Professional Documents

Culture Documents

Predicting Steam Turbine Performance

Uploaded by

karuna346Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Predicting Steam Turbine Performance

Uploaded by

karuna346Copyright:

Available Formats

,"

PREDICTING STEAM TURBINE PERFORMANCE

James T. Harriz, EIT

Waterland, Viar & Associates, Inc.

Wilmington, Delaware

ABSTRACT

Tracking the performance of extraction, back-

pressure and condensing steam turbines is a crucial

part of minimising energy and maintenance costs for

large process industries. A thorough understanding

of key equipment performance characteristics

promotes economical in-house power generation.

Proper Scheduling of of maintenance reduces

downtime. Rankine Efficiency as a function of

steam flow can be accurately predicted from several

sources of available data. Sample analysis of

predicted performance data (Willans Line, flow

versus extraction enthalpy, flow versus exhaust

temperature and flow versus used energy) and test

data are presented. Techniques for deriving

efficiency curves from each source are described.

These techniques can be applied directly to any

steam turbine reliability study effort.

INTRODUCTION

As the cost of energy resources continues to rise,

so does the incentive to produce mechanical and

electrical power while meeting process steam load

requirements. Cogeneration originally arose from a

need for reliable power, before the public utili ty

system could support large industrial loads. While

there is still a need for the generating capacity

of private industry, this need is being met with

increasingly expensive fuel. With the introduction

of PURPA regulations, additional incentive has been

placed on the private sector to produce and sell

electricity. Even without going into the electric

business, private industry will keep operating

costs down by producing prime shaft power with

efficient topping turbines to reduce purchases of

pub1ic power.

The key to economical power production (electrical

or mechanical) is to employ efficient turbines, and

maintain them at an acceptable performance

standard. Since equipment tends to degrade with

time, procedures must be established to monitor

performance. Over a period of time, the degree of

degradation can be observed and maintenance can be

scheduled on a convenient or as-necessary basis,

and the results of maintenance can be verified.

There are several approaches to predicting and

verifying the performance of steam turbines, just

as there are several different types of turbines.

However, all machines are governed by the same

first and second laws of thermodynamics, and can be

treated in fairly standard form.

ANALYSIS

Five separate sources of information may be

available to the engineer to begin turbine

performance analysis.

1. Equipment data sheets

2. Wi11ans line or extraction curves

3. Exhaust or extraction steam Enthalpy curves

4. Exhaust or extraction Used Energy curves

5. Actual performance test data

Of these five sources, the first four come from the

turbine manufacturer. While all of these are not

provided with all equipment, some (and sometimes

several) usually are. Scrounge around the archives

a bit and see what turns up.

The objective is to predict as-new expansion

efficiency for a machine under the conditions it is

actually subject to, for comparison to on-site test

data. The following examples demonstrate the

conversion of raw data into useful information.

1. EQUIPMENT DATA SHEET -- For equipment rated 200

BHP or less, the only manufacturer's data often

available is a Data Sheet. (Figure 1)

Figure 1.

This catagory of equipment is generally designed

for on/off operation to support pumping loads

(cooling water, condensate, and product transfer),

or draft fans and air blowers for boilers or

process.

106

ESL-IE-85-05-19

Proceedings from the Seventh National Industrial Energy Technology Conference, Houston, TX, May 12-15, 1985

In addition to construction details, the Data Sheet This efficiency value represents expected

includes the following design information: performance under design conditions. If any

machine ever sees design conditions, it is, rare,

0 Steam Conditions throttle pressure, temp- but within a moderate range of throttle and exhaust

erature, and exhaust pressure. (600 psig, pressures it will continue to function well.

720FTT, 35 psig)

0 Speed. (3560 RPM) 2. WILLANS LINE OR EXTRACTION CURVES Larger

0 Brake-Horsepower. (121 BHP) turbines are often designed to run partly loaded.

0 Steam (or Water) rate. (31.3 LB/HP-HR) Turbogenerators can be set up to control an

exhaust or extraction header pressure, for

In some circumstances, this information is given and vary electric generation (at constant speed) to

for several possible operating speeds. meet a steam demand. Compressor drives are jusualy

variabIe load machines. Another variablei load

From this data, design efficiency can be calculated arrangement is the common-shaft coupling ! of a

as follows: blower to a motor and turbine driver, which ,allows

load sharing between the two.

a. Ideal (100% efficiency) expansion for a turbine

would occur' at constant entropy (isentropic).

A Willans line defines net BHP or KW over a

Use steam tables, curves or a steam properties of throttle flow rates. Again, it is keyed to a

computer program to determine inlet steam

specific throttle temperature/pressure and e:xhaust

enthalpy and entropy from temperature and

pressure profile (Figure 4). From it, w,e can

pressure (1361.75 Btu/lb &1.594 Btu/lbOR).

predict efficiency and exhaust conditions over the

b. Find the enthalpy value

turbines range of operation. i

corresponding to inlet " i ;. ,T.' ;" 'I";.'. .- '". "J

entropy and exhaust pressure

.!: .1_c?,tG . - i' 1 1"

(1125.90 Btu/lb).

.: ;7400 HFj 10000; RPM I I :

c. The difference (f).h 235.86) ,00000 IE)(PECTr,;,O !

I I j"

represents the theoretical

i ". INtlNITE i"-'Z.L,: r

maximum energy (Btu's) that

could be removed from a

'''! !

j

pound of steam under these .J<'oooo.

.' ! . - 'I'

operating conditions. 'i .

i

d. Convert this ideal heat rate .. 1

", t-,

(Btu/lb) to ideal steam r..' .i;.i.' !

i

I _.. --_.. .. r-- ..

... --I

; . i-::... I

1-

.: . I'._

- _,F; RriTE - ilDUhOS PER HP-Hl(

"'SiE" is 14.7 PSIA

. i

I w .'.:1:.:-,"' .. i.' .:

: OS: G ,:Xl. 0

-r 720. (I :'..cj :

i

S',' .>:L" &TJ! .[:Ll61. 75

.._._._. ----j-

S\"C>" 1.594

.'..0. ,.:fOOO : 2000 'lOO<.> 4Q(X)

:.j. I I

"HOR5E..P,::)vvER;

:

FIGURE 4.

EFF :0.79 a. As in la, b, c, and d above, calculate the: ideal

EFF lb.bJJ - steam rate. The results are shown in Figure 5.

5C':' EFF 2:.58 b. From the Willans line, calculate steam raFe for

25J EFF 30.83 a range of flow/power pairs.

W Flow

or

Flow

Figure 2.

BHP (KW x Generator Eff)

e. The ratio of ideal to manufacturer's rated water

where generator efficiency can generaqy. be

rate yields rated efficiency (Figure 3).

concidered 93 to 97%. Space does not peJtmlt a

thorough discussion of variable

ASR Hc;ual tl>1 RATED

losses, and a fixed value will not be far off.

LB/HP-HR BTtJ/LB f<itJiLB EFF j

c. As in I.e. above, calculate Rankine

Figure 6 summarizes this calculation, with

other useful information. '

TRA"ISFER ?lJMP 3l.3 81.31 :280.1+4 34.47

Figure 3.

I I

!

--T'-

8000

-. ...,_c

,;<:ioo

I

i.

!.

I

-;-_. ..:....-

: .:

L

5000

107

ESL-IE-85-05-19

Proceedings from the Seventh National Industrial Energy Technology Conference, Houston, TX, May 12-15, 1985

--------------------

--- ---

k,

,

,.

'

W1PRESSOR DRIVE TURBINE PERFORMANCE CURVE

COMPRESSOR DRIVE TURBINE

80

TURBINE STEAl RATE - PWID5

PRESSURE IS 14.7 PSIA

HUT PRESSURE PSI6 li15.0

IUT -f 720.0

INLET E.'f"HIlLPY BTll/LBI3liO.9O

EMROPY IlTU/LBR 1.591

EXtA!ST PRESS

EFF 15.4S _

liSl' EFf 23.n

1:0 PSIS SOl' EFF 30.91

35l' EFf 44.15

Figure 5.

W1PRESSOR DRIVE TURBINE

ilrldicted Efficil!llCy tro.Manuficiurer's IHLUlNS LINE

13liO.9O BTU/L811 THROTTLE ENTIIlPV

15.4SO HR TlEORETICll. SIDlIl RATE

DELTA H WTl.ET RSR RAN<INE

FLOW PlIoER EHTJR.PY EFfICIEIICY

Ul.B/HRl HIP) (BTU/L8II) IBTU/L8II) (LB/HAlr) (l'l

45.00 1500.0 84.83 127li.07 30.00 51.SO

0.00 2250.0 95.44 1265.46 2li.li7 57.94

80.00 3355.0 101i.73 1254.17 23.85 4.79

100.00 4450.0 113.25 1247.liS 22.47 li8.75

120.00 55SO.0 117.71 1243.19 21.2 71.46

140.00 li6OO.0 119.98 1240.92 21.21 72.84

10.00 7liSO.O 121.li8 1239.22 20.92 73.87

Figure 6.

This can also be represented in graphical form,

to predict performance at any flow rate

(Figure 7).

Efficiency is now defined as a function of flow

without restriction to a particular set of steam

conditions. This curve is as valid for actual

header conditions as it is for those specified by

the manufacturer, within reasonable limits.

3. EXHAUST OR EXTRACTION ENTHALPY/TEMPERATURE

CURVES -- In addition to, or in lieu of, Willans

lines, the manufacturer sometimes provides curves

describing exhaust steam enthalpy or temperature as

a function of section flow (Figure 8). This is

particularly common for extraction machines. This

data is valid only against a specified inlet

condition, but can be readily converted to the

familiar efficiency versus flow format for more

general evaluation.

-------.... I

J.----- !

60

/f"--- I

i

I

40

I

!

20

,I

o 20 40 60 80 100 120 140 160 180

THROTTLE FLOW - 1000's LBS/Hr

Figure 7.

:" -,"cOMPRESiOR"uRiVt TURBiNE

_.... 72.0.;=.-'110"-:6..... _

'7400 HP: <cCOO RPM'

:--- .zoocqo .._.t--- ".. _.- .- -. ..

... j ; .... I .

J ! . _....... . ', ' ; .

. . . ". i. ! _ ....__ .... :_.1 :"._' _.1._"_._

:.....lbOOOO __.L._'.. _. _ _

1 !--; \!

. .. ... .- .:J

1 \:

__ .._ .. __:.:

II-i ...

,1

... "'.' ----... _-------_:_.__.'..-

.. 0 ... : '00... ;.- .. 2.00.. 300 . 400. .. 500...

'.M .. .. -.; --:-' ...:. __

: :

Figure 8.

a. Determine inlet enthalpy from known thrott Ie

temperature and pressure data found on the curve

diagram, Figure 8.

b. Calculate actual lih and steam rate for a range

of section flows; ideal steamrate is the same as

in 2a above; 15.45 lb/HP-HR.

e. Calculate Rankine Efficiency as a function of

flow (Figure 9).

Since a Willans Line was also provided for this

machine (Figure 4), the results of this calculation

can be superimposed on the manufacturer's

predictions for comparison, as shown on Figure 10.

108

ESL-IE-85-05-19

Proceedings from the Seventh National Industrial Energy Technology Conference, Houston, TX, May 12-15, 1985

----------

COMPRESSOR DRIvE TURBINE

Oredlctea Efficiency from Manufacturers EXHAUST TEMP vs FLCIj curve

INLET C()/DITICJ/S:

PRESSURE

(PSIS) 615.00 615.00 615.00 615.00

TEllPERIlTURE - (Deg Fl 720.00 720.00 720.00 720.00

ENT;R.PY - IBTU/Uill 1360.91 1360.91 1360.91 1360.91

ENTROPY - IBTU/UiI Rl 1.591 1.591 1.591 1.591

!'L(ft; - U0E3 LB/HR) 160.000 120.000 100.000 80.000

EXIAJST

PRESS IJlSlGl 110.00 110.00 110.00 110.00

(Deg Fl 425.00 430.00 440.00 455.00

ACTUAL ENTlRPY 1237.28 1239.97 1245.33 1253.27

lDEIll ENTHALPY 1196.21 1196.21 1196.21 1196.21

ACTUAL STEAM RIlTE ILB/HPHR) 20.59 21.04 22.02 23.65

lllEAi. STEAM RATE tLB/HPHR) 15.45 15.45 15.45 15.45

tET HP m2.3 5702.2 4541.5 3383.3

RANKINE EFFICIEtf:Y 75.06 73.43 70.18 .5.35

"

Figure 9.

PREDICTED PERFORMANCE CURVE

COMPRESSOR DRIVE TURBINE

I

I

I

I

I

I

40 60 8'0 100i 1'20i 140i 160 I lla i

20

THROTTLE FLOW - 1000's LB/HR

D EXHAUST TEMP DATA + WILLANS LINE DATA

Figure 10.

4. EXHAUST OR EXTRACTION USED ENERGY CURVES -- Data

of this variety is usually provided for

intermediate or tail sections of single- and

multiple-extraction turbines. This is just another

way of representing an extraction enthalpy curve,

except that an inlet condition (exhaust enthalpy

from the upstream section) must first be determined

using another method: one of the three previous

techniques wi 11 provide that value. From there,

the process is identical to the previous example.

Figure 11 represents the data from Column 3 of

Figure 6, and produces the same efficiency

versus flow curve, Figure 7.

S. PERFORMANCE TEST DATA Once all the

manufacturer's data has been reviewed and analyzed,

it is time to leave the office and go out into the

harsh environment of real equipment. Turbines

never look like the sales brochures show; they get

covered with insulation (and grime), and are hooked

up to some piece of critical equipment that nobody

wants you to (test) mess with.

.----------

-- I

.

...... l

I

61S#-720

0

FTT-liO#G

7400 HP 6000

Figure 11.

I

However, you rarely need to disturb the tJrbine to

test it. What you do need is some test

equipment. Recently calibrated and

temperature gauges are the best source of data. If

your equipment has thermowells, use them. IIf not,

then a long thermocouple can be between

pipe and insulation in the throttle andJ exhaust

lines to get fairly accurate reading.. (The

temperatures wi11 be a bit low, but about'the same

amount both up and downstream.) pressure!readings

should be taken as close to the equiPment as

possible, to avoid penalizing the turbinerfor pipe

hydraulics induced pressure losses. I

Also required is some indication of steam flow

through the turbine, corresponding to the measured

steam conditions. A recently calibrated steam

meter will provide the best data. Flow-by-

difference should be the last resort. To the

extent possible, take data for a variety of turbine

flow rates (until an operator gets rtired of

humoring you). Then convert the testI data to

efficiency, for comparison to the as-new :predicted

efficiency.

I

i

a. From inlet temperature and pressure, Idetermine

inlet enthalpy, as in La. above, for leach test

condition observed.

b. determine actual exhaust enthJl py

c. Calculate actual Ah at known flow ratesj

I

d. From inlet temperature and pressure, 4nd outlet

pressure, calculate ideal ah and ideal steam

rate as in l.b, c, and d above. I

e. Calculate actual steam rate, if throttle flow is

known. :

f. Calculate and plot turbine efficiency versus

flow against manufacturer's

I

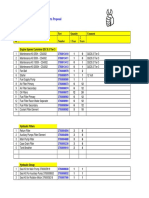

Figures 12 and 13 suuunarise field test data,

calculation of actual performance parameters, and

comparison of results to manufacturer's; predicted

efficiencies. This machine appears [ to have

suffered minor performance loss, butI may not

warrent immediate repair. Continued lnonitoring

over time will warn of further decay,

or comfirm continuing satisfactory

109

ESL-IE-85-05-19

Proceedings from the Seventh National Industrial Energy Technology Conference, Houston, TX, May 12-15, 1985

"URBil>

=::...DTEST DA,Q AAALYSIS

;',-F

P<tSSlIRE .. (PSIG)

- lDeg F)

- lBTU/,-BIIl

Rl

=l.Qw il0E3

630.00

689.00

1341.78

1.572

73.0(0)

CONDlTIONS:

PRESS iPSIS) 81.00

Del ;, 410.00

ACT:.A. ENTHR.PY 1233.49

:DEAL 1159.59

ACTUAL STEAM RATE ILB/'iJlt<9) 23.50

!DEGl STEAM IlCrE iLB/"iIi<RI :J. 9

7

'It! ,,0 3106./

RP.,..CNE 59.4.

Figure 12.

SUMMARY

630.(>(1 630.00 630.0(1

689.00 689.00 689.00

1341.78 1341.78 1341.78

1.572 1.572 l.S72

105.000 119.000 140.000

81.00 81.00 81.00

383.00 378.00 372.00

1219.15 1216.45 1213.18

1159.59 1159.59 1159.59

20.75 20.31 19.79

13.97 13.97 13.97

5059.(, 58bO.4 7074.1

67.3! &8.79 70.58

The procedure for tracking steam turbine

performance is quite straight forwarded. First,

estimate turbine efficiency, independent of steam

conditions, from any of several sources of

manufacturer's data. Then, test the equipment in

operation and convert raw data into terms of

efficiency. Plot both results on a common axis and

identify performance trends. If the equipment

seems to be doing poorly, check to see if there is

something simple to correct, like partly open hand

valves, speed control by throttling, or operating

speed far off spec. If these do not seem to be

contributing to the problem, then closer exam-

ination may be justified.

., RE.D iCTED PER,,-'-j C.UR'.... r-

COMPRESSOR DRIVE TURBINE

--_...-.--.- -------. -- -----.... -.....-----... ----- ---....--------..------.......

,

-olr_ ._. ---:r----r

_.--.... -_.-

_

_ ....._w -

'" 60-j

I

/'/

I

I

-!

"

Test Data

40)

j

c.> ,

H

1

!

201

Z i

H

-l

: I

o

o 20 40 60 80 100 120 140 160 180

THROTTLE FLOW - 1000's LB/HR

Figure 13.

The methods described are straight forward, and

readily adaptible to computer-assisted calculation

and data base record keeping to simplify trend

analyses; most of the figures presented here were

generated by computational programs.

Testing at regular intervals will provide a

chronological record of turbine performance, and

changes can be tracked to indicate when water

washing or repair is required. Timely maintenance

can improve production rates by avoiding

unscheduled down time, and head off more costly

repairs.

The long range benefits are less trouble from

better maintained equipment for less money,

supporting improved production. Sounds pretty

good, doesn't it? Start searching those archives!

110

ESL-IE-85-05-19

Proceedings from the Seventh National Industrial Energy Technology Conference, Houston, TX, May 12-15, 1985

You might also like

- Steam Turbine ExperimentDocument7 pagesSteam Turbine ExperimentEnriv YasiladNo ratings yet

- Vibratory Stress Analysis of ISB for Steam TurbineDocument12 pagesVibratory Stress Analysis of ISB for Steam TurbineRoshan Shanmughan100% (1)

- Design Consideration of Gas TurbineDocument155 pagesDesign Consideration of Gas TurbineMohammad Ibnul Hossain100% (2)

- Steam Turbine Control Valve, Governing and Lube Oil System ExplainedDocument15 pagesSteam Turbine Control Valve, Governing and Lube Oil System ExplainedPrabhu Lohakare100% (1)

- Epri HPS PDFDocument152 pagesEpri HPS PDFale sepulvedaNo ratings yet

- Turbine Heat Rate CalculationDocument2 pagesTurbine Heat Rate Calculationkaruna34650% (2)

- Asme Code For Ultrasonic Testing The Knowledge Sinequation: Ashok J. TrivediDocument7 pagesAsme Code For Ultrasonic Testing The Knowledge Sinequation: Ashok J. TrivediMax Celis CNo ratings yet

- Gas Welding Equipment - Hose Connections For Welding, Cutting and Allied ProcessesDocument12 pagesGas Welding Equipment - Hose Connections For Welding, Cutting and Allied ProcessesMustafa Ersin EkremNo ratings yet

- Condensate Cycle SystemDocument26 pagesCondensate Cycle SystemBhumit Sagathiya100% (2)

- Easy Control Valve SelectionDocument5 pagesEasy Control Valve SelectionhrtoroNo ratings yet

- Question and Answer On Steam TurbinesDocument33 pagesQuestion and Answer On Steam TurbineschunkyNo ratings yet

- Tutorial 2-Equilibrium 1Document2 pagesTutorial 2-Equilibrium 1Sai KrishnaNo ratings yet

- Expansion Joint in CAESARDocument5 pagesExpansion Joint in CAESARkaruna346No ratings yet

- Turbines - New Module Hay PDFDocument191 pagesTurbines - New Module Hay PDFThái Mai Đình100% (1)

- Turbine ManualDocument399 pagesTurbine ManualSandeep Kumar100% (2)

- Gas Turbine Performance: by Rainer KurzDocument16 pagesGas Turbine Performance: by Rainer Kurzthryee100% (1)

- Steam Gland SealingDocument118 pagesSteam Gland SealingRyan Wong100% (1)

- MHPS Jac GTDocument7 pagesMHPS Jac GTkp pkNo ratings yet

- Gas Turbine Technologies for Electric GenerationDocument54 pagesGas Turbine Technologies for Electric GenerationVeerabhadra Rao Korimilli100% (1)

- PGI2003 FastStartup&DesignForCyclingDocument20 pagesPGI2003 FastStartup&DesignForCyclingscarrion80100% (1)

- Understanding Pump Performance Curves and Best Efficiency Point (BEPDocument6 pagesUnderstanding Pump Performance Curves and Best Efficiency Point (BEPOcta RioNo ratings yet

- Inspections, As A Part of A Maintenance Program That Must Be Put in Place With TheDocument29 pagesInspections, As A Part of A Maintenance Program That Must Be Put in Place With TheFrankNo ratings yet

- Raft TT FT FT FT FT AFT AF RAFDocument31 pagesRaft TT FT FT FT FT AFT AF RAFHugo Silva100% (1)

- Steam Turbine Thermal Stress Online Monitoring Technology - EPRI PDFDocument84 pagesSteam Turbine Thermal Stress Online Monitoring Technology - EPRI PDFChetan Atrai100% (1)

- Turbine AlignmentDocument1 pageTurbine AlignmentGuru Raja Ragavendran NagarajanNo ratings yet

- Steam TurbineDocument102 pagesSteam TurbineMathivanan AnbazhaganNo ratings yet

- TR 107422 V2Document168 pagesTR 107422 V2FRANCISCO JOSE GARCIA IBAÑEZNo ratings yet

- CCI Power ApplicationsDocument57 pagesCCI Power Applicationssukanya_ravichandran100% (1)

- Failure of Secondary Reformer RefractoryDocument27 pagesFailure of Secondary Reformer RefractoryZeshanNo ratings yet

- Steam Turbine - Q & A 1Document104 pagesSteam Turbine - Q & A 1rahul_choubey_9100% (6)

- DesuperheaterDocument5 pagesDesuperheaterKrishna KumarNo ratings yet

- HRSG DescriptionDocument25 pagesHRSG DescriptionFahim Kazmi100% (1)

- Turbine Inlet Air Cooling System (Bob Omdivar) Keuntungan Dan Kelebihan Sistem PendinginDocument41 pagesTurbine Inlet Air Cooling System (Bob Omdivar) Keuntungan Dan Kelebihan Sistem Pendingindimas100% (2)

- Steam TurbineDocument10 pagesSteam TurbineBilal Qasim0% (1)

- Industrial Process Control ValvesDocument36 pagesIndustrial Process Control Valvesffown100% (1)

- HP LP Bypass System: Ravi Pal SinghDocument36 pagesHP LP Bypass System: Ravi Pal SinghMinh Hoang NguyenNo ratings yet

- Steam Turbine ValvesDocument2 pagesSteam Turbine ValvesWalter Joseph100% (1)

- Steam Turbine BasicsDocument77 pagesSteam Turbine Basicsas5236No ratings yet

- Condition Monitoring For Steam Turbines IDocument38 pagesCondition Monitoring For Steam Turbines IjavedNo ratings yet

- Quick Check On Piping FlexibilityDocument8 pagesQuick Check On Piping Flexibilitysateesh chandNo ratings yet

- Basics of Boiler DesignDocument92 pagesBasics of Boiler DesignJitender SinghNo ratings yet

- Energy Audits in Thermal Power StationDocument62 pagesEnergy Audits in Thermal Power Stationfiroj_khan995% (22)

- Wind Load NSCP 2010 SampleDocument5 pagesWind Load NSCP 2010 SampleRichard Tagle100% (1)

- V005t15a001 88 GT 150Document13 pagesV005t15a001 88 GT 150Antonio CilindroNo ratings yet

- Ash ReinjectionDocument22 pagesAsh Reinjectiongaol_bird009No ratings yet

- Supercritical Technology in BoilersDocument17 pagesSupercritical Technology in Boilersamit joshi100% (4)

- OM0401 Overview of Turbine Version GDocument41 pagesOM0401 Overview of Turbine Version Gمحمد خالدNo ratings yet

- Steam Turbine For Large OutputDocument80 pagesSteam Turbine For Large OutputAmbrish Singh100% (1)

- Gas Turbine Technologies for Sustainable Power GenerationDocument35 pagesGas Turbine Technologies for Sustainable Power GenerationEmin Çelik100% (1)

- Gas TurbineDocument127 pagesGas TurbineimranakhtarNo ratings yet

- GE Capabilities For Ansaldo FleetDocument17 pagesGE Capabilities For Ansaldo Fleetmirphan76No ratings yet

- Knovel Steam TablesDocument27 pagesKnovel Steam TablesRafael Rodriguez MedinaNo ratings yet

- 07 Development of Turbo-Expander Based Liquid Nitrogen Plant - Ranjit Kumar SahooDocument95 pages07 Development of Turbo-Expander Based Liquid Nitrogen Plant - Ranjit Kumar Sahoomohamadsadegh kamali100% (1)

- Cause and Prevention For Steam Turbine BDocument10 pagesCause and Prevention For Steam Turbine Brudi setiawanNo ratings yet

- HYDRAULIC CONTROL OIL TROUBLESHOOTING LESSONDocument6 pagesHYDRAULIC CONTROL OIL TROUBLESHOOTING LESSONmister pogiNo ratings yet

- Nuclear Power Plant Steam Turbine-Modeling For Model Based Control PurposesDocument25 pagesNuclear Power Plant Steam Turbine-Modeling For Model Based Control PurposesMuhammad Junaid DarNo ratings yet

- Performance Corrections For Steam Turbines With Multi-Pressure CondenserDocument8 pagesPerformance Corrections For Steam Turbines With Multi-Pressure CondenserSujeet Kumar50% (2)

- Boiler Drum Level Control Pid ControlDocument10 pagesBoiler Drum Level Control Pid ControlrajishrrrNo ratings yet

- Gas Turbine Range OverviewDocument2 pagesGas Turbine Range Overviewyourikats6161No ratings yet

- GT HandbookDocument5 pagesGT HandbookMohiuddin MahiNo ratings yet

- HRSG Steam Velocity AnalysisDocument3 pagesHRSG Steam Velocity Analysisaliscribd46No ratings yet

- Frame 6B High Wheel Space Temperature Conference PresentationDocument17 pagesFrame 6B High Wheel Space Temperature Conference Presentationpartha6789No ratings yet

- Ultra Super Critical TechDocument18 pagesUltra Super Critical Techdurgeshsharma2No ratings yet

- System DescriptionDocument28 pagesSystem DescriptionGloria HamiltonNo ratings yet

- 04 01 T6497 Prev Mainten A4 Color 2sided 2slides Each SideDocument18 pages04 01 T6497 Prev Mainten A4 Color 2sided 2slides Each SideDangolNo ratings yet

- Gas Turbine Compressor WashingDocument8 pagesGas Turbine Compressor Washingwolf_ns100% (1)

- WH Vacuum in Steam TurbineDocument2 pagesWH Vacuum in Steam Turbinemiths_0087No ratings yet

- Optimal Chilled Water Delta-TDocument8 pagesOptimal Chilled Water Delta-Tanup_nairNo ratings yet

- HRSG SimulationDocument7 pagesHRSG Simulationkaruna346No ratings yet

- Ris R 1500 PDFDocument84 pagesRis R 1500 PDFshivakeesNo ratings yet

- 07-264 1896-1901 PDFDocument6 pages07-264 1896-1901 PDFSugianto BarusNo ratings yet

- Piping SystemsDocument5 pagesPiping SystemsDesislavNo ratings yet

- 144 0067Document4 pages144 0067Antony BanderasNo ratings yet

- Use of Branch Connections: Standard Practice ForDocument5 pagesUse of Branch Connections: Standard Practice ForFelix Rodriguez LiraNo ratings yet

- Limit, Fits and ToleranceDocument13 pagesLimit, Fits and ToleranceAnkit NautiyalNo ratings yet

- How Was + (Noun)Document1 pageHow Was + (Noun)karuna346No ratings yet

- I Have + Noun ExamplesDocument1 pageI Have + Noun Exampleskaruna346No ratings yet

- Iam Getting ExeciseDocument1 pageIam Getting Execisekaruna346No ratings yet

- I'm good at - What you excel at and are comfortable doingDocument1 pageI'm good at - What you excel at and are comfortable doingkaruna346No ratings yet

- I Am Gonna + Verb ExeDocument1 pageI Am Gonna + Verb Exekaruna346No ratings yet

- If I Were You ExamplesDocument1 pageIf I Were You Exampleskaruna346No ratings yet

- I Have +PP ExamplesDocument1 pageI Have +PP Exampleskaruna346No ratings yet

- I Have To + Verb ExamplesDocument1 pageI Have To + Verb Exampleskaruna346No ratings yet

- I Am At, In, On ExamplesDocument1 pageI Am At, In, On Exampleskaruna346No ratings yet

- Ash Fusion TemperatureDocument2 pagesAsh Fusion Temperaturekaruna346No ratings yet

- CRH Line FailuresDocument3 pagesCRH Line Failureskaruna346No ratings yet

- Component Material Equivalent ASTMDocument1 pageComponent Material Equivalent ASTMkaruna346No ratings yet

- I Am +verb ExerciseDocument1 pageI Am +verb Exercisekaruna346No ratings yet

- Common Irregular Verb ListDocument4 pagesCommon Irregular Verb Listapi-27488371100% (1)

- Plant DesignDocument17 pagesPlant Designkaruna346No ratings yet

- Pressure DropDocument5 pagesPressure Dropkaruna346No ratings yet

- NetworksDocument31 pagesNetworksSumeet JethraNo ratings yet

- Thermal Considerations in Pipe FlowsDocument11 pagesThermal Considerations in Pipe FlowsWaqas AhmadNo ratings yet

- Feed Water Control ValveDocument3 pagesFeed Water Control Valvekaruna346No ratings yet

- Performance Impacts VKADocument5 pagesPerformance Impacts VKASherif Mohamed KhattabNo ratings yet

- Annex XDocument3 pagesAnnex XHardikNo ratings yet

- HPHT Completion Hardware (2023.05.05)Document54 pagesHPHT Completion Hardware (2023.05.05)New Auto TVNo ratings yet

- Entropy Problems AnswersDocument6 pagesEntropy Problems AnswersTots HolaresNo ratings yet

- Aero Booklet Forth Semester 2021-22Document22 pagesAero Booklet Forth Semester 2021-22PIETDS1 aeronauticalNo ratings yet

- ÍTEM 2. - MINEFLEX Hose - ESPECIFICACIONES TÉCNICAS - FLUIDOSDocument3 pagesÍTEM 2. - MINEFLEX Hose - ESPECIFICACIONES TÉCNICAS - FLUIDOSGiancarloNo ratings yet

- Numerical Simulations of Interrupted and Conventional Microchannel Heat SinksDocument12 pagesNumerical Simulations of Interrupted and Conventional Microchannel Heat SinksAnkit LonareNo ratings yet

- BMW Z4 BrochureDocument8 pagesBMW Z4 BrochureNicolo GarciaNo ratings yet

- Esas FinalDocument3 pagesEsas FinalGower LacambraNo ratings yet

- TC1625 Catalog Pgs41-43Document3 pagesTC1625 Catalog Pgs41-43G100% (1)

- Installation and Operation Manual: VRV IV System Air ConditionerDocument36 pagesInstallation and Operation Manual: VRV IV System Air Conditionerelectrowat engineeringNo ratings yet

- พอฤทัย วิริยะภาค26 3.5Document2 pagesพอฤทัย วิริยะภาค26 3.55.6 25 [พิงค์แพรว]นางสาวพอฤทัย วิริยะภาคNo ratings yet

- Effects of Shear Box Size and Silt Content on Strength of Silty SandsDocument7 pagesEffects of Shear Box Size and Silt Content on Strength of Silty SandsJavier MtNo ratings yet

- Iseki Tm3200 3240 Parts ManualDocument20 pagesIseki Tm3200 3240 Parts Manualjoseph100% (53)

- DrillchartDocument5 pagesDrillchartcc6689No ratings yet

- SECTION Theory&Verification Ver 460Document137 pagesSECTION Theory&Verification Ver 460A_saravanavelNo ratings yet

- Caddy Rod LockDocument16 pagesCaddy Rod LockcrisalevNo ratings yet

- Fluid Tests22Document28 pagesFluid Tests22son gokuNo ratings yet

- RK-2001E2 English TraductionDocument2 pagesRK-2001E2 English TraductionwxcvbnnbvcxwNo ratings yet

- sEW20Document78 pagessEW20Wan AzmiNo ratings yet

- 6 TransmissionDocument38 pages6 TransmissionKamal Jit DhimanNo ratings yet

- CS4002 U-Deck Recommended SparesDocument5 pagesCS4002 U-Deck Recommended SparesedwinNo ratings yet

- Sweeper (Brushes With Convoluted Sections) (One Piece End Caps) (72 - ) - (S - N 435400101 & Above, 783700101 & Above) - SweeperDocument3 pagesSweeper (Brushes With Convoluted Sections) (One Piece End Caps) (72 - ) - (S - N 435400101 & Above, 783700101 & Above) - SweeperCristian SchildNo ratings yet

- Motor effect concepts and applicationsDocument2 pagesMotor effect concepts and applicationsIntiser RahmanNo ratings yet

- Tcont900 InstallerDocument24 pagesTcont900 Installerapi-279886039100% (2)