Professional Documents

Culture Documents

Regulatory Perspective Mr. Joe

Uploaded by

ishtidu340 ratings0% found this document useful (0 votes)

23 views33 pagesRegulatory Perspective Mr. Joe

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentRegulatory Perspective Mr. Joe

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

23 views33 pagesRegulatory Perspective Mr. Joe

Uploaded by

ishtidu34Regulatory Perspective Mr. Joe

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 33

U.S. Dept.

of Health and Human Services

Food and Drug Administration

Center for Drug Evaluation and Research

Office of Compliance

ICH Q9 Quality Risk

Management - Regulatory

Perspective

J oseph C. Famulare

Deputy Director

Office of Compliance, CDER

Workshop on Implementation of ICH

Q8/Q9/Q10 and Other Quality Guidelines

Beijing, China, 3-5 December 2008

2

U.S. DHHS, FDA, CDER Office of Compliance

Objectives

Background

Review of Guideline

Applications

Conclusions

Quality Risk Management

A systematic process for the

assessment, control, communication

and review of risks to the quality of

the drug (medicinal) product across

the product lifecycle.

3

U.S. DHHS, FDA, CDER Office of Compliance

What is Q9?

A new paradigm of risk-

based concepts and

principles

A guideline, not a

mandate

A systemic, process-

oriented approach to

decision making that is

intended to be

practical,

applicable,

predictive,

flexible,

consistent and integrated

risk-based

concepts

and

principles

Q

8

Q

9

Q

1

0

BACKGROUND

4

U.S. DHHS, FDA, CDER Office of Compliance

What is Q9?

The ICH Q9 document:

Main body explains the What?

Annex (I) give ideas on the How?

Annex (II) give ideas on the Where?

It is designed to be implemented by industry

and regulators

Pharmaceutical development (ICH Q8) and Quality

Systems (ICH Q10) will facilitate the What?,

How? and Where?

BACKGROUND

5

U.S. DHHS, FDA, CDER Office of Compliance

Goal is to reduce patient risk

BACKGROUND

Q10 Q8

Process

Materials

Design

Manufacturing

Distribution

Patient

Facilities

Opportunities to impact

risk using quality risk

management

Q9

6

U.S. DHHS, FDA, CDER Office of Compliance

What does Q9 offer?

Quality risk management serves as a

foundation to

support other ICH Quality documents and

complement best quality practices, requirements,

standards, and guidelines within industry and

regulators.

It specifically provides guidance on the

principles and some of the tools of quality

risk management to enable consistent risk

based decisions across the product lifecycle.

BACKGROUND

7

U.S. DHHS, FDA, CDER Office of Compliance

The Desired State

Manage risk to patient, based on

science:

Product, process and facility

Robustness of Quality System

Relevant controls to assess &

mitigate risk

Level of oversight required

commensurate with the level of

risk to patient for:

Marketing authorisation

applications

Post-approval change review

GMP inspections

Barriers to continuous

improvement

reduced or removed

Improved manufacturing

efficiency

Sustained or improved product

quality

Specifications based on

parameters

that truly impact product quality

Common understanding and

language on risk

Both, industry and competent

authorities focus on areas of

greatest risk and understanding

of residual risks

BACKGROUND

8

U.S. DHHS, FDA, CDER Office of Compliance

Q9 Contents

1. Introduction

2. Scope

3. Principles of Quality Risk Management (QRM)

4. General Quality Risk Management Process

5. Risk Management Methodology

Annex I: Risk Management Methods and Tools

6. Integration of QRM process

into Industry and Regulatory operations

Annex II: Potential Applications for QRM

7. Definitions

8. References

GUIDELINE

9

U.S. DHHS, FDA, CDER Office of Compliance

1. Introduction

Terms

Risk Management

Quality Risk Management

Quality Systems

Harm

Severity

Stakeholder

Product Life Cycle

GMP Compliance

Purpose

Systematic approach

Complementary resource

Provides principles and

tools

GUIDELINE

10

U.S. DHHS, FDA, CDER Office of Compliance

2. Scope - Product Lifecycle

Research

Preclinical

Phase

Clinical

Phases

Launch

Quality

ICH Q9

Safety

Efficacy

Manufacturing

& Distribution

GLP

GCP

GMP

GDP

GUIDELINE

11

U.S. DHHS, FDA, CDER Office of Compliance

3. Principles

The evaluation of the

risk to quality should

be based on scientific

knowledge and

ultimately link back to

the protection of the

patient.

The level of effort,

formality, and

documentation of the

quality risk management

process should be

commensurate with the

level of risk.

GUIDELINE

12

U.S. DHHS, FDA, CDER Office of Compliance

4. General Process

Risk Review

Risk Assessment

Risk Evaluation

unacceptable

Risk Control

Risk Analysis

Risk Reduction

Risk Identification

Review Events

Risk Acceptance

Initiate

Quality Risk Management Process

Output / Result of the

Quality Risk Management Process

R

i

s

k

C

o

m

m

u

n

i

c

a

t

i

o

n

R

i

s

k

M

a

n

a

g

e

m

e

n

t

T

o

o

l

s

GUIDELINE

13

U.S. DHHS, FDA, CDER Office of Compliance

5. Methodology

System Risk (facility & people)

e.g., interfaces, operators risk, environment,

components such as equipment, IT, design elements

System Risk (organisation)

e.g., Quality systems, controls, measurements,

documentation, regulatory compliance

Process Risk

e.g., process operations and quality parameters

Product Risk (safety & efficacy)

e.g., quality attributes: measured data according to

specifications

GUIDELINE

14

U.S. DHHS, FDA, CDER Office of Compliance

5. Annex I: Risk Assessment Tools

Failure Mode & Effects Analysis (FMEA)

Failure Mode, Effects and Criticality Analysis

(FMECA)

Fault Tree Analysis (FTA)

Hazard Analysis of Critical Control Points (HACCP)

Hazard Operability Analysis (HAZOP)

Preliminary Hazard Analysis (PHA)

Risk ranking and filtering

Refer to: ICH Q9 Briefing Pack II, J uly 2006

http://www.ich.org/cache/compo/276-254-1.html

GUIDELINE

15

U.S. DHHS, FDA, CDER Office of Compliance

6. Integration into Operations

Quality risk management is intended to

enable and enhance compliance with

regulatory requirements and science-based

decisions when integrated into quality

systems

It is also meant to be applied where it is

feasible and valuable

GUIDELINE

16

U.S. DHHS, FDA, CDER Office of Compliance

6. Integration into Lifecycle

Say, what you do

Do, what you say

Gain experience

Improve it

Approval

Manufacture

Analyse root cause:

Continual

improvement

Update

information

(Risk of) Failure ?

GUIDELINE

Quality Risk

Management

(QRM)

17

U.S. DHHS, FDA, CDER Office of Compliance

6. Annex II: Potential Applications

Integrated quality management

Regulatory operations

Development

Facilities, equipment, utilities

Materials management

Production

Laboratory control and stability studies

Packaging and labeling

Refer to: ICH Q9 Briefing Pack II, J uly 2006

http://www.ich.org/cache/compo/276-254-1.html

GUIDELINE

18

U.S. DHHS, FDA, CDER Office of Compliance

Applies to Regulators & Industry

Regulatory

operations

Inspection and

assessment

activities

Internal systems

Industry operations

(with regulatory oversight)

Internal systems

Development

Facilities, equipment, utilities

Materials management

Production

Laboratory control, stability testing

Packaging and labelling

APPLICATIONS

19

U.S. DHHS, FDA, CDER Office of Compliance

Q8 Pharmaceutical Development

Development studies lead to information for

risk management of the product

Risk management principles help prioritize

development studies

Information relating to process in

development supports risk management in

manufacturing

APPLICATIONS

20

U.S. DHHS, FDA, CDER Office of Compliance

Q8(R1)Quality by Design

Link material attributes and process

parameters to critical quality attributes

Identify and rank parameters, e.g., process,

equipment, materials

Selection of variable within the design space

Identify variables and ranges Scale-up risks

Control strategy

Compensate for variability, e.g., raw materials

APPLICATIONS

21

U.S. DHHS, FDA, CDER Office of Compliance

Q8(R1) Variables & quality attribute

Water

Content

Drying

Granulation

Raw

Materials

Compressing

Plant

Factors

Temp/RH

Precompressing

Main Compressing

Feeder Speed

Press Speed

Punch Penetration

Depth

Temp

RH

Air Flow

Shock Cycle

Drug

Substance

P.S.

Process Conditions

LOD

Diluents

P.S.

LOD

Other

Lubricant

Disintegrant

Binder

Water

Binder

Temp

Spray Rate

Spray Pattern

P.S.

Scrape Down

Chopper Speed

Mixer Speed

Endpoint

Power

Time

Age

Tooling

Operator

Training

Analytical

Method

Sampling

Feed

Frame

Tablet

Drying

Granulation

Raw

Materials

Compressing

Plant

Factors

Temp/RH

Precompressing

Main Compressing

Feeder Speed

Press Speed

Punch Penetration

Depth

Temp

RH

Air Flow

Shock Cycle

Drug

Substance

P.S.

Process Conditions

LOD

Diluents

P.S.

LOD

Other

Lubricant

Disintegrant

Binder

Water

Binder

Temp

Spray Rate

Spray Pattern

P.S.

Scrape Down

Chopper Speed

Mixer Speed

Endpoint

Power

Time

Age

Tooling

Operator

Training

Analytical

Method

Sampling

Feed

Frame

APPLICATIONS

22

U.S. DHHS, FDA, CDER Office of Compliance

GMP

ICH Q10 Pharmaceutical Quality System

Pharmaceutical

Development

Commercial

Manufacturing

Product

Discontinuation

Technology

Transfer

Investigational products

Management Responsibilities

Process Performance & Product Quality Monitoring System

Corrective Action & Preventive Action (CAPA) System

Change Management System

Management Review

PQS

elements

Knowledge Management

Quality Risk Management

Enablers

23

U.S. DHHS, FDA, CDER Office of Compliance

Q10 Pharmaceutical Quality System

Documentation

Training and education

Outsourced activities / purchased materials

Control Strategy

Use quality risk management to establish using parameters

and attributes and related facility and equipment operating

conditions

Monitoring / Handling Quality Defects (CAPA)

The level of effort of the investigation should be

commensurate with the level of risk.

Result should be product and process improvements

APPLICATIONS

24

U.S. DHHS, FDA, CDER Office of Compliance

Q10 Pharmaceutical Quality System

Auditing / Inspection

For regulators

For companies

Periodic review

Change management / change control

Level and formality commensurate with risk

Effect of the change on the overall process and product

Effect on validation

Evaluation of the change upon implementation

Continual improvement

25

U.S. DHHS, FDA, CDER Office of Compliance

Risk Assessment

[Reference: J PharmInnov(2008) 3:7987 | DOI 10.1007/s12247-008-9034-2 | PQLI Design SpaceJ .Lepore & J .Spavins]

APPLICATIONS

26

U.S. DHHS, FDA, CDER Office of Compliance

Risk Assessment, Non-quantitative

[Reference: J PharmInnov(2008) 3:7987 | DOI 10.1007/s12247-008-9034-2 | PQLI Design SpaceJ .Lepore & J .Spavins]

APPLICATIONS

27

U.S. DHHS, FDA, CDER Office of Compliance

Industry Example

APPLICATIONS

28

U.S. DHHS, FDA, CDER Office of Compliance

Industry Example

APPLICATIONS

29

U.S. DHHS, FDA, CDER Office of Compliance

Regulatory Operations: FDA

Site selection process for human drug GMP

inspections

Veterinary drug pre-approval decision

support system (PAIDSS)

Adverse Drug Event (ADE) reporting

inspections

Human drug surveillance sampling programs

APPLICATIONS

30

U.S. DHHS, FDA, CDER Office of Compliance

Facility

Facility Size

Time since Last

CGMP Inspection

Outdated

Information

Product

Process

Score (SRP)

Score (SRP)

Therapeutic Class

Control

Contamination

Unapproved Drugs

Recalls

Establishment

Type

Last 3 District

Decisions

APPLICATIONS

FDA Site Selection Risk Model (2008-09)

31

U.S. DHHS, FDA, CDER Office of Compliance

Goals and Conclusions

Use of Risk Management Tools Provide Basis

for:

Development and Design

Degree of Regulatory Scrutiny

Control of Manufacturing Process and change

control justified by science - and - in the hands of

the manufacturer

CONCLUSIONS

32

U.S. DHHS, FDA, CDER Office of Compliance

Management Responsibilities

Ensure organisation is aware of ICH Q9

and the opportunity it affords

Appropriate education and training

Encourage open, risk aware culture

Establish & support QRM leaders across organisations

Encourage integration of Quality Risk Management

with existing Quality systems

Do NOT set up as a separate department

Coordinate implementation and resource allocation

Prioritise; start small, learn as you go

CONCLUSIONS

33

U.S. DHHS, FDA, CDER Office of Compliance

Opportunity

ICH Q9, together with Pharmaceutical

development [ICH Q8, Q8(R1)] and Quality

systems [ICH Q10], provides opportunity for a

revised, optimised and, less restrictive regulatory

paradigm

Based on scientific knowledge

Enables continual improvement

Greater transparency and efficiency

Focusing on things that add value for patients

Improved relationship between industry and competent

authorities based on trust

CONCLUSIONS

You might also like

- Risk Assessment and ManagementDocument52 pagesRisk Assessment and Managementishtidu34100% (1)

- EU GMP Requirements-Quality SystemsDocument70 pagesEU GMP Requirements-Quality Systemsishtidu34100% (1)

- Quality Risk Management - Facilities and EquipmentDocument42 pagesQuality Risk Management - Facilities and Equipmentishtidu34100% (1)

- Quality Risk ManagementDocument30 pagesQuality Risk ManagementNenad MihajlovNo ratings yet

- The New Quality Paradigm in Ich q8 q9 q10 q11Document30 pagesThe New Quality Paradigm in Ich q8 q9 q10 q11ishtidu34No ratings yet

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- O&M Manager Seeks New Career OpportunityDocument7 pagesO&M Manager Seeks New Career Opportunitybruno devinckNo ratings yet

- MEP Civil Clearance 15-July-2017Document4 pagesMEP Civil Clearance 15-July-2017Mario R. KallabNo ratings yet

- Skanda Purana 05 (AITM)Document280 pagesSkanda Purana 05 (AITM)SubalNo ratings yet

- Security AgreementDocument5 pagesSecurity AgreementGanesh TarimelaNo ratings yet

- 2017 Cannes Product Design ShortlistDocument6 pages2017 Cannes Product Design Shortlistadobo magazineNo ratings yet

- Project ReportDocument55 pagesProject Reportshrestha mobile repringNo ratings yet

- Ob Ward Timeline of ActivitiesDocument2 pagesOb Ward Timeline of Activitiesjohncarlo ramosNo ratings yet

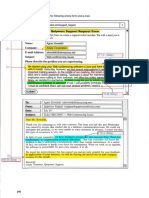

- I I I I I I I: Quipwerx Support Request FormDocument2 pagesI I I I I I I: Quipwerx Support Request Form08. Ngọ Thị Hồng DuyênNo ratings yet

- Full Download Understanding Business Ethics 3rd Edition Stanwick Test BankDocument35 pagesFull Download Understanding Business Ethics 3rd Edition Stanwick Test Bankleuterslagina100% (22)

- Achieving Excellence Guide 3 - Project Procurement LifecycleDocument27 pagesAchieving Excellence Guide 3 - Project Procurement LifecycleMoath AlhajiriNo ratings yet

- EXAMENUL DE BACALAUREAT 2008 Proba Orală La Limba EnglezăDocument2 pagesEXAMENUL DE BACALAUREAT 2008 Proba Orală La Limba EnglezăMar ConsNo ratings yet

- Quiz (14) Criteria For JudgingDocument4 pagesQuiz (14) Criteria For JudgingJemmy PrempehNo ratings yet

- Research TitleDocument5 pagesResearch TitleAthena HasinNo ratings yet

- Rural Marketing Presention - WIPDocument31 pagesRural Marketing Presention - WIPRuee TambatNo ratings yet

- Lembar Jawaban Siswa - Corona-2020Document23 pagesLembar Jawaban Siswa - Corona-2020Kurnia RusandiNo ratings yet

- 3 Macondray - Co. - Inc. - v. - Sellner20170131-898-N79m2kDocument8 pages3 Macondray - Co. - Inc. - v. - Sellner20170131-898-N79m2kKobe Lawrence VeneracionNo ratings yet

- Problem 7 - 16Document2 pagesProblem 7 - 16Jao FloresNo ratings yet

- Rite of Sodomy Vol 1Document690 pagesRite of Sodomy Vol 1Von Erarich.No ratings yet

- Software Quality Assurance FundamentalsDocument6 pagesSoftware Quality Assurance FundamentalsTrendkill Trendkill TrendkillNo ratings yet

- Tealium - State of The CDP 2022Document16 pagesTealium - State of The CDP 2022David StanfordNo ratings yet

- Lecture Law On Negotiable InstrumentDocument27 pagesLecture Law On Negotiable InstrumentDarryl Pagpagitan100% (3)

- Treasurer-Tax Collector Rewrites Investment Policy: Safety Net GoneDocument36 pagesTreasurer-Tax Collector Rewrites Investment Policy: Safety Net GoneSan Mateo Daily JournalNo ratings yet

- SNETEL Brochure 2021Document6 pagesSNETEL Brochure 2021NamNo ratings yet

- Hlimkhawpui - 06.06.2021Document2 pagesHlimkhawpui - 06.06.2021JC LalthanfalaNo ratings yet

- Understanding Plane and Solid FiguresDocument9 pagesUnderstanding Plane and Solid FiguresCoronia Mermaly Lamsen100% (2)

- Recolonizing Ngugi Wa Thiongo PDFDocument20 pagesRecolonizing Ngugi Wa Thiongo PDFXolile Roy NdlovuNo ratings yet

- Dunn, David Christopher vs. Methodist Hospital (Court 189)Document1 pageDunn, David Christopher vs. Methodist Hospital (Court 189)kassi_marksNo ratings yet

- 2016 AP Micro FRQ - Consumer ChoiceDocument2 pages2016 AP Micro FRQ - Consumer ChoiceiuhdoiNo ratings yet

- Weekly Mass Toolbox Talk - 23rd Feb' 20Document3 pagesWeekly Mass Toolbox Talk - 23rd Feb' 20AnwarulNo ratings yet

- DH 0526Document12 pagesDH 0526The Delphos HeraldNo ratings yet