Professional Documents

Culture Documents

Bhagwant Rege 1

Uploaded by

Lowis YanmaniarCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bhagwant Rege 1

Uploaded by

Lowis YanmaniarCopyright:

Available Formats

1

Review Considerations for

Transdermal Patches

Bhagwant Rege, Ph.D.

Office of Generic Drugs

Division of Chemistry I

2

Disclaimer

Opinions expressed in this presentation

are those of the speaker and do not

necessarily reflect the views or policies of

the FDA.

3

Outline

Provide definition and background on

transdermal patches

Discuss QTPP, CQAs, CMAs, CPPs,

control strategy for transdermal patches

Communicate Agencys expectations in

ANDA submissions

Discuss sample deficiencies

4

Definition-NOMENCLATURE

USP 36 <1151>: Transdermal drug delivery systems

(TDDS, Patch) are self-contained, discrete dosage forms

that, when applied to intact skin, are designed to deliver

the drug(s) through the skin to the systemic circulation.

Systemic delivery: The drug diffuses from the patch

directly through the skin into the general circulation.

The activity of the TDDS is defined in terms of:

the release rate of the drug(s) from the patch,

the total duration of drug release from the patch and,

the patch surface area.

5

TDDS (Patch)-Definition (contd)

The patch is applied to body areas consistent with the

labeling for the product.

The patches are designed to provide drug delivery at a

constant rate, such that a true steady-state blood

concentration is achieved and maintained until the patch is

removed (1- 7 days).

As long as drug concentration at the patch/skin interface

remains constant, the amount of drug in the dosage form

does not influence plasma concentrations. The functional

lifetime of the patch is defined by the initial amount of drug

in the patch and the release rate from the patch.

6

FDA

Approved TDDS Products

Clonidine (Catapres

)

Estradiol (Climara

)

Estradiol/Norethindrone

Acetate (CombiPatch

)

Estradiol/Levonorgestrel

(Climara Pro

)

Fentanyl (Duragesic

)

Methylphenidate

(Daytrana System

)

Nicotine (Nicoderm

)

Norelgestromin/Ethinyl

Estradiol (Ortho Evra

)

Nitroglycerin (Nitro-dur

)

Oxybutynin (Oxytrol

)

Scopolamine (Scop

)

Selegiline (Emsam

)

Testosterone

(Androderm

)

And Numerous Generic Products

7

Advantages and Disadvantages

Advantages:

Avoidance of gastrointestinal drug absorption difficulties (pH, enzymatic activity, and

drug-food interactions)

Noninvasive

Patient compliance

Sustained or controlled drug delivery over extended periods; Maintenance of constant

therapeutic drug levels,

Drug therapy may be terminated

Identified at anytime, and

The potential for reducing some side effects generally associated with high peak

serum drug concentrations observed after an immediate release dosage form.

Disadvantages:

Natural limits of drug entry imposed by the skins impermeability (MW <500, narrow

log P (partition co-efficiency) range and etc.)

Limitation of drug level to be administered (Daily Systemic Dose: NMT 20 mg)

Skin irritation

Safety Issues (Residual Drug in Patches after use; Dose dumping).

High cost

8

Types of TDDSs

-Reservoir Systems

Reservoir Systems consist of three major components:

the drug reservoir, the rate-controlling membrane and the

adhesive. Typically, the drug reservoir contains the drug

and excipients.

9

Types of TDDSs

-Matrix System (Drug-in-Adhesive System)

Matrix System-the drug is in the adhesive. The adhesive performs

the roles of formulation excipient (rate controlling) and adhesive. In

addition, the matrix may contain permeation enhancer, solubilizer,

crystallization inhibitor, plasticizer etc. The other components include

backing membrane, release liner and an optional overlay.

10

Development of Generic TDDS

A structured development program incorporating

the following QbD elements is highly

recommended

Quality Target Product Profile (QTPP): Begin with end

in mind

Critical Quality Attributes (CQAs)

Product and Process Understanding: Identification of

Critical Material Attributes (CMAs) and Critical

Process Parameters (CPPs)

Establish a comprehensive control strategy involving

input material controls, in-process controls (process

parameters and intermediates), and finished product

controls

11

Key Considerations for QTPP:

Analysis of RLD

RLD Label

Description

Dosage Form and Strength

Dosage and Administration

Clinical Pharmacology

Warnings and Precautions

Adverse Reactions

Indications and Usage

How Supplied/Storage and Handling

Special In use conditions or instructions

Physicochemical and Biopharmaceutical Analysis

Multiple batches including near expiration batches

Appearance, assay, CU, impurities, in vitro flux, dissolution

Special considerations: Residual monomers, penetration enhancer

content

12

QTPP for TDDS

QTPP Element Target Justification

Dosage form Transdermal patch

Pharmaceutical equivalence

requirement: same dosage form

as RLD.

Route of

administration

Transdermal

Pharmaceutical equivalence

requirement: same dosage form

as RLD.

Strength

Same delivery rate

(Residual Drug

consideration)

Pharmaceutical equivalence

requirement: same dosage form

as RLD.

Pharmacokinetics

Meet Bioequivalence

requirement

Bioequivalence requirement.

Stability

At least 24-month

shelf-life stored at

room temperature.

Equivalent or better than the

shelf-life of RLD.

13

QTPP for TDDS

QTPP Element Target Justification

Drug product

quality attributes

Physical attributes

(appearance, size, shape)

Pharmaceutical equivalence requirements:

Must meet the same compendial or other

applicable (quality) standards (i.e., identity,

assay, purity, and quality).

Patch Performance

(adhesion, cohesion, etc)

Identification

Assay

Degradation products

Residual

solvents/monomers

Content homogeneity

Drug Release

Container closure system

Suitable container

closure system to

achieve the target

shelf-life and to

ensure integrity

during shipping.

Requirement to assure

product quality over the

shelf-life of the drug

product.

Administration/ concurrence with labeling Same as RLD

Information provided in

the RLD labeling.

14

CQAs

A CQA is a physical, chemical, biological or

microbiological property or characteristic of output

materials including finished drug product that should be

within an appropriate limit, range, or distribution to

ensure the desired product quality.

Criticality is dependent on severity of harm to the patient

Assay, Uniformity of Dosage Units, Impurities, Drug

Release, XRD for polymorph control, Particle size

(distribution), Cold flow, Assay of drug in cold flow,

Microbial Test, Residual Solvents, Residual Monomer,

Enhancer (Assay and Uniformity of Dosage Units),

Adhesion Test (Peel Test, Peel from Liner Test, Probe

Tack), Cohesion Test (Shear)

15

In-Vitro Flux Studies

Key tool in assessing delivery rate of transdermal patch and

evaluate effect of CMAs on CQAs

Factors to be considered

Type of diffusion cell (e.g. Franz diffusion cell)

Type of membrane (human cadaver skin, animal skin or synthetic)

Receptor fluid, stirring speed, temperature etc.

Sponsors should provide data on how in-vitro flux studies were used

to select formulations for bioequivalence studies such as

Effect of API particle size/polymorphism

Effect of penetration enhancers

Effect of adhesive ratios / contents

In-vitro flux studies help to better define CQAs that need to be

monitored or controlled such as particle size, polymorphism,

adhesive ratios/content or penetration enhancer content

16

In-Vitro Flux Studies

Effect of exaggerated in-use conditions such as external

heat, steam, water exposure etc. from RLD label on patch

performance should be evaluated using in-vitro methods

ANDA product should give equivalent performance as RLD

Please refer to the FDA response to the CP 2012-P-0932

(see link below) for additional information.

http://www.regulations.gov/#!documentDetail;D=FDA-2012-

P-0932-0003

17

Product and Process Understanding:

Experimental Approaches

Trial and error: Should be avoided

One-factor-at-a-time (OFAT)

OFAT approach may miss important interactions between different

material attributes and/or process parameters

requires more runs for the same precision to estimate effects compared

to DOE

may not give optimal settings of factors

Design of Experiments (DOE)

A structured, organized method for determining the relationship

between factors affecting a process and the output of that process

Multivariate experiments may lead to establishment of design space that

must be verified at commercial scale

Whatever approach is chosen, the information should be able to

support conclusions on CMAs/CPPs/CQAs and control strategy

18

Critical Material Attributes (CMAs)

API

Particle size / area

Polymorph

Impurities

Solubility in formulation

matrix

Pressure Sensitive Adhesive

Adhesive type

Viscosity

Ratio (if mixture is used)

Molecular weight

Residual monomers

Permeation Enhancer

Crystallization Inhibitor

Rate Controlling membrane

Solvent

Backing membrane

Release liner

Delivery rate

Crystallization

Impurities

Delivery rate

Adhesion

Cohesion (cold flow)

Irritation /sensitization

Residual drug

Assay / Impurities

Delivery rate

Crystallization

Assay / Impurities

Patch integrity / flexibility

19

Critical Process Parameters (CPP)

Drug-in-adhesive System

Manufacture of the Drug-Containing Adhesive Mass

-Compounding process of adhesive, enhancer, other excipients and API

Potential CPPs: stirrer speed, vacuum.

Process Challenge/Scale-up: homogeneity/BUA of API and solid content;

establish mixing speed, time

Manufacture of Drug-Containing Laminate

-Coating, drying and laminating

Potential CPPs: machine speed and pressure, temperatures at various

drying tunnel,

Process Challenge/Scale-up: coating speed and temperature; laminator

speed/pressure, roll size limit

20

Critical Process Parameters (CPP)

-Drug-in-adhesive System

Slitting/Die-cutting

The drug-containing laminate is cut longitudinally into narrow rolls

and then is unwound from the roll and cut into the individual TDDS.

Potential CPP: Slit width, die dimension, machine speed

Packaging

The individual TDDS is placed between two layers of packaging

material and the packaging material is sealed around the edges.

Potential CPP: sealing temperature

21

Control Strategy

-From the Beginning to the End

Input Material Control

Establish controls on identified CMAs such as viscosity of

adhesive solution, polymorphism of API (XRD) in addition

to compendial controls or standard quality controls.

In-Process Controls and Monitoring

Establish rational controls on identified CPPs and process

intermediates (e.g. coat weight, slit width)

Finished product controls

Establish controls on CQAs such as particle size and

polymorphism of dispersed API in addition to compendial or

standard quality controls

22

Stability Expectations

Three lots of drug product manufactured from three

distinct laminates, where each lot of laminate is made

using different combination of sources of

API/adhesives/backing and/or other critical elements in

the patch

When the product contains multiple strengths, it is not

necessary to produce three different laminates for each

strength; same three laminates can be used to cut

different strengths; bracketing may be possible

Batch size: 10% of commercial batch size or 25,000

patches whichever is greater for at least 2 batches, third

batch can be smaller

23

Sample Deficiencies

API

You have indicated that you could not find any information on

polymorphs of API. However, literature search indicates several

references to polymorphs of API, both anhydrous and hydrate

having different solubilities and melting points. Please

characterize the polymorph used in your product. Please provide

rationale for your chosen polymorph.

Please provide solubility of the API in formulation components.

Please clarify if the API is soluble or dispersed or both in the

matrix. What is the ratio of dissolved API to dispersed API? How

will you insure that the ratio stays constant from batch to batch

and throughout the shelf life of the product?

Please provide particle size control for the dispersed API as it

can affect drug delivery rate from the system.

24

Sample Deficiencies

Excipients

You have provided no data other than in vitro flux

study on how you optimized crystallization inhibitor

content. Please provide supporting XRD or DSC data

to indicate that the optimized crystallization inhibitor is

able to keep the API in dissolved state throughout the

shelf life. Please also provide additional information

on solvent used in the drug product manufacture and

its impact on crystallization potential.

You have indicated that you have optimized the ratios

of high and low molecular weight adhesives for

optimum adhesion and minimal cold flow potential.

Please provide supporting experimental data.

Please provide in vitro flux studies used to optimize

the level of penetration enhancer.

25

Sample Deficiencies

Characterization

Please provide characterization of cold flow potential of your product including

cold flow weight and amount of API in cold flow. If significant amount of API is

found in cold flow, we may initiate a safety consult. We ask that you propose

suitable test and specification on cold flow.

The Agency requires evidence that the formulation of a generic product is not

less safe than the RLD. We acknowledge that it is possible that different

transdermal formulations of the same drug may have different responses to heat

and/or under other in-use conditions. The RLD labeling states that Contact

with water while bathing, swimming or showering will not affect the patch. To

ensure that the RLD labeling with respect to heat and/or other in-use conditions

are applicable to the ANDA product, the ANDA applicant should provide

information about the formulation performance to ensure that the sensitivity to

heat (or other stress conditions) of the generic product is not more pronounced

than that of the RLD. You may design and provide an in vitro study (e.g., skin flux

permeation study with heat or other stressed conditions to mimic certain in-

use conditions) to compare in vitro skin permeation flux data to the RLD at

normal and elevated temperatures. If the generic product was not more sensitive

than the RLD, it would be acceptable. Such in vitro data would assure that the

proposed generic TDDS product would not create a greater risk when exposed to

heat (or under in use conditions) than the RLD. Please refer to the FDA response

to the CP 2012-P-0932 (see link below) for additional information.

http://www.regulations.gov/#!documentDetail;D=FDA-2012-P-0932-0003

26

Sample Deficiencies

Manufacturing Process and controls

Please justify the range for laminator speed and pressure in your

commercial batch record. The proposed range is outside of the

range studied for your development batches .

Please clarify how you have optimized the coating speed, drying

time and temperature.

You have indicated that the equipment proposed for use in

commercial batches and those used in exhibit batches are of

similar design and working principles but higher capacity. Please

explain how you will adjust the critical process parameters for

each unit operation to get product with consistent quality from

batch to batch.

Please provide a list of critical process parameters (CPPs) for

each unit operation with justification. How are these parameters

controlled and monitored during batch manufacture?

27

Summary

TDDS are complex and expensive drug products

A structured development program incorporating

QbD elements is highly encouraged

The applicants should demonstrate product and

process understanding such that impact of

CMAs and CPPs on drug product CQAs is

clearly identified

The applicants should propose a comprehensive

control strategy derived from the conclusions of

product / process development

28

Acknowledgements

Dr. Bing Cai

Dr. Andre Raw

Dr. Daniel Peng

Dr. Lane Christensen

Dr. Ben Zhao

Dr. Susan Rosencrance

Dr. Lawrence Yu

You might also like

- Sains From SciencebobDocument65 pagesSains From SciencebobLowis YanmaniarNo ratings yet

- Should Marijuana Be A Medical OptionDocument8 pagesShould Marijuana Be A Medical OptionLowis YanmaniarNo ratings yet

- Jurnal Bioanalisis 015-036Document8 pagesJurnal Bioanalisis 015-036Lowis YanmaniarNo ratings yet

- Lamp IranDocument1 pageLamp IranLowis YanmaniarNo ratings yet

- Ls LOWISDocument25 pagesLs LOWISLowis YanmaniarNo ratings yet

- Paediatrica Indonesiana: Kusharisupeni, Wahyu Kurnia Y. Putra, Engkus Kusdinar AchmadDocument4 pagesPaediatrica Indonesiana: Kusharisupeni, Wahyu Kurnia Y. Putra, Engkus Kusdinar AchmadLowis YanmaniarNo ratings yet

- Daftar Pustaka Dokumen Tentang NCD dan DoxorubicinDocument1 pageDaftar Pustaka Dokumen Tentang NCD dan DoxorubicinLowis YanmaniarNo ratings yet

- Sains From SciencebobDocument65 pagesSains From SciencebobLowis YanmaniarNo ratings yet

- Drugs and Health ProductsDocument4 pagesDrugs and Health ProductsLowis YanmaniarNo ratings yet

- Sains From SciencebobDocument65 pagesSains From SciencebobLowis YanmaniarNo ratings yet

- HTTPDocument2 pagesHTTPLowis YanmaniarNo ratings yet

- HTTPDocument2 pagesHTTPLowis YanmaniarNo ratings yet

- Drug Name: Victanyl Legal Class: Drug Class: How Supplied:: OpiatesDocument55 pagesDrug Name: Victanyl Legal Class: Drug Class: How Supplied:: OpiatesLowis YanmaniarNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- Aerosols in AyurvedaDocument13 pagesAerosols in AyurvedaDr ajayNo ratings yet

- Noninvasive VentilationDocument6 pagesNoninvasive VentilationEma MagfirahNo ratings yet

- Managing Pain After Dental SurgeryDocument1 pageManaging Pain After Dental SurgeryAnonymous twcKq4No ratings yet

- Non Linear PharmacokineticsDocument64 pagesNon Linear PharmacokineticsMoganaa LakshmiNo ratings yet

- Ent KardexDocument10 pagesEnt KardexLuisaTsinaLehNo ratings yet

- Zora 197549Document15 pagesZora 197549Adriana NascimentoNo ratings yet

- AHA BLS and ACLS Training GuideDocument87 pagesAHA BLS and ACLS Training GuideArmin MercadoNo ratings yet

- ACLS Provider Manual 2015 NotesDocument5 pagesACLS Provider Manual 2015 Notescrystalshe93% (14)

- 100 Case Studies in Pathophysiology-532hlm (Warna Hanya Cover)Document11 pages100 Case Studies in Pathophysiology-532hlm (Warna Hanya Cover)Haymanot AnimutNo ratings yet

- Kendra paraDocument5 pagesKendra paraPrarthana MohapatraNo ratings yet

- Drug Price List Updated May 2016Document636 pagesDrug Price List Updated May 2016shajbabyNo ratings yet

- VLE Pharma LeatrizeDocument29 pagesVLE Pharma LeatrizeKenneth ShayNo ratings yet

- 1 - Pharmaceutical Dosage FormsDocument41 pages1 - Pharmaceutical Dosage FormsVaibhav Harish KumarNo ratings yet

- MMP Handy Chart October 2011 V2Document37 pagesMMP Handy Chart October 2011 V2ColonNo ratings yet

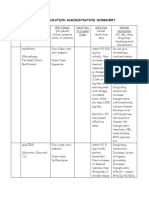

- Medication Administration WorksheetDocument6 pagesMedication Administration WorksheetCheska CarrionNo ratings yet

- Lecture Pharma Part 1 - 2011-2012Document34 pagesLecture Pharma Part 1 - 2011-2012Harley Justiniani Dela CruzNo ratings yet

- Leipzig Applicator ConeDocument3 pagesLeipzig Applicator Coneapi-295549343No ratings yet

- 1 - Pharmacokinetics IDocument20 pages1 - Pharmacokinetics IabdallaNo ratings yet

- Drug MetronidazoleDocument1 pageDrug MetronidazoleSrkocherNo ratings yet

- Nebu&CPTDocument32 pagesNebu&CPTAbigail Bantayan100% (1)

- ΔΤΦ 06082013Document1,140 pagesΔΤΦ 06082013LOUI_GRNo ratings yet

- Surgical Technology For The Surgical Technologist - Frey Kevin B SRGDocument1,305 pagesSurgical Technology For The Surgical Technologist - Frey Kevin B SRG4m96hjgr25No ratings yet

- List of Substandard Drugs2007Document11 pagesList of Substandard Drugs2007Mohammad Shahbaz AlamNo ratings yet

- Major Antimycobacterial Drugs for TuberculosisDocument35 pagesMajor Antimycobacterial Drugs for TuberculosisJunah SeninaNo ratings yet

- FTR Therapy - Preliminary Registration Form: International Integrated Holistic Cure Centre (IIHCC)Document1 pageFTR Therapy - Preliminary Registration Form: International Integrated Holistic Cure Centre (IIHCC)Ram PJNo ratings yet

- Catálogo de ProdutosDocument20 pagesCatálogo de ProdutosjessicayukiNo ratings yet

- JPMorgan 2021 Day 1Document124 pagesJPMorgan 2021 Day 1Watson TianNo ratings yet

- NAC Asthma COPD Medications Chart 2022 - A4 - WebDocument1 pageNAC Asthma COPD Medications Chart 2022 - A4 - WebkanemuraaNo ratings yet

- Xylazine Sedation Antagonized With TolazolineDocument9 pagesXylazine Sedation Antagonized With Tolazolinetaner_soysurenNo ratings yet

- SW 3 Dela ChicaDocument2 pagesSW 3 Dela ChicaMerrene Bright Divino JudanNo ratings yet