Professional Documents

Culture Documents

Heat Rejection and Temperature Limitations: Figure 1. LM2500 Maximum Allowable Casing Temperatures

Uploaded by

Denis JimenezOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Heat Rejection and Temperature Limitations: Figure 1. LM2500 Maximum Allowable Casing Temperatures

Uploaded by

Denis JimenezCopyright:

Available Formats

Heat Rejection and Temperature Limitations

The LM2500 Gas Turbine is designed to operate with inlet-air temperature from -65 to +130F and

engine-space ambient temperature from -20 to +140F. It is recommended that the engine be installed

inside an enclosure to protect it from the weather and shield operating personnel from engine heat and

noise. The enclosure must be ventilated for cooling of the gas turbine. Although the enclosure can be

negative or positive pressure, positive pressure is preferred from the gas turbine bearing sump sealing

and venting system standpoint.

Heat is released from the gas turbine by radiation and convection from hot surfaces and by hot-air

leakage from flanges and struts. Cooling must be provided to maintain casing temperature below the

maximum allowable as shown on Figure 1.

Figures 2 through 4, for use in designing the cooling system, show estimated temperatures of the gas

turbine casings and exhaust duct as functions of various values of heat flux for ambient temperature

from -20 to +120F and for various power settings. Sufficient cooling air must be provided to limit the

engine casing temperatures as shown on Figures 2 through 4. The cooling air should be uniformly

distributed to prevent warping of the engine; this applies both during operation and when the engine is

shut down. Direct impingement of forced cooling air on the engine casings is to be avoided. The

emissivity of the gas turbine casing surfaces is 0.8.

Figure 1. LM2500 Maximum Allowable Casing Temperatures

Page 1 of 6 Heat Rejection

19/11/2005 http://inside-aep.ps.ge.com/insideaep/aep/iad/engine_prod_delv/idms/lm2500/07templimi...

Figure 2. Estimated Engine Casing Temperatures for LM2500

Base Load Power, Ambient Temperature = 59qF

Figure 3. Estimated Engine Casing Temperatures for LM2500

Base Load Power, Ambient Temperature = - 20qF

Page 2 of 6 Heat Rejection

19/11/2005 http://inside-aep.ps.ge.com/insideaep/aep/iad/engine_prod_delv/idms/lm2500/07templimi...

Figure 4. Estimated Engine Casing Temperatures for LM2500

Base Load Power, Ambient Temperature = 130qF

Page 3 of 6 Heat Rejection

19/11/2005 http://inside-aep.ps.ge.com/insideaep/aep/iad/engine_prod_delv/idms/lm2500/07templimi...

If the gas turbine is installed within a building or open room, the room ventilating and cooling system

should be designed to prevent any reingestion of hot exhaust gases into the room. Hot exhaust gases

could prove detrimental to engine control devices, electrical devices and accessory components, as well

as to other peripheral equipment within the room.

Figure 5 describes casing temperature as a function of time after the engine has been shut down. This

figure applies to either (1) an emergency shutdown from full power or (2) a normal shutdown from idle

and is based on no cooling airflow during the shutdown and no radiation from the surrounding surfaces.

Figure 5. LM2500 Estimated Non-dimensional Engine Average

Surface Temperature after Shutdown from Full Power

Page 4 of 6 Heat Rejection

19/11/2005 http://inside-aep.ps.ge.com/insideaep/aep/iad/engine_prod_delv/idms/lm2500/07templimi...

Normally a secondary airflow of 15% to 30% of engine airflow is sufficient to keep the gas turbine

exterior surfaces cool. The exact quantity is a function of the air velocity over the engine and the

radiation characteristics of the Purchasers enclosure walls, and must be determined by heat transfer

analysis. Cooling flow initial estimates of 32 lbs/s (14.5 Kg/s) for regions with ambient temperatures

below 85F (30C), and a flow of 35 lbs/s (16 Kg/s) for regions with ambient temperatures above below

85F (30C) are recommended starting points. Air velocity of the cooling air should be at least 9.8 ft/s (3

m/s), average. The cooling air must meet as a minimum the same contaminant limits as the inlet air to

the gas generator.

Page 5 of 6 Heat Rejection

19/11/2005 http://inside-aep.ps.ge.com/insideaep/aep/iad/engine_prod_delv/idms/lm2500/07templimi...

Scale model flow tests of the proposed engine cooling system should be considered as a part of the

overall installation design. It is essential that local cooling flow velocities and flow directions through

the engine compartment be considered to ensure a satisfactory installation. Such testing could be

combined with any inlet/exhaust system model testing being done.

In addition to the casing temperature limits, there are limitations on the maximum temperatures of the

electrical and instrumentation devices mounted on the Gas Turbine. Cooling air adjacent to the engine

must be provided to maintain the engine electrical and instrumentation devices within the limits

described below. The controls and accessories are only minor sources of heat. Components containing

fuel and/or oil are cooled by the media they handle while the engine is operating and, therefore, only

heat soak-back after shutdown must be considered for these items. During engine cooldown, the flow of

air through the engine must not be restricted.

During commissioning the Purchaser should arrange to record actual skin temperatures of the

components listed in this Table.

Maximum Allowable Temperatures of Engine Mounted Components.

Component Maximum Temperature, F (C)

Gas Generator Speed Pickup (2) 225 (107)

Lube Supply RTDs 220 (104)

Variable Stator Vane Actuators 350 (177)

Gas Generator Accelerometer Connector 400 (204)

T48 Sensors (At Lug) 600 (316)

T48 Interface Connector 400 (204)

T3 Sensor at Connector 400 (204)

Lube and Scavenge Pump 300 (149)

Chip Detectors 350 (177)

Starter (Optional) 250 (121)

UV Flame Detectors (Optional) 200 (93)

Power Turbine Speed Sensor Connector 400 (204)

Vibration Sensor Connector 400 (204)

Page 6 of 6 Heat Rejection

19/11/2005 http://inside-aep.ps.ge.com/insideaep/aep/iad/engine_prod_delv/idms/lm2500/07templimi...

You might also like

- List of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesDocument4 pagesList of Illustrations: Lm6000 PD Gek 105061 Ge Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZNo ratings yet

- E79000-2-04-13 FS Buch WWWDocument291 pagesE79000-2-04-13 FS Buch WWWDenis JimenezNo ratings yet

- 825 Series Product Overview & General DataDocument30 pages825 Series Product Overview & General Datamauricio cañonNo ratings yet

- 1989 Aker Predicting Gas Turbine Performance Degradation Due To Compressor Fouling Using Computer Simulation TechniquesDocument8 pages1989 Aker Predicting Gas Turbine Performance Degradation Due To Compressor Fouling Using Computer Simulation TechniquesArgenomSaubiNo ratings yet

- lm2500 LubesupplyDocument3 pageslm2500 LubesupplyDenis Jimenez100% (2)

- Thermal Peaking PDFDocument26 pagesThermal Peaking PDFkhozaqiNo ratings yet

- Gek105054 File0007Document18 pagesGek105054 File0007outilprok22kNo ratings yet

- Dynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDocument3 pagesDynamics Characteristics: Figure 1. LM2500-PE Estimated Load Rejection Transient PerformanceDenis JimenezNo ratings yet

- SB LM6000 Ind 0310Document11 pagesSB LM6000 Ind 0310Daniil Serov100% (1)

- APA DOC No. 2014 PDFDocument67 pagesAPA DOC No. 2014 PDFThanapaet RittirutNo ratings yet

- GE Power Systems Explains Two-Shaft Gas Turbine ControlDocument24 pagesGE Power Systems Explains Two-Shaft Gas Turbine Controlalaal100% (1)

- CT Inspection IntervalsDocument19 pagesCT Inspection IntervalsSantiago67% (3)

- Ge LM6000 Training 1Document74 pagesGe LM6000 Training 1sasa hh100% (1)

- Caterpillar Gas Engine Data Update for GERPDocument2 pagesCaterpillar Gas Engine Data Update for GERPvictor.ciprianiNo ratings yet

- Ger 3658d Speedtronic Mark V Gas Turbine Control System PDFDocument19 pagesGer 3658d Speedtronic Mark V Gas Turbine Control System PDFyos100% (1)

- Ge Industrial Aeroderivative Gas TurbinesDocument2 pagesGe Industrial Aeroderivative Gas TurbinesJHONNATTAN RODRIGUEZ0% (1)

- GE Gas Turbines Were Basically Divided Into 3 DifferentDocument3 pagesGE Gas Turbines Were Basically Divided Into 3 Differentsaikrish36No ratings yet

- IPL Saturn 20Document56 pagesIPL Saturn 20Ranjan Shankar100% (3)

- CPM - Ap - Lm6000-Ind-024 (1) 2009Document64 pagesCPM - Ap - Lm6000-Ind-024 (1) 2009Victor Nahun ReyesNo ratings yet

- GearboxDocument16 pagesGearboxMehul zareNo ratings yet

- Ge Mid Idm 6000 1.Lm6000 PerformanceDocument10 pagesGe Mid Idm 6000 1.Lm6000 PerformanceChristopher HamptonNo ratings yet

- Gas Turbine Control & Protection: Presentation ONDocument46 pagesGas Turbine Control & Protection: Presentation ONrahulNrana100% (2)

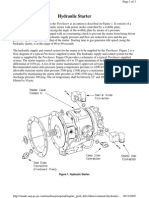

- Figure 1. Hydraulic StarterDocument3 pagesFigure 1. Hydraulic StarterDenis JimenezNo ratings yet

- Fuel System: PerformanceDocument3 pagesFuel System: PerformanceDenis JimenezNo ratings yet

- Eco 100 Wind Turbine PlatformDocument4 pagesEco 100 Wind Turbine PlatformSofiane HalimiNo ratings yet

- 2.4 MBM Combustor Dilution Air SystemDocument6 pages2.4 MBM Combustor Dilution Air SystemmiladNo ratings yet

- Siemens Gas Turbine Product Range Comparison Chart 0-130 MWDocument2 pagesSiemens Gas Turbine Product Range Comparison Chart 0-130 MWdvcher78No ratings yet

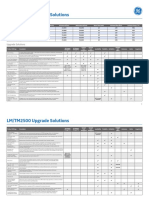

- LM TM2500 Upgrade Solutions PDFDocument2 pagesLM TM2500 Upgrade Solutions PDFLibyanManNo ratings yet

- PACSystems RX3i Max-On Hot Standby Redundancy Manual, GFK-2409Document144 pagesPACSystems RX3i Max-On Hot Standby Redundancy Manual, GFK-2409Eduardo Diaz100% (1)

- Peppers Catalogue PDFDocument64 pagesPeppers Catalogue PDFStone123456789No ratings yet

- SBLM2500 IND 174rev1Document7 pagesSBLM2500 IND 174rev1Daniil SerovNo ratings yet

- Gas Turbine ControlDocument9 pagesGas Turbine ControlHBNBILNo ratings yet

- GE Power Systems Gas Turbine Speed Control Constant Settable DroopDocument9 pagesGE Power Systems Gas Turbine Speed Control Constant Settable DroopZaki nouiNo ratings yet

- Gas Turbines Drive Pipelines CompressorsDocument20 pagesGas Turbines Drive Pipelines CompressorsRoozbeh PNo ratings yet

- NIC 13.20 Rev.01Document15 pagesNIC 13.20 Rev.01Mahmoud Ahmed100% (1)

- LM2500 16th Stage Bleed Manifold KitDocument2 pagesLM2500 16th Stage Bleed Manifold KitDenis JimenezNo ratings yet

- Gas Transport-Mallnow-Natural-Gas-Compressor-Station PDFDocument8 pagesGas Transport-Mallnow-Natural-Gas-Compressor-Station PDFJaswindersingh BhatiaNo ratings yet

- GE LM2500, LM5000, LM6000 and LMS100 Gas Turbine Engines GuideDocument35 pagesGE LM2500, LM5000, LM6000 and LMS100 Gas Turbine Engines GuidesppramNo ratings yet

- Macchi Reference ListDocument41 pagesMacchi Reference Listachraf ahassanNo ratings yet

- Constant Settable Droop Design Standard of GEDocument4 pagesConstant Settable Droop Design Standard of GEPraveen PeethambaranNo ratings yet

- GE Frame 7EA Loss of Trip Oil PressureDocument6 pagesGE Frame 7EA Loss of Trip Oil Pressurenabil160874No ratings yet

- HI 800 251 Supplementary Sheet ELOP II Factory PDFDocument4 pagesHI 800 251 Supplementary Sheet ELOP II Factory PDFBouazzaNo ratings yet

- EPS GT Base PrinciplesDocument32 pagesEPS GT Base PrinciplescdbeardsallNo ratings yet

- Fs rb211Document2 pagesFs rb211tutu20120% (1)

- Basic Tech SGT400 S4 Low ResDocument2 pagesBasic Tech SGT400 S4 Low ResWilfredo Rojo CastañoNo ratings yet

- Gas Turbine MaintenanceDocument3 pagesGas Turbine MaintenanceMohamed NawarNo ratings yet

- Gek97310 File0001Document2 pagesGek97310 File0001Mendez Francisco33% (3)

- F646 CompleteSampleDocument36 pagesF646 CompleteSampleraj4523No ratings yet

- Gas Turbine NotesDocument21 pagesGas Turbine NotesJohn BlackburnNo ratings yet

- Simjet Miniature Turbojet Engine: Owner'S ManualDocument20 pagesSimjet Miniature Turbojet Engine: Owner'S Manualamir hosseinNo ratings yet

- Advanced Compressor Less Purge ControlsDocument32 pagesAdvanced Compressor Less Purge ControlsMaha BlueNo ratings yet

- Basic GT EngineDocument22 pagesBasic GT EngineabuhurairamunirNo ratings yet

- GE LM6000 1275-GryDocument1 pageGE LM6000 1275-GryuzairmughalNo ratings yet

- GE Oil & Gas Nuovo Pignone: Title: Part List: Drawing: Gas Turbine Ms5002DDocument1 pageGE Oil & Gas Nuovo Pignone: Title: Part List: Drawing: Gas Turbine Ms5002DMohammed ElarbedNo ratings yet

- Gas Turbine Engines Characteristics and Performance Combustion ChamberDocument2 pagesGas Turbine Engines Characteristics and Performance Combustion ChamberNicolas Guatibonza LNo ratings yet

- Operating and maintenance norms for hydraulic cylindersDocument4 pagesOperating and maintenance norms for hydraulic cylinderszsmithNo ratings yet

- Dynamics in One Complex Variable. (AM-160): (AM-160) - Third EditionFrom EverandDynamics in One Complex Variable. (AM-160): (AM-160) - Third EditionNo ratings yet

- Gas Engine Technical Data: Load 100% 75% 50% Rating and EfficiencyDocument3 pagesGas Engine Technical Data: Load 100% 75% 50% Rating and Efficiencyvictor.ciprianiNo ratings yet

- 2-2 Te-2 GTDocument10 pages2-2 Te-2 GTVamsi KrishnaNo ratings yet

- Gas TurbineDocument9 pagesGas TurbineTian TianNo ratings yet

- 300 kW Power Station Components OfferDocument5 pages300 kW Power Station Components OfferLong Leo100% (1)

- Dse4610 Dse4620 Data SheetDocument2 pagesDse4610 Dse4620 Data SheetDenis Jimenez0% (1)

- Ac-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDocument12 pagesAc-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDenis JimenezNo ratings yet

- 460-119 Hoja de Especificaciones.Document2 pages460-119 Hoja de Especificaciones.Denis JimenezNo ratings yet

- 3612tale Jgd6 DesignDocument1 page3612tale Jgd6 DesignDenis JimenezNo ratings yet

- E5601 13 04 07 - PT Neu2Document5 pagesE5601 13 04 07 - PT Neu2Denis JimenezNo ratings yet

- Filter Bound CatalogDocument248 pagesFilter Bound CatalogDenis JimenezNo ratings yet

- E7700 10 10 13 - Prozesstechnik - WebDocument24 pagesE7700 10 10 13 - Prozesstechnik - WebDenis JimenezNo ratings yet

- Hydac SCADocument6 pagesHydac SCADenis JimenezNo ratings yet

- Inline Process FiltersDocument7 pagesInline Process FiltersDenis JimenezNo ratings yet

- Filter Bound CatalogDocument248 pagesFilter Bound CatalogDenis JimenezNo ratings yet

- E5601 PTKDocument4 pagesE5601 PTKDenis JimenezNo ratings yet

- E7710 1 06 11 - Leitungsfilter ProzessDocument8 pagesE7710 1 06 11 - Leitungsfilter Prozessvikram_007No ratings yet

- 1303-1512 SSPF Final InoxidableDocument16 pages1303-1512 SSPF Final InoxidableDenis JimenezNo ratings yet

- Fluid Level Gauge Fluid Level Sensor Temperature Switch Fsa / FSK / TsDocument12 pagesFluid Level Gauge Fluid Level Sensor Temperature Switch Fsa / FSK / TsDenis JimenezNo ratings yet

- E2000 0 03 11 - SYSTEMTECHNIK - WWWDocument8 pagesE2000 0 03 11 - SYSTEMTECHNIK - WWWDenis JimenezNo ratings yet

- Bell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDocument20 pagesBell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDenis JimenezNo ratings yet

- Ac-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDocument12 pagesAc-Ln / Aca-Ln / Acaf-Ln 8-14: Air Cooler IndustryDenis JimenezNo ratings yet

- 105388Document4 pages105388Denis JimenezNo ratings yet

- E831BDocument4 pagesE831BDenis JimenezNo ratings yet

- E18061 2 0 11 13 - HNS3000Document2 pagesE18061 2 0 11 13 - HNS3000Denis JimenezNo ratings yet

- Bell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDocument20 pagesBell Housings With Rigid / Flexible Pump Mounting Pts / PT: 1. Description 2. Technical SpecificationsDenis JimenezNo ratings yet

- Pumps Product OverviewDocument20 pagesPumps Product OverviewDenis Jimenez0% (1)

- 1403013194Document1 page1403013194Denis JimenezNo ratings yet

- E831BDocument4 pagesE831BDenis JimenezNo ratings yet

- 1403013194Document1 page1403013194Denis JimenezNo ratings yet

- E7109 4-03-12 RFLD Guss KatalogversionDocument8 pagesE7109 4-03-12 RFLD Guss KatalogversionDenis JimenezNo ratings yet

- E7113 4 03 12 - NFD KatalogversionDocument8 pagesE7113 4 03 12 - NFD KatalogversionDenis JimenezNo ratings yet

- E7113 4 03 12 - NFD KatalogversionDocument8 pagesE7113 4 03 12 - NFD KatalogversionDenis JimenezNo ratings yet

- Pastillas HSH 1v 1t 5wDocument1 pagePastillas HSH 1v 1t 5wDenis JimenezNo ratings yet