Professional Documents

Culture Documents

Frictional Characteristics Roadside Grass Types

Uploaded by

lirba0 ratings0% found this document useful (0 votes)

119 views11 pagesSpeed calculation - break in grass

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentSpeed calculation - break in grass

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

119 views11 pagesFrictional Characteristics Roadside Grass Types

Uploaded by

lirbaSpeed calculation - break in grass

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 11

Frictional Characteristics of Roadside Grass Types

Cenek, P.D., Jamieson, N.J. and McLarin, M.W.

Frictional Characteristics of Roadside Grass Types

Peter D. Cenek,

Neil J. Jamieson and

Maurice W. McLarin

Opus International Consultants, Central Laboratories, Gracefield, New Zealand

ABSTRACT

The level of friction provided by a grass verge is important in situations where a vehicle is

involved in a multiple surface skid, involving the roadway and the grass verge. Ideally, in

such situations the difference in friction between the two surfaces should be kept to a

minimum to avoid the likelihood of the vehicle yawing in the event of one or two wheels

skidding on the grass verge. Differential friction can either exacerbate the effects of an

emergency manoeuvre (e.g. a locked-wheel skid for example) or precipitate an emergency

during an otherwise normal manoeuvre (e.g. unexpected locking of a wheel).

Given the lack of knowledge regarding dry and wet friction levels of grass types found on

New Zealand roadside verges, a limited study involving both tyre dragging tests and locked-

wheel braking tests was undertaken to:

(1) identify if there is a significant difference in the level of dry and wet friction provided

by white clover compared to other common grasses; and

(2) establish if a potential safety issue could arise from differences in friction level

between the grass verge and the roadway.

The principal findings were as follows:

A limited comparison of friction values obtained by the tyre dragging test and the

locked-wheel braking test identified that the tyre dragging test, which utilises a lightly

loaded part tyre, produces much higher values and is more sensitive to wetness.

Therefore more comprehensive comparative testing is required to establish whether

or not it is appropriate to use the tyre dragging test to rank different grass surfaces

and other soft surfaces in terms of friction wherever locked-wheel braking tests cant

be safely performed.

The locked-wheel braking tests showed that, in dry conditions, a white clover surface

provides braking friction that is about 60% that of rye-grass. For a braking initiation

speed of 40 km/h, this equates to a difference in stopping distance of around 13 m.

Under wet conditions, the difference in braking friction is not as pronounced but still

gives a significant stopping distance difference of about 9 m. On the basis of this

result, the use of white clover on verges is not recommended.

Key Words: crash reconstruction, grass surfaces, locked-wheel braking tests.

1

Frictional Characteristics of Roadside Grass Types

Cenek, P.D., Jamieson, N.J. and McLarin, M.W.

1. INTRODUCTION

Representative coefficient of friction values for car tyres on various surfaces can be readily

found in reference texts associated with vehicle handling dynamics and accident

reconstruction. Table 1, sourced from Noon (1994) is an example of what is typically

available.

Table 1: Coefficients of Friction of Various Roadway Surfaces (Noon, 1994)

Surface Type Coefficient of Friction ()

Gravel and dirt road 0.35

Wet, grassy field 0.20

Dry asphaltic concrete 0.65

Wet asphaltic concrete 0.50

Dry concrete 0.75

Wet concrete 0.60

Snow 0.20-0.25

Ice 0.10-0.15

Loose moist dirt that allows tyre to

sink about 5 cm

0.60-0.65

The coefficients tabulated in Table 1 are average values over a slide to stop i.e. locked-

wheel braking manoeuvre. Although these coefficients were derived for American roadways,

they appear to be suitable for local conditions as values given for gravel and asphaltic

concrete are in agreement with locked-wheel braking tests performed in New Zealand by

Opus Central Laboratories and reported respectively in Cenek et al (1999) and Cenek et al

(2000). However, the applicability of the coefficient of friction for wet grassy fields to

different grass types found on road verges has been questioned by Transit New Zealand,

New Zealands national road agency.

The level of friction provided by a grass verge is important in situations where a vehicle is

involved in a multiple surface skid, involving the roadway and the grass verge. Ideally, in

such situations the difference in friction between the two surfaces should be kept to a

minimum to avoid the likelihood of the vehicle yawing in the event of one or two wheels

skidding on the grass verge. Differential friction can either exacerbate the effects of an

emergency manoeuvre (e.g. a locked-wheel skid for example) or precipitate an emergency

during an otherwise normal manoeuvre (e.g. unexpected locking of a wheel).

Given the lack of knowledge regarding dry and wet friction levels of grass types found on

New Zealand roadside verges, a limited study involving both tyre dragging tests and locked-

wheel braking tests was undertaken to:

(1) identify if there is a significant difference in the level of dry and wet friction provided

by white clover compared to other common grasses; and

(2) establish if a potential safety issue could arise from differences in friction level

between the grass verge and the roadway.

This paper summarises the numerical and physical investigations that were performed along

with the principal findings.

2

Frictional Characteristics of Roadside Grass Types

Cenek, P.D., Jamieson, N.J. and McLarin, M.W.

2. MEASUREMENT PROGRAMME

2.1 SELECTION OF TEST SITES

Two, approximately 80m long, adjacent strips of medium length white clover and rye-grass

were located at AgResearchs Aorangi Farm near Palmerston North. Another strip of mown

rye-grass was also located nearby. These strips had sufficient length and were smooth and

flat enough to enable locked-wheel braking tests to be safely performed on them.

Small areas of Browntop and Agridark, suitable only for tyre dragging tests were located at

AgResearchs nearby Grasslands complex.

The sites are summarised in Table 1 along with the type of test utilised to obtain coefficient

of friction values.

Table 2: Test Site Details

Test Type

Site No Location Surface Type

Tyre

Dragging

Locked-wheel

Braking

1

2

3

4

5

Aorangi Farm

Aorangi Farm

Aorangi Farm

Grasslands

Grasslands

Clover

Rye-grass (long)

Rye-grass (short)

Browntop

Agridark

Yes

Yes

No

Yes

Yes

Yes

Yes

Yes

No

No

Photographs of sites 1 to 4 are provided in the appendix. No photographs of site 5 are

available because of a camera malfunction.

2.2 EQUIPMENT

2.2.1 Tyre Drag Sled

A New Zealand manufactured tyre with a tread depth of about 1.5 to 2mm was cut and filled

with concrete and lead weights, then fitted with towing eyes to enable it to be dragged with a

calibrated spring balance attached. The total weight of the filled part-tyre was 15.05 kg.

Figure 1 shows a photo of the tyre drag sled being used to obtain friction coefficient

measurements.

Figure 1: Tyre dragging test in progress

3

Frictional Characteristics of Roadside Grass Types

Cenek, P.D., Jamieson, N.J. and McLarin, M.W.

2.2.2 Instrumented Test Vehicle

A non-ABS (Antilock-Braking-System) late model Hyundai Sonata, shown in Figure 2, was

used to perform test skids. It was instrumented with a calibrated Vericom

TM

VC2000 supplied

by the New Zealand Police. This single accelerometer based device, shown in Figure 3,

continuously records the deceleration time history during braking, which can be downloaded

to a computer for viewing. It is mounted on the test vehicles windscreen and can be

activated externally from the brake lights or internally by the braking force of the test vehicle.

Figure 2: Vehicle used for test skids

The Vericom

TM

VC2000 automatically processes the deceleration time history to provide the

following user selectable outputs:

Vehicle speed when braking is initiated

Time taken from when braking is initiated to when the vehicle comes to a stop

Distance travelled during the braking manoeuvre

Average and peak coefficient of friction during the braking manoeuvre

Figure 3: Vericom

TM

VC2000 unit mounted in test vehicle

4

Frictional Characteristics of Roadside Grass Types

Cenek, P.D., Jamieson, N.J. and McLarin, M.W.

2.3 DETERMINATION OF COEFFICIENT OF FRICTION

2.3.1 Tyre Dragging Tests

The concrete filled part-tyre was dragged at a steady speed along the grass surface, and the

average drag force reading from the spring balance was recorded. Care was taken to ensure

that the angle of pull was parallel to the grass surface. The coefficient of friction was simply

calculated by dividing the measured horizontal drag force by the weight of the part tyre (i.e.

15.05 kg)

The tyre dragging tests were carried out with the surface both dry and wet. Measurements

were repeated a number of times at different locations on the same grass type to obtain a

representative value of coefficient of friction. Four grass types were tested as listed in Table

2.

2.3.2 Locked-Wheel Braking Tests

Locked-wheel braking tests were conducted on three surfaces, these being white clover, and

long and short rye-grass. For all the tests, braking was restricted to an initiation speed of

between 35km/h and 45km/h for safety reasons. To assess the variability in the measured

average and peak coefficient of friction values, the locked-wheel braking tests were repeated

several times.

As the test sites each had very slight gradients, the braking tests were carried out in both

upgrade and downgrade directions. The braking tests were first performed with the surfaces

dry. Water was then applied from a water truck and the brake tests repeated on the wetted

surface.

A member of the New Zealand Police Road Patrol Group, who had received special training

and was experienced in conducting locked-wheel emergency braking tests, drove the test

vehicle.

At the completion of each braking test the standard VC2000 outputs of (1) time to stop, (2)

braking distance, (3) vehicle speed when braking initiated, (4) peak tyre-road friction value

and (5) average tyre-road friction during the braking manoeuvre were displayed and

manually recorded. The stored deceleration-time history was also downloaded for use in

resolving any anomalies between repeated tests.

3. COEFFICIENT OF FRICTION FOR ROADSIDE GRASSES

3.1 TYRE DRAGGING TESTS

The site-averaged coefficient of friction values as determined by the tyre dragging tests are

summarised in Table 3. These coefficient of friction values pertain to a steady-state condition

of a very lightly loaded tyre slipping at a very slow speed ( 3 km/h) and so are expected to

be higher than for a car sliding on a grass surface on a firm base. Therefore, the coefficient

of friction values tabulated in Table 3 should only be used for ranking purposes.

With reference to Table 3, both clover and rye-grass show a significant reduction in the

available friction when the grass becomes wet. By comparison, Browntop shows much less

difference in friction between dry and wet conditions. Overall, the best performing grass type

was the Agridark, which gave marginally the highest value for both dry and wet conditions.

5

Frictional Characteristics of Roadside Grass Types

Cenek, P.D., Jamieson, N.J. and McLarin, M.W.

Table 3: Tyre Dragging Tests Coefficients of Friction

Coefficient of Friction

Site No Grass Surface

Dry Wet

1

2

4

5

White Clover

Rye-grass (long)

Browntop

Agridark

0.68

0.77

0.77

0.80

0.59

0.59

0.71

0.74

3.2 LOCKED-WHEEL BRAKING TESTS

Coefficients of friction were determined from the Vericom

TM

VC2000 data for each upgrade

and downgrade test run. These were combined to provide average values for the white

clover and rye-grass test sites for dry and wet conditions. The resulting values are tabulated

in Table 4 below.

Table 4: Locked-Wheel Braking Tests Coefficients of Braking Friction

Coefficient of

Braking Friction

Stopping Distance (m)

from 40 km/h

Site No Grass Surface

Dry Wet Dry Wet

1

2

4

White Clover

Rye-grass (long)

Rye-grass (short)

0.21

0.36

0.38

0.17

0.21

0.24

30

17

17

37

30

26

These locked-wheel braking tests show that, in dry conditions, a white clover surface

provides braking friction that is about 60% that of rye-grass. For a braking initiation speed of

40km/h, this equates to a difference in stopping distance of around 13 m. Under wet

conditions the difference in braking friction is not as pronounced, but is still significant in

terms of stopping distance, with the difference being about 9 m.

The length of the grass did appear to have some affect on wet braking performance, the

stopping distance being 4 m less on the shorter length grass.

Further investigation into the relationship between grass length and dry and wet braking

performance appears warranted on the basis of the rye-grass results, with differences of

between 5% and 13% in coefficient of friction being observed. The investigation should

consider whether this sensitivity to length applies to other grass types and if there is a critical

length below which there is no improvement in the level of friction provided.

With reference to wet coefficient of braking friction values tabulated in Table 4, the range of

0.17 to 0.24 spans the value of 0.20 given in Table 1 for a wet, grassy field. This result gives

a degree of confidence in the lockedwheel braking tests performed.

3.3 COMPARISON OF LOW SLIP SPEED COEFFICIENT OF FRICTION VALUES

As friction was continuously recorded during the locked-wheel braking tests, it was possible

to compare the friction values when the vehicle was sliding at close to walking pace (1-3

km/h) with those obtained from the tyre dragging tests. Such a comparison permits the

sensitivity of tyre friction on grass surfaces to load to be investigated. It also provides

confidence that rankings of grass surfaces with respect to friction derived from the tyre

dragging tests will equally apply to the situation of interest, which is a skidding car.

6

Frictional Characteristics of Roadside Grass Types

Cenek, P.D., Jamieson, N.J. and McLarin, M.W.

This comparison was able to be performed for two grass surfaces only: white clover and long

length rye-grass. The associated results are tabulated in Table 5.

Table 5: Comparison of Low Slip Speed Coefficient of Friction

Coefficient of Friction (Slow Slip Speed)

Dry Wet Site

No

Grass Surface

Tyre Dragging

Test

Locked-Wheel

Braking

Tyre Dragging

Test

Locked-Wheel

Braking

1

2

White Clover

Long Rye-grass

0.68

0.77

0.36

0.42

0.59

0.59

0.33

0.38

With reference to Table 5, coefficients of friction obtained for a sliding test tyre are much

higher than for a car sliding on the grass when the sliding speeds are comparable. This

finding has also been independently reported by Fricke (1990), though it cannot be easily

explained. Fricke conjectures that there is some interaction of the tyre and grass at a light

load that does not occur with typical wheel loads. It will also be noted that the tyre dragging

test appears to be more sensitive to wetness, with differences between dry and wet

coefficients of friction being almost 3 to 4 times greater.

Nevertheless, both test results are in agreement that long rye-grass provides improved

friction characteristics over white clover for both dry and wet conditions.

3.4 UNDERLYING SOIL HARDNESS

No penetrometer tests were made to quantify the penetration resistance of the underlying

soil. This possibly could be an issue for the locked-wheel braking tests because of the

wheel loads carried, which are of the order of 400 kg for the test vehicles front wheels and

200 kg for the rear wheels. However, as the three, locked-wheel braking, test sites were all

in close proximity to each other and the ground was very hard due to a dry spell, it is unlikely

that the coefficient of braking values tabulated in Table 4 will have been influenced by

differing penetration resistance. Furthermore, because the ground was hard, these values

are likely to be at the lower range of what can be expected as, with reference to Table 1,

friction tends to increase on soft surfaces as a result of material build-up in front of the

sliding tyres.

By analogy, it is expected that the tyre dragging test results are comparatively insensitive to

soil penetration resistance because the sliding tyre has insufficient weight to cause such

build-up.

4. EFFECT OF DIFFERENTIAL FRICTION

4.1 DESCRIPTION OF MODELLING APPROACH

A numerical six degree-of-freedom vehicle handling model of a typical passenger car has

been developed by Opus Central Laboratories using Matlab (Simulink) software and

incorporates a standard tyre model implementation of the Pacejka magic tyre formula. The

model has been found to be capable of realistic handling predictions for characteristic small

roll, pitch and yaw angle changes in flat road cornering and braking manoeuvres. It was,

therefore, used for evaluating differential skidding situations resulting from a vehicle

traversing multiple surfaces

Simulation of the destabilising effect of skidding with left hand wheels on a grass shoulder

7

Frictional Characteristics of Roadside Grass Types

Cenek, P.D., Jamieson, N.J. and McLarin, M.W.

and right hand wheels on sealed road was accomplished by adjusting the tyre-surface

interface friction properties accordingly. The handling model then predicts the very high

clockwise yaw rates that result when grip is re-established after brake release. This is the

classic response following wheel lockup on surfaces that exhibit significant differences in

wheel path friction (Hayhoe and Henry, 1981).

Two situations were investigated as follows:

1. left wheels on dry white clover ( =0.21), right wheels on dry chipseal ( =0.70).

2. left wheels on dry rye-grass ( =0.37), right wheels on dry chipseal ( =0.70).

Situation 1 represents the maximum differential friction condition likely to be encountered by

a vehicle as, under wet conditions, the friction of a chipseal road surface reduces more than

white clover so the differential is reduced (i.e. =0.50 (wet chipseal) cf =0.17 (wet white

clover)). Situation 2 is representative of most common grasses and gravel.

For both situations the following emergency manoeuvre was simulated. A small front-wheel

drive vehicle travels at 80 km/h with the left wheels on the grass shoulder and the right

wheels on the chipseal surface when the brakes are fully applied for 0.5 s (resulting in wheel

lock-up) and then released.

4.2 RESULTS

Figure 4 shows the numerically generated time histories of wheel lock-up, vehicle rotation,

and vertical tyre forces for white clover (left hand-side plots) and rye-grass (right hand-side

plots).

With reference to Figure 4, maximum clockwise yaw rates occur shortly after the wheels

unlock. The values are 34 deg/s (at 1.28 s) on white clover and 22 deg/s (at 1.18 s) on rye-

grass.

The coefficient of dry rye-grass is comparable to gravel. Therefore, although a yaw rate of

22 deg/s results in a potentially hazardous situation, it is no different to what motorists are

normally exposed to when travelling on roads with shoulders that have not been sealed.

However, adoption of white clover for roadside verges will make an already hazardous

situation significantly more hazardous.

5. CONCLUSIONS AND RECOMMENDATIONS

Within the scope of the numerical and experimental study undertaken, the following

conclusions and recommendations have been drawn.

1. Dry and wet friction of different roadside grasses determined by tyre dragging tests

and locked-wheel braking tests identified that white clover was the worst performing

species by a significant margin, particularly under dry conditions. Of the other grass

species tested, rye-grass, Browntop, and Agridark, all appear to provide a similar

level of friction to that of gravel in the dry and so are preferable to clover.

2. The grass length appears to have an effect on braking performance, the shorter the

length the shorter the stopping distance. This effect is more pronounced for wet

conditions. Therefore, it is recommended that a more detailed investigation should be

performed to establish whether or not this sensitivity to length applies to grass types

other than rye-grass and to determine if there is a critical length.

8

Frictional Characteristics of Roadside Grass Types

Cenek, P.D., Jamieson, N.J. and McLarin, M.W.

Figure 4: Comparative vehicle responses with left wheels on clover and rye-grass

9

Frictional Characteristics of Roadside Grass Types

Cenek, P.D., Jamieson, N.J. and McLarin, M.W.

3. A limited comparison of friction values obtained by the tyre dragging test and the

locked-wheel braking test identified that the tyre dragging test produces much higher

values and is more sensitive to wetness. Therefore more comprehensive

comparative testing is required to establish whether or not it is appropriate to use the

tyre dragging test to rank different grass surfaces and other soft surfaces in terms of

friction because of the much lighter loading of the test tyre.

4. On the basis of tyre dragging tests, it appears that the friction provided by Browntop

and Agridark grasses may be less sensitive to wetness than rye-grass. However,

given concerns regarding the applicability of tyre dragging tests to grass surfaces, it

appears worthwhile to conduct locked-wheel braking tests on Browntop and Agridark

to quantify their dry and wet frictional characteristics under actual vehicle tyre loads

and slip speeds. Benefits would be considerable if these grasses improved on the

40% difference between dry and wet coefficient of braking friction achieved with rye-

grass.

5. The manoeuvre of brakes being applied from 80 km/h for 0.5 s and then released

was chosen to assess the hazard associated with driving a car on a differential-

frictioned surface that results from having two wheels on the verge and two wheels

on the roadway. A simulation study established that a yaw rate of about 34 deg/s

would occur if the verge comprises white clover. This yaw rate reduces by 35% to 22

deg/s if the verge is covered either with gravel or a common grass such as rye-grass.

Therefore, the possible use of white clover for verge cover represents a significant

worsening of an existing, accepted, hazard.

6. REFERENCES

Cenek, P.D., Visser, H.J ., Stewart, P.F., and Brown, D.N. (1999): Criteria for Safe Braking

Distances for T-Intersections on Unsealed Roads, Opus Central Laboratories Report No. 5-

29274.00, Lower Hutt.

Cenek, P.D., J amieson, N.J ., McLarin, M.W., and Brown, E.C. (2000): Use of the

International Friction Index (IFI) to Predict Actual Vehicle Braking Performance, presented

at The New Zealand Land Transport Symposium 2000 Engineering for Road safety,

Rotorua, 9-11 October 2000. Paper can be down loaded from www.transit.govt.nz.

Fricke, L.B. (1990): Traffic Accident Reconstruction, Volume 2 of the Traffic Accident

Investigation Manual, Northwestern University Traffic Institute.

Hayhoe, G.F. and Henry, J .J . (1981), Effects of Differential Pavement Friction on the

Response of Cars in Skidding Manoeuvres, Transportation Research Record 836, pp 61-67.

Noon, R.K. (1994): Engineering Analysis of Vehicular Accidents, CRC Press, Boca Raton.

7. ACKNOWLEDGEMENTS

The paper has been prepared with the permission of Transit New Zealand, who

commissioned the experimental programme reported. The views expressed in the paper are

those of the authors and are not necessarily those of Transit New Zealand. The assistance

of Steve Lees, Farm Manager, AgResearch Aorangi Farm and Mike Hickey, Turf Section,

Grasslands in selecting and preparing the test sites is gratefully acknowledged.

10

Frictional Characteristics of Roadside Grass Types

Cenek, P.D., Jamieson, N.J. and McLarin, M.W.

APPENDIX

Site 1: White Clover

Site 2: Long Rye-Grass

Site 3: Short Rye-Grass

Site 4: Browntop

11

You might also like

- Hector BerliozDocument5 pagesHector BerliozTristan KingsleyNo ratings yet

- Evaluating Skid Resistance of Different Asphalt Concrete MixesDocument5 pagesEvaluating Skid Resistance of Different Asphalt Concrete MixesMatej GrbacNo ratings yet

- Effects of Tire Inflation Pressure and Cti On Road Life and Vehicle Stability WoodrooffeDocument19 pagesEffects of Tire Inflation Pressure and Cti On Road Life and Vehicle Stability Woodrooffeminh tranNo ratings yet

- Skid Resistance Evaluation MethodsDocument4 pagesSkid Resistance Evaluation MethodsElliot VanceNo ratings yet

- Type of Road TestingDocument5 pagesType of Road TestingZulhairie ZubaidiNo ratings yet

- Arampamoorthy Comparison of The WehnerSchulze and PSC V TestDocument11 pagesArampamoorthy Comparison of The WehnerSchulze and PSC V TestGoran MišanovićNo ratings yet

- NADSSAE Paper2006010559 PDFDocument8 pagesNADSSAE Paper2006010559 PDFDavid DominguezNo ratings yet

- Project Wearing Surface TechnoloigyDocument20 pagesProject Wearing Surface TechnoloigySajeer SayedaliNo ratings yet

- Measurement of Radial Truck Tire Dry Cornering CharacteristicsDocument10 pagesMeasurement of Radial Truck Tire Dry Cornering CharacteristicsEfe TurkyılmazNo ratings yet

- Tire-Rim Interactions for Ultra Class Mining TrucksDocument8 pagesTire-Rim Interactions for Ultra Class Mining TrucksJuan BarrazaNo ratings yet

- Avi 8 Page ReportDocument7 pagesAvi 8 Page ReportAvinash PandithNo ratings yet

- Skid Resistance, Measurement, Characteristics, Improvements and Ontario GuidelinesDocument39 pagesSkid Resistance, Measurement, Characteristics, Improvements and Ontario GuidelinesAfzal WaseemNo ratings yet

- Laboratory For TractionDocument13 pagesLaboratory For TractionsiritapeNo ratings yet

- Skid ResistanceDocument8 pagesSkid ResistanceAbdulelah SNo ratings yet

- Hello Kitty and FriendsDocument27 pagesHello Kitty and FriendsDatin SyimaNo ratings yet

- Use of Smooth-Treaded Test Tire in Evaluating Skid ResistanceDocument8 pagesUse of Smooth-Treaded Test Tire in Evaluating Skid ResistanceAnonymous FjHknViPxNo ratings yet

- Polishing Stone Value PDFDocument5 pagesPolishing Stone Value PDFirsan100% (1)

- The Effect of Road Surfacing Condition On Tyre Life: WjvdmsteynandmhawDocument11 pagesThe Effect of Road Surfacing Condition On Tyre Life: WjvdmsteynandmhawManjunatha EikilaNo ratings yet

- Field Evaluation of Asphalt Concrete Pavement Surface Texture and Skid CharacteristicsDocument15 pagesField Evaluation of Asphalt Concrete Pavement Surface Texture and Skid CharacteristicsAnmar Al-AdlyNo ratings yet

- Experimental Research of Effectiveness of Brakes in Passenger Cars Under Selected ConditionsDocument5 pagesExperimental Research of Effectiveness of Brakes in Passenger Cars Under Selected ConditionsHITESH SONAWANENo ratings yet

- 6th Report (Skid Resistance)Document23 pages6th Report (Skid Resistance)Nurul Izzati Raihan Ramzi100% (1)

- Makmal HighwayDocument7 pagesMakmal HighwayNur Atiqah RahmanNo ratings yet

- Technical Note TN 110 Measurement and Interpretation of Skid Resistance Using A SCRIM MachineDocument7 pagesTechnical Note TN 110 Measurement and Interpretation of Skid Resistance Using A SCRIM Machineforismei5644No ratings yet

- Lucy2 Final PresentationDocument65 pagesLucy2 Final PresentationChris JosephNo ratings yet

- Characteristics of Tire FrictionDocument6 pagesCharacteristics of Tire Frictionamansax77No ratings yet

- Reduce Fat Spots and Improve Skid ResistanceDocument11 pagesReduce Fat Spots and Improve Skid ResistanceAmul KotharkarNo ratings yet

- Nasa Technical Memorandum: Effects of Runway Grooving ON Aircraft Tire Spin-Up BehaviorDocument23 pagesNasa Technical Memorandum: Effects of Runway Grooving ON Aircraft Tire Spin-Up Behaviorapi-61200414No ratings yet

- Tire Friction Dependence on Pavement Surface RoughnessDocument19 pagesTire Friction Dependence on Pavement Surface RoughnesssiritapeNo ratings yet

- In Situ Tests Field Vane Shear TestDocument5 pagesIn Situ Tests Field Vane Shear TestHi HiNo ratings yet

- A Study of In-Place Rutting of Asphalt Pavements: E. R. Brown and Stephen A. CrossDocument39 pagesA Study of In-Place Rutting of Asphalt Pavements: E. R. Brown and Stephen A. CrossHasumati SolankiNo ratings yet

- Soil Mech 2 Assignment I (1) - 1Document80 pagesSoil Mech 2 Assignment I (1) - 1vngaishNo ratings yet

- SoilDocument151 pagesSoilSubrat DashNo ratings yet

- Highway Skid ResistanceDocument20 pagesHighway Skid ResistanceMohamed Al FahlNo ratings yet

- EcoWood Soil Interaction ModelDocument87 pagesEcoWood Soil Interaction ModelSachin SithikNo ratings yet

- Skid ResistanceDocument7 pagesSkid ResistancePrabhav DeujaNo ratings yet

- Performance of Waste Tyre Rubber On Model Flexible PavementDocument4 pagesPerformance of Waste Tyre Rubber On Model Flexible PavementNimmy FredrickNo ratings yet

- CED 705 - Week 12 - Lecture 1Document27 pagesCED 705 - Week 12 - Lecture 1Charles TaloboeNo ratings yet

- PIARC Rejuvenation FrictionDocument16 pagesPIARC Rejuvenation FrictionMichael KaziNo ratings yet

- The Application of Triaxial Testing To Flexible Pavement DesignDocument17 pagesThe Application of Triaxial Testing To Flexible Pavement DesignvictorNo ratings yet

- HIGHWAY ENGINEERING (2marks) PDFDocument10 pagesHIGHWAY ENGINEERING (2marks) PDFGanesh Padmanaban100% (2)

- Sieve Analysis IntroductionDocument2 pagesSieve Analysis IntroductionJacky TanNo ratings yet

- Influencie of Shearing Rate On Interfacial Friction Between Sand and SteelDocument16 pagesInfluencie of Shearing Rate On Interfacial Friction Between Sand and SteelMaríaJosé Toledo ArcicNo ratings yet

- SOIL COMPACTION AND GRADING EQUIPMENTDocument59 pagesSOIL COMPACTION AND GRADING EQUIPMENTweston chegeNo ratings yet

- Frictional EvaluationDocument23 pagesFrictional EvaluationSHIVANSH BAGHELNo ratings yet

- 2709-Article Text-11414-1-10-20180902Document10 pages2709-Article Text-11414-1-10-20180902Dimitris DountsisNo ratings yet

- Tire Performance on Wet SurfacesDocument9 pagesTire Performance on Wet SurfacessuyogbhaveNo ratings yet

- 1227-012 Effect of Tyre Pressure and ThicknessDocument13 pages1227-012 Effect of Tyre Pressure and ThicknessAnonymous U6pIEKQghNo ratings yet

- Subgrade and Pavement MaterialsDocument30 pagesSubgrade and Pavement MaterialshimathkumarNo ratings yet

- Ce-481 Soil Mechanics II CompactionDocument36 pagesCe-481 Soil Mechanics II Compactiondaniel bulNo ratings yet

- Lab 3 Road Skid ResistanceDocument9 pagesLab 3 Road Skid ResistanceAmar AizadNo ratings yet

- Journal 10 PDFDocument6 pagesJournal 10 PDFRuzengulalebih ZEta's-ListikNo ratings yet

- Evaluate Flexible Pavements and Design Overlays with Benkelman BeamDocument17 pagesEvaluate Flexible Pavements and Design Overlays with Benkelman BeambilzinetNo ratings yet

- OTC 10991 Partially-Drained Loading of Shallow Foundations On SandDocument9 pagesOTC 10991 Partially-Drained Loading of Shallow Foundations On SandSamuel Laura HuancaNo ratings yet

- Pavement MaterialsDocument7 pagesPavement MaterialsSanjay ShawNo ratings yet

- Article Tyre UnbeadsetDocument8 pagesArticle Tyre UnbeadsetGammaNo ratings yet

- Proof RollingDocument33 pagesProof Rollingazcomp100% (8)

- Paper 1 - Wear and Abrasion of TiresDocument6 pagesPaper 1 - Wear and Abrasion of TiresRohanNo ratings yet

- Development Fundamental Skid Resistance Asphalt Mix Design ProcedureDocument15 pagesDevelopment Fundamental Skid Resistance Asphalt Mix Design Procedureعتيقة يوسفيNo ratings yet

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- Mathematical Principles of Reinforcement: Behavioral and Brain Sciences March 1994Document70 pagesMathematical Principles of Reinforcement: Behavioral and Brain Sciences March 1994lirbaNo ratings yet

- Indian Tex Users Group LaTex Tutorials - A Primer (Indian Tex User Grupo)Document155 pagesIndian Tex Users Group LaTex Tutorials - A Primer (Indian Tex User Grupo)Diego MorenoNo ratings yet

- How The Ancient Greeks Reinvented BuddhismDocument5 pagesHow The Ancient Greeks Reinvented BuddhismlirbaNo ratings yet

- Bay Area Ridge Trail MapDocument1 pageBay Area Ridge Trail MaplirbaNo ratings yet

- Differential EquationsDocument187 pagesDifferential EquationsMihai Alexandru Iulian100% (2)

- I.V.T. Example: Proving the Existence of the Cube Root of ThreeDocument1 pageI.V.T. Example: Proving the Existence of the Cube Root of ThreelirbaNo ratings yet

- Math Writing - Language GuideDocument6 pagesMath Writing - Language GuideskluxNo ratings yet

- Thesis FulltextDocument342 pagesThesis Fulltextlirba100% (1)

- 217R5A6603 - Seminar ReportDocument23 pages217R5A6603 - Seminar ReportPink TinkNo ratings yet

- PPC Prop Zoning OrdinanceDocument53 pagesPPC Prop Zoning OrdinanceBesprenPaoloSpiritfmLucena100% (1)

- Aashto T 283-2002Document9 pagesAashto T 283-2002abercio hidalgoNo ratings yet

- Infiniti FX35 Fog Light DIYDocument36 pagesInfiniti FX35 Fog Light DIYmexx4u2nvNo ratings yet

- Wiring Diagram For Active Brake Assist (ABA)Document4 pagesWiring Diagram For Active Brake Assist (ABA)Heru PurwantoNo ratings yet

- Kalokal Barangay Highway HillsDocument35 pagesKalokal Barangay Highway HillsDixie MirandaNo ratings yet

- Infoblatt Rodeln eDocument12 pagesInfoblatt Rodeln eAustrian National Tourism BoardNo ratings yet

- An Official Census 2011 Detail of MeerutDocument9 pagesAn Official Census 2011 Detail of MeerutVishal AnandNo ratings yet

- Transaction records from toll highwaysDocument4 pagesTransaction records from toll highwaysnanabuxNo ratings yet

- HW II - Chapter 5 - Unbound Pavement MaterialsDocument45 pagesHW II - Chapter 5 - Unbound Pavement Materialsabenezer abrhamNo ratings yet

- Chapter 3 - Highway Capacity and Level of ServiceDocument74 pagesChapter 3 - Highway Capacity and Level of ServiceTaha Gargoum100% (2)

- PHY BonakalDocument43 pagesPHY BonakalInapanuri Nageshwara RaoNo ratings yet

- CSR 2010Document499 pagesCSR 2010Daljeet Sidhu70% (10)

- Analyze Queuing Delays at Toll PlazaDocument17 pagesAnalyze Queuing Delays at Toll PlazaJerson OpisNo ratings yet

- Evolution of the Queensland Driver LicenceDocument2 pagesEvolution of the Queensland Driver LicenceJaram JohnsonNo ratings yet

- Cold Recycling ManualDocument9 pagesCold Recycling ManualCristian OJNo ratings yet

- Determination of Expansion Factors To Estimate Average Annual Daily Traffic For Arterials in AmmanDocument14 pagesDetermination of Expansion Factors To Estimate Average Annual Daily Traffic For Arterials in AmmanShivangi KumarNo ratings yet

- 1 HAE-SG007TheJou PDFDocument34 pages1 HAE-SG007TheJou PDFMaria ChievaNo ratings yet

- UntitledDocument65 pagesUntitledRapheal AmehNo ratings yet

- Pavement Design Guidelines (Flexible Pavement)Document37 pagesPavement Design Guidelines (Flexible Pavement)Padma Shahi60% (5)

- Indian Institute of Technology Kanpur Institute Works Department Division - IDocument12 pagesIndian Institute of Technology Kanpur Institute Works Department Division - ISantosh ThakurNo ratings yet

- American Car - November 2014 UKDocument116 pagesAmerican Car - November 2014 UKenricoio100% (1)

- Grove RT58C (18 Ton)Document14 pagesGrove RT58C (18 Ton)ROBERTO RUEDA RODRÍGUEZNo ratings yet

- Calculation of Time Motion AnalysisDocument1 pageCalculation of Time Motion Analysiscelsa virtudazo salangNo ratings yet

- Scaffolding Risk AssessmentDocument3 pagesScaffolding Risk AssessmentAlexandru GhigeaNo ratings yet

- Allison 4th Generation ControlsDocument22 pagesAllison 4th Generation Controlsmnvijaybabu100% (1)

- Sisweb Sisweb Techdoc Techdoc Print PageDocument30 pagesSisweb Sisweb Techdoc Techdoc Print PagenopainmadafakaNo ratings yet

- Rac Inspection ReportDocument13 pagesRac Inspection ReportDaniel DevineNo ratings yet

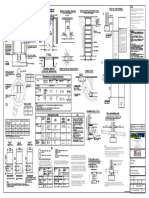

- Manhole Type B and Inspection ChamberDocument1 pageManhole Type B and Inspection ChamberComofco GibraltarNo ratings yet

- Banking Of Highways And Railway Curves: GrtanθDocument2 pagesBanking Of Highways And Railway Curves: GrtanθCacao Jayr-maeNo ratings yet