Professional Documents

Culture Documents

Bag Molding

Uploaded by

venkatkrishnaCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Bag Molding

Uploaded by

venkatkrishnaCopyright:

Available Formats

Introduction to Composite IntroductiontoComposite

MaterialsandStructures

Nachiketa Tiwari NachiketaTiwari

IndianInstituteofTechnologyKanpur

Lecture11

ManufacturingofThermoset

Composites

BagMolding g g

Bagmoldingtechniqueworkswellwithwetformingprocess,andalso g g q g p ,

withpremix/prepreg formingprocess.Itisaveryold,andyetversatile

compositefabricationprocess.

Inthisprocess,layersoffibers,impregnatedwithuncuredresin,arelaid

ontopofamold,layerbylayer.Oncethelayupiscomplete,theoverall

fiberstackupiscoveredwithaflexiblebagordiaphragm.

The overall assembly is next subjected to external pressure and Theoverallassemblyisnextsubjectedtoexternalpressureand

temperatureforpurposesofreliablycuringtheresininrelativelyshort

periodoftime.

Oncecuringiscomplete,constituentmaterialsbecomeoneintegrated

mass in desired shape. They can subsequently trimmed, and finished, massindesiredshape.Theycansubsequentlytrimmed,andfinished,

followingwhichtheycanbeusedinactualapplication.

BagMolding g g

Layingupandproperbaggingofthematerialareverycriticalstepsinthe

entireprocess,astheyinfluencethequalityofpartproduced.Toensure

this,andelaboratesetupasshowninFig.11.1isrequiredforbagging.

As shown in this schematic, the layup is setup between a steel mold plate, Asshowninthisschematic,thelayupissetupbetweenasteelmoldplate,

andcaul plate,whicharecoatedwithasprayofreleasecoatfilm,aswell

asreleasefabric,whichensurethatthepartdoesnotgetstucktothe

moldplate.Thecompositepartiscoveredwithpeelplies,whichprotectit p p p p p , p

againstcontaminatingagents.Further,thelaminateisalsocoveredwith

bleederplies,whichabsorbexcessresin,andbreatherplies,whichactasa

pathwayforairbubblesandvolatilematerialstoexitoutfromthe p y

compositeduringcuring.Theentiresetupissealedinavacuumbagusing

appropriatesealants.

Inthisprocess,whileapplicationoftemperatureisrequiredtofastenthe

curingprocess,applicationofpressureisimportanttoensuregoodsurface

finish, dimensional accuracy, and also to eliminate presence of air and finish,dimensionalaccuracy,andalsotoeliminatepresenceofairand

porosityinthecompositecomponent.

Bag Molding BagMolding

Fig.11.1:TypicalBagMoldingProcessSetup g yp g g p

BagMolding g g

Bagmoldingprocesscanbecategorized,basedonthemethodof g g p g ,

applicationofexternalpressure,intothreegroups.

Pressurebagmolding:Herepressuresexceeding1barareappliedonthecomposite

materialbeingprocessed. g p

Vacuumbagmolding:Inthisprocess,thecompositematerialsissubjectedtovacuumto

removeairbubblesfromthelaminate.Postthisstage,thematerialmaybesubjectedto

atmosphericpressurewhileitundergoescuringprocessinanoven.

Autoclavemolding:Here,thecompositeissubjectedtovacuumpressures,andalso

elevatedpressuressimultaneously,whileitundergoescuringatelevatedtemperatures.

Inthisprocess,thepartisenclosedinabagconnectedtoavacuumpump.Further,the

exteriorofthebagissubjectedtopressuresexceeding1bar.Finally,curingoftheresin

is initiated through raising the temperature of material by placing it in an autoclave isinitiatedthroughraisingthetemperatureofmaterialbyplacingitinanautoclave

chamber.

In such a process application of high pressure ensures increased removal of air and Insuchaprocess,applicationofhighpressureensuresincreasedremovalofairand

othervolatiles,increasedwetting,andimprovedimpregnationoffiberswithresin.

BagMolding g g

Pressurebagmoldingisrelativelyexpensiveduetotoolingcosts.Inthis g g y p g

method,toolingisexpensivesinceitisintegratedwithcuringpressure

system.

Further,toolsforthistypeofbagmoldingarepartspecific.

Incontrast,vacuumbagandautoclavemoldingapproachesarerelatively

inexpensiveasthebasiccuringequipmentdoesnotchange.Figures11.2

and 11 3 are illustrations of these types of bag molding process and11.3,areillustrationsofthesetypesofbagmoldingprocess.

Bag Molding BagMolding

Fig.11.2:SetupforPressureBagMoldingProcess

Bag Molding BagMolding

Fig.11.3:SetupforVacuumBagMoldingProcess

ResinTransferMoldingg

ResinTransferMolding,commonlyknownasRTM,isawetprocess,where g, y , p ,

fibersandresinareplacedinthemoldseparately.

i l f fib ( /f b i ) l d i h ld l b First,layersoffibers(ormats/fabrics,)areplacedinthemoldlayerby

layer.Onceallthelayersoffibershavebeenplaced,pressurizedresinis

introducedinthemoldtoimpregnatethefibers.Themoldcavity,into

whichresinflows,hasinletsforresin,andalsoventsforair.

Once the mold is full of resin the system is heated to initiate curing Oncethemoldisfullofresin,thesystemisheatedtoinitiatecuring.

However,incertainapplications,curingmayoccuratroomtemperature.

Inthismethod,lowviscosityresinsarechosen,assuchresinswetfibers,

andalsoenterinterfibergapsrelativelyeasily.

ResinTransferMoldingg

RTMensureimprovedcontroloverfiberorientation,asfluidpressurein p , p

resinisnotsufficientlylargeenoughtodislodgefibersfromtheirintended

location.

Vacuumassistedresintransfermolding(VARTM)isavariationofRTM,

wherevacuumpressureaidsflowofresin,andalsowettingoffibers.

ComparedtoRTM,VARTMissignificantlylessexpensive.

R f References

1. Analysis and Performance of Fiber Composites, Agarwal,

B D d B t L J J h Wil & S B.D. and Broutman, L. J., John Wiley & Sons.

2 M h i f C i M i l J R M M G 2. Mechanics of Composite Materials, Jones, R. M., McGraw

Hill.

3. Engineering Mechanics of Composite Materials, Daniel, I.

M and Ishai O Oxford University Press M. and Ishai, O., Oxford University Press.

You might also like

- Textile Composites III-composite MFGDocument10 pagesTextile Composites III-composite MFGYared FikreNo ratings yet

- Manufacturing of Green CompositesDocument20 pagesManufacturing of Green CompositesShivansh ThakurNo ratings yet

- Vacuum Bag Moulding and Compression Moulding TechniquesDocument21 pagesVacuum Bag Moulding and Compression Moulding TechniquesNagarajan Sundaram100% (1)

- Matrix MaterialDocument51 pagesMatrix MaterialA-13-M Ibrahim OMARNo ratings yet

- Manufacturing MethodDocument9 pagesManufacturing MethodMr. SeventeenNo ratings yet

- CompositesDocument24 pagesCompositesjrevanthmaniNo ratings yet

- PMC Manufacturing ProcessesDocument6 pagesPMC Manufacturing ProcessesHasham AhmadNo ratings yet

- CompositesDocument49 pagesCompositesshahriar sNo ratings yet

- Filament winding and pultrusion compositesDocument22 pagesFilament winding and pultrusion compositesHardeep SinghNo ratings yet

- Processing of Polymers and Composites: Lecture 20 - 11/03/2019Document14 pagesProcessing of Polymers and Composites: Lecture 20 - 11/03/2019MK SaravananNo ratings yet

- Manufacture of Composites: Submitted To - S.S GodaraDocument37 pagesManufacture of Composites: Submitted To - S.S GodaraRais Alfiansyah TaufiqNo ratings yet

- Manufacturing of Advanced CompositesDocument32 pagesManufacturing of Advanced CompositesGokul KNo ratings yet

- Composite Manufacturing ProDocument5 pagesComposite Manufacturing ProJogesh BarikNo ratings yet

- Composites Mod02lec01Document49 pagesComposites Mod02lec01Mathew JohnNo ratings yet

- Chapter 2 Manufacturing of CompositesDocument38 pagesChapter 2 Manufacturing of CompositesHelmi LandolsiNo ratings yet

- Thermoplastic Film Infusion Process For Long-Fiber Reinforced Composites Using Thermally Expandable Elastomer ToolsDocument8 pagesThermoplastic Film Infusion Process For Long-Fiber Reinforced Composites Using Thermally Expandable Elastomer ToolsabiliovieiraNo ratings yet

- Module 2Document54 pagesModule 2akash kumarNo ratings yet

- Manufacturing of Polymer CompositesDocument17 pagesManufacturing of Polymer CompositesMaya VargheseNo ratings yet

- FRP Processing Methods GuideDocument47 pagesFRP Processing Methods GuideABeer AkNo ratings yet

- Fabrication of Composite MaterialsDocument33 pagesFabrication of Composite MaterialsGaurav MauryaNo ratings yet

- Manufacturing Process Description: 4.1 The Manufacture of Fibre FabricDocument4 pagesManufacturing Process Description: 4.1 The Manufacture of Fibre FabricWolfMensch1216No ratings yet

- Chapter-5: 5.1 Fabrication Techniques of Composite MaterialsDocument6 pagesChapter-5: 5.1 Fabrication Techniques of Composite MaterialsSasiKumar PetchiappanNo ratings yet

- Processing of Polymers and CompositesDocument23 pagesProcessing of Polymers and CompositesMK SaravananNo ratings yet

- Composite Formation by Hand-Layup Process: Technical ReportDocument8 pagesComposite Formation by Hand-Layup Process: Technical ReportReinaldo SilvestreNo ratings yet

- Unit-Iii MANUFACTURING METHODS: Autoclave, Tape Production, Moulding Methods, FilamentDocument13 pagesUnit-Iii MANUFACTURING METHODS: Autoclave, Tape Production, Moulding Methods, FilamentSaisurendra VeerlaNo ratings yet

- Forming Composites by Hand LayupDocument8 pagesForming Composites by Hand LayupEchebiri CollinsNo ratings yet

- AM ManufacturingDocument78 pagesAM ManufacturingAarizMalikNo ratings yet

- Raw Material E-Glass FibberDocument7 pagesRaw Material E-Glass Fibberpramo_dassNo ratings yet

- Ttrial/technical: A ReviewDocument20 pagesTtrial/technical: A ReviewfernandoribeiromocNo ratings yet

- Plastic Moulding Processes OverviewDocument28 pagesPlastic Moulding Processes OverviewQUAZI ADYAN AHMAD 160419736049No ratings yet

- Fiber Spinning Gonzalez Shivokhin StringariDocument16 pagesFiber Spinning Gonzalez Shivokhin Stringariengenheirogus2859No ratings yet

- Smart Composites: Angel College of Engineering and TechnologyDocument12 pagesSmart Composites: Angel College of Engineering and Technologydolly707No ratings yet

- Farhana 872 - 125114Document5 pagesFarhana 872 - 125114Nahid AbrarNo ratings yet

- Modeo Por DiafragmaDocument5 pagesModeo Por DiafragmaAlexNo ratings yet

- Lecture # 5 Shaping Processes For Polymer Matrix CompositesDocument47 pagesLecture # 5 Shaping Processes For Polymer Matrix CompositesAhmad FadillahNo ratings yet

- Febrication ProcessesDocument5 pagesFebrication Processesnilghosh001100% (1)

- Processing of Polymers and Composites: Lecture 23 - 09/03/2020Document9 pagesProcessing of Polymers and Composites: Lecture 23 - 09/03/2020MK SaravananNo ratings yet

- Types of Composite ManufacturingDocument42 pagesTypes of Composite Manufacturingu2b11517100% (2)

- Resin Transfer Molding: A Guide to the Process and Its BenefitsDocument20 pagesResin Transfer Molding: A Guide to the Process and Its BenefitsSalman FarisNo ratings yet

- Write A Report On Composite Materials, The Reason Why They Are Used. Their Major Applications in Few Fields, and Some of The Latest Composite Materials.Document17 pagesWrite A Report On Composite Materials, The Reason Why They Are Used. Their Major Applications in Few Fields, and Some of The Latest Composite Materials.Raushan Jha100% (1)

- Filament Winding Process and ApplicationsDocument6 pagesFilament Winding Process and Applications林丽莹No ratings yet

- TrosDocument14 pagesTrosyeabsira getachewNo ratings yet

- Extrusion Based AMDocument20 pagesExtrusion Based AMashok gadewalNo ratings yet

- Lecture 11Document45 pagesLecture 11Kemal DemirNo ratings yet

- Drawing, Texturing, Intermingling and Heat Setting Process: ObjectDocument11 pagesDrawing, Texturing, Intermingling and Heat Setting Process: ObjectPRIYANSHUNo ratings yet

- Mechanical FinishingDocument28 pagesMechanical FinishingRahulKumbhareNo ratings yet

- Spinning For NonwovensDocument11 pagesSpinning For NonwovenskanonycoNo ratings yet

- Filament Winding PDFDocument11 pagesFilament Winding PDFANKITA SARMAH100% (1)

- Spmejury FusingDocument13 pagesSpmejury FusingSuman Kumar100% (2)

- Fibre Reinforcement Arrangements and Laminated Composite ManufacturingDocument2 pagesFibre Reinforcement Arrangements and Laminated Composite ManufacturingRAKESH RANJAN TRIPATHYNo ratings yet

- Composite Manufacturing ProcessesDocument4 pagesComposite Manufacturing ProcessesUmesh KsNo ratings yet

- TECHNOLOGY OF NONWOVENS - MECHANICAL FINISHING PROCESSESDocument23 pagesTECHNOLOGY OF NONWOVENS - MECHANICAL FINISHING PROCESSESmahes_tex100% (1)

- Background: The Duct Tape BookDocument5 pagesBackground: The Duct Tape BookCloudine IzonNo ratings yet

- Manufacturing Method For CompositesDocument41 pagesManufacturing Method For CompositestpmendozaNo ratings yet

- Vacuum Bag Forming and Pressure Bag FormingDocument18 pagesVacuum Bag Forming and Pressure Bag FormingaliNo ratings yet

- Processing of Polymers and Composites: Lecture 18 - 04/03/2019Document24 pagesProcessing of Polymers and Composites: Lecture 18 - 04/03/2019MK SaravananNo ratings yet

- TexturizingDocument55 pagesTexturizingKathirrveluSubramainanNo ratings yet

- POLYMER PROCESSING HandoutDocument4 pagesPOLYMER PROCESSING HandoutAmabelle SantosNo ratings yet

- Legend IsemDocument1 pageLegend Isemakkas_397050765No ratings yet

- In-Class Demonstration: Saint-Venant's Principle and Stress ConcentrationsDocument1 pageIn-Class Demonstration: Saint-Venant's Principle and Stress Concentrationsblackant007No ratings yet

- Stress Strain Relations PDFDocument40 pagesStress Strain Relations PDFvenkatkrishnaNo ratings yet

- Pecselfstudy GKHDocument667 pagesPecselfstudy GKHvenkatkrishnaNo ratings yet

- AcknowledgementsDocument7 pagesAcknowledgementsvenkatkrishnaNo ratings yet

- Isometric projection guideDocument4 pagesIsometric projection guidevenkatkrishnaNo ratings yet

- Engineering Graphics BasicsDocument27 pagesEngineering Graphics BasicsDr. B. RameshNo ratings yet

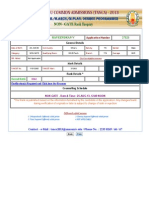

- Tamilnadu Common Admissions - 2013raviDocument1 pageTamilnadu Common Admissions - 2013ravivenkatkrishnaNo ratings yet

- Forging Stamping Plastic Deformation AnalysisDocument7 pagesForging Stamping Plastic Deformation AnalysisvenkatkrishnaNo ratings yet

- 6 Histology of Drilling MudDocument6 pages6 Histology of Drilling MudvenkatkrishnaNo ratings yet

- 4 - Coupled Structural - Thermal AnalysisDocument8 pages4 - Coupled Structural - Thermal AnalysisBaljinder SinghNo ratings yet

- ABC Tamil PDFDocument60 pagesABC Tamil PDFAravind Surya100% (1)

- mt1 May June 2014Document1 pagemt1 May June 2014venkatkrishnaNo ratings yet

- Upper and Lower Bound ProbDocument35 pagesUpper and Lower Bound ProbvenkatkrishnaNo ratings yet

- IIT Bombay P.HD Admission 2014Document1 pageIIT Bombay P.HD Admission 2014venkatkrishnaNo ratings yet

- Selection of Forging Equipment: Taylan Altan and Manas Shirgaokar, The Ohio State UniversityDocument11 pagesSelection of Forging Equipment: Taylan Altan and Manas Shirgaokar, The Ohio State UniversityEldori1988No ratings yet

- Engineering CompositesDocument193 pagesEngineering CompositesMelih AltıntaşNo ratings yet

- Advance Mechanics of Material Jan12Document4 pagesAdvance Mechanics of Material Jan12venkatkrishna0% (1)

- MBA Brochure 2012Document32 pagesMBA Brochure 2012venkatkrishnaNo ratings yet

- Pd9211-Quality Concepts in Design-R8 PDFDocument2 pagesPd9211-Quality Concepts in Design-R8 PDFSnehasish IsharNo ratings yet

- Pd9211-Quality Concepts in Design 3Document2 pagesPd9211-Quality Concepts in Design 3Vignesh Vicky100% (1)

- Use of Composites in Aircraft DesignDocument1 pageUse of Composites in Aircraft DesignvenkatkrishnaNo ratings yet

- ME College ListDocument17 pagesME College ListvenkatkrishnaNo ratings yet

- Mtech Applied MechanicsDocument28 pagesMtech Applied MechanicsvenkatkrishnaNo ratings yet

- M.E. CimDocument40 pagesM.E. CimvenkatkrishnaNo ratings yet

- Metal Casting: Design, Materials, & EconomicsDocument16 pagesMetal Casting: Design, Materials, & EconomicsraniksrNo ratings yet

- M.E. CimDocument40 pagesM.E. CimvenkatkrishnaNo ratings yet

- DFMaDocument1 pageDFMavenkatkrishnaNo ratings yet

- 4 General Types of Polymers Molecular StructureDocument3 pages4 General Types of Polymers Molecular StructureArgel Linard Francisco MabagaNo ratings yet

- Davao October 2014 Criminologist Board Exam Room AssignmentsDocument113 pagesDavao October 2014 Criminologist Board Exam Room AssignmentsPRC Board0% (1)

- Vdo Pressure GuageDocument14 pagesVdo Pressure Guagezuma zaiamNo ratings yet

- Nabll Mix DesignDocument29 pagesNabll Mix DesignPIDCL WITH SUBUDHINo ratings yet

- 9040 - User ManualDocument236 pages9040 - User ManualWallie Billingsley77% (13)

- Manufacturing of Urea Through Synthetic Ammonia Project ReportDocument5 pagesManufacturing of Urea Through Synthetic Ammonia Project ReportvishnuNo ratings yet

- G100-G102-Chassis-Manual #1Document151 pagesG100-G102-Chassis-Manual #1Daihatsu Charade BanjarnegaraNo ratings yet

- 15 Suspensions PDFDocument57 pages15 Suspensions PDFSASWAT MISHRANo ratings yet

- MSDS 42935Document3 pagesMSDS 42935EliasNo ratings yet

- Reading 03 - Iron Lady The Eiffel TowerDocument2 pagesReading 03 - Iron Lady The Eiffel TowerFernando Elías Valderrama GómezNo ratings yet

- RDSS L2 Pert Chart - PKG-04 - Joynagar.... 21082023Document5 pagesRDSS L2 Pert Chart - PKG-04 - Joynagar.... 21082023sourish69No ratings yet

- Lincoln FC ElectrodesDocument44 pagesLincoln FC ElectrodeszmcgainNo ratings yet

- Cooling Tower PDFDocument3 pagesCooling Tower PDFmaimslapNo ratings yet

- BaaN IV VDADocument126 pagesBaaN IV VDARostane Horvath ErzsebetNo ratings yet

- Inspection Checklist For Lifting Tools & TacklesDocument2 pagesInspection Checklist For Lifting Tools & Tacklesnil thaeu100% (1)

- ABS Thickness Measurement Requirement For Ship in Operation PDFDocument2 pagesABS Thickness Measurement Requirement For Ship in Operation PDFMohd Fouzi AbdullahNo ratings yet

- ECOSYS M6526cdn Fax SetupDocument204 pagesECOSYS M6526cdn Fax SetupAnonymous gn8qxxNo ratings yet

- ZMD402AT-CT Technical DataDocument7 pagesZMD402AT-CT Technical DataCarlos SandersNo ratings yet

- Nba Sar B.tech. Electronics UgDocument171 pagesNba Sar B.tech. Electronics UgSaurabh BhiseNo ratings yet

- P0562-Battery Voltage LowDocument7 pagesP0562-Battery Voltage Lowguillermoal539100% (1)

- Demo-C Tfin52 67Document5 pagesDemo-C Tfin52 67namank005No ratings yet

- Furuno GMDSS Installation Manual PDFDocument64 pagesFuruno GMDSS Installation Manual PDFEric PskdNo ratings yet

- Sika PDS E SikaRep SDocument3 pagesSika PDS E SikaRep Slwin_oo2435No ratings yet

- Lab 3 - Series and Parallel CircuitsDocument7 pagesLab 3 - Series and Parallel CircuitsHảo PhùngNo ratings yet

- Load Case CombinationsDocument5 pagesLoad Case CombinationsFrancisco UgarteNo ratings yet

- Manual JX PDFDocument263 pagesManual JX PDFArvind KumarNo ratings yet

- Understanding Japanese Management PracticesDocument16 pagesUnderstanding Japanese Management PracticesBusiness Expert Press100% (3)

- Slides - OOP With SmalltalkDocument51 pagesSlides - OOP With Smalltalkapi-3728136No ratings yet

- PC Pump ManualDocument540 pagesPC Pump ManualtelephonicaNo ratings yet

- Bricks CalculationDocument3 pagesBricks CalculationAravindanNo ratings yet