Professional Documents

Culture Documents

Unit08 - Inventory - Management

Uploaded by

sirfanalizaidi0 ratings0% found this document useful (0 votes)

15 views58 pagestechnology and operational management

Dr. Rameez Khalid

Original Title

Unit08 - Inventory_Management

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documenttechnology and operational management

Dr. Rameez Khalid

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

15 views58 pagesUnit08 - Inventory - Management

Uploaded by

sirfanalizaiditechnology and operational management

Dr. Rameez Khalid

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 58

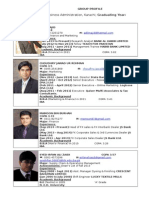

Dr.

Rameez Khalid, PMP, CQSSBB

Faculty, Department of Management

Institute of Business Administration, Karachi

Independent Demand

A

B(4) C(2)

D(2) E(1) D(3) F(2)

Dependent Demand

Independent demand is uncertain.

Dependent demand is certain.

Inventory: a stock or store of goods

Inventory

2

Types of Inventories

Raw materials & purchased parts

Partially completed goods called

work in progress (WIP)

Finished-goods inventories

(manufacturing firms)

or merchandise

(retail stores)

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 3

Types of Inventories

Replacement parts, tools, & supplies

Goods-in-transit to warehouses or customers

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 4

Functions of Inventory

To meet anticipated demand

To smooth production requirements

To decouple operations

To protect against stock-outs

To take advantage of order cycles

To help hedge against price increases

To permit operations

To take advantage of quantity discounts

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 5

Objective of Inventory Control

To achieve satisfactory levels of customer service

while keeping inventory costs within reasonable

bounds

Level of customer service

Costs of ordering and carrying inventory

Inventory turnover is the ratio of:

average cost of goods sold to

average inventory investment.

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 6

A system to keep track of inventory

A reliable forecast of demand

Knowledge of lead times

Reasonable estimates of

Holding costs

Ordering costs

Shortage costs

A classification system

Effective Inventory Management

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 7

Inventory Counting Systems

Periodic System (T or P System)

Physical count of items made at periodic

intervals

Perpetual Inventory System (Q System)

System that keeps track

of removals from inventory

continuously, thus

monitoring

current levels of

each item

Unit-8: Inventory Management

Inventory Counting Systems (Contd)

Two-Bin System - Two containers of inventory;

reorder when the first is empty

Universal Bar Code - Bar code

printed on a label that has

information about the item

to which it is attached

0

214800 232087768

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 9

Lead time: time interval between ordering and

receiving the order

Holding (carrying) costs: cost to carry an item in

inventory for a length of time, usually a year

Ordering costs: costs of ordering and receiving

inventory

Shortage costs: costs when demand exceeds

supply

Key Inventory Terms

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 10

Holding Costs

Obsolescence

Insurance

Extra staffing

Interest

Pilferage

Damage

Warehousing

Etc.

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 11

Ordering/Setup Costs

Supplies/Freight

Incoming QC

Order processing

Clerical support

Etc.

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 12

Clean-up costs

Re-tooling costs

Adjustment costs

Etc.

ABC Classification System

Classifying inventory according to some measure of

importance and allocating control efforts

accordingly.

A - very important

B - mod. important

C - least important

0

20

40

60

80

100

0 50 100

% of Inventory Items

%

A

n

n

u

a

l

$

U

s

a

g

e

A

B

C

Class % $ Vol % Items

A 80 15

B 15 30

C 5 55

Unit-8: Inventory Management

Inventory

Process

stage

Demand

Type

Number

& Value

Other

Raw Material WIP

Finished Goods

Independent

Dependent

A Items

B Items

C Items

Maintenance

Dependent

Operating

Inventory Classifications

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 14

Cycle Counting

A physical count of items in inventory

Cycle counting management

How much accuracy is needed?

When should cycle counting be performed?

Who should do it?

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 15

Fixed order-quantity models

Economic order quantity (EOQ)

Economic production quantity (EPQ)

or Production order quantity (POQ)

Quantity discount

Probabilistic models

Fixed order-period models

Help answer the

inventory planning

questions!

Inventory Models

Economic order quantity (EOQ) model

The order size that minimizes total annual cost

Economic production model

Quantity discount model

Economic Order Quantity Models

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 18

Only one product is involved

Annual demand requirements known

Demand is even throughout the year

Lead time does not vary

Each order is received in a single delivery

There are no quantity discounts

Assumptions of EOQ Model

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 19

The Inventory Cycle

Profile of Inventory Level Over Time

Quantity

on hand

Q

Receive

order

Place

order

Receive

order

Place

order

Receive

order

Lead time

Reorder

point

Usage

rate

Time

Total Cost

Annual

carrying

cost

Annual

ordering

cost

Total cost =

+

TC =

Q

2

H

D

Q

S

+

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 21

Cost Minimization Goal

Order Quantity

(Q)

The Total-Cost Curve is U-Shaped

Ordering Costs

Q

O

A

n

n

u

a

l

C

o

s

t

(optimal order quantity)

TC

Q

H

D

Q

S

2

Holding Costs

22

Deriving the EOQ

Using calculus, we take the derivative of the total

cost function and set the derivative (slope) equal to

zero and solve for Q.

Q =

2DS

H

=

2(Annual Demand )(Order or Setup Cost )

Annual Holding Cost

OPT

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 23

Minimum Total Cost

The total cost curve reaches its minimum where

the carrying and ordering costs are equal.

Q

2

H

D

Q

S

=

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 24

EOQ

A local distributor for a national tire company

expects to sell approx. 9,600 steel-belted radial

tires of a certain size and tread design next year.

Annual carrying cost is $16 per tire, and ordering

cost is $75. The distributor operates 288 days a

year.

a. EOQ?

b. How many Orders?

c. Length of an order cycle?

d. Total Annual Cost?

25

Production done in batches or lots

Capacity to produce a part exceeds the parts

usage or demand rate

Assumptions of EPQ are similar to EOQ except

orders are received incrementally during

production

Economic Production Quantity (EPQ)

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 27

EOQ EPQ Model

When To Order

Reorder

Point

(ROP)

Time

Inventory Level

Lead Time

Optimal

Order

Quantity

(Q*)

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 28

EPQ Model Inventory Levels

Inventory Level

Time

Supply

Begins

Supply

Ends

Production portion of

cycle

Demand portion of cycle with no

supply

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 29

EPQ Model Inventory Levels

Time

Inventory Level

Production

Portion of Cycle

Imax Max. Inventory

Q(1- u/p)

Q*

Supply

Begins

Supply

Ends

Inventory level with no demand

Demand portion of cycle with

no supply

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 30

Economic Run Size

Q

DS

H

p

p u

0

2

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 31

D = Demand per year

S = Setup cost

H = Holding cost

u = Demand per day

p = Production per

day

EPQ Model Equations

Optimal Order Quantity

Setup Cost

Holding Cost

= =

-

=

*

= *

=

Q

H*

u

p

Q

D

Q

S

p

*

1

(

0.5 * H * Q

-

u

p

1

)

-

u

p

1

( )

2*D*S

( )

Maximum inventory level

Imax

32

EPQ

A toy manufacturer uses 48,000 rubber wheels

per year for its popular dump truck series. The

firm makes its own wheels, which it can produce

at a rate of 800 per day. The toy trucks are

assembled uniformly over the entire year. Carrying

cost is $1 per wheel a year. Setup cost for a

production run of wheels is $45. The firm operates

240 days per year.

a. EPQ or POQ or Optimal Run Size?

b. Minimum Total Annual Cost?

c. Cycle Time?

d. Run Time?

33

Answers how much to order & when to order

Allows quantity discounts

Reduced price when item is purchased in larger

quantities

Other EOQ assumptions apply

Trade-off is between lower price & increased

holding cost

Buyers Goal:

Select the order quantity that will minimize

the total cost.

Quantity Discount Model

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 35

Total Costs with Purchasing Cost

Annual

carrying

cost

Purchasing

cost

TC = +

Q

2

H

D

Q

S

TC =

+

+

Annual

ordering

cost

PD

+

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 36

Total Costs with PD

C

o

s

t

EOQ

TC with PD

TC without PD

PD

0

Quantity

Adding Purchasing cost

doesnt change EOQ

37

Case1: Constant Holding Costs

OC

EOQ

Quantity

T

o

t

a

l

C

o

s

t

TC

a

TC

c

TC

b

Decreasing

Price

HC

a,b,c

38

Quantity Discount

When D =816 cases per year, S =$12, and

H=$4 per case per year, determine for the

following discounts:

a. Optimal Order Quantity?

b. Total Cost?

Range

Price

1 to 49

$20

50 to 79

18

80 to 99

17

100 or more 16

39

Quantity Discount

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 40

Case2: Holding Cost

as Percentage of Purchase Price

Quantity Discount

When D =4000 switches per year, S =$30,

and H=0.40P per unit per year, determine

for the following discounts:

a. Optimal Order Quantity?

b. Total Cost?

Range

Price

1 to 499

$0.90

500 to 999

0.85

1000 or more 0.80

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 42

Case2: Holding Cost

as Percentage of Purchase Price

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 43

When to Reorder with EOQ Ordering

Reorder Point - When the quantity on hand of an

item drops to this amount, the item is reordered

Safety Stock - Stock that is held in excess of

expected demand due to variable demand rate

and/or lead time.

Service Level - Probability that demand will not

exceed supply during lead time.

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 45

Determinants of the Reorder Point

The rate of demand

The lead time

Demand and/or lead time variability

Stock-out risk (safety stock)

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 46

ROP and Safety Stock

Safety

stock

reduces

risk of

Stock-out

during lead

time

ROP = d x LT

= Expected

Demand

during

Lead time

+ Safety

Stock

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 47

ROP and Safety Stock

ROP = expected demand during LT +Safety Stock

Unit10-Inventory Mgt rameez.khalid@neduet.edu.pk 48

ROP and Safety Stock

Service Level = 100% - Stock-out Risk

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 49

ROP and Safety Stock

51

Orders are placed at fixed time intervals

Order quantity for next interval?

Suppliers might encourage fixed intervals

May require only periodic checks of inventory

levels

Risk of stockout

Fill rate the percentage of demand filled by the

stock on hand

Fixed-Order-Interval Model

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 53

Time

Inventory Level

Target maximum

Period Period Period

Fixed Period Model

When to Order?

54

Benefits:

Items from same supplier may yield savings in:

Ordering

Packing

Shipping costs

May be practical when inventories cannot be

closely monitored

Disadvantages:

Requires a larger safety stock

Increases carrying cost

Costs of periodic reviews

Fixed-Interval Model

55

Too much inventory

Tends to hide problems

Easier to live with problems than to eliminate

them

Costly to maintain

Wise strategy

Reduce lot sizes

Reduce safety stock

Operations Strategy

Unit-8: Inventory Management rameezkhalid@iba.edu.pk 56

REFERENCES

Operations Management

William J . Stevenson

Operations Management

Barry Render & J ay Heizer

rameezkhalid@iba.edu.pk 58

Solution:

Slide#25 = a. 300 tires; b. 32; c. 9 working days; d. $4800

Slide#33 =a. 2400 wheels; b. $1800; c. 12 days; d. 3 days

Slide#39 =a. 100 cases; b. TC100=$13354

Slide#42 =a. 1000 switches; b. TC1000=$3480

You might also like

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5794)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (73)

- Time Sheet For Teaching Assistant, Research Assistant & Executive AssistantDocument1 pageTime Sheet For Teaching Assistant, Research Assistant & Executive AssistantsirfanalizaidiNo ratings yet

- Delays and Disruption Hudson FormulaDocument2 pagesDelays and Disruption Hudson FormulaGordan CelarNo ratings yet

- Instant Download Ebook PDF Ethical Obligations and Decision Making in Accounting Text and Cases 5th Edition PDF ScribdDocument51 pagesInstant Download Ebook PDF Ethical Obligations and Decision Making in Accounting Text and Cases 5th Edition PDF Scribddouglas.phillips23398% (41)

- Indian Money MarketDocument79 pagesIndian Money MarketParth Shah100% (5)

- STP of HPDocument4 pagesSTP of HPRitika80% (5)

- Financial Problems of StartupsDocument65 pagesFinancial Problems of StartupsSoham Dalvi100% (2)

- Set Up Actual Costing in SAPDocument29 pagesSet Up Actual Costing in SAPedward_soaresNo ratings yet

- UniLever Foods Project CharterDocument15 pagesUniLever Foods Project ChartersirfanalizaidiNo ratings yet

- Student Records - MBA ProjectDocument4 pagesStudent Records - MBA ProjectsirfanalizaidiNo ratings yet

- Student Records - MBA ProjectDocument4 pagesStudent Records - MBA ProjectsirfanalizaidiNo ratings yet

- Syed Hasan Ali - MBA FinanceDocument2 pagesSyed Hasan Ali - MBA FinancesirfanalizaidiNo ratings yet

- What Are The Products of Steel Division?Document2 pagesWhat Are The Products of Steel Division?sirfanalizaidiNo ratings yet

- MBA Graduate Profile - Syed Irfan Ali ZaidiDocument1 pageMBA Graduate Profile - Syed Irfan Ali ZaidisirfanalizaidiNo ratings yet

- Contact Directory with 18 Contacts & DetailsDocument14 pagesContact Directory with 18 Contacts & DetailssirfanalizaidiNo ratings yet

- Revo car re-launch project planDocument6 pagesRevo car re-launch project plansirfanalizaidiNo ratings yet

- Revo's Re-Launch: Terms of ReferenceDocument14 pagesRevo's Re-Launch: Terms of ReferencesirfanalizaidiNo ratings yet

- Future of Mutual Funds in PakistanDocument26 pagesFuture of Mutual Funds in PakistansirfanalizaidiNo ratings yet

- MBA Graduate Profile - Syed Irfan Ali ZaidiDocument1 pageMBA Graduate Profile - Syed Irfan Ali ZaidisirfanalizaidiNo ratings yet

- Contact Directory with 18 Contacts & DetailsDocument14 pagesContact Directory with 18 Contacts & DetailssirfanalizaidiNo ratings yet

- Introduction To The Project - Shan Single Pack SKU (Repositioning)Document5 pagesIntroduction To The Project - Shan Single Pack SKU (Repositioning)sirfanalizaidiNo ratings yet

- MBA Project Handbook - FinalDocument22 pagesMBA Project Handbook - FinalsirfanalizaidiNo ratings yet

- MBA - Institute of Business Administration, Karachi Graduating Year: Spring 2015Document1 pageMBA - Institute of Business Administration, Karachi Graduating Year: Spring 2015sirfanalizaidiNo ratings yet

- Market Potential Analysis of Neutraceutical IndustryDocument6 pagesMarket Potential Analysis of Neutraceutical Industrysirfanalizaidi100% (1)

- Hospital Waste TOR - DraftDocument13 pagesHospital Waste TOR - DraftsirfanalizaidiNo ratings yet

- Syed Hasan Ali - MBA FinanceDocument2 pagesSyed Hasan Ali - MBA FinancesirfanalizaidiNo ratings yet

- MBA Project Handbook - FinalDocument22 pagesMBA Project Handbook - FinalsirfanalizaidiNo ratings yet

- Final Mba Project Report Final VersionDocument199 pagesFinal Mba Project Report Final VersionsirfanalizaidiNo ratings yet

- Group Profile For MBA ProjectDocument1 pageGroup Profile For MBA ProjectsirfanalizaidiNo ratings yet

- Spring 2015: MBA - Institute of Business Administration, Karachi Graduating YearDocument1 pageSpring 2015: MBA - Institute of Business Administration, Karachi Graduating YearsirfanalizaidiNo ratings yet

- AFDMDocument9 pagesAFDMsirfanalizaidiNo ratings yet

- Introduction To The Project - Shan Single Pack SKU (Repositioning)Document4 pagesIntroduction To The Project - Shan Single Pack SKU (Repositioning)sirfanalizaidiNo ratings yet

- Final Mba Project Report Final VersionDocument199 pagesFinal Mba Project Report Final VersionsirfanalizaidiNo ratings yet

- Syed Hasan Ali - MBA FinanceDocument2 pagesSyed Hasan Ali - MBA FinancesirfanalizaidiNo ratings yet

- ABL AMC ConfirmationDocument4 pagesABL AMC ConfirmationsirfanalizaidiNo ratings yet

- ABL AMC ConfirmationDocument4 pagesABL AMC ConfirmationsirfanalizaidiNo ratings yet

- Syed Hasan Ali - MBA FinanceDocument1 pageSyed Hasan Ali - MBA FinancesirfanalizaidiNo ratings yet

- Practice Final Bus331 Spring2023Document2 pagesPractice Final Bus331 Spring2023Javan OdephNo ratings yet

- 2.2 Organizational Structure DelayeringDocument8 pages2.2 Organizational Structure DelayeringDania QistinaNo ratings yet

- MSD Company ProfileDocument19 pagesMSD Company Profilecentral parabotNo ratings yet

- TP1 - Introduction To Accounting & AuditDocument21 pagesTP1 - Introduction To Accounting & AuditAntonius MulyonoNo ratings yet

- Thapelo Khambule Adidas Cover Letter.Document2 pagesThapelo Khambule Adidas Cover Letter.Thapelo KhambuleNo ratings yet

- Standard Costs and Variance Analysis ExplainedDocument24 pagesStandard Costs and Variance Analysis ExplainedLuke Robert HemmingsNo ratings yet

- Communicating Positioning StrategyDocument3 pagesCommunicating Positioning StrategyShafi SaifNo ratings yet

- Assignment 2 (19PMHS010)Document4 pagesAssignment 2 (19PMHS010)GOURAB ROYNo ratings yet

- 1.identifying The Target Market:: Geographical SegmentationDocument4 pages1.identifying The Target Market:: Geographical SegmentationAhmer NaveerNo ratings yet

- Updated Franchise PresentationDocument51 pagesUpdated Franchise PresentationDeo DoktorNo ratings yet

- Seminar on Operations Management Functions and BasicsDocument17 pagesSeminar on Operations Management Functions and BasicsMahtab ANo ratings yet

- Audit of ExpensesDocument18 pagesAudit of Expenseseequals mcsquaredNo ratings yet

- Financial Reporting Standards and Conceptual FrameworkDocument20 pagesFinancial Reporting Standards and Conceptual FrameworkSyed Aquib AbbasNo ratings yet

- Basic Framework of Management Accounting: Prof. Mark Jing D. Tayactac, CPA, MBA, MDMDocument10 pagesBasic Framework of Management Accounting: Prof. Mark Jing D. Tayactac, CPA, MBA, MDMMaria Christina CandelarioNo ratings yet

- Buyers' Cartels An Empirical Study of Prevalence and Economic CharacteristicsDocument48 pagesBuyers' Cartels An Empirical Study of Prevalence and Economic CharacteristicsmgNo ratings yet

- Dina Sri Hastuti 2203003 MRPDocument5 pagesDina Sri Hastuti 2203003 MRPsyaifaeza.jbgNo ratings yet

- Audit Bureau of Circulation - IntroDocument12 pagesAudit Bureau of Circulation - IntrodorcaslnuNo ratings yet

- Strategic AllianceDocument12 pagesStrategic AllianceMadhura GiraseNo ratings yet

- Evaluation of Change in Credit PolicyDocument5 pagesEvaluation of Change in Credit PolicyJhunorlando DisonoNo ratings yet

- Principles of Accounting Chapter 12Document40 pagesPrinciples of Accounting Chapter 12myrentistoodamnhigh100% (2)

- What Is A Commercial BankDocument12 pagesWhat Is A Commercial BankDEEPUNo ratings yet

- Stages in Budgeting ProcessDocument20 pagesStages in Budgeting Processsalsabila naharuddin67% (3)

- 7 Int Parity RelationshipDocument40 pages7 Int Parity RelationshipumangNo ratings yet

- Using Accounting Information Exercises IIDocument34 pagesUsing Accounting Information Exercises IIDedi AntoniNo ratings yet