Professional Documents

Culture Documents

Fuel Cell Methanol Reformer for Submarines

Uploaded by

Bùi Xuân Đức0 ratings0% found this document useful (0 votes)

96 views8 pagesFuel cell systems offer submarines significant advantages over traditional diesel-electric systems by allowing vessels to remain submerged for longer periods. Howaldtswerke-Deutsche Werft (HDW) has developed a methanol reformer system to generate hydrogen onboard for fuel cells. The system uses a steam reformer to convert methanol and water into hydrogen at high pressure. Testing of a full-scale demonstrator showed the reformer produced very pure hydrogen with no impact on fuel cell performance compared to stored hydrogen. The overall system efficiency exceeds 90%, offering a promising alternative to hydrogen storage cylinders for extending submarine endurance.

Original Description:

good

Original Title

Fuel Cell Methanol Reformer System for Submarines - HP4a_9_Krummrich_rev0605

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentFuel cell systems offer submarines significant advantages over traditional diesel-electric systems by allowing vessels to remain submerged for longer periods. Howaldtswerke-Deutsche Werft (HDW) has developed a methanol reformer system to generate hydrogen onboard for fuel cells. The system uses a steam reformer to convert methanol and water into hydrogen at high pressure. Testing of a full-scale demonstrator showed the reformer produced very pure hydrogen with no impact on fuel cell performance compared to stored hydrogen. The overall system efficiency exceeds 90%, offering a promising alternative to hydrogen storage cylinders for extending submarine endurance.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

96 views8 pagesFuel Cell Methanol Reformer for Submarines

Uploaded by

Bùi Xuân ĐứcFuel cell systems offer submarines significant advantages over traditional diesel-electric systems by allowing vessels to remain submerged for longer periods. Howaldtswerke-Deutsche Werft (HDW) has developed a methanol reformer system to generate hydrogen onboard for fuel cells. The system uses a steam reformer to convert methanol and water into hydrogen at high pressure. Testing of a full-scale demonstrator showed the reformer produced very pure hydrogen with no impact on fuel cell performance compared to stored hydrogen. The overall system efficiency exceeds 90%, offering a promising alternative to hydrogen storage cylinders for extending submarine endurance.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 8

Fuel Cell Methanol Reformer System for Submarines

Stefan Krummrich, Howaldtswerke-Deutsche Werft GmbH, Germany

1 Introduction

After the successful market introduction of Fuel Cell powered submarines, HDW is ahead of

the market in the field of conventional submarines equipped with Air-Independent propulsion

(AIP) systems. Today HDW offers different types of submarines including fuel cell systems

like the classes U212A (Germany, Italy) or the class 214. All these submarines are based on

fuel cell systems with metal hydride storage cylinders for the hydrogen.

In the recent decades conventional submarines were based on diesel-electric propulsion with

lead batteries for submerged operation. Improvements to these systems have been gradually

since WW II, small steps leading to improvements mainly in the field of signatures of the

submarine. But still the snorkel operation to recharge the batteries is mandatory at least

every few days.

In Comparison submarines equipped with Fuel Cells offer remarkable operational

advantages. The AIP-equipped submarines can stay submerged during operation for a much

longer time than before at similar performance regarding noise level. This is caused by the

fact that fuel cells produce electrical energy without any moving parts, similar to a battery.

Generally the requirements of the AIP Systems in addition to the enlarged submerged

operation period are as follows:

high efficiency (low heat discharge to sea water)

low noise level

low magnetic signature

small size

low weight

low effort for maintenance / no extra crew

Fuel cells have been under development by Howaldtswerke-Deutsche Werft for more than

20 years. In 1988 first sea tests were performed with a fuel cell plant in the submarine U1.

Today four submarines of Class U212A are in service at the German Navy. Furthermore

several export contracts could be realised, also with some submarines already in operation.

Compared to other applications, fuel cells in submarines made its way because of the

enormous customer benefit they offer. The development was based on a completely new

approach, not on the replacement of any existing system [1].

2 Proven Technology

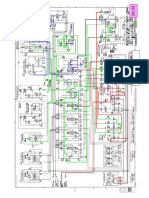

The system installed onboard the HDW submarines today consists of the components shown

in Figure 1.

Figure 1: Overview about Fuel Cell System components.

The PEM fuel cells deliver the electrical energy for the boats power network system via a

DC/DC-converter. The waste heat from the fuel cell is used to release the hydrogen from the

metal hydride storage cylinders and to evaporate liquid oxygen for the operation of the H

2

/O

2

fuel cells. The reaction water is collected onboard to prevent the need for weight

compensation with sea water. In case of Class 209 and 214, two Siemens FCM 120 Fuel

Cells are used, with 240 kW maximum system power output [2].

In total the system has a very high electrical efficiency of up to 60 %, and offers many

benefits regarding submarine specific requirements.

3 Reasons for Reforming onboard Submarines

Even if the existing fuel cell system offers many advantages, the tendency in submarine

development goes to higher amounts of stored AIP-Energy. The system based on metal

hydride storage is relatively heavy, resulting in the fact that the amount of hydrogen stored

onboard is limited by the size of the submarine, having in mind the principle of Archimedes.

Generally liquid fuels have high volumetric and gravimetric energy content and are easy to

handle. These advantages in combination with the fuel cells performance motivated HDW to

start with the development of a reformer system for onboard hydrogen production [3].

4 Choice of Feedstock

The choice of the best fuel for a reformer system for submarines has great influence not only

on the system design, but also on the submarines design and performance. Generally the

feedstock for a reformer system can be hydrocarbon or alcohol. Compared to the storage of

pure hydrogen, this implies the production of CO

2

onboard. As CO

2

cannot be stored

onboard like e.g. the product water of the fuel cell, it has to be discharged into the

surrounding sea. To realize a weight balanced system (principle of Archimedes), the lost

weight of the CO

2

has to be compensated with sea water.

The reformer has to be operated with fuel + oxygen (+ water). The oxygen is stored onboard

as a liquid in a cryogenic tank. This LOX-tank is the dominant component regarding system

size. Consequently, the oxygen consumption of the AIP-System is very important and should

be kept as low as possible. Considering the entire AIP-System, the chemical products are

water (H

2

O) and carbon dioxide (CO

2

). Therefore, the ratio of H to C in the chemical structure

should be high, because the oxidation of C requires more oxygen then the oxidation of H.

Furthermore the overall system efficiency is of importance for the oxygen consumption, and

of course for the fuel consumption.

Further factors are important for the choice of feedstock are the worldwide availability, the

safety (handling etc.), the purity (avoidance of additional adsorbers etc.) and the reforming

temperature to keep the reformer easy.

Summarized the requirements for the feedstock are:

high hydrogen content in the chemical structure

high efficiency of the reforming process

worldwide availability

easy storage onboard

easy handling for e.g. refuelling

easy reformation

HDW has considered three feedstocks for submarine reforming: Diesel (C

13.57

H

27.14

) Ethanol

(C

2

H

5

OH) and Methanol (CH

3

OH). The final choice was made for Methanol because of the

following reasons4:

H/C ratio is highest for Methanol

highest efficiency of reforming process

very easy reformation (T app. 250 C; for Diesel > 850 C, for Ethanol >700 C

required)

worldwide availability

high purity (no sulphur etc.)

5 System Configuration

At the beginning of the development the requirements for the reformers have been defined. A

major requirement was the operation based on the existing and proven Siemens Fuel Cells.

Furthermore the exhaust gas (CO

2

) pressure should be high, to enable the discharge of

exhaust gas into the surrounding seawater without the need for an additional exhaust gas

compressor. Of major importance was the overall system efficiency and the reliability and

availability of the system.

Based on these requirements, the choice was a methanol steam reformer system operated

at elevated pressure. The hydrogen purification is performed with a membrane purification

unit. The required thermal energy is produced in a high-pressure oxygen burner. An overview

about the process is shown in Figure 2.

Figure 2: Overview of Methanol Reformer System.

The methanol is mixed with water, evaporated and fed to the steam reformer. The reforming

reactor is heated by a boiling water cycle. The methanol-water mixture is converted into a

hydrogen-rich gas mixture at typical methanol reforming temperatures. This reformate gas is

further processed in a gas purification unit. The major fraction of hydrogen is separated and

can be fed directly to the Siemens Fuel Cell. The rest of the reformate gas is burned, to

provide the required heat for the reforming process. The only product gas from the reformer

is CO

2

at elevated pressure, the H

2

O in the exhaust gas is condensed and reused internally.

The methanol reformer itself will be operated in an encapsulation comprising several safety

features, to prevent the crew from any harmful gases and liquids.

6 Status of Development

The reformer development at HDW started many years ago under the assumption that the

German Navy would choose reformer technology for their second batch of Class 212

Submarines. After the decision to stay with the metal hydride storage cylinders, the

development of reformer systems for submarines has been performed with reduced

resources. Today the efforts have been increased again, to have the chance to offer the

system to potential costumers worldwide.

HDW operates a full size functional demonstrator in the test facilities in Kiel. The

demonstrator has formerly been built up with COTS components most of the components

used cannot be applied onboard a submarine. Now single components and systems are

developed and installed to achieve a submarine-proven design, and to test them under real

process conditions in the functional demonstrator.

The major milestone in 2009 was the realisation and testing of a new gas purification. The

purification unit has passed a shock test under operating conditions (temperature, and

pressure difference) as part of military approval of the component. Furthermore the

performance of the unit could be verified. The hydrogen is of a very high purity, the

requirement of the Siemens Fuel Cell is fulfilled. In February 2010 the Reformer has been

coupled with a submarine fuel cell with very good results no difference in fuel cell

performance could be detected compared to Hydrogen from the cryogenic storage tank at

HDW.

The test runs with the reformer showed a very high efficiency of the system. The efficiency

(H

u_H2

/ H

u_CH3OH

) was measured to be >90 %.

The system integration has been worked out, a picture of the unit is shown in Figure 3.

Another picture including the encapsulation is shown in Figure 4.

Figure 3: Methanol Reformer System

Figure 4: Encapsulation of MRS

7 Outlook

The reformer system will be further developed to meet all demands for onboard operation.

During a reconstruction period in this year the heat integration will be further improved, and

the valves in the plant will be replaced.

The operation of Reformer with fuel cell will be extended to implement and test a new

DC/DC-converter.

Further major steps in the development will be the operation of the reformer system together

with an exhaust gas treatment unit, to discharge CO

2

directly into the surrounding seawater.

All these further steps will bring the Fuel Cell Methanol Reformer System closer to

application. With this technology HDW offers a second option of Fuel Cell AIP solution, that

will confirm the leadership of HDW in AIP-Systems for submarines.

References

[1] Pommer, H.; Hauschildt, P.; Teppner, R. and Hartung, W. (2006) - Air Independent

Propulsion System for Submarines. ThyssenKrupp techforum 01/2006

[2] Hammerschmidt, A. (2006) - Fuel Cell Propulsion of Submarines. Advanced Naval

Propulsion Symposium 2006

[3] Psoma, A.; Sattler, G. (2002) - Fuel cell systems for submarines: from the first idea to

serial production. Journal of Power Sources, Volume 106

[4] Kolb, G. (2008) Fuel Processing for Fuel Cells. Wiley-VCH

You might also like

- PEM Fuel Cell Systems – An Attractive Energy Source for SubmarinesDocument5 pagesPEM Fuel Cell Systems – An Attractive Energy Source for SubmarinesIshwar ChandraNo ratings yet

- Curs 4 Mept - en - Rev 2021Document63 pagesCurs 4 Mept - en - Rev 2021Necula Alexandra Mihaela100% (1)

- Increasing Oil Pump Efficiency Reduces CO2 EmissionsDocument4 pagesIncreasing Oil Pump Efficiency Reduces CO2 EmissionsDon LorimerNo ratings yet

- 32405b27 PDFDocument7 pages32405b27 PDFSteffy Devi IntanNo ratings yet

- STEAM AND SOFC REFORMING OPTIONS FOR PEM FUEL CELLSDocument16 pagesSTEAM AND SOFC REFORMING OPTIONS FOR PEM FUEL CELLSNader Ragab AmmarNo ratings yet

- Upgrading The Bottom of The BarrelDocument7 pagesUpgrading The Bottom of The BarrelmmintakaNo ratings yet

- Offshore Vessel Hybrid Power Plant Reduces EmissionsDocument10 pagesOffshore Vessel Hybrid Power Plant Reduces EmissionsYunizar Natanael PragistioNo ratings yet

- A Compact Fuel Processor Integrated With 75kw PEM Fuel CellsDocument5 pagesA Compact Fuel Processor Integrated With 75kw PEM Fuel CellsLavanya ManiNo ratings yet

- Simulation of bitumen upgrading processes modelling and optimisationDocument6 pagesSimulation of bitumen upgrading processes modelling and optimisationDonato MontroneNo ratings yet

- Technical Feasibility of Hybrid Propulsion Systems To Reduce ExhaustDocument15 pagesTechnical Feasibility of Hybrid Propulsion Systems To Reduce ExhaustP Venkata SureshNo ratings yet

- 4000 MTPD Ammonia Plant PaperDocument8 pages4000 MTPD Ammonia Plant PaperJose DenizNo ratings yet

- DOE targets for onboard hydrogen storageDocument2 pagesDOE targets for onboard hydrogen storageCindy FengNo ratings yet

- 1 s2.0 S0360319923063565 MainDocument8 pages1 s2.0 S0360319923063565 MainFlames ShoppingNo ratings yet

- Fertilizer Technology Ammonia Production ProcessesDocument29 pagesFertilizer Technology Ammonia Production ProcessesNitin HansaliaNo ratings yet

- Cb&i HcuDocument4 pagesCb&i HcuPrithikalulu KishoreNo ratings yet

- UNMANNED UNDERWATER VEHICLES (UUVSDocument11 pagesUNMANNED UNDERWATER VEHICLES (UUVSmad serviecNo ratings yet

- Topsoe Large Scale Hydrogen ProducDocument20 pagesTopsoe Large Scale Hydrogen ProducAnonymous j9s0eQ0uNo ratings yet

- When engine speed reduces with decreasing load, selective catalyst reduction is kept operational achieving substantial reductions in NOx emissionsDocument25 pagesWhen engine speed reduces with decreasing load, selective catalyst reduction is kept operational achieving substantial reductions in NOx emissionsAleksandr GolovatskyiNo ratings yet

- Hydrogen storage methods for a sustainable futureDocument9 pagesHydrogen storage methods for a sustainable futureCevdet AyazNo ratings yet

- Final Report F&CDocument11 pagesFinal Report F&CpallabNo ratings yet

- 2008 Npra Iso Therming PresentationDocument26 pages2008 Npra Iso Therming PresentationGarry DavidNo ratings yet

- LNG Reliquefaction Systems2Document14 pagesLNG Reliquefaction Systems2123habib123fikriNo ratings yet

- Ibp1502 12Document9 pagesIbp1502 12Marcelo Varejão CasarinNo ratings yet

- Chevron Richmond Refinery Revised Renewal Project - Conditional Use Permit/Amended EIR ApplicationDocument20 pagesChevron Richmond Refinery Revised Renewal Project - Conditional Use Permit/Amended EIR ApplicationCVX_Richmond_RenewalNo ratings yet

- Key Issues For The Control of Refueling Outage Duration and Costs in PWR Nuclear Power PlantsDocument11 pagesKey Issues For The Control of Refueling Outage Duration and Costs in PWR Nuclear Power PlantsRajAnandNo ratings yet

- LNG - Gas Combustion UnitsDocument13 pagesLNG - Gas Combustion UnitsmorgothsNo ratings yet

- Commercial Scale Potential of Clean Hydrogen ProductionDocument10 pagesCommercial Scale Potential of Clean Hydrogen ProductionkglorstadNo ratings yet

- VFD EnergyEfficiency - Rasanen - Schreiber - ABB - 27 04 2012Document11 pagesVFD EnergyEfficiency - Rasanen - Schreiber - ABB - 27 04 2012Ronald DecirNo ratings yet

- Clean Fuel TechnologyDocument7 pagesClean Fuel TechnologyGarry DavidNo ratings yet

- Hydrogen Storage MaterialsDocument36 pagesHydrogen Storage MaterialsSameer AgaleNo ratings yet

- CO2 RemovalDocument8 pagesCO2 RemovalVinh PhamthanhNo ratings yet

- Pem 1Document10 pagesPem 1RandomV D.ENo ratings yet

- Abb RRTC PaperDocument24 pagesAbb RRTC PapersyaplinNo ratings yet

- Eldakiki How We Can Produce HydrogenDocument10 pagesEldakiki How We Can Produce HydrogenMohamed Gaber El-NaggarNo ratings yet

- Waste Heat Recovery System (WHRS)Document32 pagesWaste Heat Recovery System (WHRS)metasoniko2014No ratings yet

- Diesel Engines & Gas TurbinesDocument13 pagesDiesel Engines & Gas TurbinesPriscila KImNo ratings yet

- Processes and Pump Services in The LNG Industry: by David A. Coyle and Vinod PatelDocument7 pagesProcesses and Pump Services in The LNG Industry: by David A. Coyle and Vinod PatelhwdyangNo ratings yet

- IPTC-20219-MS A Systematic Approach To Increase Banyu Urip Crude OilDocument15 pagesIPTC-20219-MS A Systematic Approach To Increase Banyu Urip Crude OilGilbert OmittaNo ratings yet

- Targets Onboard Hydro StorageDocument2 pagesTargets Onboard Hydro StorageBL SalviNo ratings yet

- Diesel Engines and Gas Turbines in Cruise Vessel PropulsionDocument13 pagesDiesel Engines and Gas Turbines in Cruise Vessel PropulsionFuchsbauNo ratings yet

- Cavitation Hydrocarbon CrackingDocument28 pagesCavitation Hydrocarbon Crackingfaradinti100% (1)

- Review of Hydrogen Conversion Technologies for Power GenerationDocument15 pagesReview of Hydrogen Conversion Technologies for Power GenerationAlex CoțNo ratings yet

- Combined Cycles for Ships Review Past Work ImplicationsDocument8 pagesCombined Cycles for Ships Review Past Work ImplicationsCocoNo ratings yet

- Article 123Document14 pagesArticle 123Jumana SharanikNo ratings yet

- Experiences in The OperationDocument7 pagesExperiences in The OperationUsama Bin SabirNo ratings yet

- AIAA-2005-4455 Hydrogen Peroxide Catalyst Beds Are Ligher Than Liquid InjectorsDocument7 pagesAIAA-2005-4455 Hydrogen Peroxide Catalyst Beds Are Ligher Than Liquid InjectorsCarlos AméricoNo ratings yet

- Research Article Tailored Centrifugal Turbomachinery For Electric Fuel Cell TurbochargerDocument14 pagesResearch Article Tailored Centrifugal Turbomachinery For Electric Fuel Cell TurbochargerBharath kumarNo ratings yet

- Innovations in LNG TechnologyDocument15 pagesInnovations in LNG TechnologyCraigUnderwoodNo ratings yet

- Government Engineering College Hydrogen InfrastructureDocument13 pagesGovernment Engineering College Hydrogen InfrastructureStream stuffNo ratings yet

- Hydrogen generation design for modern refineriesDocument4 pagesHydrogen generation design for modern refineriesJosiph BukairNo ratings yet

- LindeDocument24 pagesLindeMarcin MałysNo ratings yet

- Sodium Borohydride Fuel Cell AVRCDocument25 pagesSodium Borohydride Fuel Cell AVRCksksirhotNo ratings yet

- Cryocomp ReportDocument48 pagesCryocomp ReportbrahmendraNo ratings yet

- Analysis and Assessment of Partial Re-Liquefaction System For Liquefied Hydrogen Tankers Using Liquefied Natural Gas (LNG) and H Hybrid PropulsionDocument16 pagesAnalysis and Assessment of Partial Re-Liquefaction System For Liquefied Hydrogen Tankers Using Liquefied Natural Gas (LNG) and H Hybrid PropulsionVinicius dos Santos MirandaNo ratings yet

- Concept Design of A Bulk Carrier Retrofit With LNG FUELDocument7 pagesConcept Design of A Bulk Carrier Retrofit With LNG FUELHenrique costa melloNo ratings yet

- Pounder's Marine Diesel Engines and Gas TurbinesFrom EverandPounder's Marine Diesel Engines and Gas TurbinesRating: 4 out of 5 stars4/5 (15)

- Carbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyFrom EverandCarbon Capture and Storage: The Legal Landscape of Climate Change Mitigation TechnologyNo ratings yet

- A Guide to Ship Repair Estimates in Man-hoursFrom EverandA Guide to Ship Repair Estimates in Man-hoursRating: 4.5 out of 5 stars4.5/5 (5)

- Howo D12 Euro IIIDocument27 pagesHowo D12 Euro IIIBùi Xuân ĐứcNo ratings yet

- Howo HW19710Document24 pagesHowo HW19710Bùi Xuân ĐứcNo ratings yet

- Howo HW19710TDocument20 pagesHowo HW19710TBùi Xuân ĐứcNo ratings yet

- Hiatchi EX550-3 W116E-00 Workshop ManualDocument330 pagesHiatchi EX550-3 W116E-00 Workshop ManualBùi Xuân ĐứcNo ratings yet

- Hitachi Tt1v7-E-00 CircuitDocument1 pageHitachi Tt1v7-E-00 CircuitBùi Xuân ĐứcNo ratings yet

- W1V7 e 00Document490 pagesW1V7 e 00khaled boulahlib80% (10)

- Sinotruk Howo 12JS200TDocument20 pagesSinotruk Howo 12JS200TMapleNo ratings yet

- Technical Manual: TroubleshootingDocument634 pagesTechnical Manual: Troubleshootingkhaled boulahlib100% (6)

- 425681154-Furukawa-Hcr-1500-1200 DrawingDocument31 pages425681154-Furukawa-Hcr-1500-1200 DrawingBùi Xuân Đức75% (4)

- Parts List for Guide Shell Repair KitsDocument22 pagesParts List for Guide Shell Repair KitsLinzaw WinNo ratings yet

- Hcr1200-Ds3 Kit PartsDocument22 pagesHcr1200-Ds3 Kit PartsBùi Xuân ĐứcNo ratings yet

- HCR Filter KitDocument26 pagesHCR Filter KitBùi Xuân Đức100% (1)

- Hcr1200-Ed2 Kit PartsDocument22 pagesHcr1200-Ed2 Kit PartsBùi Xuân ĐứcNo ratings yet

- Hitachi 300 350 Tt1v7 e 00 - CircuitDocument9 pagesHitachi 300 350 Tt1v7 e 00 - CircuitBùi Xuân ĐứcNo ratings yet

- 2.3 .Trouble Shooting For Engine (2010 + )Document51 pages2.3 .Trouble Shooting For Engine (2010 + )Bùi Xuân ĐứcNo ratings yet

- Maintain Your DE12TI/DE12TIS EngineDocument23 pagesMaintain Your DE12TI/DE12TIS EngineBùi Xuân Đức100% (1)

- IECU-U0243, Data Link: Integrated Electronic Control Unit/IC Control UnitDocument7 pagesIECU-U0243, Data Link: Integrated Electronic Control Unit/IC Control UnitBùi Xuân ĐứcNo ratings yet

- IECU-P0853, Power Relay CoilDocument2 pagesIECU-P0853, Power Relay CoilBùi Xuân ĐứcNo ratings yet

- 2 Euro 3 Engine Ñ-÷ (2 )Document1 page2 Euro 3 Engine Ñ-÷ (2 )Bùi Xuân Đức100% (1)

- Daewoo 1.6 + ++2 +n+s + ( Ú )Document97 pagesDaewoo 1.6 + ++2 +n+s + ( Ú )Bùi Xuân Đức100% (1)

- IECU Data Link Fault DiagnosisDocument5 pagesIECU Data Link Fault DiagnosisBùi Xuân ĐứcNo ratings yet

- Dv15Tis: Mechanical System Fuel SystemDocument2 pagesDv15Tis: Mechanical System Fuel SystemBùi Xuân ĐứcNo ratings yet

- Technical tips for maintaining DV15TIS enginesDocument14 pagesTechnical tips for maintaining DV15TIS enginesBùi Xuân ĐứcNo ratings yet

- 2 Euro 3 Engine Ñ-÷ (2 )Document1 page2 Euro 3 Engine Ñ-÷ (2 )Bùi Xuân ĐứcNo ratings yet

- Chassis - K9a6f Part No.Document361 pagesChassis - K9a6f Part No.Bùi Xuân ĐứcNo ratings yet

- IECU-U0155, Data Link: Integrated Electronic Control UnitDocument7 pagesIECU-U0155, Data Link: Integrated Electronic Control UnitBùi Xuân ĐứcNo ratings yet

- IECU-U0100, Data Link: Integrated Electronic Control UnitDocument7 pagesIECU-U0100, Data Link: Integrated Electronic Control UnitBùi Xuân ĐứcNo ratings yet

- Iecu-U114b, Iecu Control UnitDocument1 pageIecu-U114b, Iecu Control UnitBùi Xuân ĐứcNo ratings yet

- IECU-U0010, Data Link: Integrated Electronic Control unit/ABS ControlDocument8 pagesIECU-U0010, Data Link: Integrated Electronic Control unit/ABS ControlBùi Xuân ĐứcNo ratings yet

- IECU-U010E, Data Link: Integrated Electronic Ontrol Unit/IC Control UnitDocument6 pagesIECU-U010E, Data Link: Integrated Electronic Ontrol Unit/IC Control UnitBùi Xuân ĐứcNo ratings yet

- H2 Chemistry QuestionsDocument56 pagesH2 Chemistry Questionskitonium100% (2)

- Gasoline FAQ 4Document25 pagesGasoline FAQ 4Claudia MmsNo ratings yet

- Cs-Supertrends 22 Eng RGBDocument47 pagesCs-Supertrends 22 Eng RGBWildan AriefNo ratings yet

- The Chemical Basis of Life: Chapter ObjectivesDocument12 pagesThe Chemical Basis of Life: Chapter Objectivesirene9tan9ailianNo ratings yet

- MCQ Madness 2 PDFDocument18 pagesMCQ Madness 2 PDFnotabc gamerNo ratings yet

- Catalysts and Processes For Paraffin and Olefin Dehydrogenation PDFDocument12 pagesCatalysts and Processes For Paraffin and Olefin Dehydrogenation PDFKimberly Pasqualin100% (1)

- IGCSE Chemistry 0620 - Ques Paper w10 - QP - 12Document16 pagesIGCSE Chemistry 0620 - Ques Paper w10 - QP - 12MinakshiNo ratings yet

- English 2013Document17 pagesEnglish 2013AhmedSaad647100% (1)

- Chemical Blowing Agent Composition EndoawawDocument5 pagesChemical Blowing Agent Composition EndoawawProton HutabaratNo ratings yet

- Aea Chem SpmsDocument23 pagesAea Chem Spmssdd104No ratings yet

- VANZAN Brochure English Web PDFDocument18 pagesVANZAN Brochure English Web PDFMarielaIkutaNo ratings yet

- Bebidas CarbonatadasDocument5 pagesBebidas CarbonatadasVanessa PenaNo ratings yet

- Chemistry Class 11 Part 2Document162 pagesChemistry Class 11 Part 2Aniket Sharma100% (2)

- Chem FM 3 Pre Tahossa - 20Document4 pagesChem FM 3 Pre Tahossa - 20Mycovich MycoNo ratings yet

- Atomic Structure NumericalsDocument6 pagesAtomic Structure Numericalssupermannn1972No ratings yet

- Enel's Fusina Hydrogen-Fed Power GenerationDocument8 pagesEnel's Fusina Hydrogen-Fed Power GenerationFelipe Ignacio Corrales CapdevillaNo ratings yet

- Chemistry at A GlanceDocument132 pagesChemistry at A GlanceJames Roy100% (2)

- Numerical Approaches For A Mathematical Model of An Fccu RegeneratorDocument16 pagesNumerical Approaches For A Mathematical Model of An Fccu RegeneratorSagar SrinivasNo ratings yet

- Ammonia and The Haber Process Notes by Sean Chua Winners EducationDocument8 pagesAmmonia and The Haber Process Notes by Sean Chua Winners EducationHå LàåndNo ratings yet

- Kundalini in Ecuador PDFDocument136 pagesKundalini in Ecuador PDFRenê PinheiroNo ratings yet

- Formaldehyde Synthesis From Methanol Over Silver Catalysts: Min Qian, M.A. Liauw, G. EmigDocument12 pagesFormaldehyde Synthesis From Methanol Over Silver Catalysts: Min Qian, M.A. Liauw, G. EmigKrishna DangiNo ratings yet

- CBSE Sample Question Papers For Class 12 Chemistry 2020Document16 pagesCBSE Sample Question Papers For Class 12 Chemistry 2020Emtiaz AnsariNo ratings yet

- Fiitjee Class 11th Phase Test 1 (JEE Mains)Document15 pagesFiitjee Class 11th Phase Test 1 (JEE Mains)Shlok Sah77% (26)

- KS4 Questions for A Level Initial AssessmentDocument18 pagesKS4 Questions for A Level Initial AssessmentsimonbamfordNo ratings yet

- Selective Hydrogen at I On of Phenol and Related DerivativesDocument16 pagesSelective Hydrogen at I On of Phenol and Related DerivativesLuiz Rodrigo AssisNo ratings yet

- 6379 Topper 21 129 510 2 2192 Gaseous State Up201612091655 1481282727 7964Document47 pages6379 Topper 21 129 510 2 2192 Gaseous State Up201612091655 1481282727 7964BhootNo ratings yet

- Equivalent Weight Class XI DPPDocument3 pagesEquivalent Weight Class XI DPPAshwin Jambhulkar0% (1)

- Fundamental of Gas Measument 1Document6 pagesFundamental of Gas Measument 1resureNo ratings yet

- Our Chemistry Pun Galore ! Oh Well.. at Least We Chemis-Tried.Document4 pagesOur Chemistry Pun Galore ! Oh Well.. at Least We Chemis-Tried.NORBERTUS KRISNU PRABOWONo ratings yet

- Grade 8 Revision Hydrogen and WaterDocument2 pagesGrade 8 Revision Hydrogen and WaterdimondNo ratings yet