Professional Documents

Culture Documents

Attachment - 2 - ASSOA Technical FAQ No. 1

Uploaded by

Mihir Jha0 ratings0% found this document useful (0 votes)

19 views1 pageCS to SS Welding

Original Title

Attachment_2__ASSOA Technical FAQ No. 1

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCS to SS Welding

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

19 views1 pageAttachment - 2 - ASSOA Technical FAQ No. 1

Uploaded by

Mihir JhaCS to SS Welding

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 1

Contact between dissimilar metals

occurs frequently but is often not

a problem. The aluminium head

on a cast iron block, the solder on

a copper pipe, galvanising on a

steel purlin and the steel fastener

in an aluminium sheet are common

examples.

WHAT CAUSES GALVANIC

CORROSION?

For galvanic or dissimilar or

electrolytic corrosion to occur,

three conditions must be met:

the metal join must be wet

with a conductive liquid

there must be metal to metal contact

the metals must have sufficiently

different potentials.

Wetting the join

The conductive liquid (or electrolyte) could

be rainwater or water absorbed into

surface deposits if the relative humidity

(RH) is high enough or even simple

condensation. If the deposits are sea salt,

then they will start to dissolve if the RH

exceeds 34% because of the magnesium

chloride. The greater the conductivity the

more severe the galvanic effects. Salt or

industrial pollution significantly increases

the conductivity of water so galvanic

effects are normally more severe near the

coast or in heavy industrial areas. Low

conductivity, pure rainwater will only cause

slight galvanic effects. One complication is

that during evaporation, water films

become more conductive so initially

benign water may cause quite active

galvanic effects as the liquid in the crevice

under a bolt or clamp becomes more

concentrated. Water may be excluded by

design or the use of adhesive sealants or

by painting the noble metal for 30 to

50mm beyond the join to prevent charged

atom (ion) transport in any thin water film.

Painting the active metal (carbon steel or

aluminium or zinc) can cause deep holes

at coating defects.

Metal to metal contact

Galvanic corrosion can only occur if the

dissimilar metals are in electrical contact.

The contact may be direct or by an

external pipe or wire or bolt. If the

dissimilar metals are insulated from each

other by suitable plastic strips, washers or

sleeves then galvanic corrosion cannot

occur. Paint is not a reliable electrical

insulator especially under bolt heads or

nuts or washers or near edges of sheets of

metal. The paint is usually damaged on

installation or by subsequent movement.

Note that the chromium oxide film layer

on the stainless steel is very thin and not

an electrical insulator. Therefore the

chromium oxide film will not prevent

galvanic corrosion.

Potential differences

All metals dissolve to some extent when

they are wetted with a conductive liquid.

The degree of dissolution is greatest with

active or sacrificial metals such as

magnesium and zinc and they have the

most negative potential. In contrast, noble

or passive metals such as gold or graphite

are relatively inert and have a more

positive potential. Stainless steel is in the

middle although it is more noble than

carbon steel. The potential can be

measured with a reference electrode and is

used to construct a galvanic series as

shown on page 2 (ASTM Standard G82).

When two metals are connected and in

contact with a conducting liquid, the more

active metal will corrode and protect the

noble metal. Zinc is more negative than

steel and so the zinc coating of galvanised

steel will corrode to protect the steel at

scratches or cut edges. The stainless steels,

including 304 and 316, are more positive

than zinc and steel, so when stainless steel

is in contact with galvanised steel and is

wet, the zinc will corrode first, followed by

the steel, while the stainless steel will be

protected by this galvanic activity and will

not corrode. The rate of galvanic attack is

governed by the size of the potential

difference.

The graph shows that stainless steels have

two ranges of potential. The usual, passive

behaviour is shown by the light hatching.

However, if the passive film breaks down,

the stainless steel corrodes and its

potential is in the dark bar range.

As a rule of thumb, if the potential

difference is less than 0.1 volt, then it is

unlikely that galvanic corrosion will be

significant.

If all three conditions are met then

galvanic corrosion is probable and the rate

of corrosion will be influenced by the

relative area and the current density

delivered by the noble metal.

RELATIVE WETTED SURFACE

AREA

If a noble metal like stainless steel has a

large surface area in contact with the

electrolyte while the sacrificial metal (such

as aluminium) has a very small surface area

in contact with the electrolyte, then the

stainless steel will generate a large

corrosion current which will be

concentrated on a small area of sacrificial

metal. The aluminium will corrode quickly

first the aluminium then the underlying

steel and so aluminium fasteners in

stainless steel are not acceptable. However,

a stainless screw in aluminium is frequently

used although corrosion of the aluminium

immediately around the stainless is quite

possible. This is because the ratio of

wetted noble fastener in an active metal

might change from a 1:50 ratio to 1:1

during drying after a rainstorm. If

contaminants are significant this means

that avoiding dissimilar metal pairs may be

a preferred option to prevent galvanic

attack.

As a rule of thumb, if the wetted area of

the corroding metal is 10 times the wetted

area of the noble metal, then galvanic

effects are not serious although the larger

the ratio the less the effect.

GALVANIC/DISSIMILAR METAL CORROSION

What it is and how to avoid it

1

ASSDA

Technical FAQ No 1

Edition 2, May 2009

AUSTRALIAN STAINLESS STEEL DEVELOPMENT ASSOCIATION

Attachment # 2

You might also like

- IndianOils Paradip Refinery: Dedicated in The Service of The Nation (Company Update)Document7 pagesIndianOils Paradip Refinery: Dedicated in The Service of The Nation (Company Update)Shyam SunderNo ratings yet

- Flexitallic Spiral Wound Gasket MaterialsDocument1 pageFlexitallic Spiral Wound Gasket Materialsmihir_jha2No ratings yet

- FoodDocument2 pagesFoodMihir JhaNo ratings yet

- Payment ReceiptDocument1 pagePayment ReceiptAnjan Debnath75% (4)

- M&Y Values 1-2010Document7 pagesM&Y Values 1-2010mihir_jha2No ratings yet

- Galvanic CorrosionDocument2 pagesGalvanic CorrosionkeronsNo ratings yet

- Korea Seal Tech Gasket GuideDocument42 pagesKorea Seal Tech Gasket Guidemihir_jha2No ratings yet

- Stainless: Steels - Propert,'c.s 8: U.5e-S. . 1 - WC - .-.7Document1 pageStainless: Steels - Propert,'c.s 8: U.5e-S. . 1 - WC - .-.7Mihir JhaNo ratings yet

- Payment ReceiptDocument1 pagePayment ReceiptAnjan Debnath75% (4)

- Ywxz G G Gag O P G : ̰G G G G G G G G R - Thypgrhs Hup - /WXW) T) QQQQQQDocument5 pagesYwxz G G Gag O P G : ̰G G G G G G G G R - Thypgrhs Hup - /WXW) T) QQQQQQMihir JhaNo ratings yet

- Flexitallic Spiral Wound Gasket MaterialsDocument1 pageFlexitallic Spiral Wound Gasket Materialsmihir_jha2No ratings yet

- Galvanic CorrosionDocument2 pagesGalvanic CorrosionkeronsNo ratings yet

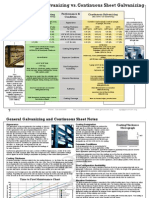

- Hot-Dip Galvanizing Vs Continuous Sheet GalvanizingDocument2 pagesHot-Dip Galvanizing Vs Continuous Sheet GalvanizingMihir JhaNo ratings yet

- Ywxz G G Gag O P G : ̰G G G G G G G G - Ywxy) T/QQQQQQDocument3 pagesYwxz G G Gag O P G : ̰G G G G G G G G - Ywxy) T/QQQQQQMihir JhaNo ratings yet

- Coal ImpagesDocument1 pageCoal ImpagesMihir JhaNo ratings yet

- Glass Reinforced Plastic Vessels and Tanks: Guidance Note PM75 (Third Edition)Document18 pagesGlass Reinforced Plastic Vessels and Tanks: Guidance Note PM75 (Third Edition)Syed Arsalan Afsar100% (2)

- en 10204 2004 BDocument4 pagesen 10204 2004 BblaireauxxNo ratings yet

- High Performance Butterfly ValvesDocument8 pagesHigh Performance Butterfly ValvesTejas JasaniNo ratings yet

- The Coal Resource, A Comprehensive Overview of Coal (World Coal Institute)Document48 pagesThe Coal Resource, A Comprehensive Overview of Coal (World Coal Institute)alabamacoal100% (1)

- The Coal Resource, A Comprehensive Overview of Coal (World Coal Institute)Document48 pagesThe Coal Resource, A Comprehensive Overview of Coal (World Coal Institute)alabamacoal100% (1)

- Hot-Dip Galvanizing Vs Continuous Sheet GalvanizingDocument2 pagesHot-Dip Galvanizing Vs Continuous Sheet GalvanizingMihir JhaNo ratings yet

- API Tank DesignDocument189 pagesAPI Tank DesignDD3NZ91% (11)

- Hvu HasDocument9 pagesHvu Hassri_amartNo ratings yet

- Flare SystemDocument68 pagesFlare SystemMihir JhaNo ratings yet

- API Tank DesignDocument189 pagesAPI Tank DesignDD3NZ91% (11)

- EPA 450 TankDocument102 pagesEPA 450 TankMihir JhaNo ratings yet

- Sprinkler SystemDocument9 pagesSprinkler Systempetroyston909937No ratings yet

- Hvu HasDocument9 pagesHvu Hassri_amartNo ratings yet

- Single Pass AES Exchanger-1Document1 pageSingle Pass AES Exchanger-1Mihir JhaNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5782)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- QSHE Dashboard GBU 2018.09Document218 pagesQSHE Dashboard GBU 2018.09Syerifaizal Hj. MustaphaNo ratings yet

- Gulf Steel Works Assembly ListDocument36 pagesGulf Steel Works Assembly ListLalit Bom MallaNo ratings yet

- Cal Land Engineering, Inc. Dba Quartech Consultants: April 18, 2011 Parkway Investment, LLCDocument20 pagesCal Land Engineering, Inc. Dba Quartech Consultants: April 18, 2011 Parkway Investment, LLC63223118No ratings yet

- Bearings BookDocument96 pagesBearings BookLaurence Green100% (8)

- STEAM-PIPES AND FITTINGS REGULATIONSDocument7 pagesSTEAM-PIPES AND FITTINGS REGULATIONSRajivharolikar100% (2)

- Selecto Fixe mk3Document28 pagesSelecto Fixe mk3voisinNo ratings yet

- Saes K 002Document9 pagesSaes K 002mika cabelloNo ratings yet

- Rebuilding in Post Gorkha Earthquake Nepal: Mainstreaming Resilience of SchoolsDocument40 pagesRebuilding in Post Gorkha Earthquake Nepal: Mainstreaming Resilience of SchoolsHarry PoterNo ratings yet

- Study On Settlement Characteristics of Combined Pile Raft Foundation Founded On Sand With Various Arrangements of Piles Using Plaxis-3DDocument8 pagesStudy On Settlement Characteristics of Combined Pile Raft Foundation Founded On Sand With Various Arrangements of Piles Using Plaxis-3DRyan WijayaNo ratings yet

- Troubleshooting HYDRAULICSDocument62 pagesTroubleshooting HYDRAULICSamguna4056100% (3)

- Aspect North Brightwater Property ReportDocument62 pagesAspect North Brightwater Property ReportMick MillanNo ratings yet

- DSD 200 Compressor Parts Manual Sections and ComponentsDocument17 pagesDSD 200 Compressor Parts Manual Sections and ComponentsatsarcomprimidoNo ratings yet

- 6oilccopdngglobal2152008 Voll III 20piping 20 20 MechanicalDocument643 pages6oilccopdngglobal2152008 Voll III 20piping 20 20 Mechanicaldinesh2u85No ratings yet

- Future of Construction IndustryDocument2 pagesFuture of Construction IndustryPratik MaudgalNo ratings yet

- Flat Slab ExampleDocument103 pagesFlat Slab ExampleShishir Kumar Nayak100% (3)

- Eurodrip KatalougeDocument4 pagesEurodrip KatalougebhupsjangirNo ratings yet

- Astoria 52: Alfresco Meals BalconyDocument2 pagesAstoria 52: Alfresco Meals BalconyindyanexpressNo ratings yet

- GFC Set of DrawingsDocument11 pagesGFC Set of DrawingsVaishali SalveNo ratings yet

- Steposol MET-10U: Technical InformationDocument3 pagesSteposol MET-10U: Technical Informationpkh29No ratings yet

- Residential Electrical Wiring SafetyDocument3 pagesResidential Electrical Wiring SafetyAt Home DIY Repair TipsNo ratings yet

- 190326quadax Valves Coating SpecificationsDocument5 pages190326quadax Valves Coating SpecificationsS MhNo ratings yet

- PCAB Renewal Form-2019 PDFDocument24 pagesPCAB Renewal Form-2019 PDFAlan Zenith100% (5)

- CHIREC INTERNATIONAL SCHOOL MEP SHOP DRAWING TRACKER-26.05.2023 FinalDocument15 pagesCHIREC INTERNATIONAL SCHOOL MEP SHOP DRAWING TRACKER-26.05.2023 FinalMansoor KhanNo ratings yet

- M S S P A: 2018 ICC G4 Guideline For CommissioningDocument75 pagesM S S P A: 2018 ICC G4 Guideline For Commissioningvin ssNo ratings yet

- Ete Esterdan FM BicapaDocument15 pagesEte Esterdan FM BicapaRubiiKzzNo ratings yet

- Engineers House Fire Fighting Course FP 03Document92 pagesEngineers House Fire Fighting Course FP 03Mahmoud Abdelghafar ElhussienyNo ratings yet

- Lake George Septic System Maintnance FlyerDocument2 pagesLake George Septic System Maintnance Flyerlrosenthal6680No ratings yet

- Materials 13 04110Document23 pagesMaterials 13 04110Boy AlfredoNo ratings yet

- Detail Praxis - Timber ConstructionDocument55 pagesDetail Praxis - Timber Constructionarch.soares6030No ratings yet

- Vertical glandless pump installation guideDocument22 pagesVertical glandless pump installation guideYoutube For EducationNo ratings yet