Professional Documents

Culture Documents

Influence of Pyrite Content On The Flotation of Chalcopyrite After Regrinding With Isamill

Uploaded by

Hugo Carcamo0 ratings0% found this document useful (0 votes)

19 views10 pagesIn the flotation of copper ores several processing plants report that copper recovery is affected by the proportion and type of pyrite in the ore. A model mix mineral system consisting of chalcopyrite and pyrit. Flotation tests showed that. The flotation chemistry and recovery of chalcopyrite are affected by the. Proportion of pyrites present. X-ray photoelectron spectroscopy (xps) results confirm that copper activation increases with increasing

Original Description:

Original Title

OwusoZanin

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentIn the flotation of copper ores several processing plants report that copper recovery is affected by the proportion and type of pyrite in the ore. A model mix mineral system consisting of chalcopyrite and pyrit. Flotation tests showed that. The flotation chemistry and recovery of chalcopyrite are affected by the. Proportion of pyrites present. X-ray photoelectron spectroscopy (xps) results confirm that copper activation increases with increasing

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views10 pagesInfluence of Pyrite Content On The Flotation of Chalcopyrite After Regrinding With Isamill

Uploaded by

Hugo CarcamoIn the flotation of copper ores several processing plants report that copper recovery is affected by the proportion and type of pyrite in the ore. A model mix mineral system consisting of chalcopyrite and pyrit. Flotation tests showed that. The flotation chemistry and recovery of chalcopyrite are affected by the. Proportion of pyrites present. X-ray photoelectron spectroscopy (xps) results confirm that copper activation increases with increasing

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 10

INFLUENCE OF PYRITE CONTENT ON THE FLOTATION OF

CHALCOPYRITE AFTER REGRINDING WITH ISAMILL

Clement Owusu, Max Zanin

*

, Daniel Fornasiero and Jonas Addai-Mensah

*

Ian Wark Research Institute, University of South Australia, Mawson Lakes, SA 5095,

Australia

Email: massimiliano.zanin@.unisa.edu.au

ABSTRACT

In the flotation of copper ores several processing plants report that copper recovery is

affected by the proportion and type of pyrite in the ore, with the effect becoming more

intense when the feed ore particles are fine, i.e. in fine regrinding. In this work, a model

mix mineral system consisting of chalcopyrite and pyrite with varying pyrite content (in

the range 20-80 wt. %) was used to investigate the effect of pyrite content on the pulp

chemistry and chalcopyrite recovery. Surface species responsible for the flotation

performance of the various blends were quantified with X-ray photoelectron

spectroscopy (XPS). Flotation tests showed that the flotation chemistry and recovery of

chalcopyrite are affected by the proportion of pyrite present. Both chalcopyrite flotation

recovery and grade decreased with increasing pyrite content. XPS results confirm that

copper activation of pyrite increases with increasing pyrite content, reflecting the

attenuation in chalcopyrite recovery.

INTRODUCTION

Copper exists in the earth crust as copper iron sulphide or copper sulphide minerals.

Examples of such minerals include chalcopyrite (CuFeS

2

), bornite (CusFeS

4

), chalcocite

(Cu

2

S) and covellite (CuS). In recent time, it is very rare to find large copper mineral

deposits with head grade averaging about 2% Cu (Davenport et al., 2002) due to the

presence of other metal sulphides and non-sulphide gangue minerals such as pyrite

(FeS

2

) sphalerite, quartz, etc (Aplan and Chander, 1988; Kydros et al., 1994).

Chalcopyrite, a major mineral for copper production, is not exceptional. It is often in

association with iron sulphide minerals, particularly pyrite and minor amounts of

sphalerite and molybdenite (Habashi, 1987; Wang, 2005).

Recent studies indicate that the selective separation of chalcopyrite from pyrite is very

difficult due to several interactions that occur at the mineral surfaces during the

processes of grinding and conditioning (Fuerstenau, 1982; Finkelstein, 1997). Galvanic

interactions occurring between pyrite and chalcopyrite surfaces during grinding and

conditioning, prior to flotation, lead to chalcopyrite oxidation and copper activation of

the former. This also results in the formation of hydrophilic surface coatings of iron

hydroxide species that inhibit chalcopyrite flotation. Copper activation of pyrite

increases collector adsorption onto pyrite surface, promoting its flotation which

subsequently lowers the overall chalcopyrite recovery and grade (Xu et al., 1995; Peng

et al., 2003). For improved mineral liberation due to changes in ore mineralogy in order

to increase flotation recovery and grade of the final concentrate (Gaudin, 1939;

Sutherland 1989), regrinding to very fine particle size is performed. However, Ye et al.

(2010) showed that the surface chemistry of minerals which impacts on the optimum

Owusu et al.

2

mineral separation may change significantly after regrinding depending upon the type of

mill and grinding media used. Similarly, reports from various processing plants show

that chalcopyrite recovery after regrinding is affected by the proportion and type of

pyrite in the ore, the effect becoming more intense when the feed ore particles are fine

(Yong, personal communication).

In this study, a model mineral system comprising different proportions pyrite and

chalcopyrite was studied to investigate the effect of pyrite content in chalcopyrite

recovery, grade and selectivity after ore regrinding with an IsaMill. Surface species

formed on the mineral surfaces before and after regrinding were determined using XPS

spectroscopy.

EXPERIMENTAL

Materials

Chalcopyrite (Cp) and pyrite (Py) minerals of size fractions 2-400 m and 2-600 m

obtained from Mannum minerals and a Peruvian mine, respectively, were used for this

study. The chemical compositions of the two samples are reported in Table 1. Sodium

isopropyl xanthate (SIPX) and Dowfroth 250 (poly propylene glycol, AR grade) were

used as a collector and a frother, respectively. Analytical reagent grade lime was used

throughout the whole experiment for pH regulation, unless otherwise stated.

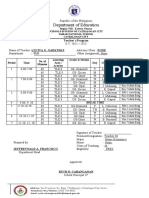

Tab. 1: Chemical composition of chalcopyrite and pyrite samples used for the studies

Elements (mass %) Mineral

Zn Fe S Ca Cu Si Pb Mn Mg

Chalcopyrite 0.012 28.9 29.0 1.76 26.4 4.20 0.34 0.02 0.68

Pyrite 0.180 44.9 53.5 0.44 0.13 0.69 0.02 0.02 0.08

Experimental procedures

Flotation

A 200 g ore sample comprising different proportions of pyrite and chalcopyrite (20 %,

50% and 80% Py) together with demineralised water and lime was milled in a Galigher

Mill to d

80

of 105 m at pH 10 using stainless steel rods. The mill product was

conditioned in a 1.5 L flotation cell (Agitair Model LA-500R) with xanthate collector

(200 g/t SIPX) for 2 min and pH adjusted to 10.5 with lime. The conditioned pulp was

reground to d

80

of 20 m in a 1 L IsaMill for 15 min. The mill discharge was then

transferred back into the 1.5 L Agitair flotation cell and conditioned with 50 g/t of SIPX

and frother (25 g/t Dowfroth 250) for 2 and 1 min, respectively, before flotation. A

summary of the flotation procedure is shown in Figure 1. Pulp agitation speed, pH and

aeration during conditioning and flotation in the cell were maintained at 1000 rpm, 10.5

and 2 L/m respectively for all experiments. Pulp oxidation potential (Eh) and dissolved

oxygen level (DO) were measured at the start of conditioning, before and after collector

addition, at the start of 1

st

concentrate collection and in the tailings at the end of

flotation. Four concentrates were collected at time intervals of 1, 2, 3 and 4 min. These

Owusu et al.

3

concentrates were filtered and dried overnight in an oven at 50

o

C. The dry weights of

the four concentrates and tailings were determined and chemical assays undertaken for

their elemental compositions using X-Ray Fluorescence Spectroscopy (XRF). In some

tests the amount of collector added was kept constant through all experiments whilst in

others it was scaled to the amount of Cu in the mixture (200 g/t after primary grinding

and 50 g/t after regrinding, referred to the mass of chalcopyrite in the mixture).

Recovery versus time data were fitted to a first order rate equation ) 1 (

max

kt

e R R

= ,

where R is the recovery at time t, R

max

is the maximum recovery at infinite time and k is

flotation rate constant. From this equation, R

max

and (k) were calculated for both

chalcopyrite and pyrite.

Fig. 1: Flowsheet of the experimental flotation.

After chemical analysis, the elemental compositions (i.e. %Cu and %Fe) of each sample

were converted into mineral composition using the following mathematical relations for

each of the elements based on stoichiometric compositions of chalcopyrite (Cp) and

pyrite (Py) (i.e. under ideal conditions).

( )

5 . 63

3 . 183

% ) (% = Cu Cp (Chalcopyrite) (1)

( )

5 . 63

8 . 55

% % %

*

= Cu Fe Fe (Iron present as pyrite) (2)

( )

8 . 55

8 . 119

% %

*

= Fe Py (Pyrite in sample) (3)

Surface analysis (XPS)

To understand the surface species responsible for the flotation behaviour of both

minerals, samples were collected after regrinding with the IsaMill. These samples after

collection were purged with nitrogen gas for 2 min before placing them in liquid

nitrogen and stored in a refrigerator at 4

o

C prior to XPS analysis. This was done to

prevent further surface oxidation.

Dissolved oxygen demand test

Dissolved oxygen demand (DO) was measured to investigate if the reduction in oxygen

content in the pulp during conditioning was due to the presence of pyrite. The oxygen

demand test was conducted in an airtight container vessel equipped with a stirrer to keep

the mineral particles in suspension (Figure 2). Eh, DO and pH were recorded to

determine the changes in the pulp as a function oxygen addition with time.

Owusu et al.

4

The rougher concentrate obtained after IsaMilling (1 L IsaMill) was used for the DO

demand tests. Mill discharge (d80 = 10 to 30 m) obtained after IsaMilling for 15 min

was transferred into an airtight container and stirred for 2 min to obtain a homogeneous

pulp after which the initial readings for Eh, DO, and pH were recorded. The pulp was

purged with oxygen at a pressure of 200 KPa for 2 min, at 5 L/min. After 2 min, the

oxygen tap was closed and the decay in oxygen content monitored for 10 min. This

procedure was repeated several times until oxygen concentration reached equilibrium.

During the oxygen demand experiment, the pulp pH, DO and Eh values were monitored

at time 10 sec intervals

RESULTS AND DISCUSSION

Reproducibility of flotation results

The flotation experiments for the various blends were repeated several times in order to

assess reproducibility of the results. As an example, values of chalcopyrite (Cp) and

pyrite (Py) recovery after 10 min of flotation, and the first order flotation rate constant

(k) for three tests with 20% pyrite content are summarised in Table 2.

Tab. 2: Reproducibility of results for the baseline flotation test

20% Py addition recovery (%) k (min

-1

})

Test # Cp Py Cp Py

1 98 48 0.945 0.473

2 99 43 0.950 0.477

3 97 49 0.925 0.490

Average 98 47 0.940 0.480

Standard deviation 1.0 3.2 0.013 0.089

Effect of pyrite content on flotation

The effect of pyrite content on the flotation recovery and grade of chalcopyrite after

IsaMilling is shown in Figures 3 and 4. The initial experiments (Figure 3) were carried

out at a constant collector addition of 250 g/t, irrespective of the proportion of

chalcopyrite in the mixture, whilst in subsequent experiments (Figure 4), the amount of

collector added was scaled to the amount of chalcopyrite present. This was done to

deconvolute the effects of two mechanisms:

Surface modifications on chalcopyrite (oxidation) and reduced floatability,

Copper activation of pyrite and subtraction of collector available for

chalcopyrite.

For tests with constant collector addition (Figure 3), an increase in pyrite content from

0% to 80% resulted in a decrease in chalcopyrite recovery from 98% to 80% and a

concomitant decrease in the flotation rate constant from 0.94 to 0.42 min

-1

(Table 3).

In the tests at scaled collector addition (Figure 4), chalcopyrite recovery and flotation

rate constant decreased from 98% to 60% and from 0.94 to 0.39 min

-1

, respectively.

Fig. 3: Recovery of chalcopyrite (a) and pyrite (b) versus time as a function of the

content of pyrite in the blend (pH=10.5; [SIPX] =250 g/t in all tests)

=

Fig. 4: Recovery of chalcopyrite (a) and pyrite (b) versus time as a function of the

content of pyrite in the blend (pH=10.5; Cu to [SIPX])

In contrast to chalcopyrite, the recovery of pyrite gradually increased as the amount of

chalcopyrite present in the mixture increased (Figures 3b and 4b). For example, in the

scaled collector addition test at 20% chalcopyrite addition (80% pyrite), the maximum

pyrite recovery was 15%. However with an increase in chalcopyrite content to 80%

(20% pyrite), 30% of pyrite was recovered.

A comparative study of results in Figures 3 and 4 reveals consistent trends, where the

pulp containing the lowest pyrite proportion (20%) attained the highest chalcopyrite

recovery followed by intermediate (50%) and (80%) pyrite addition resulting in the

lowest chalcopyrite recovery. Similar trend was also observed for the flotation rate

constant. The only difference between the results in Figures 3 and 4 is the fact that, in

the former, chalcopyrite flotation recovery and flotation rate constant are generally

(a (b)

(a)

(b)

Owusu et al.

6

higher, and the detrimental effect of pyrite is less pronounced. Furthermore, pyrite

recovery in the tests at constant collector addition (Figure 3b) was much higher,

suggesting that pyrite competes with chalcopyrite for collector adsorption, with the

collector dosage being critical.

These results correlate well with those obtained by Young (2010), where the recovery of

copper after regrinding was affected by the proportion of pyrite in the ore. There is also

good agreement with the results reported by Ekmekci and Demirel (1997), where the

flotation behaviour of chalcopyrite and pyrite was controlled by their proportions in the

mixture.

It is clearly shown in Table 3 that an increase in pyrite content or proportion leads to a

decrease of the pulp Eh. For example, at 20% pyrite addition the Eh was 203 mV whilst

at 80% pyrite addition the Eh dropped to 176 mV (Table 2). Similar trend was also

observed for the dissolved oxygen level in the pulp at the start of the flotation

experiment. This effect may be attributed to the fact that pyrite is more cathodic and

hence consumes oxygen thereby resulting in a significant deleterious impact on flotation

recovery.

Table 3: Summary of results

Experiments

Equal amount of Collector addition after IsaMilling (250 g/t SIPX)

Mixtures (Cp-

Py)

Eh

Rate constant

(min-1)

Recovery %

Grade %

pH =10.5 mV Cp Py Cp Py Cp Py

20 % Py 240 0.94 0.48 98 47 68 23

50% Py 195 0.77 0.32 94 34 63 33

80 % Py 190 0.42 0.22 80 18 41 52

Collector addition after IsaMilling scaled to copper (250 g SIPX / t of Cp)

20 % Py 203 0.93 0.34 96 30 85 14

50% Py 190 0.52 0.18 87 21 65 25

80 % Py 176 0.39 0.17 60 15 47 44

Dissolved oxygen demand

The exact role of oxygen in sulphide mineral flotation is complicated. Various studies

(Gaudin and Finkelstin 1965; Gaudin 1974; Woods 1984; Laajalehto et al., 1993)

clearly indicate its strong influence when it comes to collector adsorption onto sulphide

mineral surfaces. The presence of oxygen in a flotation pulp changes the oxidation state

of sulphide minerals, which consequently results in the formation of surface species that

can either promote or inhibit mineral floatability.

In theory, pyrite is more cathodic than chalcopyrite, hence it is expected that its oxygen

consumption rate will be higher than that of chalcopyrite. Figure 5 actually confirms

that theory. At 0%, 50% and 100% pyrite addition, the rate constant for the decrease in

oxygen concentration in the pulp (k

O2

) was 0.023, 0.045 and 0.26 mg dm

-3

min

-1

,

respectively.

Owusu et al.

7

Fig 5: Oxygen concentration decay for different proportions of pyrite

Figure 6 shows the results of tests at intermittent oxygenation of the slurry (2 mi on and

5 min off). In this type of test, the progressive oxidation of mineral surfaces and reduced

activity were monitored with time. For example, in Figure 6 (100% Py), after an initial

oxygenation of 2 min and monitoring for 5 min, the end point of dissolved oxygen

concentration in the pulp decreased from 20 to 5.2 mg/dm

3

. However, when the pulp

was oxygenated for six cycles, the end point of dissolved oxygen concentration was

22 mg/dm

3

. This is because an increase in oxygenation time increases the oxidative

reaction occurring on the mineral surface. This reaction continues until the total surface

of the mineral is oxidized and further oxygenation results in no consumption. Figure 7

displays the end point dissolved oxygen content for the individual minerals.

Fig.6: Effect of increased oxygenation on

DO levels pyrite

Fig 7: End point oxygen content vs.

conditioning time (Cp and Py)

It is observed that pyrite is much more oxygen consuming than chalcopyrite,

and that it continues to adsorb oxygen from the system even after 30 min of continuous

O

2

purging of the pulp (the end point DO concentration in Fig, 7 is 22 ppm, well below

the saturation level of XX, indicating that oxygen is still consumed at the mineral

Owusu et al.

8

surface). This presupposes that the required amount of oxygen for maximum flotation

selectivity in a chalcopyrite/pyrite blend will definitely vary according to the relative

abundance of the two minerals.

Surface analysis

The atomic and weight percent (%) of elements on the mineral surface for different

blends of chalcopyrite and pyrite mixtures as measured by XPS are shown in Table 4.

Table 5 is the bulk weight percent (Bulk wt %) of elements in the feed material. From

Tables 4 and 5, surface to bulk ratio of elements (wt %) was calculated (Table 6). Both

Tables 4 and 5 indicate that the surface and bulk concentration of Cu in the mixed phase

pulp decreased with increasing pyrite content as expected.

Tab. 4: Atomic and Weight percent (%) of element on mineral surface (Cp-Py Mix)

Atomic (%) Weight (%)

Mixture Cu Fe O S Cu Fe O S

20% Py 13.4 12.3 44.2 30.1 25.6 21.2 24.1 29.2

50% Py 9.50 11.5 47.6 31.4 19.2 21.0 27.5 32.3

80% Py 6.60 11.0 45.4 36.9 13.7 20.6 26.9 38.8

Tab. 5: Bulk weight percent (wt %) of

element on mineral surfaces (Cp-Py)

Tab. 6: Surface to bulk ratio (wt %) of

element (Cp-Py Mix)

Bulk weight (%)

Mixture Cu Fe S

20% Py 21.9 34.8 32.3

50% Py 13.1 38.6 40.3

80% Py 5.3 42.4 48.2

Surface to bulk ratio (%)

Mixture Cu Fe S

20% Py 1.2 0.6 0.9

50% Py 1.5 0.5 0.8

80% Py 2.6 0.5 0.8

The data in Table 6 show that the concentration of Cu at mineral surface increases with

respect to the bulk concentration, as the pyrite content in the blend increases. The

abundance of Cu on the surface is possibly the result of the transfer of Cu species onto

pyrite particle surface. Also, it can be observed that the surface to bulk ratio of Fe and S

in all samples is <1 and 1 respectively (Table 6). This could be attributed to the

oxidation of the sulphide mineral surfaces with formation of oxide/hydroxide species,

with O replacing S on the surface (Table 4). This also implies that an increase in pyrite

content promotes the formation of Fe and Cu oxidation species.

The XPS results show that the decrease in chalcopyrite recovery can be attributed to the

formation of stable hydrophilic metal oxide/hydroxides coatings on the chalcopyrite

surface, thereby minimizing or preventing the adsorption of collector onto the

chalcopyrite surface (Majima and Takeda, 1968; Peng et al., 2003). Such surface

oxide/hydroxide species decrease the chalcopyrite hydrophobicity and collector

adsorption, thereby impacting on the flotation response of the mineral. In contrast, the

Owusu et al.

9

relative increase in pyrite recovery at pH 10.5 can be attributed to copper activation of

pyrite (Fuerstenau, 1982; Finkelstein, 1997). Pyrite in contact with chalcopyrite during

grinding and conditioning generates galvanic coupling that leads to anodic dissolution

of chalcopyrite with the release of Cu

2+

ions into solution which adsorbs onto and

activates pyrite for enhanced collector adsorption. These increase pyrite surface

hydrophobicity and subsequently promote flotation in alkaline conditions (Xe et al.,

1995; Ekmeki and Demirel, 1997).

CONCLUSIONS

After IsaMilling, chalcopyrite flotation kinetics and final recovery decrease with

increasing the pyrite content in the mixture. The chalcopyrite grade also

decreases as a result of higher pyrite recoveries.

Pulp dissolved oxygen content (DO) and pulp oxidation potential also decrease

with increasing pyrite content in the mixture. Surface analysis (XPS) suggests

that oxidation of chalcopyrite and copper activation of pyrite occurs.

Decrease in chalcopyrite flotation recovery is possibly a result of the formation

of hydrophilic metal oxide/hydroxide species on the surface of chalcopyrite and

the consumption of collector by copper activated pyrite.

During processing of chalcopyrite-pyrite mixtures, it is likely that different

dissolved oxygen levels in the pulp are required for optimum mineral separation,

depending on the relative abundance of the two minerals in the feed.

ACKNOWLEDGEMENTS

The financial support for this work from AMIRA international and discussion with

Michael Young (Xstrata) are gratefully acknowledged.

REFERENCES

Aplan, F.F. and Chander, S., (1988), Collectors for sulphide Minerals flotation, In: (P.

Somasundaran and B. M. Moudgil, Editors) Reagents in Mineral Technology,

Marcel Dekker Inc., NY, pp. 335-369

Davenport, W.G., King, M. and Schlesinger, M. (2002), Extractive Metallurgy of

Copper. Tech & Eng. , Oxford OX5 IGB, UK

Ekmeki, Z. and Demirel, H., (1997). Effects of galvanic interaction on collectorless

flotation behavior of chalcopyrite and pyrite. Int. J. Min. Proc., 52(1): 31-48.

Finkelstein, N. P., (1997). The activation of sulphide minerals for flotation: a review.

Int. J. Min. Proc., 52(2-3): 81-120.

Fuerstenau, D.W and Fuerstenau, M.C., (1982). The flotation of oxide and silicate

minerals. In: King, R.P. (Ed.), Principles of Flotation. S.A Inst. Min and Metall.

Johannesburg.

Gaudin, A. M., (1939). Principles of mineral dressing. McGraw-Hill Book, New York.

Habashi (1978). Chalcopyrite: its chemistry and metallurgy, McGrand-Hill, USA,

Kydros, K.A., Gallios, G.P. and Matis, K.A., (1994). Modification of Pyrite and

Sphalerite Flotation by Dextrin. Separation Science and Technology, 29 (17): 2663-

2275.

Owusu et al.

10

Peng, Y., Grano, S., Fornasiero, D. and Ralston, J., (2003). Control of grinding

conditions in the flotation of chalcopyrite and its separation from pyrite. Int. J. Min.

Proc., 69(1-4): 87-100.

Sutherland, D.N (1989). Batch flotation behavior of composite particles. Miner. Eng.,

2(3): 351-367

Wang, X.-H. and Eric Forssberg, K. S., (1991). Mechanisms of pyrite flotation with

xanthates. Int. J. Min. Proc., 33(1-4): 275-290.

Xu, M., Finch, J. A., Rao, S. R. and Lin, D., (1995). Reverse flotation of pyrite from a

zinc-concentrate using nitrogen. Miner. Eng., 8(10): 1159-1173.

Ye, X., Gredelj, S., Skinner, W., and Grano, S.R., (2010). Regrinding Sulphide

Minerals Distinguishing the Effects of Particle Size, Surface Contamination, and

Exposure of New Mineral Surfaces. Int. J. Min. Proc., submitted.

Gaudin, A.M., and Finkelestin, N.P., (1965). Interactions in the System Galena-

Potassium Ethyl Xanthate Oxygen. Nature, 207: 389-391.

Gaudin, A.M., ( 1974). The role of oxygen in flotation, J. Colloid Interface Sci., 47(2):

99-314.

Laajalehto, K., Nowak, P., and Suoninen, E., (1993). The XPS and IR identification of

the products of Xanthate Sorption at the Surface of Galena. Int. J. Min. Proc., 37:

123-147

Woods, R., (1984), Flotation of sulphide Minerals, Principles of Mineral Flotation, The

Wark Symposium (Editors: M.H. Jones and J. T woodcock), The Australasian Inst.

of Min. Met., Melbourne, pp. 91-115.

BIOGRAPHY

Clement Owusu is currently at the first year of his 3-year PhD degree program in the

Ian Wark Research Institute (IWRI), University of South Australia. This work forms

part of his research project entitled Effect of pulp oxidation potential in the separation

of chalcopyrite from pyrite after regrinding with an IsaMill. Clement obtained his

Bachelor of Science degree in Minerals Engineering (2009) from University of Mines

and Technology (UMaT), Tarkwa, Ghana.

You might also like

- Pyrite On Chalco FlotationDocument9 pagesPyrite On Chalco FlotationBale SharingNo ratings yet

- Beneficiation of Egyptian PDFDocument11 pagesBeneficiation of Egyptian PDFRachid FaouziNo ratings yet

- Correlation Between Copper Activated Pyrite Flotation and Su - 2005 - Minerals EDocument6 pagesCorrelation Between Copper Activated Pyrite Flotation and Su - 2005 - Minerals Emkhfacebook.khorasaniNo ratings yet

- Makanza Flotation (2008)Document23 pagesMakanza Flotation (2008)Richard CookNo ratings yet

- Amer Et AlDocument8 pagesAmer Et AlNadarlis Binti DarmawiNo ratings yet

- Evaluation of Bauxite As A Raw Material For Extraction of AluminumDocument5 pagesEvaluation of Bauxite As A Raw Material For Extraction of AluminumtaxxolNo ratings yet

- Concentration of Itakpe Iron OreDocument9 pagesConcentration of Itakpe Iron OreChima C. UgwuegbuNo ratings yet

- Research Paper Sulphur Fractionation in The Sediments of Cochin EstuaryDocument6 pagesResearch Paper Sulphur Fractionation in The Sediments of Cochin EstuaryShyleshNairNo ratings yet

- 1 Abdel Khalek 2012 OKDocument6 pages1 Abdel Khalek 2012 OKjacianymayaraNo ratings yet

- Stability of Clay Minerals in AcidDocument12 pagesStability of Clay Minerals in Acidjose luis pachecoNo ratings yet

- Froth Flotation of Mixed Feldspar: Chairoj Rattanakawin and Benjapol ThacomDocument5 pagesFroth Flotation of Mixed Feldspar: Chairoj Rattanakawin and Benjapol ThacomMarco Antonio Ojeda PradoNo ratings yet

- 1 s2.0 0304386X9400011Q Main PDFDocument21 pages1 s2.0 0304386X9400011Q Main PDFCenon MalabananNo ratings yet

- Clay AcidityDocument9 pagesClay AcidityccatrineNo ratings yet

- Art. - Compoting ETM - Chemosphere - 2005 With Cover PageDocument11 pagesArt. - Compoting ETM - Chemosphere - 2005 With Cover PageFatima ZahraNo ratings yet

- The Effect of Aerophine 3418A Collector Dosage On NiğdeDocument5 pagesThe Effect of Aerophine 3418A Collector Dosage On NiğdeEduardo CandelaNo ratings yet

- Flota Arsenopyrite Sep1Document14 pagesFlota Arsenopyrite Sep1Mohamed DraaNo ratings yet

- Kaya 2016Document12 pagesKaya 2016Herman_MLNo ratings yet

- Control of Grinding Conditions in The Flotation o - 2003 - International JournalDocument14 pagesControl of Grinding Conditions in The Flotation o - 2003 - International Journalmkhfacebook.khorasaniNo ratings yet

- Microstructural Studies and Carbochlorination Kinetics of Xenotime OreDocument7 pagesMicrostructural Studies and Carbochlorination Kinetics of Xenotime OreresaNo ratings yet

- Sintesis Hidroksiapatit Dari Cangkang KeDocument8 pagesSintesis Hidroksiapatit Dari Cangkang KeDwi suparwatiNo ratings yet

- Technical Note Wastewater Treatment at The Petroleum Refinery, Kirikkale, Turkey Using Some Coagulants and Turkish Clays As Coagulant AidsDocument5 pagesTechnical Note Wastewater Treatment at The Petroleum Refinery, Kirikkale, Turkey Using Some Coagulants and Turkish Clays As Coagulant AidsВладислав ГазинNo ratings yet

- Kinetics of Arsenopyrite Oxidative Dissolution by Oxygen: Forest P. Walker, Madeline E. Schreiber, J. Donald RimstidtDocument9 pagesKinetics of Arsenopyrite Oxidative Dissolution by Oxygen: Forest P. Walker, Madeline E. Schreiber, J. Donald RimstidtBiSOPNo ratings yet

- Jur UtamaDocument11 pagesJur UtamaEtrinaldi Lawan CariNo ratings yet

- Speciation of heavy metals in sewage sludge co-compostedDocument7 pagesSpeciation of heavy metals in sewage sludge co-compostedCristian CarrascoNo ratings yet

- Heavy metal removal using aquatic plantDocument4 pagesHeavy metal removal using aquatic plantRamona DanyNo ratings yet

- Increasing Fine Copper Recovery at The Ok Tedi Concentrator, Papua New GuineaDocument17 pagesIncreasing Fine Copper Recovery at The Ok Tedi Concentrator, Papua New GuineaW ZuoNo ratings yet

- Ammoniacal Thiosulphate Leaching of Gold Ore: R.K. Rath, N. Hiroyoshi, M. Tsunekawa, T. HirajimaDocument9 pagesAmmoniacal Thiosulphate Leaching of Gold Ore: R.K. Rath, N. Hiroyoshi, M. Tsunekawa, T. HirajimaGustavo CabreraNo ratings yet

- Flotacion de Cpy CC PyDocument9 pagesFlotacion de Cpy CC PyCamilo Gonzalez DiazNo ratings yet

- Reprint in JASR 233-239 2013-Libre PDFDocument7 pagesReprint in JASR 233-239 2013-Libre PDFWali YudinNo ratings yet

- Pyrite PaperDocument6 pagesPyrite PaperPham Thi HoaNo ratings yet

- Uptake of trivalent chromium from aqueous solutions using protonated dry alginate beadsDocument8 pagesUptake of trivalent chromium from aqueous solutions using protonated dry alginate beadsSebastian Andres Zapata AhumadaNo ratings yet

- High Pressure Acid Leaching of A Refractory Lateritic Nickel OreDocument10 pagesHigh Pressure Acid Leaching of A Refractory Lateritic Nickel OreFabian MansillaNo ratings yet

- Depresion de ArsénicoDocument15 pagesDepresion de ArsénicoRENASANo ratings yet

- Assessment and Modelling of The Environmental Chemistry and Potential For Remediative Treatment of Chromium-Contaminated LandDocument7 pagesAssessment and Modelling of The Environmental Chemistry and Potential For Remediative Treatment of Chromium-Contaminated LandRoger SiguayroNo ratings yet

- Immobilisation of Cu, PB and ZN in Scrap Metal Yard Soil Using Selected Waste MaterialsDocument6 pagesImmobilisation of Cu, PB and ZN in Scrap Metal Yard Soil Using Selected Waste MaterialsMauro Porcel de PeraltaNo ratings yet

- Reductive Atmospheric Acid Leaching of West Australian Smectitic Nickel Laterite inDocument6 pagesReductive Atmospheric Acid Leaching of West Australian Smectitic Nickel Laterite inandre_lange_1No ratings yet

- Aciego - A New Procedure For Separating and Measuring Radiogenic Isotopes (U, TH, Pa, Ra, SR, ND, HF) in Ice Cores - 2009Document11 pagesAciego - A New Procedure For Separating and Measuring Radiogenic Isotopes (U, TH, Pa, Ra, SR, ND, HF) in Ice Cores - 2009mu cNo ratings yet

- Kinetics and Equilibrium Adsorption Study of Lead (II) Onto Activated Carbon Prepared From Coconut ShellDocument7 pagesKinetics and Equilibrium Adsorption Study of Lead (II) Onto Activated Carbon Prepared From Coconut ShellsureshbabuchallariNo ratings yet

- Removal of Cu (II) With Hydroxyapatite (Animal Bone) As An Inorganic Ion ExchangerDocument5 pagesRemoval of Cu (II) With Hydroxyapatite (Animal Bone) As An Inorganic Ion ExchangernguyenthithuvinhhangNo ratings yet

- Rajesh 2004Document6 pagesRajesh 2004zahiraNo ratings yet

- A.Mgaidi Et AlDocument16 pagesA.Mgaidi Et AlNelson EspinelNo ratings yet

- Adebowale, Unuabonah, Olu-Owolabi - 2005 - Adsorption of Some Heavy Metal Ions On Sulfate - and Phosphate-Modified KaolinDocument4 pagesAdebowale, Unuabonah, Olu-Owolabi - 2005 - Adsorption of Some Heavy Metal Ions On Sulfate - and Phosphate-Modified Kaolincukaasam123456No ratings yet

- Fluoride Content of Clay Minerals and Argillaceous Earth MaterialsDocument7 pagesFluoride Content of Clay Minerals and Argillaceous Earth MaterialsLaura TartauNo ratings yet

- Dhindsa2003 PDFDocument12 pagesDhindsa2003 PDFRizqnNo ratings yet

- Characterization of Mesoporous Activated Carbons Prepared by Pyrolysisnext Term of Sewage Sludge With PyrolusiteDocument5 pagesCharacterization of Mesoporous Activated Carbons Prepared by Pyrolysisnext Term of Sewage Sludge With PyrolusiteyemresimsekNo ratings yet

- Adsorption Potentials of Fadama Clays Towards Heavy Metals (Zinc and Cobalt)Document10 pagesAdsorption Potentials of Fadama Clays Towards Heavy Metals (Zinc and Cobalt)Mohammad MiyanNo ratings yet

- Pyrite Behaviour in A Tailings Pond: C. Garcı A, A. Ballester, F. Gonza Lez, M.L. Bla ZquezDocument12 pagesPyrite Behaviour in A Tailings Pond: C. Garcı A, A. Ballester, F. Gonza Lez, M.L. Bla Zquezosvaldohumberto1974No ratings yet

- Recovery of Platinum From Spent Reforming Catalyst by Acid Leaching and CoprecipitationDocument6 pagesRecovery of Platinum From Spent Reforming Catalyst by Acid Leaching and CoprecipitationFitriyanti IzinilahNo ratings yet

- IMWA2005 048 Grebenwqeqeedqqeq Qwe QweDocument9 pagesIMWA2005 048 Grebenwqeqeedqqeq Qwe QweAnonymous odYB0pH5STNo ratings yet

- Tratamiento HidrotermalDocument11 pagesTratamiento HidrotermalCocó QuijadaNo ratings yet

- Batch and Column Sorption of Heavy Metal From Aqueous Solution Using A Marine Alga Sargassum TenerrimumDocument8 pagesBatch and Column Sorption of Heavy Metal From Aqueous Solution Using A Marine Alga Sargassum Tenerrimumkingsen000No ratings yet

- Art 2Document8 pagesArt 2Erika-Timea NagyNo ratings yet

- SCHAUM Et Al Ny Phosphorus Recovery From Sewage Sludge AshDocument8 pagesSCHAUM Et Al Ny Phosphorus Recovery From Sewage Sludge AshMir Hasib Ul LatifNo ratings yet

- Structural characterisation of Middle Jurassic coals linked to coal seam gasDocument9 pagesStructural characterisation of Middle Jurassic coals linked to coal seam gasMafeGonzalezNo ratings yet

- Adsorption of Heavy Metal Ions From Aqueous Solution by Fly AshDocument5 pagesAdsorption of Heavy Metal Ions From Aqueous Solution by Fly Ashdungnv2733No ratings yet

- Banana Peel Extracts Heavy MetalsDocument6 pagesBanana Peel Extracts Heavy MetalsOgunranti RasaqNo ratings yet

- Calcium Silicate RenewableDocument14 pagesCalcium Silicate RenewableEka PratiwiNo ratings yet

- Preparation and Characterization of Succinylated Starch As Adsorbent For The Removal of PB (II) Ions From Aqueous MediaDocument7 pagesPreparation and Characterization of Succinylated Starch As Adsorbent For The Removal of PB (II) Ions From Aqueous MediaresearchinventyNo ratings yet

- Archaeological Soil and Sediment MicromorphologyFrom EverandArchaeological Soil and Sediment MicromorphologyCristiano NicosiaNo ratings yet

- Carbonates in Continental Settings: Geochemistry, Diagenesis and ApplicationsFrom EverandCarbonates in Continental Settings: Geochemistry, Diagenesis and ApplicationsNo ratings yet

- Modelos de Molinos HPGRDocument11 pagesModelos de Molinos HPGRHugo CarcamoNo ratings yet

- Grinding Ball CriteriaDocument10 pagesGrinding Ball CriteriaHugo CarcamoNo ratings yet

- Ts Alpha Ph190 Rev1Document44 pagesTs Alpha Ph190 Rev1Hugo CarcamoNo ratings yet

- Depresionpiritacon CianuroDocument7 pagesDepresionpiritacon CianuroHugo CarcamoNo ratings yet

- Occurrence of Iron-Titanium Oxides in Igneous Rocks1Document36 pagesOccurrence of Iron-Titanium Oxides in Igneous Rocks1maorui LiuNo ratings yet

- The Jade Enigma: Jill HobbsDocument17 pagesThe Jade Enigma: Jill HobbsOuchyNo ratings yet

- Nickel-Cobalt Laterite Deposits on Maniang IslandDocument7 pagesNickel-Cobalt Laterite Deposits on Maniang IslandAmira SiregarNo ratings yet

- Byron KnelsonDocument8 pagesByron KnelsonJuan Carlos Quintuna EspinNo ratings yet

- 6761.chemistry Selection TableDocument189 pages6761.chemistry Selection Tablejubo123No ratings yet

- Densities of Typical Rock Types and Minerals PDFDocument3 pagesDensities of Typical Rock Types and Minerals PDFbima pribadiNo ratings yet

- Proportions Grading Scales Gia Natural Diamond Grading ReportDocument1 pageProportions Grading Scales Gia Natural Diamond Grading ReportMister JonasNo ratings yet

- BEngTech Mineral Processing 2B Exam GuideDocument3 pagesBEngTech Mineral Processing 2B Exam GuideONNDWELA RAMALAMULANo ratings yet

- EFFECTS OF MINING ON WATER QUALITY AND THE ENVIRONMENT A CASE STUDY OF PARTS OF THE JOS PLATEAU, NORTH CENTRAL NIGERIA 1GYANG, J.D and 2ASHANO, E.CDocument9 pagesEFFECTS OF MINING ON WATER QUALITY AND THE ENVIRONMENT A CASE STUDY OF PARTS OF THE JOS PLATEAU, NORTH CENTRAL NIGERIA 1GYANG, J.D and 2ASHANO, E.Cwilolud9822No ratings yet

- The Role of Clay Minerals IN Influencing Porosity AND Permeability Characteristics in The Bridport Sands of Wytch Farm, DorsetDocument14 pagesThe Role of Clay Minerals IN Influencing Porosity AND Permeability Characteristics in The Bridport Sands of Wytch Farm, DorsetDaniel Mauricio Rojas CaroNo ratings yet

- SIP BibliographyDocument2 pagesSIP BibliographyLakhani PareshNo ratings yet

- Mineral Resource ClassificationDocument5 pagesMineral Resource ClassificationMuhammad OsamaNo ratings yet

- AISI Inco 713 Nickel Alloys - Chemical Composition & Other Alloy PropertiesDocument4 pagesAISI Inco 713 Nickel Alloys - Chemical Composition & Other Alloy PropertiesNovindra Ades WNo ratings yet

- RocksDocument5 pagesRocksangelic dailyNo ratings yet

- Mining Geology and ExplorationDocument17 pagesMining Geology and ExplorationNand Bhagat VidyaNo ratings yet

- Matching Curves Sykes Pumps Coal MineDocument7 pagesMatching Curves Sykes Pumps Coal MineGyan D RenNo ratings yet

- GRAPHITEDocument1 pageGRAPHITEimpetuskolNo ratings yet

- Extension On Prospecting LicenceDocument2 pagesExtension On Prospecting LicenceSherlock MasileNo ratings yet

- Inclusions in Aquamarine From Ambatofotsikely MadagascarDocument4 pagesInclusions in Aquamarine From Ambatofotsikely Madagascarkaveh25100% (1)

- 1 PBDocument5 pages1 PBE4-78Muhamad Afif Alfian IPBNo ratings yet

- Mining Report On BrazilDocument24 pagesMining Report On BrazilKatherine SmithNo ratings yet

- W05 GubelinDocument30 pagesW05 GubelinZoltánSáfár100% (1)

- Gems and Gemmolgy FALL 03 PDFDocument83 pagesGems and Gemmolgy FALL 03 PDFZoltánSáfár100% (2)

- Teachers Program 2022 2023 1Document25 pagesTeachers Program 2022 2023 1Jeffreynald Arante FranciscoNo ratings yet

- IS - 7422 Part-1 1974 AbbrevationsDocument14 pagesIS - 7422 Part-1 1974 AbbrevationsSourabh PalNo ratings yet

- A Compendium of Concrete Aggregates Used in SW EnglandDocument136 pagesA Compendium of Concrete Aggregates Used in SW EnglandPetrolabNo ratings yet

- HOT-SPRING Au-Ag DEPOSITSDocument15 pagesHOT-SPRING Au-Ag DEPOSITSJose Aranibar Aguilar100% (2)

- Haywood Junior Exploration On Juggernaut TSX-V JUGRDocument2 pagesHaywood Junior Exploration On Juggernaut TSX-V JUGRJames HudsonNo ratings yet

- Mineral PDFDocument57 pagesMineral PDFMasuda SultanaNo ratings yet

- Fairly Simple Mineral Identification ExerciseDocument7 pagesFairly Simple Mineral Identification ExerciseJanine Ochea GolesNo ratings yet