Professional Documents

Culture Documents

Palm Oil Mill Effluent

Uploaded by

Chrisna Saputra ArchlordOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Palm Oil Mill Effluent

Uploaded by

Chrisna Saputra ArchlordCopyright:

Available Formats

PALM OIL MILL EFFLUENT

Palm oil mill effluent (POME) is the waste water discharged from the sterilization process, crude oil clarification

process and cracked mixture separation process. POME produced huge amount of methane gas from its

anaerobic process and has 21 times Global Warming Potential (GWP) compared to the other gasses. However it

can be solved, if it can be utilized as fuel for power generation and cogeneration. Notwithstanding the huge

potential, existence of proven technologies and availability of knowledge and incentives, biogas utilization is still

in a very early stage in Malaysia.

Wastewater treatment facility is amongst the most important component in the palm oil mill system. This is

because the facility is to treatment palm oil mill effluent (POME) that is being generated in large volume during

the production of crude palm oil (CPO). Due to the chemical and physical properties of POME, the most efficient

system used in the initial stage of the wastewater plant is the anaerobic treatment. The current systems meet the

requirement of the palm oil mill operators to safely discharge the treated POME. However, the systems release

one of the green house gases (GHG), CH4 into the atmosphere as the by-products of anaerobic digestion of

POME.

BIOGAS/METHANE RECOVERY AND POWER GENERATION

Biogas with Methane (CH4) as major gas fraction from the POME could be recovered in the POME treatment

facility by changing the anaerobic lagoons to closed/covered digesting ponds or sealed digesting tanks as shown

in Figure below. Electric power therefore is generated via the combustion of the CH4 in the gas turbine. Power

generated then is supplied to Sarawak Energy.

The overall power generation potential from effluent treatment can be estimated based on the calculated

methane yield from anaerobic POME treatment. According to Malaysia Palm Oil Board (MPOB), 0.65 m3 POME

is generated from every processed ton of fresh fruit bunch.

Figure: Proposed biogas recovery and power generation

In the following Figure, the composition of biogas from POME has been determined as 62.5 % methane, 37 %

Carbon dioxide and 1,500-3,000 vppm hydrogen sulphide. The calorific value for the generated biogas is 22,000

kJ/m3. The heating value (average caloric value) of methane was 36.3 MJ m3 at standard conditions (Matteson

and Jenkins, 2005). This corresponds to 10.888 kWh of energy per 1 m3 of methane.

Figure: Schematic diagram of methane recovery from POME

Based on annual production of 9,288,000 tons of FFB process in Sarawak; resulting in an annual effluent

generation of 6,037,200 m3 and therefore 150,930,000 m3 of biogas could be harnessed. Assuming that the

effluent is treated properly under anaerobic conditions, the total methane production amounted to 94,000,000 m3.

The calorific value of methane is stated as 10kWh/m3. The annual energy content of the generated methane gas

can be calculated to 940 GWh (~108 MW).

Based on a conversion efficiency of 38 % (gas engine), the potential annual electrical power generation would be

360 GWh. Assuming 100 % availability of the conversion system shall results in an installed power generation

capacity of 41 MW from POME derived methane gas. This is summarized in Table below.

Parameters

Value

Unit

FFB 9,288,000 ton/year

POME yield 6,037,200 m3/ton-FFB

Biogas yield from POME 25 m3-biogas/m3-POME

CH4 gas fraction in biogas 0.625 m3-CH4/m3-biogas

CH4 emitted 0.94E+08 m3

Electricity equivalent (38 % eff) 3.6E+08 or (41) kWh or (MW)

Table: Parameters for estimating CH4 from POME

In spite the substantial potential for biogas utilization in Malaysia especially in palm oil industry, only very few

operation biogas utilization applications could be identified in Peninsula Malaysia. Deployment of biogas

technology such as anaerobic biogas reactor would furthermore lead to a drastic reduction of GHG emission and

also could bring a profitable energy business in the future. There are possibilities to harness this bio-methane

from POME for generating Green electricity from fuel cell in the future fuel cell applications.

PALM OIL MILL EFFLUENT (POME) - PALM OIL BIOGAS (POB) POWER GENERATION

AND COGENERATION TECHNOLOGIES

Since the palm oil mills have abundant biomass waste resources, their energy systems were designed to be

cheap rather than efficient. Most of the existing biomass combustion systems in Malaysia utilize low efficiency

low-pressure boilers. The average conversion efficiencies in process steam and electricity generation are 35 %

and 3 %, respectively. The average overall cogeneration efficiency is 38 %. An additional source of energy in

palm oil mills is the biogas produced in the anaerobic decomposition (for wastewater treatment purposes) of

POME. Presently, POME-derived biogas is not recovered and used. This CH4 rich (65 %) gas is allowed to

dissipate freely into the atmosphere.

Commercially proven technologies are available in the international market for efficient production of power and

heat from major biomass resources - bagasse, wood waste, palm oil waste, straw, and rice husk. The state-of-

the-art modern technologies utilize efficient high pressure boilers. Some of these boilers are capable of dual fuel

burning, utilizing either liquid (e.g., diesel oil) or gas (e.g., natural gas) fuel as supplementary energy source. Dual

fired boilers will be used in palm oil waste-fired boilers to facilitate the use of POME-derived biogas as

supplementary fuel.

Local manufacturing capacity of efficient high-pressure steam generators in Malaysia is presently low. Most of the

equipment for a biomass-based power generation and CHP has to be imported, making the capital cost of a

conventional biomass power plant or CHP facility in the country high (typically around US$ 1,500/kW). Moreover,

with the market potentials of biomass-based power projects and a suitable government policy on power pricing,

the local boiler industry could possibly take up the manufacturing of high-pressure biomass boilers, when the

market and demand for efficient biomass power technology takes off.

Technologies for the effective treatment and handling of POME have been applied in several palm oil mills in

Malaysia. The present systems typically involve the anaerobic decomposition of the organic components of

POME and are sufficient to meet the required final effluent BOD (biochemical oxygen demand) limits imposed by

the government. As to the biogas produced during POME treatment, there are no government regulations yet

requiring palm oil mills to prevent its release to the atmosphere.

You might also like

- Energy BalanceDocument6 pagesEnergy BalanceAnissa MuniraNo ratings yet

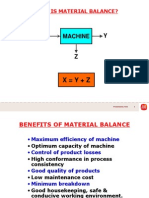

- Material Balance Palm Oil MillDocument9 pagesMaterial Balance Palm Oil Millmalikldu100% (2)

- Mechanisation of Oil PalmDocument33 pagesMechanisation of Oil PalmCephas J. B. Samwini89% (9)

- Bunch Analysis of Oil Palm - BakDocument0 pagesBunch Analysis of Oil Palm - BakJohn OneilNo ratings yet

- Chapter 3 Technical FeasibilityDocument88 pagesChapter 3 Technical FeasibilityAnissa Munira100% (2)

- Palm Oil Mill - Clarification StationDocument1 pagePalm Oil Mill - Clarification StationkiraikNo ratings yet

- Palm Oil Mill EffluentDocument6 pagesPalm Oil Mill Effluentankitsaxena123100% (2)

- Tabel Standart Losis Minyak Sawit Standart Losis Terhadap % Contoh TBSDocument5 pagesTabel Standart Losis Minyak Sawit Standart Losis Terhadap % Contoh TBSYunus RangkutiNo ratings yet

- Oil Palm Fertilization - Sharing Some PerspectivesDocument7 pagesOil Palm Fertilization - Sharing Some PerspectivesLucy LimNo ratings yet

- Harga PMKS 30 TonDocument6 pagesHarga PMKS 30 TonmuhammadnainNo ratings yet

- Crude Palm Oil Mill Process IntroductionDocument2 pagesCrude Palm Oil Mill Process IntroductionMarcel MrcNo ratings yet

- Palm Oil Mill EffluentDocument3 pagesPalm Oil Mill EffluentAmir AimanNo ratings yet

- Palm Oil Mill Processing SystemDocument20 pagesPalm Oil Mill Processing Systemreza32393100% (3)

- Palm Oil Mill Design Procedure Ch1Document2 pagesPalm Oil Mill Design Procedure Ch1Amin Buhari Md Zain100% (3)

- 4.0 Palm OilDocument87 pages4.0 Palm OillynNo ratings yet

- Palm Oil Mill ProcessDocument20 pagesPalm Oil Mill Processmuhdjusri50% (2)

- Palm Oil Mill Organization ChartDocument1 pagePalm Oil Mill Organization Chartmarthynzhuchee100% (1)

- Oil Palm CultivationDocument59 pagesOil Palm Cultivationshini1308100% (23)

- Calcul Conveioare SurubDocument2 pagesCalcul Conveioare SurubgvisanNo ratings yet

- Depericarping & Kernel Recovery StationDocument6 pagesDepericarping & Kernel Recovery Stationmyrichmat100% (1)

- Cpo MillDocument13 pagesCpo MillHendi HendriansyahNo ratings yet

- Spare Part Pabrik Kelapa SawitDocument25 pagesSpare Part Pabrik Kelapa SawitEvin_manurungNo ratings yet

- Palm OilDocument8 pagesPalm OilHadiBiesNo ratings yet

- Palm Oil Small Holder LivelihoodsDocument32 pagesPalm Oil Small Holder Livelihoodsrvm1010No ratings yet

- India's edible oil imports projected to rise 9% in 2010Document18 pagesIndia's edible oil imports projected to rise 9% in 2010Ln Chakky100% (1)

- Westfalia in Palm Oil MillDocument24 pagesWestfalia in Palm Oil MillSupatmono NAINo ratings yet

- Mpob - Grading Manual - NEW2Document47 pagesMpob - Grading Manual - NEW2Flyingweng ㊣ Weng88% (17)

- 2.0 SDPA - Palm Oil Mill ProjectDocument19 pages2.0 SDPA - Palm Oil Mill ProjectAmeen Zenn100% (1)

- Palm Oil Process - The Principle & Operational TechniquesDocument269 pagesPalm Oil Process - The Principle & Operational TechniquesLiew Kiat Shing88% (26)

- MPOB Sterilizer Process ControlDocument9 pagesMPOB Sterilizer Process ControlgerrykhangNo ratings yet

- FFB GradingDocument13 pagesFFB Gradingeddypurwanto100% (12)

- PIPOC 2011 Congress on Palm Oil Fortification and EnergizationDocument42 pagesPIPOC 2011 Congress on Palm Oil Fortification and EnergizationBung HarunNo ratings yet

- Palm Oil Factory Process Handbook: Part 1 #Document1 pagePalm Oil Factory Process Handbook: Part 1 #John HastingNo ratings yet

- Dokumen - Tips - Westfalia in Palm Oil Mill PDFDocument24 pagesDokumen - Tips - Westfalia in Palm Oil Mill PDFagus rasidNo ratings yet

- TOC Oil Palm HB Immature - 2Document6 pagesTOC Oil Palm HB Immature - 2Jackson Jerome50% (6)

- Palm Oil Mill Effluent Treatment PlantDocument15 pagesPalm Oil Mill Effluent Treatment PlantSyukri MiazawaNo ratings yet

- Sterilizer TiltingDocument23 pagesSterilizer Tiltingofchis50% (2)

- Information About Oil Palm NutritionDocument28 pagesInformation About Oil Palm Nutritionquepos09100% (6)

- Engineering Company CatalogueDocument19 pagesEngineering Company CataloguefanyfabrianaNo ratings yet

- Palm Oil Effluent Treatment SchemeDocument11 pagesPalm Oil Effluent Treatment SchemebathalapalliNo ratings yet

- Synopsis by WambeckDocument671 pagesSynopsis by WambeckSteve Ubiam100% (3)

- Poeb130 YosriDocument9 pagesPoeb130 YosriNa'imusyahmi Ghazali100% (1)

- Intro To Palm Oil ProcessingDocument113 pagesIntro To Palm Oil ProcessingReinaldo Sembiring92% (13)

- Palm Oil Mill EffluentDocument4 pagesPalm Oil Mill EffluentjomoltNo ratings yet

- DCAMM Report S123Document320 pagesDCAMM Report S123lux0008No ratings yet

- Methanol Plant Process Description LurgiDocument6 pagesMethanol Plant Process Description LurgiGaukharAlzhanova0% (1)

- Poeb120-Nasrin - Co FiringDocument4 pagesPoeb120-Nasrin - Co FiringtekpolnregionalNo ratings yet

- Organic Rankine CycleDocument11 pagesOrganic Rankine CycleslamienkaNo ratings yet

- Renewable Hydrogen-Methanol-2007Document18 pagesRenewable Hydrogen-Methanol-2007krishnaNo ratings yet

- A Rapid Gas Chromatographic Method For The Determination of Poly Hydroxybutyric Acid in Microbial BiomassDocument9 pagesA Rapid Gas Chromatographic Method For The Determination of Poly Hydroxybutyric Acid in Microbial BiomassAdamu OnakpaNo ratings yet

- Generate Electricity from BiogasDocument8 pagesGenerate Electricity from BiogasMokaNo ratings yet

- Design and Analysis of Energy Efficient IntegratedDocument9 pagesDesign and Analysis of Energy Efficient IntegratedAbyan100% (1)

- Inovasi Pengolahan Limbah Cair Kelapa Sawit (POME) Net-Zero Emission Menjadi ListrikDocument16 pagesInovasi Pengolahan Limbah Cair Kelapa Sawit (POME) Net-Zero Emission Menjadi ListrikAzizah AdrNo ratings yet

- Netherlands Brochure PDFDocument6 pagesNetherlands Brochure PDFmuhammadnainNo ratings yet

- Efb Uses in MsiaDocument4 pagesEfb Uses in MsiaLai Mei EeNo ratings yet

- Energy MixDocument10 pagesEnergy MixPara DiseNo ratings yet

- Biomass Conversion PDFDocument8 pagesBiomass Conversion PDFVivek Rajkumar GNo ratings yet

- Referensi BiomassaDocument2 pagesReferensi BiomassaMuthiaNurFadhilahNo ratings yet

- Biogas From POME - BioEnergy ConsultDocument9 pagesBiogas From POME - BioEnergy ConsultAnonymous DJrec2No ratings yet

- WasdabDocument13 pagesWasdabfakhri84No ratings yet

- Job's Method of Continuous VariationDocument11 pagesJob's Method of Continuous Variationalex3bkNo ratings yet

- Brake System Troubleshooting GuideDocument98 pagesBrake System Troubleshooting Guideruben7mojicaNo ratings yet

- Coca-Cola's CSR efforts to refresh world sustainablyDocument4 pagesCoca-Cola's CSR efforts to refresh world sustainablyAfolarin AdioNo ratings yet

- ClindamycinDocument1 pageClindamycinTanalie Dulawan100% (3)

- TN EpasssDocument2 pagesTN EpasssStephenrajNo ratings yet

- Star T: Flowchart "Physical Fitness Test"Document1 pageStar T: Flowchart "Physical Fitness Test"Eller-Jed Manalac MendozaNo ratings yet

- Redraw Rod For Multiwire DrawingDocument6 pagesRedraw Rod For Multiwire DrawingWajeeh BitarNo ratings yet

- PP Ceylon Graphite Corp February 2023Document16 pagesPP Ceylon Graphite Corp February 2023Siddhant DhallNo ratings yet

- Understanding Steam Turbine VibrationDocument30 pagesUnderstanding Steam Turbine VibrationkatibraNo ratings yet

- Recent Developments in Carbapenems: ReviewDocument16 pagesRecent Developments in Carbapenems: ReviewFrancielleNo ratings yet

- Cap Dev Dimalinao 2023-2027Document4 pagesCap Dev Dimalinao 2023-2027CA T HeNo ratings yet

- Arc Flash ProtectionDocument11 pagesArc Flash ProtectioncastrojpNo ratings yet

- Fem 3202-1 IntroductionDocument29 pagesFem 3202-1 IntroductionRon ChongNo ratings yet

- HPC ReportDocument316 pagesHPC ReportmamansgNo ratings yet

- Masagana High School: Module 4: Planning For Continuing Professional Development and Lac PlanningDocument6 pagesMasagana High School: Module 4: Planning For Continuing Professional Development and Lac PlanningjhonaNo ratings yet

- The Problem of Drop Outs and School Building ConstructionDocument26 pagesThe Problem of Drop Outs and School Building ConstructionSweetaddy castilloNo ratings yet

- Comparative Analysis of Mineral Constituents of Ethanol Leaf and SeedDocument9 pagesComparative Analysis of Mineral Constituents of Ethanol Leaf and SeedKIU PUBLICATION AND EXTENSIONNo ratings yet

- Food Salt: By: Saad, Rehan, Asad, Hasan, Adil, Abdur Rehman, AzharDocument10 pagesFood Salt: By: Saad, Rehan, Asad, Hasan, Adil, Abdur Rehman, AzharsaadNo ratings yet

- Sara Salon and SpaDocument4 pagesSara Salon and Spasania zehraNo ratings yet

- Usos HummusDocument36 pagesUsos HummusAlisson FernandaNo ratings yet

- ABS and Air Conditioner Wiring DiagramDocument207 pagesABS and Air Conditioner Wiring Diagramservice_00783% (30)

- Making your own Agar PlateDocument8 pagesMaking your own Agar PlateCheska EngadaNo ratings yet

- Everything You Need to Know About Gas Metal Arc Welding (GMAWDocument31 pagesEverything You Need to Know About Gas Metal Arc Welding (GMAWAhmetDuranCeyhanNo ratings yet

- Save Our Forests Through Sustainable DevelopmentDocument33 pagesSave Our Forests Through Sustainable DevelopmentGeehthanJINo ratings yet

- BOS II SlickDocument2 pagesBOS II SlickDineu OliveiraNo ratings yet

- JD - Hygiene Promotion OfficerDocument2 pagesJD - Hygiene Promotion OfficerBeauty ChigwazaNo ratings yet

- Res Ipsa LoquiturDocument6 pagesRes Ipsa LoquiturZydalgLadyz NeadNo ratings yet

- Geoheritage of Labuan Island: Bulletin of The Geological Society of Malaysia December 2016Document14 pagesGeoheritage of Labuan Island: Bulletin of The Geological Society of Malaysia December 2016songkkNo ratings yet

- Evonik Copi BrochureDocument5 pagesEvonik Copi BrochureRovshan HasanzadeNo ratings yet