Professional Documents

Culture Documents

lm2500 Lubesupply

Uploaded by

Denis JimenezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

lm2500 Lubesupply

Uploaded by

Denis JimenezCopyright:

Available Formats

Lube Supply

The LM2500 gas generator requires a supply of 18 gpm of MIL-L-23699 or MIL-L-7808 oil, or other

approved lubricant shown in MID-TD-0000-6. Prior to starting the engine, the inlet to the lube pump

shall have a flooded suction, but the pressure shall not exceed 3.5 psig. During starting with cold oil, the

inlet pressure to the pump shall not be less than 5 psia. During normal operation with 140 to 160F oil,

the inlet pressure to the pump shall not be less than 12 psia. The oil flow varies with gas generator

speed.

During starting and acceleration to idle, the temperature of the oil supply to the lube pump inlet must be

above +20F for MIL-L-23699 oil and above -20F for MIL-L-7808 oil. This is required in order to

assure an acceptable viscosity (700 cSt maximum) of the oil used to operate the compressor variable-

stator control system. Subsequent transients above idle should be restricted until the oil supply

temperature is at least 90F in order to assure complete transient capability of the variable-stator control

system.

The lube-supply element of the lube and scavenge pump is equipped with a pressure relief valve that has

an initial cracking pressure of 100 psid and a full bypass flow set of 200 psid. The Purchaser-supplied

components between the lube pump discharge port (Interface L2) and the lube supply manifold

connection (L4) should therefore be rated for 200 psig minimum. The Purchaser-supplied piping and

components should also be selected to ensure that the lube supply element does not operate on the relief

valve except under a failure condition.

Lube and Scavenge Pump Interfaces.

Figure 1 defines the nominal lube supply pressure as measured at the pressure tap on the lube supply

manifold (L5) for combinations of gas generator speed, lube supply temperature, oil type, and stator

vane control configuration for MIL-L-23699 Oil. If the Purchaser plans to use MIL-L-7808, please

contact GE for lube supply pressure characteristics. In addition, an allowance of 15 psid shall be made

for the lube supply system check valve provided with the gas turbine.

The lube oil supply manifold is equipped with an antistatic leak check valve to prevent flooding of the

Page 1 of 3 Lubrication

19/11/2005 http://inside-aep.ps.ge.com/insideaep/aep/iad/engine_prod_delv/idms/lm2500/09lubesupp...

gas turbine gearbox and sumps from an elevated lube supply system when the engine is not in operation.

The maximum static head pressure that can be applied by the Purchasers lube supply system to the lube

supply manifold (L4) is 3.5 psig. Although the 3.5 psig maximum static head pressure is equivalent to a

lube oil head of 8 feet, it is suggested that, where possible, the actual head imposed be limited to not

more than 3 feet to further minimize potential for flooding the sumps in the event of malfunction or

leakage through the antistatic leak check valve.

The oil supplied to the gas generator shall not contain more than 10% by volume of entrained air. The

engine oil system will "gulp" approximately 4.5 gallons from the non-operating condition; therefore, the

oil supply tank must be sized to accommodate this amount of oil.

A pressure tap is provided on the gas turbine, for determining the oil supply pressure to the bearings,

and another in the oil scavenge line, for determining scavenge oil pressure. Sensors are provided in each

of the scavenge oil lines and from the accessory gearbox for monitoring oil scavenge temperature.

During normal operation, the Purchasers oil temperature control system should regulate the oil supply

temperature to the bearings between 140 and 160F. The oil supplied to the bearings must be filtered to

10 nominal. GE recommends the use of 10 nominal filtration in both the lube supply and the

scavenge system.

Figure 1. Nominal Lube Supply Pressure with MIL-L-23699 Oil.

Page 2 of 3 Lubrication

19/11/2005 http://inside-aep.ps.ge.com/insideaep/aep/iad/engine_prod_delv/idms/lm2500/09lubesupp...

Page 3 of 3 Lubrication

19/11/2005 http://inside-aep.ps.ge.com/insideaep/aep/iad/engine_prod_delv/idms/lm2500/09lubesupp...

You might also like

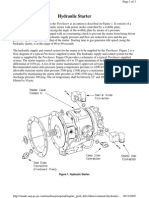

- Figure 1. Hydraulic StarterDocument3 pagesFigure 1. Hydraulic StarterDenis JimenezNo ratings yet

- GE Marine Gas Turbine ManualDocument72 pagesGE Marine Gas Turbine ManualMiguel Francisco Goytia100% (1)

- Lm2500 DescripDocument2 pagesLm2500 DescripDenis Jimenez100% (1)

- LM 2500Document12 pagesLM 2500pramodtryNo ratings yet

- LM2500+ Shutdown SequencesDocument6 pagesLM2500+ Shutdown Sequencesrenzobermudez89No ratings yet

- LM2500 Wtui 2015Document106 pagesLM2500 Wtui 2015abelsg100% (2)

- LM6000-InD-239 - Improved LPT Coupling NutDocument9 pagesLM6000-InD-239 - Improved LPT Coupling NutIqbal UsmaniNo ratings yet

- Lm2500 InstrumentationDocument4 pagesLm2500 InstrumentationDenis JimenezNo ratings yet

- (GAS TURBINE MS 5001 PA) Volume IDocument159 pages(GAS TURBINE MS 5001 PA) Volume Ihayder ahmed100% (2)

- Gek105054 File0007Document18 pagesGek105054 File0007outilprok22kNo ratings yet

- Dynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDocument3 pagesDynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDenis JimenezNo ratings yet

- Curso de Introducción A Turbinas LM2500Document197 pagesCurso de Introducción A Turbinas LM2500yasserdekNo ratings yet

- Natural Gas Fuel Specifications for GE Gas TurbinesDocument29 pagesNatural Gas Fuel Specifications for GE Gas Turbinesphoenix609No ratings yet

- Gas Turbine Performance MonitoringDocument109 pagesGas Turbine Performance MonitoringSamir Benabdallah100% (1)

- Training ManualDocument551 pagesTraining ManualSeif Charaf100% (3)

- Frame 7EA 2021Document30 pagesFrame 7EA 2021Ender Galvis0% (1)

- Lm2500 LubricationDocument2 pagesLm2500 LubricationDenis Jimenez100% (2)

- CatalogoPGT25 PDFDocument4 pagesCatalogoPGT25 PDFshihabjamaan100% (4)

- Fuel Control Requirements: Fuel Scheduling at Steady State OperationDocument11 pagesFuel Control Requirements: Fuel Scheduling at Steady State OperationDenis Jimenez100% (1)

- Ger4250 LM2500G4Document12 pagesGer4250 LM2500G4Denis JimenezNo ratings yet

- Usn LM2500 Asme Paper GT2010-22811 61410 JalDocument7 pagesUsn LM2500 Asme Paper GT2010-22811 61410 Jalferrerick0% (1)

- Siemens Gas Turbine Product Range Comparison Chart 0-130 MWDocument2 pagesSiemens Gas Turbine Product Range Comparison Chart 0-130 MWdvcher78No ratings yet

- 02 Ms5001 DescriptionDocument58 pages02 Ms5001 DescriptionHafiz Usman Mahmood100% (5)

- LM2500 AssessmentDocument3 pagesLM2500 AssessmentKALPUSH50% (2)

- Ge MS 5000 5341Document45 pagesGe MS 5000 5341helmybh100% (3)

- Gas Turbine MaintenanceDocument11 pagesGas Turbine Maintenancemoinuddinmohdyusuf100% (4)

- Descripcion SGT 400Document7 pagesDescripcion SGT 400Wilfredo Rojo Castaño100% (1)

- GE LM6000 Gas Turbine Generator Drive Application Control PackageDocument3 pagesGE LM6000 Gas Turbine Generator Drive Application Control Packageabhaymehta67100% (1)

- List of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesDocument4 pagesList of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZNo ratings yet

- Starting Gas TurbineDocument3 pagesStarting Gas Turbineanup_nairNo ratings yet

- LM6000 PC Time Limited ComponentsDocument7 pagesLM6000 PC Time Limited ComponentsmstaszelNo ratings yet

- 2.3.8 Liquid FuelDocument16 pages2.3.8 Liquid FuelSarah CohenNo ratings yet

- LM6000 PC O&M - GEK 105059 CHG 06Document1,988 pagesLM6000 PC O&M - GEK 105059 CHG 06Alejandro J. Vigo50% (2)

- Proven Solutions GE-EvuletDocument48 pagesProven Solutions GE-EvuletmohamedhasNo ratings yet

- 3 - Gas Turbine Overview 8.09Document25 pages3 - Gas Turbine Overview 8.09Sujeet Kumar100% (1)

- LM2500 PerformanceDocument2 pagesLM2500 PerformanceLi Fang HuangNo ratings yet

- R 232 MS5001 Technical DescriptionDocument7 pagesR 232 MS5001 Technical Descriptionscribdkhatn100% (4)

- GER3620L Nov 3 09b RevDocument60 pagesGER3620L Nov 3 09b RevGTENG CPINo ratings yet

- ALLISON 501-KC5 & KB5: (Construction Details)Document32 pagesALLISON 501-KC5 & KB5: (Construction Details)Anand Mishra100% (1)

- Ge LM6000 Training 1Document74 pagesGe LM6000 Training 1sasa hh100% (1)

- Powering the world with innovative gas turbinesDocument22 pagesPowering the world with innovative gas turbinesBony DiazgNo ratings yet

- GT Gas Fuel and Air FlowDocument38 pagesGT Gas Fuel and Air FlowhinaNo ratings yet

- LM 2500 PlusDocument2 pagesLM 2500 Plusalexandr_popov_2No ratings yet

- Trent 60 WLE Power Package Training ManualDocument39 pagesTrent 60 WLE Power Package Training ManualRicardo Cabrera Osinaga100% (6)

- DLE Overview PDFDocument53 pagesDLE Overview PDFMijail David Felix Narvaez80% (5)

- C10518078 PDFDocument20 pagesC10518078 PDFJessica ChandlerNo ratings yet

- PDFDocument124 pagesPDFEmanuel Conde100% (1)

- LM6000 Gas Fuel Spec.Document11 pagesLM6000 Gas Fuel Spec.cdbeardsall100% (2)

- GE User QnA 6BDocument31 pagesGE User QnA 6Bsatyandaru100% (1)

- Ger 3658d Speedtronic Mark V Gas Turbine Control System PDFDocument19 pagesGer 3658d Speedtronic Mark V Gas Turbine Control System PDFyos100% (1)

- TFE 731 Chap 79Document24 pagesTFE 731 Chap 79Egor8550% (2)

- ER 58.11startup ProcedureDocument3 pagesER 58.11startup Proceduredongosuperstar100% (2)

- Service Bulletin RT-18.4: Technical Information To All Owners / Operators of Wärtsilä RTA and RT-flex EnginesDocument14 pagesService Bulletin RT-18.4: Technical Information To All Owners / Operators of Wärtsilä RTA and RT-flex Engineszbkt07No ratings yet

- VSG Compressor: For Natural Gas and Process Gas ApplicationsDocument8 pagesVSG Compressor: For Natural Gas and Process Gas ApplicationsbracioNo ratings yet

- Turner Compact Plus Transmission ManualDocument74 pagesTurner Compact Plus Transmission Manualbeto06100% (8)

- SM 03 BDocument34 pagesSM 03 BMark OreschnickNo ratings yet

- Lube Oil System Description PDFDocument26 pagesLube Oil System Description PDFWole Oyefisayo100% (1)

- Instruction ManualDocument36 pagesInstruction ManualJoséNo ratings yet

- Installation, Operation and Service Guide for LeROI Gas CompressorsDocument49 pagesInstallation, Operation and Service Guide for LeROI Gas Compressorscesosqui0% (1)

- TFE 731 Chap 73Document34 pagesTFE 731 Chap 73Egor85100% (2)

- 3612tale Jgd6 DesignDocument1 page3612tale Jgd6 DesignDenis JimenezNo ratings yet

- Filter Bound CatalogDocument248 pagesFilter Bound CatalogDenis JimenezNo ratings yet

- 460-119 Hoja de Especificaciones.Document2 pages460-119 Hoja de Especificaciones.Denis JimenezNo ratings yet

- Dse4610 Dse4620 Data SheetDocument2 pagesDse4610 Dse4620 Data SheetDenis Jimenez0% (1)

- E7700 10 10 13 - Prozesstechnik - WebDocument24 pagesE7700 10 10 13 - Prozesstechnik - WebDenis JimenezNo ratings yet

- Inline Process FiltersDocument7 pagesInline Process FiltersDenis JimenezNo ratings yet

- E7710 1 06 11 - Leitungsfilter ProzessDocument8 pagesE7710 1 06 11 - Leitungsfilter Prozessvikram_007No ratings yet

- 1303-1512 SSPF Final InoxidableDocument16 pages1303-1512 SSPF Final InoxidableDenis JimenezNo ratings yet

- Hydac SCADocument6 pagesHydac SCADenis JimenezNo ratings yet

- E2000 0 03 11 - SYSTEMTECHNIK - WWWDocument8 pagesE2000 0 03 11 - SYSTEMTECHNIK - WWWDenis JimenezNo ratings yet

- E79000-2-04-13 FS Buch WWWDocument291 pagesE79000-2-04-13 FS Buch WWWDenis JimenezNo ratings yet

- Filter Bound CatalogDocument248 pagesFilter Bound CatalogDenis JimenezNo ratings yet

- Bell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDocument20 pagesBell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDenis JimenezNo ratings yet

- Ac-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDocument12 pagesAc-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDenis JimenezNo ratings yet

- Ac-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDocument12 pagesAc-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDenis JimenezNo ratings yet

- E18061 2 0 11 13 - HNS3000Document2 pagesE18061 2 0 11 13 - HNS3000Denis JimenezNo ratings yet

- Fluid Level Gauge Fluid Level Sensor Temperature Switch Fsa / FSK / TsDocument12 pagesFluid Level Gauge Fluid Level Sensor Temperature Switch Fsa / FSK / TsDenis JimenezNo ratings yet

- Bell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDocument20 pagesBell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDenis JimenezNo ratings yet

- E5601 13 04 07 - PT Neu2Document5 pagesE5601 13 04 07 - PT Neu2Denis JimenezNo ratings yet

- E5601 PTKDocument4 pagesE5601 PTKDenis JimenezNo ratings yet

- Pumps Product OverviewDocument20 pagesPumps Product OverviewDenis Jimenez0% (1)

- E831BDocument4 pagesE831BDenis JimenezNo ratings yet

- E831BDocument4 pagesE831BDenis JimenezNo ratings yet

- 1403013194Document1 page1403013194Denis JimenezNo ratings yet

- 105388Document4 pages105388Denis JimenezNo ratings yet

- E7109 4-03-12 RFLD Guss KatalogversionDocument8 pagesE7109 4-03-12 RFLD Guss KatalogversionDenis JimenezNo ratings yet

- E7113 4 03 12 - NFD KatalogversionDocument8 pagesE7113 4 03 12 - NFD KatalogversionDenis JimenezNo ratings yet

- 1403013194Document1 page1403013194Denis JimenezNo ratings yet

- E7113 4 03 12 - NFD KatalogversionDocument8 pagesE7113 4 03 12 - NFD KatalogversionDenis JimenezNo ratings yet

- Pastillas HSH 1v 1t 5wDocument1 pagePastillas HSH 1v 1t 5wDenis JimenezNo ratings yet

- Report 5b - Junk Shop SurveyDocument30 pagesReport 5b - Junk Shop SurveyJing Suarez Nazareno67% (3)

- Cryogenic Air Separation For The Production of NitrogenDocument24 pagesCryogenic Air Separation For The Production of NitrogenJackie_Demyan_7107No ratings yet

- BRCGS Standard For Packaging Materials Issue 6: P614 - Guidance Document Disposable Food Contact Packaging/consumer ItemsDocument5 pagesBRCGS Standard For Packaging Materials Issue 6: P614 - Guidance Document Disposable Food Contact Packaging/consumer ItemsJamal ZamrudiNo ratings yet

- Pentens: Water-Base Zinc Rich EpoxyprimerDocument2 pagesPentens: Water-Base Zinc Rich Epoxyprimeramelinda jocelinNo ratings yet

- Renold Giunti Cat Gen Eng PDFDocument96 pagesRenold Giunti Cat Gen Eng PDFInformational kya kaiseNo ratings yet

- Reliably Detect 3D Printer Filament Feed Issues for Under $20Document8 pagesReliably Detect 3D Printer Filament Feed Issues for Under $20ksolomon75No ratings yet

- Cat Pdn1000-2us PVDocument4 pagesCat Pdn1000-2us PVsenamotoNo ratings yet

- Time Lag Earth Fault Relay TestDocument8 pagesTime Lag Earth Fault Relay TestAnna RiNo ratings yet

- University of Texas Report On Galvanized Slip Coefficients Draft Final 4915Document37 pagesUniversity of Texas Report On Galvanized Slip Coefficients Draft Final 4915Jay ZengNo ratings yet

- Asnzs 3000+5033Document3 pagesAsnzs 3000+5033IceMan3No ratings yet

- Indoor or Outdoor Current Transformer: Type CLCDocument4 pagesIndoor or Outdoor Current Transformer: Type CLCDarwin Canchari VillcaraniNo ratings yet

- Wet GranulationDocument18 pagesWet GranulationRafeek Shaikh100% (1)

- Lanko 173 Floor Leveller v1.2Document5 pagesLanko 173 Floor Leveller v1.2Rwin GuiseNo ratings yet

- Ce6021-Repair and Rehabilitation StructuresDocument46 pagesCe6021-Repair and Rehabilitation StructuresChandan Kumar100% (1)

- HT 305 B1 (B)Document15 pagesHT 305 B1 (B)Scribd user VNo ratings yet

- Manitou Telescopico Mrt2150 E3 Parts ManualsDocument20 pagesManitou Telescopico Mrt2150 E3 Parts Manualswilliam100% (20)

- SD 5 15 Rectangular Precast Concrete Manhole 1220 X 813 Max. Pipe 750mmDocument1 pageSD 5 15 Rectangular Precast Concrete Manhole 1220 X 813 Max. Pipe 750mmسجى وليدNo ratings yet

- BWS Residential Distribution PDF CatalogDocument142 pagesBWS Residential Distribution PDF Catalogmantenimiento sondexNo ratings yet

- Electric Heating: Understanding the BasicsDocument21 pagesElectric Heating: Understanding the BasicsGopi RamNo ratings yet

- Indice Perfil Del SelloDocument34 pagesIndice Perfil Del Sellojuanchis650No ratings yet

- PSID 096 FMI 1: Low Rail Pressure TroubleshootingDocument6 pagesPSID 096 FMI 1: Low Rail Pressure TroubleshootingMohan Preeth100% (6)

- Eng. Rashid Sher Mohd Introduces Enhanced Oil Recovery MethodsDocument19 pagesEng. Rashid Sher Mohd Introduces Enhanced Oil Recovery Methodsbu7amud83% (6)

- Panasonic - VRLA Handbook 2013Document70 pagesPanasonic - VRLA Handbook 2013hendra20No ratings yet

- Science MCQDocument6 pagesScience MCQSupreeti KoneruNo ratings yet

- Welding ConsumablesDocument20 pagesWelding ConsumablesThillaivananNo ratings yet

- 1006 1009Document4 pages1006 1009SinhrooNo ratings yet

- Ravago Petrokimya Sustainable Material Solutions OverviewDocument34 pagesRavago Petrokimya Sustainable Material Solutions Overviewsara rafieiNo ratings yet

- Engineering Failure Analysis of a Helicopter GearboxDocument16 pagesEngineering Failure Analysis of a Helicopter GearboxAPINo ratings yet

- 3.0 Cooling Load CalculationDocument29 pages3.0 Cooling Load CalculationRenneil De PabloNo ratings yet

- Chapter - 02 Centrifugal PumpDocument83 pagesChapter - 02 Centrifugal Pumpdewidar1234100% (4)