Professional Documents

Culture Documents

Autoset ATS6V0A Manual UK 062003

Uploaded by

segovaOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Autoset ATS6V0A Manual UK 062003

Uploaded by

segovaCopyright:

Available Formats

INSTALLATION

INSTRUCTIONS

AUTOSET

LEVEL CONTROL

ATEX APPROVED

type ATS6V0A

600

II1D T100C Tamb -20C to +50C IP65

Cert. No: BAS01ATEX1403

BRAME ELEVATOR COMPONENT8 LTD. UK

8ETEM. FRANCE

To Order: Specify AUTOSET ATS6V0A + length of probe required

Guarantee

The equipment is covered by a 12 months guarantee from the date of shipment.

Any faults arising due to faulty materials or workmanship, within the guarantee

period, will be corrected free of charge providing the equipment is returned to us

carriage paid.

>:ATEXATS6VOAMAN 642-028

OVERALL SPECIFICATION - ATS6V0A

Type/Certificate No: ........... ATS6VOA M300227A BAS01ATEX1403

Approval: ............................ II1D T100C Tamb -20C to +50C IP65

Protection: .......................... IP65.

Enclosure: .......................... Modified Polyamide 66.

Mounting: ........................... Via 1" BSP Parallel thread.

Voltage: .............................. 110V/230V ac 50/60 Hz or 24V dc

(+6.5%.to-10%).

Rating: ................................ 2.5VA.

Operating Temperature: ... -20 to +50C.

Output: ................................ S.P.C.O contacts rated at 2.5A 240V non-

inductive.

Timer Delay: ...................... 0 - 128 second variable. (prevents false signal-

ing from splashing). Set via pushbutton.

Earth Bonding: ................... Earth stud located on exterior of main case.

This stud must be connected to earth, bonded

to container or metalwork of container &, if

used, connected to exterior of armour cabling.

Probe Length: 100mm, 1 metre, 2 metre or 10 metre

wire rope.

When this product is incorporated into other machinery or apparatus,

that apparatus must not then be put into service (in the E.C) until it has

been declared in conformity with the appropriate E.C Directive/s.

THIS PRODUCT CONFORMS TO THE REQUIREMENTS FOR CE MARKING

600

BRAIME ELEVATOR

COMPONENTS LTD.

England. LS10 1JZ

Telephone: (0113)2457491

Fax: (0113)2435021

Web: www.braime.com

e-mail: information@braime.co.uk

S E T E M

9, route de Corbie

80800 LAMOTTE WARFUSEE

Tl: (33) 03 22 42 32 26

Fax: (33) 03 22 42 37 33

Email: setem@aol.com

www.braime.com /setem

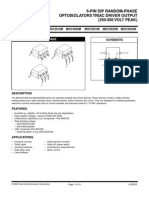

Powershield Detail

DIMENSIONS (FIG 5)

POWERSHIELD DETAIL (FIG 6)

NOTES:-

a) The AUTOSET sensitivity is proportional to the surface area of the

probe. When using a 16mm dia. probe the minimum length to use, for the

majority of materials, is 200mm. This should be treated as the minimum if

possible..

If the probe length needs to be reduced to less than 200mm, the surface

area should be maintained. This can be achieved by increasing the

diameter, by fitting a metal tube over the probe, or by bending the probe

rod. In certain high density materials it may be possible to reduce the

length without compensation.

72

Po we r shie ld m ust p ro tr ud e

a s f ar as po ssib le int o ve sse l

a nd n ot less t ha n 6mm ( 1/ 4 ")

Conduit entry tapped 20mm

External ground connection

100

Blind conduit entry tapped 20mm.

Drill out to use.

1" BSP parallel mounting thread

144

?

1

5

7

4x Stainless steel

captive fixing screws

SYNATEL

132

DIGI MATIC

AUTOSET

E a r th

B o nd

E

N

11 0v

2 4v

0 v

2 30 v

AC

D C

Introduction

Installation

The AUTOSET is a fixed point Level Controller incorporating a microcomputer

which is used to automatically calibrate the probe to suit the material being

detected. Full manual override facilities are included. The unit has full ATEX

approval for use in dust hazard installations, such as flour mills, saw mills or

any application where dust may be present.

The AUTOSET employs a power shield to minimise the effect of material

adhering to the probe making it ideal for detecting most materials including

sticky or viscous types. It is equally suited to both liquids and solids . The

probe may be a solid rod, metal plate or wire rope.

The self contained AUTOSET is normally supplied with a loose probe, avail-

able as a stainless steel rod in standard lengths of 100mm, 1 metre or 2

metres, or as a 10 metre wire rope suspension probe and weight. The probe

should be screwed to the AUTOSET. Prior to attachment, the probe length

can be reduced or increased, if desired, but see notes a) and b) regarding

minimum surface area.

Connections (fig 1)

A thread locking compound is already applied to the probe fixing stud of the

AUTOSET. This will prevent the probe rod from vibrating loose. Once fitted,

the compound is fully hardened after 20 minutes.

AUTOSET will operate on 110V/230V ac 50/60Hz or 24V dc supplies. The

unit may be wired in ordinary un-screened cable of any length and need not be

separated from other cables.

A SUPPLY EARTH IS ESSENTIAL!

When mounting the AUTOSET, care must be taken to ensure that the ex-

posed end of the power shield protrudes into the container. See fig. 6. Mount

unit securely to minimise vibration.

Connect in accordance with fig 1, and set High/Low switch to required position

(see fig 2), ensure that cable gland and back cover are fully tightened when

finished. The AUTOSET has two 20mm cable entries, one of which is blank,

the blank may be drilled out carefully if required; it must not be knocked out.

The unit should be wired and earthed in accordance with appropriate Electrical

Regulations. The unit must be earthed and the terminal MUST be bonded to

the earth bond stud.

On metal containers, unit earth MUST be bonded to the container. If the

container is non-metallic, metal flanges or couplings used to mount probe

should be bonded to earth. This also applies to probes mounted in wooden or

plastic tops of metal bins.

IMPORTANT NOTE:

The AUTOSET is supplied

with a fuse fitted in the AC

fuseholder, fit into the DC

position for 24V dc operation.

The fuse rating for this unit is

80mA anti-surge, IEC.

NO OTHER RATING MAY BE USED

Commissioning

The AUTOSET can be calibrated automatically, manually or by a combination

of the two methods. Usually, automatic calibration is the simplest method,

particularly when the vessel can be filled to cover the probe.

Manual calibration is useful when a number of probes in similar applications

need to be set. Once the correct calibration has been determined and noted,

on one system, the remainder can be set to the same setting.

Display Functions

The display shows a number of different values depending upon whether the

unit is in manual or auto mode, and cal or park mode.

Park Mode

In normal operation the display shows a value representing the capacitance

measured by the probe at the time.

Pressing the button will cause the display to show uxxx followed by rxxx.

Pressing the button will cause the display to show cxxx followed by rxxx.

cxxx is the probe covered value measured during calibration, uxxx is the

uncovered value and rxxx is the relay operating point which the Digimatic

calculates and is half way between the two measured values.

Note: The settings are "view only" in park mode, they cannot be altered.

Cal Mode - auto/man switch set to auto

In this mode, pressing the button will cause the unit to measure and

display the uncovered value and recalibrate the relay operating point if neces-

sary. Pressing the button (with the probe covered) will cause the unit to

measure and display the covered value, again recalibrating the relay operating

point if necessary.

Fail Safe Setting

The High/Low switch (fig 2), sets the fail safe mode. In the High position,

therelay is de-energised with material present. In the Low position, the relay

is energised with material present. Normally, the High position is used for

high level probes and the Low for low level probes. Intermediate probe set-

tings depend upon individual requirements.

FIG 2

SW3 SW1 SW5

A ut o/ M a n S w it c h

H ig h/ L ow S w it c h

C a l/ Pa rk Sw i tc h

Earth

Bond

SW3

E

N

110v

24v

0v

230v

SW1 SW5

FIG 3

Covered/Raise Button

Un-covered/Lower Button

4 Digit Display

Timer Button

Power On LED

Calibrating LED

Output LED

Switch Functions:

SW1 = Auto/Man

SW3 = Cal/Park

SW5 = High/Low

Cal Mode - auto/man switch set to man

In this mode, pressing the button will cause the display to momentarily

display the present relay operating point and then to increment the setting

slowly and then rapidly to set a higher operating point. Pressing the button

will cause the display to momentarily show the current relay operating point,

and then decrement the setting, slowly and then rapidly.

Once adjusted in manual mode, any previous settings will be lost. The cxxx

reading will be 1 above the relay operating point and the uxxx reading 1 below.

Note: Always return to Park (after calibration)

Automatic Calibration - material available

1) Set Park/Cal switch to Cal and Auto/Man switch to Auto. The Cal LED will

flash.

2) Ensure that the probe is uncovered and press and hold the button. The

display will show uxxx followed by rxxx.

3) Fill the vessel sufficiently to cover the probe and then press the button.

Display will show cxxx followed by rxxx.

4) Return the Park/Cal switch to park. The unit is now calibrated. uxxx &

cxxx values can be viewed but not altered by pressing the & buttons.

Semi Automatic Calibration - material not available

5) Follow steps 1 & 2 above.

6) Set Cal/Park switch to Park and press the button. Note the uxxx

reading but ignore the rxxx reading. Return the Cal/Park switch to Cal and set

the Auto/Man switch to Man.

7) From the table below, select the nearest material to the type to be detected

and add the value to the uxxx reading determined in (6).

8) Press the button to raise the reading and the button to lower the

reading to achieve the calculated setting.

9) Return the Cal/Park switch to Park and press the & buttons to

confirm that the relay operating point rxxx is correctly set. The uxxx & cxxx

settings will be one below and one above the readings.

Table of Typical Settings

Material Type Increment

Light +15

Medium +30

Heavy +60 or greater

Time Delay

The AUTOSET has an adjustable delay from zero to 128 seconds, the timer

operating on both material arriving and leaving. To set the time delay, proceed

as follows.

10) Set the Cal/Park switch to Cal.

11) Press and hold the button. The display will show t000 which incre-

ments from zero and adds one second each time the button is pressed.

Release the button when the required delay time is shown.

12) Return the Cal/Park switch to Park and press to confirm the timer

setting.

13) The timer can be altered to a longer or shorter delay by repeating the

procedure from 10) above.

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Auto-Pilot: Simplified Block DiagramDocument8 pagesAuto-Pilot: Simplified Block Diagrammmishra914100% (1)

- Moto E7 Power Service Manual V1.0Document97 pagesMoto E7 Power Service Manual V1.0Felipe de san anicetoNo ratings yet

- Accessories CatalogDocument152 pagesAccessories Catalogsky100% (1)

- How to cash out cc and cvv's using online shoppingDocument2 pagesHow to cash out cc and cvv's using online shoppingSteph BryattNo ratings yet

- PL2303 Windows Driver User Manual v1.7.0 PDFDocument20 pagesPL2303 Windows Driver User Manual v1.7.0 PDFbrave_ftNo ratings yet

- PL2303 Windows Driver User Manual v1.7.0 PDFDocument20 pagesPL2303 Windows Driver User Manual v1.7.0 PDFbrave_ftNo ratings yet

- Monitoring - Energy - Use Schneider-Electric PDFDocument12 pagesMonitoring - Energy - Use Schneider-Electric PDFsegovaNo ratings yet

- MOC3021Document10 pagesMOC3021RamonNo ratings yet

- DIY k180Document8 pagesDIY k180jisteeleNo ratings yet

- Xbp24z7sit PDFDocument2 pagesXbp24z7sit PDFsegovaNo ratings yet

- Xbee Multipoint RF Modules: Product DatasheetDocument2 pagesXbee Multipoint RF Modules: Product DatasheetsegovaNo ratings yet

- X-CTU ManualDocument16 pagesX-CTU ManualAb PerezNo ratings yet

- Project Manual VLT 2800 ENGDocument171 pagesProject Manual VLT 2800 ENGKrzysiek PodsiadłoNo ratings yet

- Xbp24z7sit PDFDocument2 pagesXbp24z7sit PDFsegovaNo ratings yet

- Nguyen Jennifer Usf ResumeDocument1 pageNguyen Jennifer Usf Resumeapi-681358722No ratings yet

- Cisco Aironet 1140 Series Getting Started GuideDocument34 pagesCisco Aironet 1140 Series Getting Started GuideDmitryNo ratings yet

- Chapter 2 - TCP/IP ArchitectureDocument22 pagesChapter 2 - TCP/IP ArchitectureJuan SantiagoNo ratings yet

- Ivent101 Operator'S ManualDocument184 pagesIvent101 Operator'S ManualTrang PhạmNo ratings yet

- ESR Review TV Mag Jun05Document2 pagesESR Review TV Mag Jun05Dimitris DimitriadisNo ratings yet

- The Perfect Server - CentOS 6-1Document11 pagesThe Perfect Server - CentOS 6-1GemilangParhadiyanNo ratings yet

- CSE 451: Operating Systems Semaphores and MonitorsDocument30 pagesCSE 451: Operating Systems Semaphores and MonitorsrinspdNo ratings yet

- Observation of Topological Phenomena in A Programmable Lattice of 1,800 QubitsDocument17 pagesObservation of Topological Phenomena in A Programmable Lattice of 1,800 QubitsAnonymous HUY0yRexYfNo ratings yet

- X12D - X15D: 1,000 Watt Active LoudspeakerDocument16 pagesX12D - X15D: 1,000 Watt Active LoudspeakerHanafy GarengNo ratings yet

- Hull Me S Her ManualDocument121 pagesHull Me S Her ManualCông TuấnNo ratings yet

- 20-25 DMini 2.0Document100 pages20-25 DMini 2.0juancarlosllinasNo ratings yet

- EE 577A Spring 2022 - VLSI System Design Homework 1: TH TH THDocument4 pagesEE 577A Spring 2022 - VLSI System Design Homework 1: TH TH THvedeshNo ratings yet

- Cryptography Networks and Security SystemsDocument42 pagesCryptography Networks and Security Systemspokemonlover14116666No ratings yet

- Daftar-Harga-Fire-Alarm-Addressable-ASENWARE-Diskon-20-Jan-2021 Endless JakartaDocument2 pagesDaftar-Harga-Fire-Alarm-Addressable-ASENWARE-Diskon-20-Jan-2021 Endless JakartaMuliawan TjandraNo ratings yet

- Es Lab Manual-JntukDocument22 pagesEs Lab Manual-JntukMelissa GuerraNo ratings yet

- Deleted FilesgrDocument270 pagesDeleted FilesgrFerdinand OrtizNo ratings yet

- ER Diagrams for Industrial and Hospital Case StudiesDocument7 pagesER Diagrams for Industrial and Hospital Case StudiesMuhammad ShahbazNo ratings yet

- Technical Bulletin - ACP - ACS - Connect - Tool - v1.0 - B-307Document6 pagesTechnical Bulletin - ACP - ACS - Connect - Tool - v1.0 - B-307Fabian ArayaNo ratings yet

- i5/OS Commands ExplainedDocument18 pagesi5/OS Commands Explainedrachmat99No ratings yet

- Hidden Active Cellphone DetectorDocument27 pagesHidden Active Cellphone DetectorPradipta BiswasNo ratings yet

- Data WarehousingDocument24 pagesData Warehousingkishraj33No ratings yet

- CV Finance Marketing MBA Payroll UAEDocument4 pagesCV Finance Marketing MBA Payroll UAEAkhil B SinghNo ratings yet

- Cny 17Document9 pagesCny 17Krista TranNo ratings yet

- 1997 Vol 23 No 2 1001 AbstractDocument1 page1997 Vol 23 No 2 1001 AbstractFatih KantaşNo ratings yet

- LTE Serving Cell Performance Report for Semarang 3 NetworkDocument11 pagesLTE Serving Cell Performance Report for Semarang 3 NetworkNarto MujiatmikoNo ratings yet

- Review Questions For Chapter 1 Business Information SystemsDocument2 pagesReview Questions For Chapter 1 Business Information Systemsrobj20076404No ratings yet