Professional Documents

Culture Documents

PCT100

Uploaded by

lockas222Original Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

PCT100

Uploaded by

lockas222Copyright:

Available Formats

Bytronic Ltd PCT-100-PL0111

P Pr ro oc ce es ss s C Co on nt tr ro ol l T Te ec ch hn no ol l o og gy y P PC CT T- -1 10 00 0

Key Features:

Control and Measurement of Temperature,

Level, Pressure and Flow

PID control PC SCADA type software with

Control and Data Acquisition

LCD meters and LEDs provides instant

information

Mimic of the rig on the control console

Test and measurement points for the

transducers and fault insertion switches

Connection to PC through a USB

Control Console can be connected to either

PC or a PLC

Clear Process Tank and pipes

The PCT-100, Process Control Technology unit, is a fully integrated, self-contained bench top apparatus consisting of a

Process Module, and a Control Console with a built in power supply. A Windows based software with full control and

data acquisition is included. A number of experiments in process control are included covering Flow, Level, Pressure,

Temperature, and combinations of the processes.

The Control Console is easily connected to a PC using the USB connection or to a PLC using a D type connector. The

Console has a mimic of the Process Module on the front and includes fault switches, and test points from all of the

transducers. Level is measured using a 0 to10v Magnetostrictive sensor; pressure is measured using a Gage 0 to 5bar

sensor and Flow using A turbine flow rate sensor. PT1000 are used to measure temperature in both the sump and process

tank. A diverter valve can be used to direct the liquid through a forced air cooling process to cool the liquid in the system.

Two proportional valves are used to control flow in to and out of the process tank, a manually adjustable needle valve is

used to add disturbances to the system and a pressure relief valve fitted for safety.

Data is displayed on the five LCD displays fitted to the Process Module, and through the software data can be monitored,

saved or printed. The software has a PID controller with Supervisory Control and Data Acquisition and trending features.

Curriculum Coverage

Introduction

On/off control

Open loop control

Closed loop control

Basic control principles

1st. order systems

Transfer functions

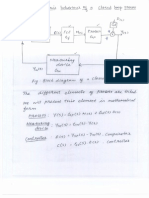

Block diagrams

Assessment of system

performance

Transient responses

Control system instability

Final value theorem

The Routh-Hurwitz test

Bode plots

Bode phase lag versus

frequency plot

Nyquist plots

Process modelling

Process models from step

data tests

Process models from

frequency response tests

Process models from time

domain tests

PID controllers

Proportional control term

Integral control term

Derivative control term

Multi term control

Ziegler Nichols tuning

Digital control

The analysis of digital control

systems

Pulse transfer functions

Z transform initial and final

value theorems

Stability of sampled data

control systems

Inverse Z transformations

Digital controllers

Digital three term controller

The effects of sampling time

Use of simulation

Labworks

Proportional control

Proportional and integral control

Saturation and integral windup

Three term or PID control

Ziegler / Nichols tuning

Temperature control

Fluid level control

Open loop control

Bode plots

Flow loop model using Caldwells method

Flow loop model using Sundaresans method

Design of controller for PCT-100 flow loop.

Bytronic Ltd PCT-100-PL0111

Process Module

Sump Tank Volume 8 Litres

Process Tank Volume 4.5 Litres

Maximum Flow Rate ~ 3 Litres per minute

Heating Element Power 48v dc 400W

Control Elements 2 x 24V d.c. Proportional Valves

1 x Manually Adjustable Disturbance Needle Valve with Incremental Markings

1 x Finger Type Drain Valve

Pressure Transducer 0 to 5 bar

Level Transducer Magnetostrictive Position Sensor

Flow Transducer

Operating pressure

Burst pressure

Operating temperature

Input power

Accuracy

Repeatability

Flow range

Turbine Flow Rate Sensor

14 bar maximum

170 bar

-20C to 100C (ambient +80C for cable)

5 to 24 VDC @ 8mA

3% of reading

0.5% of full scale

Litres per Minute 0.5 to 5

Temperature Transducers 2 x Pt1000 Platinum Resistance Thermometers

Pump 24v 6 Litres per minute with 1.5 bar safety cut-out

Safety Switch 3 bar Cracking Valve

Cooling System Radiator with Forced Air Cooling

Number of LCD Displays 5 x Fluid Level: Process Tank and Sump Tank Temperature: Pressure Level and Flow Rate

Indicators 4 x Heater On: Drain Valve Open: Diverter Solenoid Active and Cooler Active

Connections 1 x 15 way D Connector and 1 x 25 way D Connector

1 x Power Connector for Heater

Control Console

Fault switches 6 x Illuminated Push to Latch, (self resetting on power off)

Front of Console Graphical representation of Process Module

Test Points 5 x Heater Output; Level Output; Sump Tank and Process Tank Temperature Output, Flow Rate

Indicators 6 x Heater On; Drain Valve Open; Flow and Diverter Solenoid Active; Pump Active and Cooler Active

Connections 1 x 15 way D Connector and 1 x 25 way D Connector

1 x Power Connector for Heater

1 x USB connection for PC

1 x Mains power connector

Power Supply voltage 100-250V AC @ 50/60Hz.

Software

Windows based SCADA type software and interface with data logging, printing and saving features

Weights and Dimensions

Un-Packed

Approximate

Dimensions (mm)

Approximate

Weights

Module (Rig) 1030W x 750H x 380D

Control Console 340W x 250H x 200D

Module (Rig) - 34Kg

Control Console 10Kg

Packed

Approximate

Dimensions (mm)

Approximate

Weights

Module (Rig) 1100L x 850H x 460D

Control Console - 500L x 380H x 500D

Module (Rig) - 39Kg

Control Console 12Kg

Required

A suitable PC with Minimum; Pentium processor, 1GB RAM, 20GB HDD, CDROM Drive, USB 2 interface and Windows XP or above

Ordering Information

Model Number: PCT-100

Consists of:

1 x Process Module

1 x Control Console with Power Supply

1 x Set connecting cables; USB, Power cord, D and heater connector cables

1 x User and courseware Manual

1 x CD with Windows Based SCADA type Software

Bytronic Limited

124 Anglesey Court, Towers Business Park,

Rugeley, Staffordshire, WS15 1UL.

United Kingdom

Tel; +44(0)8456 123 155 Fax; +44(0)8456 123 156

Email: sales@bytronic.net Website: www.bytronic.net

You might also like

- Proses Trainer DatasheetDocument2 pagesProses Trainer DatasheetDenny ChrisnandaNo ratings yet

- Tech - 16a2d0707412ca70pct 100 071Document2 pagesTech - 16a2d0707412ca70pct 100 071lockas222No ratings yet

- PCT100 PL0214Document2 pagesPCT100 PL0214Wael AhmedNo ratings yet

- Process Control Trainer Technical Specs and SoftwareDocument5 pagesProcess Control Trainer Technical Specs and SoftwareAika CatalanNo ratings yet

- Se201 (A4)Document4 pagesSe201 (A4)Mehran Rasheed GorayaNo ratings yet

- Level Control TrainerDocument1 pageLevel Control TrainerVirender RanaNo ratings yet

- TBMC12Document10 pagesTBMC12Joel E ValenciaNo ratings yet

- The PROCON PH Process Control System Is Based Around The PH Rig and Is A SelfDocument10 pagesThe PROCON PH Process Control System Is Based Around The PH Rig and Is A Selfmiantahir89No ratings yet

- LevelDocument4 pagesLevelsankathali srikanthNo ratings yet

- Pressure Control TrainerDocument1 pagePressure Control TrainerVirender RanaNo ratings yet

- Computer Controlled Heat Exchangers Training System with SCADA and PID ControlDocument37 pagesComputer Controlled Heat Exchangers Training System with SCADA and PID ControlMusa MohammadNo ratings yet

- PCT23MkII _ Process Plant Trainer (Process Control Trainer)Document10 pagesPCT23MkII _ Process Plant Trainer (Process Control Trainer)veronicaNo ratings yet

- Process Control and Common TermsDocument210 pagesProcess Control and Common TermsGeorge Markas100% (1)

- Industrial Electronics Class Review on Process Control SystemsDocument3 pagesIndustrial Electronics Class Review on Process Control SystemsHammad AnsariNo ratings yet

- AFTCDocument8 pagesAFTCJoão Vitor Apolinário FerreiraNo ratings yet

- Unit IV PLC ProgrammingDocument61 pagesUnit IV PLC ProgrammingHOD MechanicalNo ratings yet

- Instruction Manual: Pid Based Pressure Loop TrainerDocument28 pagesInstruction Manual: Pid Based Pressure Loop TrainerKiran BennyNo ratings yet

- Process Control Lab Experiment on PCT-100 Flow ControlDocument10 pagesProcess Control Lab Experiment on PCT-100 Flow ControlBagas Ghosa HidajatNo ratings yet

- Item Reference Description Qty.: Refrigeration. Medium Module (5 Cai + Cal) Ref: 0911/5SDocument6 pagesItem Reference Description Qty.: Refrigeration. Medium Module (5 Cai + Cal) Ref: 0911/5SA94leo14hsetmaNo ratings yet

- UCP Computer Controlled Process Control System: (With Electronic Control Valve)Document6 pagesUCP Computer Controlled Process Control System: (With Electronic Control Valve)Wilmark R. CahiligNo ratings yet

- Item Reference Description Qty.: Refrigeration. Medium Module (20 Cai + Cal) Ref: 0911/20SDocument6 pagesItem Reference Description Qty.: Refrigeration. Medium Module (20 Cai + Cal) Ref: 0911/20SA94leo14hsetmaNo ratings yet

- Ultra-Low Temp Chillers for Labs & PlantsDocument2 pagesUltra-Low Temp Chillers for Labs & PlantsBibin VijayakumarNo ratings yet

- TRCVCDocument4 pagesTRCVCedwin dableoNo ratings yet

- PID control of tank level using PLC and simulationDocument9 pagesPID control of tank level using PLC and simulationarnisiNo ratings yet

- PID ControllerDocument4 pagesPID ControllerRaja SimhanNo ratings yet

- Automation and Process Control CRT - Temperature Control and Regulation Study UnitDocument4 pagesAutomation and Process Control CRT - Temperature Control and Regulation Study Unitjoao0honoratoNo ratings yet

- CLL 361 Instrumentation & Automation: Munawar A. ShaikDocument28 pagesCLL 361 Instrumentation & Automation: Munawar A. ShaikRakeshKumarNo ratings yet

- DDC ControlsDocument85 pagesDDC Controlssui1981100% (1)

- What Is Instrument Hook Up Diagram ? Instrument Hook Up Diagram Is Also Called Installation Drawing, Specifies The ScopeDocument31 pagesWhat Is Instrument Hook Up Diagram ? Instrument Hook Up Diagram Is Also Called Installation Drawing, Specifies The ScopevrajakisoriDasiNo ratings yet

- Enertec DG Control ModuleDocument2 pagesEnertec DG Control Modulemrashid286No ratings yet

- Flow Switch With 4-20 Ma OutputDocument20 pagesFlow Switch With 4-20 Ma OutputHariprasad ManavalanNo ratings yet

- Design and Application of Marine Boiler Control System Based On PLC and Touch ScreenDocument4 pagesDesign and Application of Marine Boiler Control System Based On PLC and Touch ScreenWai Min ThuNo ratings yet

- PID CONTROLLER EXPERIMENTDocument13 pagesPID CONTROLLER EXPERIMENTMohd KhairiNo ratings yet

- Relee Numaratoare ElmarkDocument2 pagesRelee Numaratoare ElmarkwawinNo ratings yet

- Computer Controlled Process Control System With SCADA and PID ControlDocument12 pagesComputer Controlled Process Control System With SCADA and PID Controldwi meyNo ratings yet

- Feedback 38-004Document15 pagesFeedback 38-004aditya narayan shuklaNo ratings yet

- CTACDocument13 pagesCTACTimothy FieldsNo ratings yet

- System For Water Level & Flow Regulation by PID: Products 2 Years GuaranteeDocument33 pagesSystem For Water Level & Flow Regulation by PID: Products 2 Years GuaranteeAugusto CamposNo ratings yet

- PSP330Document4 pagesPSP330Ali HadiNo ratings yet

- Clif Mock Lgs 2000 Sampling SystemDocument4 pagesClif Mock Lgs 2000 Sampling SystemPaula RiveraNo ratings yet

- Temperature Control Trainer PID TuningDocument17 pagesTemperature Control Trainer PID TuningRohit KalyanNo ratings yet

- Pressure Control TrinerDocument35 pagesPressure Control TrinerSourav Sarkar50% (2)

- Water Level Control System PCT-100Document10 pagesWater Level Control System PCT-100Danang Pradika PurnomoNo ratings yet

- 6 2011 DeltaV Process Control SystemDocument23 pages6 2011 DeltaV Process Control SystemSrikar Reddy GummadiNo ratings yet

- Level and Flow Rig IntroductionDocument48 pagesLevel and Flow Rig IntroductionPaul100% (1)

- Computer Controlled Heat Conduction Unit, With SCADA and PID ControlDocument15 pagesComputer Controlled Heat Conduction Unit, With SCADA and PID Controlmohamadreza1368No ratings yet

- Introduction to Procon Process Control SystemsDocument98 pagesIntroduction to Procon Process Control Systemsrizzagorospe100% (1)

- 05 - C&iDocument120 pages05 - C&iBhargav ChaudhariNo ratings yet

- Exp - P6 - Temperature ControlDocument10 pagesExp - P6 - Temperature ControlSiddesh PatilNo ratings yet

- Training on Instrumentation & Controls BasicsDocument28 pagesTraining on Instrumentation & Controls BasicsLe Manh Hai100% (1)

- Air Compressor Study Unit: SolteqDocument4 pagesAir Compressor Study Unit: Solteqrahulpatel07No ratings yet

- P6..W..EV-BAC 1 0 enDocument10 pagesP6..W..EV-BAC 1 0 enZoran DanilovNo ratings yet

- Temperature Control SystemDocument5 pagesTemperature Control SystemGoutham HereNo ratings yet

- Automation and control processes explainedDocument16 pagesAutomation and control processes explainednatrix029No ratings yet

- P&ID SeminarDocument66 pagesP&ID Seminar蔡蕲82% (11)

- User's Manual: FDC 4100 / 7100 / 8100 / 9100 Auto-Tune Fuzzy / PID Process / Temperature ControllerDocument60 pagesUser's Manual: FDC 4100 / 7100 / 8100 / 9100 Auto-Tune Fuzzy / PID Process / Temperature ControllerkmpoulosNo ratings yet

- Germany Guideline SBDocument123 pagesGermany Guideline SBlockas222No ratings yet

- Historic DeLand Building Earns LEED CertificationDocument30 pagesHistoric DeLand Building Earns LEED Certificationlockas222No ratings yet

- 04 - AbsorbersDocument11 pages04 - AbsorbersRafael ReyesNo ratings yet

- MVC Desalination Process Modeling and AnalysisDocument44 pagesMVC Desalination Process Modeling and Analysislockas222No ratings yet

- PDC Chapter 10.1Document16 pagesPDC Chapter 10.1lockas222No ratings yet

- Supply Chain QuestionDocument22 pagesSupply Chain Questionlockas22280% (5)

- Green Building RevolutionDocument229 pagesGreen Building Revolutionlockas222No ratings yet

- Ammonia Plant DesignDocument75 pagesAmmonia Plant Designlockas22288% (16)

- Design of Acetone HYSYSDocument6 pagesDesign of Acetone HYSYSlockas222100% (1)

- 04 - AbsorbersDocument11 pages04 - AbsorbersRafael ReyesNo ratings yet

- Chapter 4 Shell and Tube Heat ExchangersDocument45 pagesChapter 4 Shell and Tube Heat Exchangerslockas222No ratings yet

- PDC CH 10.3 (Problems)Document6 pagesPDC CH 10.3 (Problems)lockas222No ratings yet

- Manufacturing Process FertilizerDocument14 pagesManufacturing Process FertilizermoentaseerNo ratings yet

- Chapter 7Document28 pagesChapter 7lockas222No ratings yet

- Manufacturing Process FertilizerDocument14 pagesManufacturing Process FertilizermoentaseerNo ratings yet

- Chapter 4Document106 pagesChapter 4lockas222No ratings yet

- Fluid Mechanics IntroductionDocument49 pagesFluid Mechanics IntroductionIastraNo ratings yet

- Acetone BDocument9 pagesAcetone BIrdani IdrisNo ratings yet

- Start AgainDocument1 pageStart Againlockas222No ratings yet

- BackgroundDocument9 pagesBackgroundlockas222No ratings yet

- Start AgainDocument1 pageStart Againlockas222No ratings yet

- BackgroundDocument9 pagesBackgroundlockas222No ratings yet

- Material BalanceDocument42 pagesMaterial Balancealireza_e_20% (1)

- A Summary of Thermodynamic FundamentalsDocument11 pagesA Summary of Thermodynamic Fundamentalslockas222No ratings yet

- Neraca Massa ATKDocument49 pagesNeraca Massa ATKMuhammad KholidinNo ratings yet

- Neraca Massa ATKDocument49 pagesNeraca Massa ATKMuhammad KholidinNo ratings yet

- W 0700m6 - Gas Mixer PDFDocument5 pagesW 0700m6 - Gas Mixer PDFPopa MihaiNo ratings yet

- Types CR, CRC, CRP and CRD Directional Overcurrent Relays: CautionDocument32 pagesTypes CR, CRC, CRP and CRD Directional Overcurrent Relays: CautionRida JavidNo ratings yet

- Data SheetDocument47 pagesData Sheetestevao_moraesNo ratings yet

- Final Year Project - (Power Electronics/Systems, Electrical Machines IEEE 2016-17 Project ListDocument69 pagesFinal Year Project - (Power Electronics/Systems, Electrical Machines IEEE 2016-17 Project ListSPECTRUM SOLUTIONS100% (1)

- Wireless Charging of Electric Vehicles Using Dual Spiral Coil Magnetic Resonant CouplingDocument6 pagesWireless Charging of Electric Vehicles Using Dual Spiral Coil Magnetic Resonant CouplingIJRASETPublicationsNo ratings yet

- NVRAM Floor Height Table SUM Error: Point of Detection ApplicationDocument1 pageNVRAM Floor Height Table SUM Error: Point of Detection ApplicationDaniel GatdulaNo ratings yet

- Pir-Am612 Teoria PDFDocument5 pagesPir-Am612 Teoria PDFEloy TorresNo ratings yet

- Two-Stage Power Decoupling For A Single-Phase Photovoltaic Inverter by Controlling The DC-Link Voltage Ripple in The DQ FrameDocument6 pagesTwo-Stage Power Decoupling For A Single-Phase Photovoltaic Inverter by Controlling The DC-Link Voltage Ripple in The DQ FrameAkbar aliNo ratings yet

- FormulaDocument7 pagesFormulahelenarajNo ratings yet

- Differences between 8-bit 8085 and 16-bit 8086 microprocessorsDocument3 pagesDifferences between 8-bit 8085 and 16-bit 8086 microprocessorsFaisal Al-Balushi100% (4)

- Edc Lab ManualDocument92 pagesEdc Lab ManualPranav GangwarNo ratings yet

- S7L1D-D4 Wdg.312 - Technical Data SheetDocument9 pagesS7L1D-D4 Wdg.312 - Technical Data Sheet3efooNo ratings yet

- Passive Optical Network (Pon) : Different Types of PonsDocument4 pagesPassive Optical Network (Pon) : Different Types of PonsAnees Ur RehmanNo ratings yet

- TB6600 DatasheetDocument33 pagesTB6600 DatasheetDragan ŠašićNo ratings yet

- Main Specifications of Generator SetsDocument3 pagesMain Specifications of Generator SetsReal IDNo ratings yet

- Windrock Tips and TricksDocument38 pagesWindrock Tips and TricksOdlanier José MendozaNo ratings yet

- Altistart 48 - ATS48C32QDocument5 pagesAltistart 48 - ATS48C32Qabdur rafayNo ratings yet

- Module 4 Sheet 1.1 OHS PoliciesDocument23 pagesModule 4 Sheet 1.1 OHS PoliciesRalfh De GuzmanNo ratings yet

- Control Valves (ABB Kent)Document816 pagesControl Valves (ABB Kent)anhkietvt100% (1)

- Astm e 426Document4 pagesAstm e 426김경은No ratings yet

- ElectronicsForYou201401 Rotation CounterDocument2 pagesElectronicsForYou201401 Rotation CounterAnonymous JoB5ZxgNo ratings yet

- Datasheet LA76812Document3 pagesDatasheet LA76812Kevin Villacis AvelinoNo ratings yet

- Pathfinder Manual 2012Document192 pagesPathfinder Manual 2012shawqiNo ratings yet

- Summary Table of Electl Material Device and Eqpt SurveyDocument4 pagesSummary Table of Electl Material Device and Eqpt SurveyAngellica Ruth MatroNo ratings yet

- AJB-D DatasheetDocument2 pagesAJB-D DatasheetYash PalNo ratings yet

- Fizik Lab ReportDocument5 pagesFizik Lab ReportnajwaNo ratings yet

- PFC Device Corporation: 40A 60V MOS Schottky RectifierDocument7 pagesPFC Device Corporation: 40A 60V MOS Schottky RectifierАндрей АкимовNo ratings yet

- 1-SOP For Operation of LV Panel PDFDocument21 pages1-SOP For Operation of LV Panel PDFFareh Khan100% (1)

- EPM 04 04C 04CS EN A4034 Rev9Document4 pagesEPM 04 04C 04CS EN A4034 Rev9khaldoun samiNo ratings yet

- Base Band ELEDocument7 pagesBase Band ELEUmber IsmailNo ratings yet