Professional Documents

Culture Documents

Is.2449.1963 - Silver Oxide

Uploaded by

Kaka BabaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Is.2449.1963 - Silver Oxide

Uploaded by

Kaka BabaCopyright:

Available Formats

Disclosure to Promote the Right To Information

Whereas the Parliament of India has set out to provide a practical regime of right to

information for citizens to secure access to information under the control of public authorities,

in order to promote transparency and accountability in the working of every public authority,

and whereas the attached publication of the Bureau of Indian Standards is of particular interest

to the public, particularly disadvantaged communities and those engaged in the pursuit of

education and knowledge, the attached public safety standard is made available to promote the

timely dissemination of this information in an accurate manner to the public.

!"#$%&# '(%)

!"# $ %& #' (")* &" +#,-.

Satyanarayan Gangaram Pitroda

Invent a New India Using Knowledge

/0)"1 &2 324 #' 5 *)6

Jawaharlal Nehru

Step Out From the Old to the New

7"#1 &" 8+9&"), 7:1 &" 8+9&")

Mazdoor Kisan Shakti Sangathan

The Right to Information, The Right to Live

!"# %& ;<" =7"#" > 72 &(: ?0)"@" #AB 7" <&*" A*

Bhart+hariN,ti-atakam

Knowledge is such a treasure which cannot be stolen

IS 2449 (1963): Silver oxide [CHD 1: Inorganic Chemicals]

IS : 2449 - 1963

Indian Standard

SPECIFICATION FOR

SILVER OXIDE

UDC 661.857.22

Copyright 1963 by

INDIAN STANDARDS INSTITUTION

MANAK BHAVAN, 9 MATHURA ROAD

August 1963

NEW DELHI 110002

AMENDMENT NO FEBRUARY, 1981

TO

IS:2449-1963 SPECIFICATION FOR SILVER OXIDE

Co r r i g e n d u m

(Page 7, clause A-6.1.1) - S u b s t i t u t e t h e

f ol l owi ng f or t h e e x i s t i n g c l a u s e :

'A-6.1.1 Dilute Hydrochloric Acid'

( CDC 3 )

Repr ogr aphy Un i t , I S I , New De l h i , I n d i a

1

IS : 2449 - 1963

Indian Standard

SPECIFICATION FOR

SILVER OXIDE

Fine Chemicals ( Organi c &

Chairman

SHRI C. A. SUDRAHMANYAM

Members

DR. AMI R CHAND

SHRI N. K. SEN ( Alternate )

DR. U. P. BASU

DR. S. P. BHATTACHARYA

SHRI S. L. MEHRA ( Alternate )

SHRI S. K. BORKAR

Inorganic ) Sectional Committee, CDC 4

Representing

Hi ndus t an Organi c Chemicals Lt d. , New Delhi

Mi ni st ry of Defence ( R & D )

Bengal I mmuni t y Co. Lt d. , Cal cut t a

Depar t ment of Techni cal Devel opment ( Mi ni st ry

of Economi c & Defence Co-ordination )

Di r ect or at e General of Heal t h Services ( Mi ni st ry

of Heal t h )

SHRI P. S. RAMACHANDRAN ( Alternate )

SHRI R. C. DASGUPTA Gover nment Test House, Cal cut t a

SHRI K. L. BANERJ EE ( Alternate )

SHRI M. B. DESAI Kesar Sugar Wor ks Lt d. , Bombay

SHRI N. G. MADAM (Alternate)

S HRI S. V. DESAI

SHRI J. H. DOSHI ( Alternate )

DR. J . GUPTA

DR. SUKH DEV ( Alternate )

SHRI AMI YA KUMAR LAHI RI

Amar Dye-Chem Lt d. , Bombay

Nat i onal Chemical Labor at or y ( CSIR ), Poona

Bengal Chemical & Phar maceut i cal Works Lt d. ,

Cal cut t a

SHRI M. C. BAKSHI ( Alternate )

SHRI B. MAI TRA

SHRI M. ROHATGI ( Alternate )

SHRI SATYADEV MAYOR

DR. S. L. MUKHERJ EE

I ndi an Chemical Manuf act ur er s' Association,

Cal cut t a

Sat yadov Chemicals Pr i vat e Lt d. , Baroda

Sar abhai Chemieuls, Bar oda

SHRI B. SRINIVASAN ( Alternate )

DR. S. K. MUNSHI

MR. P. S. STROSS ( Alternate )

DR. NI TYA NAND

SHRI S. SAHA

SHRI B. SENGUPTA

SHRI B. V. SHAH

S HRI S. M. MUHTA ( Alternate )

Bri t i sh Drug Houses ( I ndi a ) Pr i vat e Lt d. ,

Bombay

Cent ral Drug Research I ns t i t ut e ( CSI R) ,

Lucknow

Tariff Commission, Bombay

Di r ect or at e General of Supplies and Disposals,

Ministry of Economic & Defence Co-ordi-

nat i on

The At ul Pr oduct s Lt d. , At ul

( Continued on page 2 )

INDIAN STANDARDS INSTITUTION

MANAK BHAVAN, 9 MATHURA ROAD

NEW DELHI 110002

Convener

SHRI M. B. DESAI Kesar Sugar Wor ks Lt d. , Bombay

Members

SHRI N. G. MADAN ( Alternate t o

Shri M. B. Desai )

SHRI C. H. GANDHI Sarabhai Merck Pr i vat e Lt d. , Bar oda

SHRI AMI YA KUMAR LAHI RI Bengal Chemical & Phar maceut i cal Works Lt d. ,

Cal cut t a

SHRI SARAL NATH GHOSH ( Alternate )

SHRI B. MAI TRA I ndi an Chemical Manuf act ur er s' Association,

Cal cut t a

SHRI B. SRI NI VASAN ( Alternate )

SHRI C. S. RAO Mi ni st ry of Defence ( R & D )

SHRI G. L. RAWAL Geoffrey Manners & Co. Pr i vat e Lt d. , Bombay

SHRI J . C. J AI N ( Alternate )

SHRI V. B. SHENOY British Dr ug Houses ( I n d i a ) Pr i vat e Lt d. ,

Bombay

SHRI C. C. SHROFF Excel I ndust r i es Pr i vat e Lt d. , Bombay

SHRI K. K. CHAYYA ( Alternate )

2

IS : 2449 - 1963

( Continued from page 1 )

Members

SHRI R. A. SHAH

DR. SADGOPAL,

Deput y Di rect or ( Chem )

Representing

Ronuk I ndust r i es Lt d. , Bombay

Di rect or, I SI ( Ex-officio Member )

Secretary

DR. G. M. SAXENA

Ext r a Assi st ant Di rect or ( Chem ), I SI

Inorganic Salts Subcommittee, CDC 4 : 5

IS : 2449 - 1963

Indian Standard

SPECIFICATION FOR

SILVER OXIDE

0. FOREWORD

0.1 This Indian Standard was adopted by the Indi an Standards Institu-

tion on 14 June 1963, after the draft finalized by the Fine Chemicals

( Organic & Inorganic ) Sectional Committee had been approved by the

Chemical Division Council.

0.2 The production of silvered mica plates has been firmly established

in the country and silver oxide is an important raw material for this

industry. This standard is intended to assist the indigenous manufac-

turers of silver oxide in producing a material of the required quality.

0.3 Wherever a reference to any Indian Standard appears in this speci-

fication, it shall be taken as a reference to the latest version of the

standard.

0.4 For the purpose of deciding whether a particular requirement of

this st andard is complied with, the final value, observed or calculated,

expressing the result of a test or analysis, shall be rounded off in accord-

ance with IS : 2-1960 Rules for Rounding Off Numerical Values

( Revised ). The number of significant places retained in the rounded off

value should be the same as t hat of the specified value in this st andard.

0.5 This standard is intended chiefly to cover the technical provisions

relating to silver oxide, and it does not include all the necessary

provisions of a contract.

1. SCOPE

1.1 This st andard lays down requirements and methods of sampling

and test for silver oxide. The material is used in the production of

silvered mica plates in the manufacture of capacitors for electronics

industry.

2. REQUIREMENTS

2.1 Description The material shall be dark brown in colour, and shall

be free from dirt, reduced silver and other gritty matter.

3

IS : 2449 - 1963

2.2 Particle Size The material shall completely pass through

63-micron IS Sieve.

NOTE BS Sieve 240, ASTM Sieve 230 and Tyl er Sieve 250 have t hei r aper t ur es

wi t hi n t he limits specified for t he IS t est sieve ment i oned above and may,

t herefore, be used as 03-micron IS Sieve.

2.3 The material shall also comply with the requirements prescribed

in Tabl e I when tested according to the methods given in Appendix A.

Reference to the relevant clauses of Appendix A is given in col 4 of the

table.

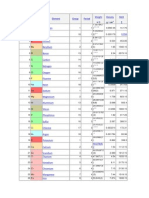

TABLE I REQUIREMENTS FOR SILVER OXIDE

SL

No .

(1)

i)

ii)

iii)

iv)

v)

vi)

CHARACTERISTIC

(2)

Silver oxide ( as Ag

2

O ), percent

wei ght , Min

Copper, lead and iron

Sul phat es ( a s SO

4

) , per cent

wei ght , Max

Chlorides ( as Cl ), percent

weight, Max

Ni t r at es ( as NO

3

) , percent

weight, Max

Al kal i ni t y ( as Na

2

O ), percent

weight, Max

by

by

by

by

by

REQUIREMENT

(3)

99.3

To pass tost

0.005

0.05

0.01

0.06

METHOD OF TEST

( REF TO C L No .

IN AP P E NDI X A )

(4)

A-2

A-3

A-4

A-5

A-6

A-7

3. PACKING AND MARKING

3.1 Packing The size and material of construction of the containers

shall be subject to agreement between the purchaser and the supplier.

3.2 Marking The containers shall be securely closed and marked

with the name and weight of the material in the container; manufactu-

rer' s name and trade-mark, if any; batch number; and the year of

manufacture.

3.2.1 The containers may also be marked with the ISI Certification

Mark.

NOTE The use of t ho I SI Certification Mark is governed by t he provisions

of t he I ndi an St andar ds I nst i t ut i on (Certification Mar ks) Act , and t he Rul es

and Regul at i ons made t her eunder . Presence of t hi s mar k on pr oduct s covered

by an I ndi an St andar d conveys t he assurance t hat t hey have been produced t o

comply with t he r equi r ement s of t hat St andar d, under a well-defined syst em of

4

IS : 2449 - 1963

inspection, testing and quality control during production. This system, which is

devised and supervised by ISI and operated by the producer, has the further

safeguard that the products as actually marketed are continuously checked by

ISI for conformity to the Standard. Details of conditions, under which a licence

for the use of the ISI Certification Mark may be granted to manufacturers

or processors, may be obtained from the Indian Standards Institution.

4. SAMPLING

4.1 Representative samples of the material shall be drawn as prescribed

in Appendix B.

AP P E NDIX A

( Clause 2.3 )

ANALYSIS OF SILVER OXIDE

A-1. QUALITY OF REAGENTS

A-1.1 Unless specified otherwise, pure chemicals and distilled water

[ see IS : 1070-1960 Specification for Water, Distilled Quality ( Revised ) ]

shall be used in tests.

NOTE ' Pur e chemicals' shall mean chemicals which do not contain impurities

that affect the results of analysis.

A-2. DETERMINATION OF SILVER OXIDE

A-2.1 Reagents

A-2.1.1 Dilute Nitric Acid 1: 1.

A-2.1.2 Sodium Chloride Solution 10 percent.

A-2.2 Procedure Weigh accurately about 0.15 to 0.2 g of the material,

previously dried at 105 2C for 2 hours and cooled. Dissolve in the

minimum quant i t y of dilute nitric acid and boil to expel nitrous fumes.

Dilute to about 100 ml with water. Filter off the insoluble matter and

wash well with hot water. Collect the washings and the filtrate and

heat to 60 to 70C. Add sodium chloride solution slowly with

constant stirring till no more precipitate of silver chloride develops.

Boil for 5 minutes to coagulate the precipitate. Allow it to settle in a

dark place for 5 to 6 hours. Filter the precipitate through a weighed

sintered crucible No. 3 or filter paper ( What man No. 40 or equivalent ).

Wash well with cold water acidified slightly with nitric acid and finally

with cold water alone. Dry the precipitate in an air oven to constant

weight at 130 to 150C.

5

IS : 2449 - 1963

A-2.3 Calculation

Silver oxide ( as Ag

2

O ), percent by weight =

where

B = weight in g of the precipitate, and

A = weight in g of the material taken for the test.

A-3. TEST FOR COPPER, LEAD AND IRON

A-3.1 Reagents

A-3.1.1 Dilute Nitric Acid 1: 1.

A-3.1.2 Dilute Ammonium Hydroxide 1 : 1.

A-3.1.3 Ammonium Molybdate Solution 10 percent.

A-3.2 Procedure Dissolve 5.000 g of the material in dilute nitric acid

and boil off the nitrous fumes. Dilute to 200 to 300 ml with water.

Add dilute ammonium hydroxide until the precipitate which is formed

just dissolves. Let it stand for three hours. The material shall be taken

to have passed the test for iron if there is no brown precipitate, and for

copper if the solution does not show a blue colour. To the clear solu-

tion, add 1 ml of ammonium molybdate solution. The material shall

be taken to have passed the test for lead if no turbidity or precipitate is

formed.

A-4. TEST FOR SULPHATES

A-4.1 Reagents

A-4.1.1 Dilute Nitric Acid approximately 5 N.

A-4.1.2 Barium Nitrate Solution 6 percent.

A-4.2 Procedure Dissolve 2.000 g of the material in dilute nitric acid

and boil to expel nitrous fumes. Dilute to 200 ml and add 5 ml of

barium nitrate solution. Let it stand for one hour. Prepare a blank for

comparison.

A-4.2.1 The material shall be considered as not having exceeded the

limit prescribed in Table I if no turbidity or precipitate is produced.

A-5. TEST FOR CHLORIDES

A-5.1 Apparatus

A-5.1.1 Nessler Tubes 50-ml capacity.

6

IS : 2449 - 1963

A-5.2 Reagents

A-5.2.1 Dilute Nitric Acid approximately 5 N.

A-5.2.2 Standard Chloride Solution Dissolve 1.64 g of sodium

chloride, previously dried at 105 2C, in water and dilute to 1 000 ml

in a volumetric flask. Further dilute 100 ml of the solution to 1 000 ml.

One millilitre of the solution contains 0.1 mg of chlorides ( as Cl ).

A-5.2.3 Silver Nitrate Solution 10 percent.

A-5.3 Procedure Dissolve 0.200 g of the material in 10 ml of dilute

nitric acid. Boil to expel nitrous fumes. Cool and transfer to a Nessler

tube and dilute to the mark. In another Nessler tube, take 1 ml of

standard chloride solution, add 10 ml of dilute nitric acid and 1 ml of

silver nitrate solution. Dilute to the mark. Compare the turbidity pro-

duced in the two Nessler tubes.

A-5.3.1 The material shall be taken as not having exceeded the limit

prescribed in Table I if the turbidity produced with the material is not

greater than that produced in the control test.

A-6. TEST FOR NITRATES

A-6.1 Reagents

A-6.1.1 Dilute Nitric Acid approximately 5 N.

A-6.1.2 Standard Indigo Carmine Solution Dissolve 0.2 g of indigo

carmine in 500 ml of dilute sulphuric acid, add 20 ml of hydrochloric

acid and sufficient dilute sulphuric acid to produce 1 000 ml. Standar-

dize the solution so that 10 ml added to 3.3 ml of M/1 000 potassium

nitrate solution is just decolourized on adding 13 ml of sulphuric acid

and heating to boiling.

A-6.1.3 Dilute Sulphuric Acid 5 N.

A-6.2 Procedure Suspend 1.000 g of the material in 10 ml of water, mix

well and allow to settle. Take the supernatant clear liquid, add 0.5 ml

of standard indigo carmine solution and 5 ml of dilute sulphuric acid

and heat to boiling.

A-6.2.1 The limit prescribed shall be taken as not having been

exceeded if the blue colour produced does not entirely disappear.

A-7. TEST FOR ALKALINITY

A-7.1 Reagents

A-7.1.1 Standard Sulphuric Acid 0.05 N.

7

IS : 2449 - 1963

A-7.1.2 Phenolphthalein Indicator Solution Dissolve 0.1 g of phenolph-

thalein in 60 ml of rectified spirit conforming to IS : 323-1959 Specifica-

tion for Rectified Spirit ( Revised ) and dilute with water to 100 ml.

A-7.2 Procedure Take 10.0 g of the material in a flask and add 500 ml

of water. Reflux on a hot water-bath for about one hour. Filter 50 ml

of the clear supernatant liquid. Add a few drops of phenolphthalein

indicator solution and titrate against standard sulphuric acid.

A-7.3 Calculation

Alkalinity ( as Na

2

O ), percent by weight =

where

V = volume in ml of standard sulphuric acid used,

N = normality of standard sulphuric acid, and

W = weight in g of the material taken for the test.

AP P ENDIX B

( Clause 4.1 )

SAMPLING OF SILVER OXIDE

B-1. GENERAL REQUIREMENTS OF SAMPLING

B-1.0 In drawing, preparing, storing and handling samples, the follow-

ing precautions and directions shall be observed.

B-1.1 Samples shall be taken in a protected place.

B-1.2 The sampling instrument shall be clean and dry.

B-1.3 Precautions shall be taken to protect the samples, the material

being sampled, the sampling instrument and the containers for samples

from adventitious contamination.

B-1.4 To draw a representative sample, the contents of each container

selected for sampling shall be mixed as thoroughly as possible by suit-

able means.

B-1.5 The samples shall be placed in suitable, clean, dry and air-tight

glass bottles or other suitable containers on which the material has no

action.

8

IS : 2449 - 1963

B-1.6 The sample containers shall be of such a size that they are almost

completely filled by the sample.

B-1.7 Each sample container shall be scaled air-tight after filling, and

marked with full details of sampling.

B-2. SCALE OF SAMPLING

B-2.1 Lot All the containers in a single consignment of the material

drawn from a single batch of manufacture shall constitute a lot. If a

consignment is declared or known to consist of different batches of

manufacture, the containers belonging to the same batch shall be group-

ed together and each such group shall constitute a separate lot.

B-2.1.1 Samples shall be tested for each lot for ascertaining confor-

mity of the material to the requirements of the specification.

B-2.2 The number of containers ( n ) to be selected from the lot shall

depend on the size of the lot ( N ) and shall be in accordance with col 1

and 2 of Table II.

TABLE II NUMBER OF CONTAINERS TO BE SELECTED FOR SAMPLING

LOT SI ZE

N

(1)

4 to 15

10 ,, 40

41 65

66 110

111 and above

No, OF CONTAI NERS

TO BE SELECTED

n

(2)

3

4

5

7

10

NOTE When t he size of t ho lot is 3 or less, t he number of cont ai ners to be

selected and tho criterion for j udgi ng t he conformity of the lot to t he specification

shall be as agreed to between t he purchaser and t he supplier.

B-2.3 These containers shall be selected at random from the lot and in

order to ensure the randomness of selection, the following procedure

shall be adopted:

Arrange all the containers in the lot in a systematic manner

and starling from any one, count them as 1, 2, 3 , etc, up to r

and so on, where r is the integral part of N/n. Every rth

container thus counted shall be taken out.

9

IS : 2449 - 1963

B-3. PREPARATION OF TEST SAMPLES AND REFEREE SAMPLE

B-3.1 From each of the containers selected according to B-2.3, draw,

with an appropriate sampling instrument, a representative portion of

the material, about 25 g.

B-3.2 Out of these portions collected from all the selected containers,

equal quantity of the material ( about 15 g ) shall be taken and mixed

thoroughly to form a composite sample. The composite sample so

formed shall be divided into three equal parts, one for the purchaser,

another for the supplier and the third to be used as referee sample.

B-3.3 The remaining portion of the material from each container shall be

divided into three equal parts and each such part shall constitute an

individual sample. One set of the individual samples shall be marked

for the purchaser, another for the supplier and the third one for the

referee.

B-3.4 All the individual and composite samples shall be immediately

transferred to separate containers and labelled with full identification

particulars.

B-3.5 The referee sample, consisting of a composite sample and a set

of n individual samples shall bear the seal of both the purchaser and the

supplier. These shall be kept at a place agreed to between the purchaser

and the supplier to be used in case of a dispute between the two.

B-4. NUMBER OF TESTS

B-4.1 Tests for the determination of silver oxide shall be conducted on

each of the individual samples separately.

B-4.2 Tests for the determination of all other characteristics shall be

conducted on the composite sample.

B-5. CRITERIA FOR CONFORMITY

B-5.0 A lot shall be declared as conforming to the requirements of this

specification if the conditions given in B-5.1 and B-5.2 are satisfied.

B-5.1 For Individual Samples From the individual test results for silver

oxide, the mean (x) and the range (R) of the test results shall be com-

puted ( range being defined as the difference between the maximum and

minimum of the test results ).

B-5.1.1 The value of the expression ( 0.6 R ) calculated from the

test results shall be greater than or equal to 99.3.

B-5.2 For Composite Sample The test results for those characteristics

which have been determined on the composite sample shall satisfy the

relevant requirements given in the specification.

10

PUBLICATIONS OF INDIAN STANDARDS INSTITUTION

I NDI AN S TANDARDS

Acids

Adhesives

Alcohols and Allied Product s

Brushware

Chemical Product s

Coal and Coke

Coal Carbonization Products

Cosmetics and Toilet Goods

Drying Oils

Explosive and Pyrot echni c

Materials

Fertilizers

Fillers, St opper s and Put t i es

Foot wear

Glass and Glassware

Industrial Gases

Inks and Allied Products

Laboratory Glassware and

Related Apparat us

Lac and Lac Products

Leather and Leather Goods

Lubricants

Metal Cont ai ners and Cl osures

Oil Pastes

Pai nt ers' Materials (Miscellaneous)

Paper and Allied Product s

Perfumery Materials, Natural and

Synthetic

Pet rol eum and Pet r ol eum Product s

Photographic Chemicals

Pi gment s and Ext ender s

Plastics

Pri nt i ng Inks

Ready Mixed Paints and Enamels

Rubber Product s

Soaps

Thi nners and Solvents

Treated Fabrics

Varnishes and Lacquers

Veget abl e Oils

Wat er and Wa t e r Tr eat ment

OTHER PUBLICATIONS

ISI Bulletin ( Published Every Two Months )

Single Copy

Annual Subscription

Annual Reports ( from 1948-49 Onwards )

Rs

2.00

10.00

2.00 to 3.00 each

Handbook of ISI Publications 1962 ( Rs 5.00 per copy ) gives brief

reviews and other particulars of Indian Standards

Available from :

Over 2 300 Indian Standards, broadly classified under t he following

main heads, have been issued so far:

Ag r i cu l t u r e & F o o d E n g i n e e r i n g

B u i l d i n g Str u ctu r al & Me t al s

C he m i cal s Te xt i l e s

E l e ct r o t e chn i cal Mi s ce l l an e o u s

Of t hese, t he st andards belonging to t he Chemicals Gr oup fall under

t he following categories:

INDIAN STANDARDS INSTITUTION

Headquarters

Manak Bhavan, 9 Mathura Road, New Del hi 1

P h o n e s : 273611-18 G r a ms : ' Ma n a k s a n s t h a ' N e w De l h i

B r a n c h O f f i c e s

2 3 2 Dr . Da d a b h o y Na o r o j i Roa d

1 1 S o o t e r k i n S t r e e t

14/69 Ci vi l Li nes

54 Ge n e r a l P a t t e r s Roa d

Bo mb a y 1

Ca l c u t t a 13

Ka n p u r

Ma d r a s 2

Ph o n e

262945

21-1823

37695

87278

G r a ms

Ma n a k s a n s t h a

Manaksanstha

Manaksanstha

Manaksanstha

Printed at Delhi Printers, Delhi-6, India

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Disclosure To Promote The Right To InformationDocument15 pagesDisclosure To Promote The Right To InformationKaka BabaNo ratings yet

- Nfpa Hydrogen StandardsDocument17 pagesNfpa Hydrogen StandardsKaka BabaNo ratings yet

- Laboratory Chemical Hygiene Plan - 2012Document99 pagesLaboratory Chemical Hygiene Plan - 2012Kaka BabaNo ratings yet

- Bgcse Sda Paper 1 2016Document21 pagesBgcse Sda Paper 1 2016anne0% (1)

- Secrets of OrmusDocument6 pagesSecrets of OrmusMrOntop100% (3)

- A Guide For Flammable and Combustible LiquidsDocument15 pagesA Guide For Flammable and Combustible LiquidsKaka Baba100% (1)

- Nfpa 497 2012Document1 pageNfpa 497 2012Kaka Baba100% (1)

- Lifeforce Compact Ez 1Document4 pagesLifeforce Compact Ez 1ctaslacaNo ratings yet

- NDT ProcessingFilms TechDataDocument17 pagesNDT ProcessingFilms TechDataAli Ben AmorNo ratings yet

- HAZOP Hazard Operability StudiesDocument4 pagesHAZOP Hazard Operability StudiesSrinivas BobbyNo ratings yet

- VOC - Steel IndustaryDocument9 pagesVOC - Steel IndustaryKaka BabaNo ratings yet

- Summer 07Document12 pagesSummer 07Kaka BabaNo ratings yet

- Is 567 1993Document16 pagesIs 567 1993Kaka BabaNo ratings yet

- Work Permit PDFDocument11 pagesWork Permit PDFSundar_1975No ratings yet

- Waste Disposal Flow ChartDocument1 pageWaste Disposal Flow ChartKaka BabaNo ratings yet

- Is 567 1993Document16 pagesIs 567 1993Kaka BabaNo ratings yet

- Ferro SiliconDocument16 pagesFerro SiliconKaka BabaNo ratings yet

- Disclosure To Promote The Right To Information: IS 6135 (1981) : Soda Ash, Fused, Technical (CHD 1: Inorganic Chemicals)Document17 pagesDisclosure To Promote The Right To Information: IS 6135 (1981) : Soda Ash, Fused, Technical (CHD 1: Inorganic Chemicals)Kaka BabaNo ratings yet

- Is Code 6512 1984 Criteria For Design of Solid Gravity DamsDocument28 pagesIs Code 6512 1984 Criteria For Design of Solid Gravity DamsSrinath BonakurthiNo ratings yet

- Disclosure To Promote The Right To InformationDocument36 pagesDisclosure To Promote The Right To InformationKaka BabaNo ratings yet

- Is Code 6512 1984 Criteria For Design of Solid Gravity DamsDocument28 pagesIs Code 6512 1984 Criteria For Design of Solid Gravity DamsSrinath BonakurthiNo ratings yet

- Is 9052 1978Document16 pagesIs 9052 1978Kaka BabaNo ratings yet

- Disclosure To Promote The Right To InformationDocument19 pagesDisclosure To Promote The Right To InformationgovimanoNo ratings yet

- Disclosure To Promote The Right To InformationDocument20 pagesDisclosure To Promote The Right To InformationKaka BabaNo ratings yet

- Disclosure To Promote The Right To InformationDocument20 pagesDisclosure To Promote The Right To InformationKaka BabaNo ratings yet

- Is Code 6512 1984 Criteria For Design of Solid Gravity DamsDocument28 pagesIs Code 6512 1984 Criteria For Design of Solid Gravity DamsSrinath BonakurthiNo ratings yet

- Is Code 6512 1984 Criteria For Design of Solid Gravity DamsDocument28 pagesIs Code 6512 1984 Criteria For Design of Solid Gravity DamsSrinath BonakurthiNo ratings yet

- Is 7812 1975Document16 pagesIs 7812 1975Kaka BabaNo ratings yet

- Disclosure To Promote The Right To InformationDocument13 pagesDisclosure To Promote The Right To InformationKaka BabaNo ratings yet

- Caustic Soda IsiDocument20 pagesCaustic Soda Isiginga716No ratings yet

- Is 3605 1984Document14 pagesIs 3605 1984Kaka BabaNo ratings yet

- Is 9744 1981Document15 pagesIs 9744 1981Kaka BabaNo ratings yet

- Is 7278 1993Document13 pagesIs 7278 1993Kaka BabaNo ratings yet

- Disclosure To Promote The Right To InformationDocument10 pagesDisclosure To Promote The Right To InformationKaka BabaNo ratings yet

- Effectiveness - Conformal - Coatings - Preventing - Resistor - Silver - Sulfide Corrosion - SmtaDocument8 pagesEffectiveness - Conformal - Coatings - Preventing - Resistor - Silver - Sulfide Corrosion - SmtaTin NguyenNo ratings yet

- Mercury2 RemovalDocument27 pagesMercury2 RemovalElbahi DjaalabNo ratings yet

- CableDocument296 pagesCablevinaybabaNo ratings yet

- Physical ChemistryDocument1 pagePhysical ChemistryEnsemble StarsNo ratings yet

- Detection of Heavy Metals in SamplesDocument3 pagesDetection of Heavy Metals in SamplesAlphaRaj MekapoguNo ratings yet

- ElementsDocument143 pagesElementsJaiKrishnaMcaNo ratings yet

- 19181111Document104 pages19181111Jennifer HaasNo ratings yet

- WBCS 2020 (Preliminary) MOCK TEST No.: 5 (Answer Paper) Full Marks-200 Time-2 Hr. 30 MinDocument46 pagesWBCS 2020 (Preliminary) MOCK TEST No.: 5 (Answer Paper) Full Marks-200 Time-2 Hr. 30 Minsouparna duttaNo ratings yet

- Lab Report Sample 1Document7 pagesLab Report Sample 1Muhammad Bin Abdulaziz Usman Jr.No ratings yet

- Casting Metals in DentistryDocument11 pagesCasting Metals in Dentistryionescu augustinNo ratings yet

- Grassini, S. Et Al. Plasma Treatment For Cleaning and Protecting Metal Artefacts. 2007Document6 pagesGrassini, S. Et Al. Plasma Treatment For Cleaning and Protecting Metal Artefacts. 2007Trinidad Pasíes Arqueología-ConservaciónNo ratings yet

- Bbet+tre-2018-C-X (Paper-1) - At+pcmDocument22 pagesBbet+tre-2018-C-X (Paper-1) - At+pcmSubham NagNo ratings yet

- Binder 2 EdexcelDocument9 pagesBinder 2 EdexcelahmedNo ratings yet

- (Edu - Joshuatly.com) Pahang JUJ SPM 2014 Chemistry Set A (C581CAB5)Document67 pages(Edu - Joshuatly.com) Pahang JUJ SPM 2014 Chemistry Set A (C581CAB5)伟铭No ratings yet

- Xam Idea Science Solutions Class 10 Chapter 1 Chemical Reactions and EducationsDocument20 pagesXam Idea Science Solutions Class 10 Chapter 1 Chemical Reactions and Educationsexam ascentNo ratings yet

- US5888954 Benzotriazole As Silver Corrosion Inhibitor in Dishwashing DetergentsDocument7 pagesUS5888954 Benzotriazole As Silver Corrosion Inhibitor in Dishwashing DetergentsLaban KantorNo ratings yet

- Synthesis of Silver Nanoparticles by Chemical Reduction of Tollen's Reagent.Document6 pagesSynthesis of Silver Nanoparticles by Chemical Reduction of Tollen's Reagent.nadeemmahamedNo ratings yet

- Kodak Silver RecoveryDocument4 pagesKodak Silver Recovery程杰No ratings yet

- Inorganic Compounds: Group I-A: Alkali MetalsDocument7 pagesInorganic Compounds: Group I-A: Alkali MetalsJessica GutierrezNo ratings yet

- Silver Recovery MachineDocument3 pagesSilver Recovery MachineNicolas CarraraNo ratings yet

- Chemisrty Worksheets2Document3 pagesChemisrty Worksheets2Karthikeyan LakshmananNo ratings yet

- Soldering and WeldingDocument102 pagesSoldering and WeldingSwati PawarNo ratings yet

- ZDFHZDocument2 pagesZDFHZiyoemNo ratings yet

- 11231308Document360 pages11231308esam a gadNo ratings yet

- Electrochemical Cleaningof Artificially Tarnished SilverDocument11 pagesElectrochemical Cleaningof Artificially Tarnished SilverRahmi Nur Anisah Nasution 2003114489No ratings yet