Professional Documents

Culture Documents

Application TA 049e

Uploaded by

Diego Fernado AvendañoOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Application TA 049e

Uploaded by

Diego Fernado AvendañoCopyright:

Available Formats

- 1 -

N0. OCT.1988

Oxidation Induction Time

Measurements by DSC

1. Introduction

Polymer is oxidized in the atmosphere including Oxygen which deteriorates mechanical

strength and electrical property. This decomposition by the oxidation starts from the low

temperature than thermal decomposition in the inert gas. For example of Polyethylene, the

oxidation decomposition starts below than 200C in the air to the contrary of the thermal

decomposition from the vicinity of 400C in the Nitrogen gas. For this reason, antioxidizing agent

protecting from oxidization deterioration is added into the polymer such as Polyethylene as the

industrial material.

DSC is one of the evaluation methods of oxidative stability; Oxidation Induction Time (OIT).

The measurement procedure is the followings:

1) Sample is heated in the Nitrogen atmosphere. And temperature is kept at the specified

temperature.

2) Change the atmosphere to the Oxygen.

3) After changing to the Oxygen, the time from the gas change to the observed exothermic

peak is measured.

In this brief, the oxidation induction time (OIT) of Polyethylene (PE) is measured.

Figure 1 Oxidation induction time measurement result for PE at 205C

- 2 -

Figure 3 Cu influences on the oxidation induction time for PE

Isothermal temperature : 205C

2. Measurements

DSC200 is used. Measurement condition is 5mg of sample, isothermal temperature is 200C,

205C, 210C, and 215C. In the Nitrogen and Oxygen atmosphere, the flow rate is 40m/min.

Change from Nitrogen to Oxygen is automatically performed by the programming using gas

controller unit.

3. Results

Figure 1 show the measurement result of the oxidation induction time at 205C for PE. This is

the DSC curve after changing the gas from Nitrogen to Oxygen. During 17 minutes after gas

change, DSC curve does not show any change due to the effect of antioxidizing agent; however,

the exothermic peak appears due to the oxidization after 17 minutes. From this result, the

oxidation induction time of PE at 205C is measured as 17.2 minutes.

Figure 2 Temperature dependence of oxidation induction time for PE

- 3 -

Figure 4 Measurement results of three different grades of PE

Isothermal temperature : 205C

Figure 2 shows the measurement results at the 200C, 205C, 210C, and 215C. The higher

the isothermal temperature is, the shorter the oxidation induction time becomes. Higher

temperature results in a higher rate of oxidization.

Figure 3 shows the analysis of Cu influences on the oxidation induction time for PE. Contrary

to the 17 minutes of oxidation induction time of PE, it is 6 minutes in the case that Cu is

contacted to PE. It shows that Cu accelerates the oxidization reaction of PE. PE is used as a wire

coating material. The oxidation induction time enables the material evaluation considering the

catalyst effect of Cu.

Figure 4 shows the measurement results of three different grades of PE. In this result, C, B, A,

is long, in the order. It shows the oxidation induction time differs depends on the grade of PE.

4. Summary

DSC can analyze the oxidation induction time (OIT). By this method, oxidative stability of

various polymer materials can be evaluated effectively.

You might also like

- Ignition and Devolatilization of Pulverized Bituminous Coal Particles During Oxygen Carbon Dioxide Coal CombustionDocument8 pagesIgnition and Devolatilization of Pulverized Bituminous Coal Particles During Oxygen Carbon Dioxide Coal CombustionthinhklNo ratings yet

- Benz JapanDocument5 pagesBenz JapanDert Nero ErthNo ratings yet

- Journal of Industrial and Engineering Chemistry: Hiroshi Yamada, Hiromasa Mori, Tomohiko TagawaDocument3 pagesJournal of Industrial and Engineering Chemistry: Hiroshi Yamada, Hiromasa Mori, Tomohiko TagawaNiammMbladdushNo ratings yet

- THE EFFECT OF FOAMY SLAG IN THE ELECTRIC ARC FURNACES ON ELECTRIC Energy Consumption PDFDocument10 pagesTHE EFFECT OF FOAMY SLAG IN THE ELECTRIC ARC FURNACES ON ELECTRIC Energy Consumption PDFManojlovic VasoNo ratings yet

- Effect of MoistureDocument10 pagesEffect of Moisturemukesh vikramNo ratings yet

- CT 02 - Salbidegoitia Et AlDocument3 pagesCT 02 - Salbidegoitia Et AlJon Bisu DebnathNo ratings yet

- Modernization of Unit For Elimination of Vocs by Catalytic OxidationDocument6 pagesModernization of Unit For Elimination of Vocs by Catalytic Oxidationoverlord5555No ratings yet

- Activation Energy of An Ionic ReactionDocument10 pagesActivation Energy of An Ionic ReactionBazil Bolia100% (1)

- CARBOTHERMAL REDUCTIONDocument7 pagesCARBOTHERMAL REDUCTIONIbrahim MücahitNo ratings yet

- The Reactivity and Kinetics of Yanzhou Coal Chars From Elevated Pyrolysis Temperatures During Gasification in Steam at 900 - 120088888CDocument9 pagesThe Reactivity and Kinetics of Yanzhou Coal Chars From Elevated Pyrolysis Temperatures During Gasification in Steam at 900 - 120088888CAlfiDahliaArofaniNo ratings yet

- OIT Polyolefins DSC PDFDocument16 pagesOIT Polyolefins DSC PDFM. Shoaib100% (1)

- Case Study of Converter Performance Evaluation On Sulfuric Acid ProductionDocument5 pagesCase Study of Converter Performance Evaluation On Sulfuric Acid Productionhafidz maNo ratings yet

- Ijaiem 2014 01 15 029Document8 pagesIjaiem 2014 01 15 029International Journal of Application or Innovation in Engineering & ManagementNo ratings yet

- MAXWELL Oxygen Probe Is An Entirely New Method of Measuring Oxygen in Hot GasesDocument6 pagesMAXWELL Oxygen Probe Is An Entirely New Method of Measuring Oxygen in Hot GasesmichaelNo ratings yet

- Coke Quality and Thermal Reserve Zone PDFDocument6 pagesCoke Quality and Thermal Reserve Zone PDFhalder_kalyan9216No ratings yet

- CatalDocument16 pagesCatalSoumyadeep PaulNo ratings yet

- Mechanism of CO Formation in Reverse Water-Gas Shift Reaction Over Cu/Al O CatalystDocument4 pagesMechanism of CO Formation in Reverse Water-Gas Shift Reaction Over Cu/Al O CatalystUmesh Kumar Sharma RamamoorthiNo ratings yet

- AC Catalst PTDocument5 pagesAC Catalst PTJarretNo ratings yet

- CEMENT PROCESS ENGINEERING VADE-MECUM SECTION 7 - NOX, SOX, DUST, CO2 EMISSION GUIDEDocument14 pagesCEMENT PROCESS ENGINEERING VADE-MECUM SECTION 7 - NOX, SOX, DUST, CO2 EMISSION GUIDEMKPashaPashaNo ratings yet

- Mimura2000 PDFDocument6 pagesMimura2000 PDFVARUN JAGANNATH KAUSHIKNo ratings yet

- 3syngas in Perspective - Rostrup-Nielsen, J. R. Catalysis Today, 2002, 71, (3-4), 243-247 (2003) (10.1016 - s0140-6701 (03) 90583-2) - Libgen - LiDocument1 page3syngas in Perspective - Rostrup-Nielsen, J. R. Catalysis Today, 2002, 71, (3-4), 243-247 (2003) (10.1016 - s0140-6701 (03) 90583-2) - Libgen - Liamerico molinaNo ratings yet

- A014 PDFDocument18 pagesA014 PDFRastraPatriaNo ratings yet

- Highly Preheated Air Combustion Research in Sweden: Blasiak W, Dong W, Lille SDocument18 pagesHighly Preheated Air Combustion Research in Sweden: Blasiak W, Dong W, Lille SSaptarshi SenguptaNo ratings yet

- 2011 - Reduction of Carbon Dioxide in Hydrothermal Craking of Polymer WastesDocument4 pages2011 - Reduction of Carbon Dioxide in Hydrothermal Craking of Polymer WastesMaría Andérez FernándezNo ratings yet

- Synthesis GasDocument8 pagesSynthesis GasTotok IswantoNo ratings yet

- JNS1119381648841400Document12 pagesJNS1119381648841400nugrohoNo ratings yet

- Ignition and Combustion Reaction: Hisao Makino, Hirofumi Tsuji, and Ryoichi KuroseDocument5 pagesIgnition and Combustion Reaction: Hisao Makino, Hirofumi Tsuji, and Ryoichi Kurosehuyphuca2No ratings yet

- Vol41 1Document509 pagesVol41 1Gaurav AcharyaNo ratings yet

- Process Simulation of An Integrated Coke Dry Quenching Combined GasificationDocument8 pagesProcess Simulation of An Integrated Coke Dry Quenching Combined GasificationSaurabh ShashankNo ratings yet

- CO2 Adsorption Method Using Fixed BedDocument5 pagesCO2 Adsorption Method Using Fixed Bedsmastic8884985No ratings yet

- Waste CFB CombustionDocument15 pagesWaste CFB CombustionmihugirNo ratings yet

- MET 49 2 79 82 TerpakDocument4 pagesMET 49 2 79 82 Terpaknaser hasan fauziNo ratings yet

- Specific Heat Capacity of Lithium Polymer Battery Components: Thermochimica Acta June 2003Document7 pagesSpecific Heat Capacity of Lithium Polymer Battery Components: Thermochimica Acta June 2003Arghya MukherjeeNo ratings yet

- Kinetic Feasibility of A Chemical Heat Pump For Heat Utilization of High TemperatureDocument16 pagesKinetic Feasibility of A Chemical Heat Pump For Heat Utilization of High TemperaturededyNo ratings yet

- Che3190 f2023 Reactordesignproject FinalreportDocument11 pagesChe3190 f2023 Reactordesignproject Finalreportapi-538155231No ratings yet

- CO Oxidation Studied Using Fast' XPS and A Molecular Beam ReactorDocument4 pagesCO Oxidation Studied Using Fast' XPS and A Molecular Beam ReactorDwi WidyawatiNo ratings yet

- An Experimental Investigation of A Flue GasDocument9 pagesAn Experimental Investigation of A Flue GasmichaelNo ratings yet

- Production of Lithium Oxide by Decomposition Lithium Carbonate in The Flow of A Heat CarrierDocument6 pagesProduction of Lithium Oxide by Decomposition Lithium Carbonate in The Flow of A Heat CarrierArdu StuffNo ratings yet

- ScriptDocument6 pagesScriptNaufal MuflihNo ratings yet

- Autothermal Reforming ProcessDocument9 pagesAutothermal Reforming ProcessOliver Everett EspinoNo ratings yet

- Bachelor Thesis WielendDocument38 pagesBachelor Thesis Wielendaq10thNo ratings yet

- Comparative Study Between Fluidized Bed and Fixed Bed ReactorsDocument14 pagesComparative Study Between Fluidized Bed and Fixed Bed Reactorsanon_982022273No ratings yet

- BF ThermoDocument5 pagesBF ThermoLucky AliNo ratings yet

- Hydrogen From SMR 1Document2 pagesHydrogen From SMR 1Pramanshu RajputNo ratings yet

- Anisotropic Injection Molding of Strontium Ferrite Using PP/PEG BinderDocument3 pagesAnisotropic Injection Molding of Strontium Ferrite Using PP/PEG BinderAmina DinariNo ratings yet

- Combined Steam and CO Reforming of Methane Using Catalytic Nickel Membrane For Gas To Liquid (GTL) ProcessDocument8 pagesCombined Steam and CO Reforming of Methane Using Catalytic Nickel Membrane For Gas To Liquid (GTL) ProcessKeysler PonceNo ratings yet

- Azargohar 2005Document7 pagesAzargohar 2005gueabdelkaderNo ratings yet

- Energies: A Predictive Model For Coal Coking Based On Product Yield and Energy BalanceDocument16 pagesEnergies: A Predictive Model For Coal Coking Based On Product Yield and Energy BalanceRutens NdreaNo ratings yet

- Effect of Hydrogen Addition On Reduction Kinetics of Iron Oxides in Gas-Injection BFDocument9 pagesEffect of Hydrogen Addition On Reduction Kinetics of Iron Oxides in Gas-Injection BFПолина СмирноваNo ratings yet

- Zirconia-Supported Copper Catalysts Show High NO-CO Reaction Activity at Low TemperaturesDocument7 pagesZirconia-Supported Copper Catalysts Show High NO-CO Reaction Activity at Low TemperaturesLucas MarchiniNo ratings yet

- MW 12Document8 pagesMW 12dio prabowoNo ratings yet

- Carbon-Hydrogen-Type PolymersDocument29 pagesCarbon-Hydrogen-Type PolymersEvansChombaNo ratings yet

- Evaporation (Lab Report)Document5 pagesEvaporation (Lab Report)Ynno0% (1)

- Effect of EgrDocument10 pagesEffect of EgrSumit JainNo ratings yet

- Char Formation and Gas Products of Woody Biomass PyrolysisDocument8 pagesChar Formation and Gas Products of Woody Biomass Pyrolysisb186No ratings yet

- Feasibility of In-Situ Combustion of Tar From A Tarmat ReservoirDocument16 pagesFeasibility of In-Situ Combustion of Tar From A Tarmat ReservoirReservorio UagrmNo ratings yet

- Coke Formation in The Thermal CrackinDocument7 pagesCoke Formation in The Thermal Crackinfaez100% (1)

- 38.3 Electrical Cable Fire ToxicityDocument32 pages38.3 Electrical Cable Fire ToxicityRichard HollidayNo ratings yet

- EPL-0001009 ArticleDocument9 pagesEPL-0001009 ArticleArief M FirdausNo ratings yet

- Combustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasFrom EverandCombustion of Pulverised Coal in a Mixture of Oxygen and Recycled Flue GasNo ratings yet

- Top 10 Management Skills You NeedDocument5 pagesTop 10 Management Skills You NeedDiego Fernado AvendañoNo ratings yet

- MD 1Document31 pagesMD 1Anonymous mzF3JvyTJsNo ratings yet

- Vol 35 Issue 73Document20 pagesVol 35 Issue 73Diego Fernado AvendañoNo ratings yet

- Media Web ServerDocument2 pagesMedia Web ServerDiego Fernado AvendañoNo ratings yet

- Galvanizing Note1Document7 pagesGalvanizing Note1pandey008No ratings yet

- Emissivity Measurements of Common Construction MaterialsDocument9 pagesEmissivity Measurements of Common Construction MaterialsDiego Fernado AvendañoNo ratings yet

- Sheet Steel Gauges - What They Mean 2009 PDFDocument2 pagesSheet Steel Gauges - What They Mean 2009 PDFDiego Fernado AvendañoNo ratings yet

- 10 Mistakes Doctoral Students Avoid for SuccessDocument26 pages10 Mistakes Doctoral Students Avoid for SuccessDiego Fernado AvendañoNo ratings yet

- Galvanizing Note1Document7 pagesGalvanizing Note1pandey008No ratings yet

- ASTM D256 TITLEDocument3 pagesASTM D256 TITLEDiego Fernado AvendañoNo ratings yet

- White Paper How To Ensure Accurate Fire Code Reporting of Your Chemical InventoryDocument18 pagesWhite Paper How To Ensure Accurate Fire Code Reporting of Your Chemical InventoryDiego Fernado AvendañoNo ratings yet

- Fatigue PolymersDocument1 pageFatigue PolymersglihkrNo ratings yet

- Interpretation of DSCDocument28 pagesInterpretation of DSCgreghesNo ratings yet

- Weathering PresentationDocument32 pagesWeathering PresentationDiego Fernado AvendañoNo ratings yet

- Vol 35 Issue 75Document20 pagesVol 35 Issue 75Diego Fernado AvendañoNo ratings yet

- Vol 36 Issue 78Document20 pagesVol 36 Issue 78Diego Fernado AvendañoNo ratings yet

- Vol 35 Issue 74Document20 pagesVol 35 Issue 74Diego Fernado Avendaño100% (1)

- Weathering PresentationDocument32 pagesWeathering PresentationDiego Fernado AvendañoNo ratings yet

- Vol 35 Issue 73Document20 pagesVol 35 Issue 73Diego Fernado AvendañoNo ratings yet

- Zeus Weathering of PlasticsDocument7 pagesZeus Weathering of PlasticsDiego Fernado AvendañoNo ratings yet

- HDT 3 & 6 VICAT Instrument for Quality Control TestingDocument6 pagesHDT 3 & 6 VICAT Instrument for Quality Control TestingDiego Fernado AvendañoNo ratings yet

- Uv WeatheringDocument12 pagesUv WeatheringDiego Fernado AvendañoNo ratings yet

- Fg52 Berstdruck EnglischDocument2 pagesFg52 Berstdruck EnglischDiego Fernado AvendañoNo ratings yet

- XRD ArcillaDocument2 pagesXRD ArcillaDiego Fernado AvendañoNo ratings yet

- Bus Interior Fire Test Methods ComparisonDocument12 pagesBus Interior Fire Test Methods ComparisonDiego Fernado AvendañoNo ratings yet

- Positive Material IdentificationDocument1 pagePositive Material IdentificationDiego Fernado AvendañoNo ratings yet

- X RayDiffractionDocument123 pagesX RayDiffractionDiego Fernado AvendañoNo ratings yet

- Tunneling Microscopy and Spectroscopy: L. J. W, Naval Research Laboratory, Washington, DC 20375-5342Document23 pagesTunneling Microscopy and Spectroscopy: L. J. W, Naval Research Laboratory, Washington, DC 20375-5342Diego Fernado AvendañoNo ratings yet

- Thermo Electron 14Document2 pagesThermo Electron 14Diego Fernado AvendañoNo ratings yet

- Quanto DeskDocument4 pagesQuanto DeskDiego Fernado AvendañoNo ratings yet

- # 6030 PEN OIL: Grade: Industrial Grade Heavy Duty Penetrating OilDocument3 pages# 6030 PEN OIL: Grade: Industrial Grade Heavy Duty Penetrating OilPrakash KumarNo ratings yet

- 2 Biogas Kristianstad Brochure 2009Document4 pages2 Biogas Kristianstad Brochure 2009Baris SamirNo ratings yet

- Letter To Local Residents From Sutton Council Re. Lidl Development To Replace Matalan Ref DM2019-02113 10 January 2020Document5 pagesLetter To Local Residents From Sutton Council Re. Lidl Development To Replace Matalan Ref DM2019-02113 10 January 2020etajohnNo ratings yet

- Rising Stem Ball ValveDocument6 pagesRising Stem Ball ValveAnupam A. GandhewarNo ratings yet

- Jotafloor SL UniversalDocument6 pagesJotafloor SL UniversalrogandatambunanNo ratings yet

- FC Vs FBDocument8 pagesFC Vs FBMiguel SanchesNo ratings yet

- CH Sravan KumarDocument5 pagesCH Sravan KumarJohnNo ratings yet

- August 2017Document72 pagesAugust 2017Treatment Plant Operator MagazineNo ratings yet

- Microstructures and Mechanical Properties of Ultrafine Grained Pure Ti Produced by Severe Plastic DeformationDocument10 pagesMicrostructures and Mechanical Properties of Ultrafine Grained Pure Ti Produced by Severe Plastic Deformationsoni180No ratings yet

- Ficha Tecnica 750 GPMDocument156 pagesFicha Tecnica 750 GPMByron Chele0% (2)

- ANR causes and solutionsDocument2 pagesANR causes and solutionsPRAKHAR SRIVASTAVANo ratings yet

- V 2172 0020 0031 - Rev - 6 (3458748) PDFDocument262 pagesV 2172 0020 0031 - Rev - 6 (3458748) PDFLG Milton LuisNo ratings yet

- Hublit Limphaire Leaflet India PDFDocument2 pagesHublit Limphaire Leaflet India PDFAkshay RaiNo ratings yet

- Plett DawsonDocument270 pagesPlett DawsonRaghu0% (1)

- CV Ali EzzeddineDocument3 pagesCV Ali EzzeddineOmar RajadNo ratings yet

- Abstracts Book Nanotech 2013Document151 pagesAbstracts Book Nanotech 2013felipe de jesus juarez torresNo ratings yet

- Sitsyll PDFDocument57 pagesSitsyll PDFpreranaNo ratings yet

- Newsletter Template NewDocument4 pagesNewsletter Template Newapi-458544253No ratings yet

- F1FR80 Series Quick-Response SprinklersDocument6 pagesF1FR80 Series Quick-Response SprinklersAtila AmayaNo ratings yet

- Enclosed Product Catalogue 2012Document24 pagesEnclosed Product Catalogue 2012Jon BerryNo ratings yet

- Vlsi Implementation of Integer DCT Architectures For Hevc in Fpga TechnologyDocument12 pagesVlsi Implementation of Integer DCT Architectures For Hevc in Fpga TechnologyRaghul VishnuNo ratings yet

- Fire Pump ChecklistDocument11 pagesFire Pump ChecklistLD Jr FrancisNo ratings yet

- Designing The Marketing Channels 13Document13 pagesDesigning The Marketing Channels 13Gajender SinghNo ratings yet

- India's Growing Social Media Landscape and Future TrendsDocument5 pagesIndia's Growing Social Media Landscape and Future Trendspriyaa2688No ratings yet

- BSC Prospectus 2019-20Document37 pagesBSC Prospectus 2019-20Gaurav VamjaNo ratings yet

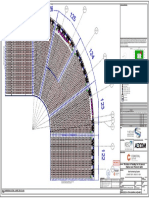

- SE01 SE04 SE03 SE02 E14 E13: As BuiltDocument1 pageSE01 SE04 SE03 SE02 E14 E13: As BuiltgenricNo ratings yet

- 176Document3 pages176Karthik AmigoNo ratings yet

- EOG Project2010Document34 pagesEOG Project2010Amey Kadam100% (2)

- Oracle Baseline Security ChecklistDocument15 pagesOracle Baseline Security ChecklistChidi OkerekeNo ratings yet

- Form 1 Lesson 88 SpeakingDocument2 pagesForm 1 Lesson 88 Speakinga multifandom fangirlNo ratings yet