have a trim suitable for the required service and chemical.

Stand alone safety valve:

If installed, shall operate in parallel with surface test tree production wing valve.

Shall have possibility to be overridden for pressure testing purposes.

Choke manifold:

The choke manifold shall have two flow paths, one with facilities to install and change fixed

chokes an done with an adjustable choke. Each flow path shall have minimum two closing valves

with bleed off facilities between the valves and ports for pressure measurements both up and

down stream of chokes. All valves in the choke manifold shall have the same pressure rating.

Provision for installation of fixed chokes in both flow paths shall be arranged.

Adjustable choke shall be so designed as to allow accurate adjustments in 4/64 increments,

maintain accuracy over time in use and shall not cause accidental plugging of the flow path.

Heat exchanger:

The heat exchanger shall be arranged with an external heating source, preferably steam.

The heat exchanger shall have a minimum of two coils with interconnection by means of a choke

Well testing systems D-SR-007

Annex A Rev. 1, J anuary 1996

NORSOK standard 13 of 38

SERVICE DATA SHEET

TITLE:

ANNEX 3 SURFACE EQUIPMENT SYSTEM REQUIREMENTS

box either submerged inside the vessel or by an external connection.

Bleeding off coils for the purpose of changing choke shall be possible through double isolation

valves, with the discharge led to the low pressure relief header of safe area.

The adjustable choke assembly shall have pressure test capabilities for the purpose of testing

high pressure coil tubes.

Shall be equipped with a temperature control system regulating the external heating source based

on the required well fluid discharge temperature.

Shall be equipped with pressure and temperature sensors up- and down-stream of choke.

Shall be equipped with by-pass line with double valve arrangement together with isolation valves

on inlet and outlet of coils.

Shall be equipped with two independent pressure relief devices protecting the steam vessel

against rupture. Each individual device shall be capable of discharging the maximum well

production rate in case of coil or tube rupture.

Shall be equipped with gas detection system for the steam-condensate discharged from the

heater. This system shall be connected to an automatic shut-off device preventing gas laden

condensate returning back to the supplying boiler. By preference this detection shall be sampled

from the main vessel before the gas is allowed to enter into the condensate system.

If the secondary coil has a lower pressure rating than the primary coil and/or the downstream

valve, the coil shall be equipped with a pressure relief device.

The steam inlet shall be equipped with a non return valve.

Separator:

The separator shall be suitable for three phase gas/oil/water separation.

The following features shall be included:

Pressure control system

Oil and water level control system with liquid level glasses for water/oil and oil gas interface.

Positions for both data acquisition and analogue pressure and temperature measurement on

vessel, gas and oil line.

Oil, water and gas metering facilities to cover the full flow capacity range of the separator.

Injection point for:

Chemical at inlet manifold

Methanol or glycol downstream gas metering device, upstream of pressure control valve.

Sampling outlets at oil-, gas- and water-lines.

Flange connection for isokinetic sampling.

Shall be equipped with shrinkage tester to assess gas content in oil leaving the separator.

Shall be equipped with manhole situated so that internal visual inspection and cleaning can be

performed while the skid is still hooked up on the rig.

Inlet manifold shall enable by-pass of fluid to either oil or gas discharge line. The manifold

shall be equipped with sufficient valves to isolate the vessel itself.

Shall be equipped with two independent pressure relief devices protecting the vessel against

rupture. Each individual device shall be capable of discharging the design production rate in case

of overpressure.

Shall be equipped with pressure relief device protecting separator inlet/by-pass manifold.

Well testing systems D-SR-007

Annex A Rev. 1, J anuary 1996

NORSOK standard 14 of 38

SERVICE DATA SHEET

TITLE:

ANNEX 3 SURFACE EQUIPMENT SYSTEM REQUIREMENTS

Surge tank:

Shall be equipped with pressure control system.

Shall be equipped with level glasses for liquid/gas interface.

Shall be equipped with positions for analog pressure and temperature measurement on vessel.

Inlet manifold shall enable by-pass of fluid to oil discharge line. The manifold shall be equipped

with sufficient valves to isolate the vessel itself.

Shall be equipped with an independent pressure relief device protecting the vessel against

rupture. The device shall be capable of discharging the liquid production rate with associated gas

in case of over pressure due to liquid overfill or gas blow-by.

Shall be equipped with manhole situated so that internal visual inspection and cleaning can be

performed while the skid is still hooked up on the rig.

Transfer pump:

Shall be installed to give sufficient NPSH to enable continuos operation of the pump if used to

discharge crude oil to burners when operating the surge tank as a 2nd stage separator.

Crude oil burners:

Shall be capable of complete combustion of crude oil without fall-out or pollution to sea.

The oil and compressed air inlet lines on the burner shall be equipped with non return valves if

there is any remote possibility that the two media could enter the opposite media line and

develop a combustible mixture.

The burners shall be equipped with remotely controlled rotation device, if required for burning

efficiency, ignition system and a pilot light for each atomised fluid stream.

The burners shall be equipped to remotely select number of heads or guns to effectively select the

optimal number for the produced fluid content.

If the pressure rating of the burners are less than that of the input source, the burners shall be

equipped with a pressure relieving device.

Air compressors:

Shall be suitable for installation in zone 2 area when indicated in data sheet.

Shall be equipped with automatic shutdown device in case of exposure to hydrocarbon gases.

Test laboratory cabin:

Shall be pressurised and equipped with gas sensors on the air intake, fire extinguishing system

and two escape routes.

PSD and ESD system:

The PSD (Production Shut Down) system shall be capable of shutting in the well on the

flowhead production wing valve. Activation shall take place as automatic functions from sensors

installed as mutually agreed using API 14C as a guideline, or by manual activation of PSD

buttons located at the following minimum places:

Driller cabin

Separator area

Inside or outside Operators office

The ESD (Emergency Shut Down) system shall be capable of shutting in the well on the subsea

test tree by manual activation of ESD buttons located at the following minimum places:

Outside Operators office

Well testing systems D-SR-007

Annex A Rev. 1, J anuary 1996

NORSOK standard 15 of 38

SERVICE DATA SHEET

TITLE:

ANNEX 3 SURFACE EQUIPMENT SYSTEM REQUIREMENTS

One additional convenient location

The PSD and ESD buttons shall be separated, have protective cover and be clearly marked.

The PSD and ESD system shall be equipped with two levels where level 1 shall be a PSD which

stops the flow by closure of in-line valves. Level 2 shall be an ESD which will blow down the

pressurised vessels in the plan after discontinuation of flow has been confirmed.

Well testing systems D-SR-007

Annex A Rev. 1, J anuary 1996

NORSOK standard 16 of 38

SERVICE DATA SHEET

TITLE:

ANNEX 4:RESERVOIR INFORMATION DATA SYSTEM REQUIREMENTS

Downhole pressure and temperature gauges:

The recorded data shall be read, processed and presented in hardcopy on site.

Electronic gauges shall be able to secure storage of recorded data in case of power failure

downhole.

Gauge operating procedure shall include positive verification of gauge recorder operation prior to

instalment in the carrier.

Any cartridge that could accumulate an accidental pressure build-up inside shall be so designed

that projection of components shall not be possible during disassembly.

The recorded data shall be read, processed and presented in hardcopy and ASCII datafile on site.

All gauges shall have a valid calibration certificate describing both Master calibration and

Calibration check over the entire pressure range at the expected downhole temperature. These

certificates shall be made available to the Operator prior to shipment.

After the job, a post calibration check shall be carried out at the same temperature and repeating

the pressure steps used in the pre job calibration check.

If pre- or post-test calibrations indicates deviations from specified accuracy, a new master

calibration shall be performed.

Calibration results shall be included in the final report.

Gauge carrier:

Gauges shall be installed in the carrier while on deck, and carrier pressure integrity tested.

Contractor shall provide means for pressure testing on deck with gauges installed. It must be

possible to connect the gauge carrier to the string without breaking tested seals.

Gauge carriers shall be internally concentric.

Bottom hole sampling:

Sampling equipment shall be of mercury free type.

Shall be designed so that several samplers can be run in the well simultaneously and fired

individually by surface activation or by mechanical clocks.

There shall be provisions for checking opening pressure and bubble point of the sample prior to

transferring it from the sampler to the shipping bottle, or preparing the sample chamber for

transportation to shore.

The activation of the sampling mechanism shall be designed so that any accidental release of

sampling valves is prevented. This includes release in case of mechanical shock.

For electrically triggered samplers, sampling may not be initiated by any other electrical or radio

signal than that transmitted through the cable on which the sampler is run.

The minimum volume of each sample shall be 0,6 litres. Once activated, the sample shall be

filled in a controlled manner (maximum 5 minutes) in order to prevent drawdown below bubble

point.

Surface sampling:

Pressurised sampling equipment is to be of mercury free type.

Sample containers for pressurised samples shall have been cleaned out and re-certified prior to

use. Certification documentation is to be available with bottle.

Provisions shall be made for single phase hydrocarbon sampling at wellhead.

Well testing systems D-SR-007

Annex A Rev. 1, J anuary 1996

NORSOK standard 17 of 38

SERVICE DATA SHEET

TITLE:

ANNEX 4:RESERVOIR INFORMATION DATA SYSTEM REQUIREMENTS

Simultaneous sampling of oil and gas from separator at controlled pressure and temperature shall

be possible. Pressure and temperature shall be monitored during sampling and shall be recorded

on sample form to be included with bottle.

Provisions shall be available for two phase sampling in gas outlet line from separator, or other

site for monitoring of separator efficiency and carry over.

Trace element and wellsite chemistry analysis:

Shall include on-site monitoring of well stream properties and components which influence well

stream processing and/or are of importance with respect to safety, health and environment.

Shall provide onsite analysis of gas and fluid properties including densities adjusted to standard

temperature.

Shall provide chemical analysis of water with determination of density, resistivity, salinity and

quantification of essential ions.

Surface data acquisition:

Provision shall be available for continuos monitoring of wellhead pressure and temperature at

surface test tree, upstream and downstream of choke, annulus pressure, sand detection sensor,

separator oil, gas and water flow rates, separator pressure and temperature and separator

downstream parameters.

Monitoring system shall have 100% redundancy and shall be able to secure storage of recorded

data in case of power failure.

All sensors and interconnecting cables shall be suitable for installation in a zone 2 environment.

All sensors and metering devices shall have valid calibration certificates. Documentation to be

available on site.

Original raw data and all parameters used in the calculations shall be available upon request.

The data shall be available on-line in real-time. Printed reports and ASCII data file(s) shall be

available on site.

Well testing systems D-SR-007

Annex A Rev. 1, J anuary 1996

NORSOK standard 18 of 38

SERVICE DATA SHEET

TITLE:

ANNEX 5 TEST TUBING SYSTEM REQUIREMENTS

Test tubing:

The test tubing shall be equipped with connections providing a gas tight seal at rated pressure.

Length of joints of test tubing shall be 100% inside the tolerance of the specified API range, but

with a minimum length of no less than 8,84m.

All tubular goods shall be internally cleaned and all mill scale removed prior to inspection,

coating and delivery. All materials used to clean and/or prepare tubular for inspection or repair

shall be harmless to the pieces being inspected.

After successful thread inspection, the threads shall be thoroughly cleaned, coated, doped, and

thread protectors fitted. Anti-galling requirements will be specified in the Data sheet.

The tubing shall be drifted using an API standard drift.

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 19 of 38

ANNEX B EQUIPMENT DATA SHEET

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.1 DATASHEET 0: GENERAL INFORMATION

Well information

Type of well Wildcat, Exploration, Appraisal

Possibility of sand production Low, Medium, High

Max. Sand Free Rate Test Yes, No

Possibility of water production Low, Medium, High

Possibility of hydrate formation Low, Medium, High

Possibility of emulsion problems Low, Medium, High

Possibility of foaming problems Low, Medium, High

Maximum oil production rate m

3

/d, BOPD

Maximum gas production rate MSm

3

/d, MMSCF/d

Maximum water production rate m

3

/d, BWPD

Maximum H

2

S concentration ppm

Maximum CO

2

concentration % (Vol, mol)

Maximum bottom hole pressure Bar, psi

Maximum bottom hole temperature C, F

Maximum wellhead pressure Bar, psi

Maximum wellhead temperature C, F

Maximum well inclination degrees

Maximum well depth m, ft

Mud system used during drilling OBM, WBM

Completion fluid / packer fluid

Completion fluid / packer fluid specific gravity

Cushion type

Casing diameter mm, inch

Casing grade (API)

Casing weight kg/m, lbs/ft

m, ft MD below RKB Bottom Top

Perforating interval no 1 m, ft

Perforating interval no. 2 m, ft

Perforating interval no. 3 m, ft

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 20 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.1 DATASHEET 0: GENERAL INFORMATION

Drilling unit information

Piping between drill floor and test area

Nominal diameter mm, inch

Pressure rating Bar, psi

Inlet connection (Hub, flange, dimension)

Outlet connection (Hub, flange, dimension)

Standpipe available Yes, no

Standpipe data Nominal ID/Rating/Connections/Height

Piping to burner boom

High pressure gas line (connection, size, rating)

Low pressure gas line (connection, size, rating)

Oil line (connection, size, rating)

Water line (connection, size, rating)

Air line (connection, size, rating)

Pressure relief system To burner/below well

Electrical power available for pumps and lab cabin, utility

Voltage Volt

Maximum current Amp

Frequency Hz

Maximum output power kW, hk

Terminal connection

Other information

Steam supply (capacity at pressure and temperature) kg/hr

Air supply for burners ltr/min

Water supply for burners m

3

/hr

Maximum burner head weight limitation kg, lbs

Remote control shutdown lines installed Yes, no

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 21 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.1 DATASHEET 0: GENERAL INFORMATION

Coaming of well test area available Yes, no

Maximum load to be placed on deck area Metric ton/m

2

Riser - BOP configuration

BOP manufacturer

Size Inch

Minimum internal diameter mm, inch

Pressure rating Bar, psi

BOP ram temperature rating C, F

Ram locations

Datum to centre lower pipe ram mm, inch

Datum to centre middle pipe ram mm, inch

Datum to centre upper pipe ram mm, inch

Datum to centre shear/blind ram mm, inch

Ram thickness mm, inch

Location of lowest choke line inlet/outlet

Wellhead configuration

Manufacturer

Wear bushing size Inch

Wear bushing taper angle degrees

Distance datum to wear bushing nominal ID mm, inch

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 22 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.2 DATASHEET 1 DRILL STEM TEST TOOLS

Operators min.

requirem.

Vendors data

Packer

Type (brand name)

For casing diameter mm, inch

For casing grade (API)

For casing weight lbs/ft

Pressure rating Bar, psi

Temperature rating C, F

Maximum differential pressure (collapse) Bar, psi

Maximum differential pressure (burst) Bar, psi

External diameter/OD mm, inch

Internal diameter/ID mm, inch

Top connection (API/Hydril/Vam/etc.)

Bottom connection (API/Hydril/Vam/etc.)

Tensile strength kg, lbs

Tester valve

Type (name)

Pressure rating Bar, psi

Temperature rating C, F

Maximum test pressure form above Bar, psi

Maximum differential opening pressure from below Bar, psi

Operating pressure range to open Bar, psi

Can valve be permanently closed by over pressure Yes, no

External diameter/OD mm, inch

Internal diameter/ID mm, inch

Top connection (API/Hydril/Vam/etc.)

Bottom connection (API/Hydril/Vam/etc.)

Tensile strength kg, lbs

Tester valve reference tool

Pressure rating Bar, psi

Temperature rating C, F

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 23 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.2 DATASHEET 1 DRILL STEM TEST TOOLS

Operators min.

requirem.

Vendors data

Operating pressure range to close Bar, psi

External diameter/OD mm, inch

Internal diameter/ID mm, inch

Top connection (API/Hydril/Vam/etc.)

Bottom connection (API/Hydril/Vam/etc.)

Tensile strength kg, lbs

Tubing operating circulating valve

Type

Pressure rating Bar, psi

Temperature rating C, F

Minimum differential opening pressure Bar, psi

Closing method

Number of operating cycles Single, no. multi cycles

Maximum rate tubing to annulus l/min, gpm

Maximum rate annulus to tubing l/min, gpm

External diameter/OD mm, inch

Internal diameter/ID mm, inch

Top connection (API/Hydril/Vam/etc.)

Bottom connection (API/Hydril/Vam/etc.)

Tensile strength kg, lbs

Annulus operated circulating valve

Type 1

Pressure rating Bar, psi

Temperature rating C, F

Maximum differential opening pressure Bar, psi

Operating pressure range to open Bar, psi

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 24 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.2 DATASHEET 1 DRILL STEM TEST TOOLS

Operators min.

requirem.

Vendors data

Operating pressure range to close Bar, psi

Number of operating cycles Single, no. multi cycles

Maximum rate tubing to annulus l/min, gpm

Maximum rate annulus to tubing l/min, gpm

External diameter/OD mm, inch

Internal diameter/ID mm, inch

Top connection (API/Hydril/Vam/etc.)

Bottom connection (API/Hydril/Vam/etc.)

Tensile strength kg, lbs

Type 2

Pressure rating Bar, psi

Temperature rating C, F

Maximum differential opening pressure Bar, psi

Operating pressure range to open Bar, psi

Operating pressure range to close Bar, psi

Number of operating cycles Single, no. multi cycles

Maximum rate tubing to annulus l/min, gpm

Maximum rate annulus to tubing l/min, gpm

External diameter/OD mm, inch

Internal diameter/ID mm, inch

Top connection (API/Hydril/Vam/etc.)

Bottom connection (API/Hydril/Vam/etc.)

Tensile strength kg, lbs

Slip joint

Pressure rating Bar, psi

Temperature rating C, F

Total stroke required mm, inch

Total stroke pr. slip joint mm, inch

External diameter/OD mm, inch

Internal diameter/ID mm, inch

Top connection (API/Hydril/Vam/etc.)

Bottom connection (API/Hydril/Vam/etc.)

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 25 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.2 DATASHEET 1 DRILL STEM TEST TOOLS

Operators min.

requirem.

Vendors data

Tensile strength kg, lbs

Hydraulic jar

Pressure rating Bar, psi

Temperature rating C, F

Force to activate (maximum pull before jar) kg, lbs

Stroke length mm, inch

Tensile strength (maximum pull after jar) kg, lbs

External diameter/OD mm, inch

Internal diameter/ID mm, inch

Top connection (API/Hydril/Vam/etc.)

Bottom connection (API/Hydril/Vam/etc.)

Tensile strength kg, lbs

Safety joint

Type

Pressure rating Bar, psi

Temperature rating C, F

Operating method

Torque required Nm, ft, lbs

Safety joint, continuation

Pull required kg, lbs

External diameter/OD mm, inch

Internal diameter/ID mm, inch

Top connection (API/Hydril/Vam/etc.)

Bottom connection (API/Hydril/Vam/etc.)

Tensile strength kg, lbs

Tubing tester valve

Type (flapper/ball)

Pressure rating Bar, psi

Temperature rating C, F

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 26 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.2 DATASHEET 1 DRILL STEM TEST TOOLS

Operators min.

requirem.

Vendors data

Pressure to permanently open Bar, psi

Method to verify opening

External diameter/OD mm, inch

Internal diameter/ID mm, inch

Top connection (API/Hydril/Vam/etc.)

Bottom connection (API/Hydril/Vam/etc.)

Tensile strength kg, lbs

Sampling tool

Type

Pressure rating Bar, psi

Temperature rating C, F

Operating method

Maximum sample pressure rating Bar, psi

Closing means (ball/sleeve)

Pressure range to close Bar, psi

External diameter/OD mm, inch

Sampling tool, continued

Internal diameter/ID mm, inch

Top connection (API/Hydril/Vam/etc.)

Bottom connection (API/Hydril/Vam/etc.)

Tensile strength kg, lbs

Downhole safety valve

Type

Pressure rating Bar, psi

Temperature rating C, F

Pressure to activate Bar, psi

External diameter/OD mm, inch

Internal diameter/ID mm, inch

Top connection (API/Hydril/Vam/etc.)

Bottom connection (API/Hydril/Vam/etc.)

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 27 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.2 DATASHEET 1 DRILL STEM TEST TOOLS

Operators min.

requirem.

Vendors data

Tensile strength kg, lbs

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 28 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.3 DATASHEET 2 LANDING STRING EQUIPMENT

Operators min.

requirem.

Vendors data

Fluted hanger

Type/model

Dimensions/OD mm, inch

Pressure rating Bar, psi

Temperature rating C, F

Steel quality (DIN, ASTM, BS, etc.)

Top connection (type, dimension, etc.)

Bottom connection (type, dimension, etc.)

Tensile strength at zero pressure kg/lbs

Tensile strength at max. pressure kg/lbs

Slick joint

Pressure rating Bar, psi

Temperature rating C, F

Length mm, inch

External diameter/OD mm, inch

Internal diameter/ID mm, inch

Top connection (type, dimension, etc.)

Bottom connection (type, dimension, etc.)

H

2

S; CO

2

, Acid service

Tensile strength at zero pressure kg/lbs

Tensile strength at max. pressure kg/lbs

Lubricator valve

Type/model

Pressure rating Bar, psi

Temperature rating C, F

Length mm, inch

Lubricator valve, continued

External diameter/OD mm, inch

Internal diameter/ID mm, inch

Top connection (type, dimension, etc.)

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 29 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.3 DATASHEET 2 LANDING STRING EQUIPMENT

Operators min.

requirem.

Vendors data

Bottom connection (type, dimension, etc.)

H

2

S; CO

2

, Acid service Yes, no

Tensile strength at zero pressure kg/lbs

Tensile strength at max. pressure kg/lbs

Subsea test tree

Type/model

Pressure rating Bar, psi

Temperature rating C, F

Overall length mm, inch

Length disconnected mm, inch

Transmittal torque range Nm, ft, lbs

Maximum working water depth m, ft

Maximum load carrying capacity at zero pressure kg, lbs

Maximum load carrying capacity at max. pressure kg, lbs

External diameter/OD mm, inch

Internal diameter/ID mm, inch

Top connection (type, dimension, etc.)

Bottom connection (type, dimension, etc.)

H

2

S; CO

2

, Acid service Yes, no

Chemical injection Yes, no

Close valve and unlatch time 150m water depth sec

350m water depth sec

600m water depth sec

1000m water depth sec

Subsea test tree, continued

Coiled tubing w/7/32 cable cutting capabilities Yes, no

7/16 logging cable cutting capabilities Yes, no

Retainer valve

Type/model

Pressure rating Bar, psi

Temperature rating C, F

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 30 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.3 DATASHEET 2 LANDING STRING EQUIPMENT

Operators min.

requirem.

Vendors data

Length mm, inch

External diameter/OD mm, inch

Internal diameter/ID mm, inch

Top connection (type, dimension, etc.)

Bottom connection (type, dimension, etc.)

H

2

S; CO

2

, Acid service Yes, no

Maximum load carrying capacity at zero pressure kg, lbs

Maximum load carrying capacity at max. pressure kg, lbs

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 31 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.4 DATASHEET 3 SURFACE EQUIPMENT

Operators min.

requirem.

Vendors data

Surface test tree

Type/model

Pressure rating Bar, psi

Maximum temperature rating C, F

Minimum temperature rating C, F

Maximum load carrying capacity at zero pressure kg, lbs

Maximum load carrying capacity at max. pressure kg, lbs

Internal diameter/ID mm, inch

Steel quality (ASTM, DIN, BS)

Weight kg, lbs

Flowline connection (type, dimension, etc.)

Kill-line connection (type, dimension, etc.)

Top connection (type, dimension, etc.)

Bottom connection (type, dimension, etc.)

H

2

S; CO

2

, Acid service Yes, no

Tubing swivel

Type/model

Pressure rating Bar, psi

Maximum temperature rating C, F

Minimum temperature rating C, F

Maximum load carrying capacity at zero pressure kg, lbs

Maximum load carrying capacity at max. pressure kg, lbs

Internal diameter/ID mm, inch

Steel quality (ASTM, DIN, BS)

Weight kg, lbs

Top connection (type, dimension, etc.)

Bottom connection (type, dimension, etc.)

H

2

S; CO

2

, Acid service Yes, no

Flowline manifold/dataheader

Pressure rating Bar, psi

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 32 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.4 DATASHEET 3 SURFACE EQUIPMENT

Operators min.

requirem.

Vendors data

Maximum temperature rating C, F

Minimum temperature rating C, F

Internal diameter/ID mm, inch

Inlet connection (type, dimension, etc.)

Outlet connection (type, dimension, etc.)

Number of outlets

Outlet threads/connections Type

Connection point for sand detector Type

H

2

S; CO

2

, Acid service Yes, no

Chemical injection pumps - High volume fluids

Type/model

Maximum output pressure Bar, psi

Capacity at maximum pressure l/min, gpm

Power kW

Chemical injection pumps - PPM fluids

Type/model

Maximum output pressure Bar, psi

Capacity at maximum pressure l/min, gpm

Power kW

Choke manifold

Pressure rating Bar, psi

Maximum temperature rating C, F

Minimum temperature rating C, F

Nominal size mm, inch

Maximum fixed choke size mm, inch

Choke manifold, continuation

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 33 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.4 DATASHEET 3 SURFACE EQUIPMENT

Operators min.

requirem.

Vendors data

Maximum adjustable choke size mm, inch

Weight kg, lbs

Inlet connection (type, dimension, etc.)

Outlet connection (type, dimension, etc.)

H

2

S; CO

2

, Acid service Yes, no

Heat exchanger

Type/model

Pressure rating Bar, psi

Pressure rating HP coil or tubes Bar, psi

Pressure rating LP coil or tubes Bar, psi

Maximum temperature rating C, F

Minimum temperature rating C, F

Dimension of HP coil or tubes mm, inch

Dimension of LP coil or tubes mm, inch

Submerged adj. choke between HP and LP coil/tube Yes, no

Maximum adjustable choke size mm, inch

Heating source

Heating power kW, BTU/day

Steam requirement (at pressure and temperature) kg/hr, lbs/hr

Inlet connection (type, dimension, etc.)

Heat exchanger, continue

Outlet connection (type, dimension, etc.)

Steam connection (type, dimension, etc.)

Weight kg, lbs

H

2

S; CO

2

, Acid service

Separator(s)

Type/model (vertical/horizontal)

Design code (ASME, DIN, BS, TBK)

Pressure rating Bar, psi

Maximum temperature rating C, F

Minimum temperature rating C, F

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 34 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.4 DATASHEET 3 SURFACE EQUIPMENT

Operators min.

requirem.

Vendors data

Oil capacity m

3

/d, BOPD

Gas capacity at low liquid level Mm

3

/d, MMSCF/d

Gas capacity at high liquid level Mm

3

/d, MMSCF/d

Water capacity m

3

/d, BOPD

Inlet connection (type, dimension, etc.)

Gas outlet connection (type, dimension, etc.)

Oil outlet connection (type, dimension, etc.)

Water outlet connection (type, dimension, etc.)

Isokinetic sampling connection (type, dimension, etc.)

Weight kg, lbs

H

2

S; CO

2

, Acid service Yes, no

Relief system capacity

Surge tank

Type/model (vertical/horizontal)

Design code (ASME, DIN, BS, TBK)

Pressure rating Bar, psi

Surge tank, continuation

Maximum temperature rating C, F

Minimum temperature rating C, F

Volume m

3

, bbl

Gas capacity Mm

3

/d, MMSCF/d

Equipped for gas measurement Yes, no

Equipped for liquid rate measurement Yes, no

Inlet connection (type, dimension, etc.)

Gas outlet connection (type, dimension, etc.)

Oil outlet connection (type, dimension, etc.)

Drain outlet connection (type, dimension, etc.)

Weight - empty kg, lbs

Weight - high liquid level kg, lbs

H

2

S; CO

2

, Acid service Yes, no

Relief system capacity

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 35 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.4 DATASHEET 3 SURFACE EQUIPMENT

Operators min.

requirem.

Vendors data

Transfer pump

Type/model

Prime mover

Output power kW, hp

Power requirement (current, AC/DC, voltage, frequency)

Capacity m

3

/hr, bbl/hr

Inlet connection (type, dimension, etc.)

Outlet connection (type, dimension, etc.)

Weight kg, lbs

H

2

S; CO

2

, Acid service Yes, no

Interconnecting piping safety system

Type of system to guard against over pressure

Burners

Number of heads/nozzles

Oil flow rate m

3

/d, BOPD

Gas inlet connection (type, dimension, etc.)

Oil inlet connection (type, dimension, etc.)

Water inlet connection (type, dimension, etc.)

Air inlet connection (type, dimension, etc.)

Air supply requirement m

3

/min, ft

3

/min

Water supply requirement m

3

/hr, bbl/hr

Weight kg, lbs

H

2

S; CO

2

, Acid service Yes, no

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 36 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.5 DATASHEET 4 RESERVOIR INFORMATION ACQUISITION

Operators min.

requirem.

Vendors data

Recorder element

Sensor type

Pressure range Bar, psi

Temperature rating C, F

Memory capacity (sets of pressure, temperature, time)

Type of memory

Type of programming

Minimum sampling interval sec

Pressure sensor

Range Bar, psi

Accuracy % FS

Repeatability % FS

Resolution (at sampling interval) mbar, psi

Long term stability % FS

Response time sec

Temperature sensor

Type C, F

Accuracy C, F

Resolution C, F

Power supply/battery section

Type

Length mm, inch

Maximum OD mm, inch

Gauge carrier

Type/model

Pressure rating Bar, psi

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 37 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.5 DATASHEET 4 RESERVOIR INFORMATION ACQUISITION

Operators min.

requirem.

Vendors data

Collapse pressure Bar, psi

Burst pressure Bar, psi

External diameter/OD mm, inch

Drift diameter mm, inch

Internal diameter/ID mm, inch

Rotating diameter mm, inch

Number of gauges

Top connection

Bottom connection

Sampling tool

Pressure rating Bar, psi

Temperature rating

External diameter mm, inch

Length mm, inch

Total sampler volume cc

Sampler activation mechanism

Delay (max./min)

Sampler chamber type

Shipping bottle volume

Shipping bottle maximum pressure capacity

Onsite sample transfer Yes, no

Heating bath and/or jacket included Yes, no

Transfer medium

Test tubing

Number of joints

Length of joints m, ft

Nominal outside diameter mm, inch

Wall thickness mm, inch

Weight per foot kg/m,lbs/ft

Steel grade

Well testing systems D-SR-007

Annex B Rev. 1, J anuary 1996

NORSOK standard 38 of 38

EQUIPMENT DATA SHEET

TITLE:

6.1.1.1.5 DATASHEET 4 RESERVOIR INFORMATION ACQUISITION

Operators min.

requirem.

Vendors data

Coupling types

Drift diameter mm, inch

External collapse pressure Bar, psi

Internal burst pressure Bar, psi

Tube body yield strength KdaN, 1000 lbs

J oint strength KdaN, 1000 lbs

Bore size mm, inch

Environments (H

2

S, CO

2

, Acid, etc.)

Ovality %

Anti galling treatment

Make-up torque Nm, ft, lbs

Type of thread protector

Type of thread compound

External/internal protection

Marking

X-overs

You might also like

- Well Testing Recommended PracticesDocument40 pagesWell Testing Recommended Practicessajithv78100% (1)

- Drilling Facilities: NORSOK Standard D-001Document70 pagesDrilling Facilities: NORSOK Standard D-001Well Control100% (1)

- API 14A UpdateDocument13 pagesAPI 14A UpdateAnonymous 70lCzDJv100% (1)

- HPHT UK HSE Report PDFDocument62 pagesHPHT UK HSE Report PDFWaleed Barakat Maria100% (1)

- Performance Testing and Certification of Boots & Coots CT Well Control Accumulator SystemDocument37 pagesPerformance Testing and Certification of Boots & Coots CT Well Control Accumulator SystemHKHKBOOKSNo ratings yet

- 5A. The Drilling RiserDocument31 pages5A. The Drilling Riserconcord1103100% (1)

- Operation Manual 11-3000psi Shear Ram BopDocument30 pagesOperation Manual 11-3000psi Shear Ram BopBoedi SyafiqNo ratings yet

- Norsok GuidelineDocument34 pagesNorsok GuidelineDuongthithuydung100% (2)

- 2P36606 Spring Loaded ERVDocument42 pages2P36606 Spring Loaded ERVYM Edwin Gil BeltranNo ratings yet

- S-003 (Environmental Care)Document36 pagesS-003 (Environmental Care)syamsudin2006No ratings yet

- SOP - 04 - Pressure Testing Procedure - Rev03Document10 pagesSOP - 04 - Pressure Testing Procedure - Rev03HasnainNo ratings yet

- SPM Safety Iron Inspection and Maintenance ProcedureDocument19 pagesSPM Safety Iron Inspection and Maintenance ProcedureIvan RojasNo ratings yet

- 09 LSR Suspended LoadDocument7 pages09 LSR Suspended LoadchinarNo ratings yet

- Section 9, Rigging Up and DownDocument24 pagesSection 9, Rigging Up and Downhammami100% (1)

- IBU-SMO-DC D002 Barrier Guidelines - Revision 3.1 (2020)Document51 pagesIBU-SMO-DC D002 Barrier Guidelines - Revision 3.1 (2020)Boedi Syafiq100% (1)

- Tenaris University - International Standards and Recommended Practices For Assuring Structural Reliability On Octg ProductsDocument31 pagesTenaris University - International Standards and Recommended Practices For Assuring Structural Reliability On Octg ProductsSudish Bhat100% (1)

- D 007 Well Testing System PDFDocument32 pagesD 007 Well Testing System PDFLaw100% (1)

- Section 7, Introduction To Well Testing EquipmentDocument54 pagesSection 7, Introduction To Well Testing EquipmenthammamiNo ratings yet

- Well Examination Handbook - SourceDocument12 pagesWell Examination Handbook - SourceDavide BoreanezeNo ratings yet

- Compact Flanged Connections L-005Document12 pagesCompact Flanged Connections L-005Ranjan ShankarNo ratings yet

- Daily HSE Summary Report 16-02-2018Document3 pagesDaily HSE Summary Report 16-02-2018Mahmoud Ahmed Ali AbdelrazikNo ratings yet

- Procedure For Well TestingDocument4 pagesProcedure For Well TestingTg TarroNo ratings yet

- Cameron - CAMCHEC Riser Inspection - TC1484Document4 pagesCameron - CAMCHEC Riser Inspection - TC1484jahehe2000No ratings yet

- API 6A Pressure EquipmentDocument13 pagesAPI 6A Pressure EquipmentLee Sweningson100% (1)

- Safety Communications Log Sheet 2008Document1 pageSafety Communications Log Sheet 2008Abdul Hameed OmarNo ratings yet

- Flowback Audit: Sample Oil CompanyDocument11 pagesFlowback Audit: Sample Oil CompanyWade Davis0% (1)

- Precision Drilling International Task Risk Assessment WorksheetDocument1 pagePrecision Drilling International Task Risk Assessment WorksheetAbdul Hameed OmarNo ratings yet

- Install 500 Ton Slips & ElevatorDocument1 pageInstall 500 Ton Slips & ElevatorAbdul Hameed OmarNo ratings yet

- Bop Ram ChangeDocument2 pagesBop Ram ChangeAbdul Hameed OmarNo ratings yet

- Safety & Life SavingDocument15 pagesSafety & Life SavingNurul JannatiNo ratings yet

- Norsok C-004, Edition 2, May2013 PDFDocument24 pagesNorsok C-004, Edition 2, May2013 PDFseluarbolaNo ratings yet

- Subsea Technology Development in Deep WaterDocument36 pagesSubsea Technology Development in Deep WaterSpthefania DiazNo ratings yet

- Lay Down Drill PipeDocument2 pagesLay Down Drill PipeAbdul Hameed OmarNo ratings yet

- D-010 Well Integrity in Drilling and Well OperationsDocument224 pagesD-010 Well Integrity in Drilling and Well OperationsJeong Hui Lee100% (4)

- Thread InspectionDocument41 pagesThread InspectionAhmed MushtaqNo ratings yet

- Z 015 2004Document54 pagesZ 015 2004mreavy7399No ratings yet

- LHR Safety Hand Tools and TaglinesDocument1 pageLHR Safety Hand Tools and TaglinesebeNo ratings yet

- Drill floor safety best practicesDocument22 pagesDrill floor safety best practicesPaul100% (2)

- ZaneGrey Well Completion Report - Basic Data Rev B GovDocument1,018 pagesZaneGrey Well Completion Report - Basic Data Rev B GovHtetAungMoeNo ratings yet

- Drill String InspectionsDocument13 pagesDrill String Inspectionsamin peyvandNo ratings yet

- SNS Well P&ADocument15 pagesSNS Well P&Aravide76No ratings yet

- D-002 System Requirements Well Intervention EquipmentDocument70 pagesD-002 System Requirements Well Intervention Equipmentbrucce13No ratings yet

- Temporary Pipe Installation GuideDocument17 pagesTemporary Pipe Installation GuideTeguh Setiono100% (1)

- HPHT Check ListsDocument15 pagesHPHT Check ListsWaleed Barakat MariaNo ratings yet

- API Norsok Standardise For Well Intervention EquipmentDocument70 pagesAPI Norsok Standardise For Well Intervention EquipmentMai KawayapanikNo ratings yet

- Rite Naming Convention PDFDocument6 pagesRite Naming Convention PDFKamelFaizeenAbdullahNo ratings yet

- 01 BOP and Control SystemDocument79 pages01 BOP and Control SystemAustin AsuquoNo ratings yet

- Rotary Slips "RDL" "RD" "RDS": Side Door Elevator 150 TON 250 TON 350 TONDocument11 pagesRotary Slips "RDL" "RD" "RDS": Side Door Elevator 150 TON 250 TON 350 TONShaikh Sabir HussainNo ratings yet

- Sps Mk2 Bhs ManualDocument78 pagesSps Mk2 Bhs ManualKerryjames Campbell StenhouseNo ratings yet

- Caodc RP 6.0 Inspection and Certification of BopDocument19 pagesCaodc RP 6.0 Inspection and Certification of BopEDWIN M.P0% (1)

- Inspection: AIR Winch Ingersoll RandDocument19 pagesInspection: AIR Winch Ingersoll RandAbdou BoucheritNo ratings yet

- 34-SAMSS-514 - Dec. 26. 2013Document10 pages34-SAMSS-514 - Dec. 26. 2013LainhatanhNo ratings yet

- Change Out Rig Tong DiesDocument1 pageChange Out Rig Tong DiesAbdul Hameed OmarNo ratings yet

- Introduction and Overview of Subsea EngineeringDocument58 pagesIntroduction and Overview of Subsea Engineeringmaxwell777100% (2)

- NORSOK D-SR-005 On Coiled TubingDocument17 pagesNORSOK D-SR-005 On Coiled TubingJozsef MagyariNo ratings yet

- Coiled Tubing EquipmentDocument17 pagesCoiled Tubing EquipmentRombo RootNo ratings yet

- NORSOK Piping Design, Layout and Stress Analysis StandardDocument19 pagesNORSOK Piping Design, Layout and Stress Analysis StandardDhakshina KNo ratings yet

- Piping Design, Layout and Stress Analysis: Foreword 1 Scope 2 Normative References 3 Definitions and AbbreviationsDocument15 pagesPiping Design, Layout and Stress Analysis: Foreword 1 Scope 2 Normative References 3 Definitions and AbbreviationsWalid LabidiNo ratings yet

- Snubbing EquipmentDocument18 pagesSnubbing EquipmentDanny Dwi JuniarkoNo ratings yet

- KDP Well Test Procedures ManualDocument77 pagesKDP Well Test Procedures ManualJacob Keemink100% (2)

- 1890-91 - Astrologer's Magazine Vol.1 - Alan Leo - Frederick LaceyDocument291 pages1890-91 - Astrologer's Magazine Vol.1 - Alan Leo - Frederick LaceyBoris ZaslichkoNo ratings yet

- Obama Fixed StarsDocument31 pagesObama Fixed Starsgannwong100% (2)

- Annie LennoxDocument23 pagesAnnie LennoxBoris ZaslichkoNo ratings yet

- Bill GatesDocument24 pagesBill GatesBoris ZaslichkoNo ratings yet

- Modern Report A Solar Writer Report For Amy Winehouse (Sunrise Chart)Document25 pagesModern Report A Solar Writer Report For Amy Winehouse (Sunrise Chart)San YıldırımNo ratings yet

- Paul Councel - Your Stars and DestinyDocument26 pagesPaul Councel - Your Stars and DestinyBoris Zaslichko100% (1)

- 1891-92 - Astrologer's Magazine Vol.2 - Alan Leo - Frederick LaceyDocument288 pages1891-92 - Astrologer's Magazine Vol.2 - Alan Leo - Frederick LaceyBoris Zaslichko100% (1)

- 1890-91 - Astrologer's Magazine Vol.1 - Alan Leo - Frederick LaceyDocument291 pages1890-91 - Astrologer's Magazine Vol.1 - Alan Leo - Frederick LaceyBoris ZaslichkoNo ratings yet

- 1906 - The Astrologer's Annual - Alan LeoDocument65 pages1906 - The Astrologer's Annual - Alan LeoBoris ZaslichkoNo ratings yet

- Jyotish - Gopala RatnakarDocument12 pagesJyotish - Gopala RatnakarRajesh S VNo ratings yet

- Willis I Miham - How To Identify The StarsDocument43 pagesWillis I Miham - How To Identify The StarsBoris ZaslichkoNo ratings yet

- Project Hindsight - The Treatise On The Bright Fixed StarsDocument63 pagesProject Hindsight - The Treatise On The Bright Fixed StarsBoris Zaslichko100% (1)

- Bible Astrology Handbook Reveals Cosmic Codes in ScripturesDocument45 pagesBible Astrology Handbook Reveals Cosmic Codes in ScripturesBoris ZaslichkoNo ratings yet

- Devos Trix - Stars of Destiny The Ancient Science of AstrologyDocument76 pagesDevos Trix - Stars of Destiny The Ancient Science of AstrologyBoris ZaslichkoNo ratings yet

- Jyotish - Sarvajna BhushanaDocument13 pagesJyotish - Sarvajna BhushanaBoris ZaslichkoNo ratings yet

- The Nakshatra of Vedic AstrologyDocument9 pagesThe Nakshatra of Vedic Astrologyashishbhagoria100% (1)

- Lagna Bhava 1st House InsightsDocument14 pagesLagna Bhava 1st House InsightsSubhash H Desai100% (1)

- User Manual RAM BOPDocument102 pagesUser Manual RAM BOPAdolfo Angulo100% (1)

- Bhaskara Bhava DeepikaDocument33 pagesBhaskara Bhava Deepikajyothibs100% (1)

- Drawing - Signs - Stars ChartDocument1 pageDrawing - Signs - Stars ChartBoris ZaslichkoNo ratings yet

- Gandanta Dosha - Sarajit PoddarDocument4 pagesGandanta Dosha - Sarajit PoddarBoris ZaslichkoNo ratings yet

- G and Antha Case Studies B WDocument19 pagesG and Antha Case Studies B WastrologyjupiterNo ratings yet

- Standards Issued 2017 PDFDocument1 pageStandards Issued 2017 PDFEnrique L BlancoNo ratings yet

- Diagram of the 27 NakshatrasDocument2 pagesDiagram of the 27 NakshatrasBoris ZaslichkoNo ratings yet

- ENI - Well Control Policy Manual PDFDocument92 pagesENI - Well Control Policy Manual PDFDaniel TovarNo ratings yet

- Mil STD 271 PDFDocument100 pagesMil STD 271 PDFBoris ZaslichkoNo ratings yet

- Drawing Nakshtra KP WheelDocument1 pageDrawing Nakshtra KP WheelBoris ZaslichkoNo ratings yet

- Handbook of In-Service Inspection-Clifford MathewsDocument704 pagesHandbook of In-Service Inspection-Clifford MathewsBoris Zaslichko100% (3)

- ENI - Completion Design ManualDocument295 pagesENI - Completion Design ManualKingsley Okenyi100% (1)

- Iso/Np 13534Document18 pagesIso/Np 13534Boris ZaslichkoNo ratings yet

- Mosfet 101Document15 pagesMosfet 101Victor TolentinoNo ratings yet

- Ultra Slimpak G448-0002: Bridge Input Field Configurable IsolatorDocument4 pagesUltra Slimpak G448-0002: Bridge Input Field Configurable IsolatorVladimirNo ratings yet

- Audio - Questions: Safety Equipment Reliability Handbook (SERH) 4th EditionDocument29 pagesAudio - Questions: Safety Equipment Reliability Handbook (SERH) 4th EditionLuc SchramNo ratings yet

- Checklist of Requirements For OIC-EW Licensure ExamDocument2 pagesChecklist of Requirements For OIC-EW Licensure Examjonesalvarezcastro60% (5)

- Nagina Cotton Mills Annual Report 2007Document44 pagesNagina Cotton Mills Annual Report 2007Sonia MukhtarNo ratings yet

- Correlation Degree Serpentinization of Source Rock To Laterite Nickel Value The Saprolite Zone in PB 5, Konawe Regency, Southeast SulawesiDocument8 pagesCorrelation Degree Serpentinization of Source Rock To Laterite Nickel Value The Saprolite Zone in PB 5, Konawe Regency, Southeast SulawesimuqfiNo ratings yet

- ArDocument26 pagesArSegunda ManoNo ratings yet

- Kate Elizabeth Bokan-Smith ThesisDocument262 pagesKate Elizabeth Bokan-Smith ThesisOlyaGumenNo ratings yet

- Composite Structures: A. Grimaldi, A. Sollo, M. Guida, F. MaruloDocument15 pagesComposite Structures: A. Grimaldi, A. Sollo, M. Guida, F. MaruloSharan KharthikNo ratings yet

- Chromate Free CoatingsDocument16 pagesChromate Free CoatingsbaanaadiNo ratings yet

- 4 Factor DoeDocument5 pages4 Factor Doeapi-516384896No ratings yet

- Factors of Active Citizenship EducationDocument2 pagesFactors of Active Citizenship EducationmauïNo ratings yet

- Easa Management System Assessment ToolDocument40 pagesEasa Management System Assessment ToolAdam Tudor-danielNo ratings yet

- Iphoneos 31Document159 pagesIphoneos 31Ivan VeBoNo ratings yet

- 2018 NAMCYA CHILDREN'S RONDALLA ENSEMBLE GuidelinesDocument3 pages2018 NAMCYA CHILDREN'S RONDALLA ENSEMBLE GuidelinesJohn Cedrick JagapeNo ratings yet

- Consensus Building e Progettazione Partecipata - Marianella SclaviDocument7 pagesConsensus Building e Progettazione Partecipata - Marianella SclaviWilma MassuccoNo ratings yet

- Build A Program Remote Control IR Transmitter Using HT6221Document2 pagesBuild A Program Remote Control IR Transmitter Using HT6221rudraNo ratings yet

- Ansible Playbook for BeginnersDocument101 pagesAnsible Playbook for BeginnersFelix Andres Baquero Cubillos100% (1)

- C4 ISRchapterDocument16 pagesC4 ISRchapterSerkan KalaycıNo ratings yet

- Galaxy Owners Manual Dx98vhpDocument10 pagesGalaxy Owners Manual Dx98vhpbellscbNo ratings yet

- Propoxur PMRADocument2 pagesPropoxur PMRAuncleadolphNo ratings yet

- Masteringphys 14Document20 pagesMasteringphys 14CarlosGomez0% (3)

- 7 Aleksandar VladimirovDocument6 pages7 Aleksandar VladimirovDante FilhoNo ratings yet

- Statistical Decision AnalysisDocument3 pagesStatistical Decision AnalysisTewfic SeidNo ratings yet

- Philippine Army BDU BidDocument2 pagesPhilippine Army BDU BidMaria TeresaNo ratings yet

- Meet Your TeamDocument2 pagesMeet Your TeamAyushman MathurNo ratings yet

- Special Power of Attorney: Benedict Joseph M. CruzDocument1 pageSpecial Power of Attorney: Benedict Joseph M. CruzJson GalvezNo ratings yet

- Lab StoryDocument21 pagesLab StoryAbdul QadirNo ratings yet

- Consumers ' Usage and Adoption of E-Pharmacy in India: Mallika SrivastavaDocument16 pagesConsumers ' Usage and Adoption of E-Pharmacy in India: Mallika SrivastavaSundaravel ElangovanNo ratings yet

- Exercise-01: JEE-PhysicsDocument52 pagesExercise-01: JEE-Physicsjk rNo ratings yet