Professional Documents

Culture Documents

A319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 29 Hydraulic Power

Uploaded by

AhmedHamdyElsaidy100%(9)100% found this document useful (9 votes)

2K views236 pagesA320 TECH MANUAL29-HYDRAULIC

Original Title

29-HYDRAULIC

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentA320 TECH MANUAL29-HYDRAULIC

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

100%(9)100% found this document useful (9 votes)

2K views236 pagesA319/A320/A321 Technical Training Manual Mechanics / Electrics & Avionics Course 29 Hydraulic Power

Uploaded by

AhmedHamdyElsaidyA320 TECH MANUAL29-HYDRAULIC

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 236

A319/A320/A321

TECHNICAL TRAINING MANUAL

MECHANICS / ELECTRICS & AVIONICS COURSE

29 HYDRAULIC POWER

This document must be used for training purpose only

Under no circumstances should this document be used as a reference.

It will not be updated.

All rights reserved.

No part of this manual may be reproduced in any form,

by photostat, microfilm, retrieval system, or any other means,

without the prior written permission of Airbus Industrie.

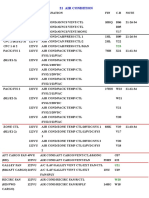

** System Presentation (1) 1 . . . . . . . . . . . . . . . . . . . . . . .

** System Controls (1) 7 . . . . . . . . . . . . . . . . . . . . . . . . . . . .

** Hydraulic System Users (1) 11 . . . . . . . . . . . . . . . . . . .

** Circuit Identification and Routing (2) 15 . . . . . .

** ECAM Page Presentation (1) 25 . . . . . . . . . . . . . . . . . . .

** Hydraulic System Warnings (3) 33 . . . . . . . . . . . . . . . .

** Green Hydraulic System D/O (3) 37 . . . . . . . . . . . . . . .

** Blue Hydraulic System D/O (3) 45 . . . . . . . . . . . . . . . .

** Yellow Hydraulic Syst D/O (3) 53 . . . . . . . . . . . . . . . .

** Leak Measurement System Presentation (3) 63 . . . .

** Hyd. Reservoir Pressurizing Syst D/O (3) 69 . . . .

** Hyd. Reservoir Filling Presentation (2) 75 . . . . .

** Seal Drain System Presentation (2) 79 . . . . . . . . . .

** Green System Components (3) 87 . . . . . . . . . . . . . . . . . .

** Blue System Components (3) 119 . . . . . . . . . . . . . . . . . .

** Yellow System Components (3) 151 . . . . . . . . . . . . . . . .

** Hyd Reservoir PRESS Syst Components (3) 185 . . . .

** Power Transfer Unit Components (3) 193 . . . . . . . . .

MAINTENANCE PRACTICES

** Reservoir Depressurization (2) 201 . . . . . . . . . . . . .

** Reservoir Filling (2) 205 . . . . . . . . . . . . . . . . . . . . . . .

** RAT Stowage and Servicing (2) 209 . . . . . . . . . . . . . . .

** RAT Test (3) 215 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HYD Leakage (3) 219 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SPECIFIC PAGES

** CFDS Specific Page Presentation (3) 221 . . . . . .

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

EFFECTIVITY

ALL

29 HYDRAULIC POWER

UFD4200 TABLE OF CONTENTS Page

29 CONTENTS

Page i

Dec 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

EFFECTIVITY

ALL

29 HYDRAULIC POWER

UFD4200 TABLE OF CONTENTS Page

29 CONTENTS

Page ii

Dec 31/00

THIS PAGE INTENTIONALLY LEFT BLANK

29 - HYDRAULIC SYSTEM

29-00-00 SYSTEM PRESENTATION

CONTENTS:

General

Reservoirs

Fire Shut-off Valves

Engine Driven Pumps

Electric Pumps

Hand Pump

Ram Air Turbine

Accumulators

Power Transfer Unit

Self Examination

T

M

U

H

Y

D

2

0

1

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 1

Mar 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 1

EFFECTIVITY

ALL

SYSTEM PRESENTATION

GENERAL

There are three independent hydraulic systems : Green,

Blue and Yellow.

In normal operation, the green and yellow hydraulic

systems are powered by Engine Driven Pumps (EDPs), and

the blue hydraulic system by an electric pump.

Auxiliary power is provided by an electric pump in the

yellow system.

A bidirectional Power Transfer Unit (PTU) enables the

green system to be powered by the yellow system or

vice versa, without fluid transfer.

A Ram Air Turbine (RAT) is provided in the blue system

for emergency use.

A hand pump is provided in the yellow system for cargo

door manual operation.

RESERVOIRS

Each hydraulic system has its own reservoir.

It supplies hydraulic fluid to the system pumps, and

is pneumatically pressurized.

The green reservoir is located in the main landing

gear bay, the yellow reservoir in the yellow hydraulic

compartment and the blue reservoir above the blue

ground service panel.

All the reservoirs are filled from the green ground

service panel.

FIRE SHUT-OFF VALVES

On the green and yellow systems, a fire shut-off valve

is positioned upstream of the engine driven pump to

isolate the system.

They are operated by their respective engine fire

pushbutton switches to isolate the engine driven pump

in case of engine fire.

ENGINE DRIVEN PUMPS

The green and yellow systems are each pressurized by

a pump driven respectively by engine 1 and engine 2.

Engine Driven Pumps (EDPs) are located on the accessory

gearbox of each engine. They are of the variable

displacement type.

Normal system operating pressure is 3000 psi

(206 bars).

ELECTRIC PUMPS

The blue system is pressurized by an electric pump.

An electric pump allows the yellow system to be

pressurized enabling ground operations when the

engines are stopped.

Normal system operating pressure is 3000 psi

(206 bars).

HAND PUMP

The hand pump is used to operate the cargo doors when

no electrical power is available.

It is located on the yellow ground service panel.

T

M

U

H

Y

D

2

0

1

-

T

0

1

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 2

Mar 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 2

EFFECTIVITY

ALL

SYSTEM PRESENTATION

T

M

U

H

Y

D

2

0

1

-

P

0

1

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 3

Mar 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 3

EFFECTIVITY

ALL

RAM AIR TURBINE

A Ram Air Turbine extends automatically in the event

of both engine and APU generator failures and allows

the blue hydraulic system to be pressurized.

RAT delivered pressure is 2500 psi (172 bars).

Manual operation from the cockpit is always possible.

The Ram Air turbine is located in the blue hydraulic

compartment.

NOTE: RAT stowage is possible on ground only.

ACCUMULATORS

An accumulator, in each circuit helps to maintain a

constant pressure during normal operation, by covering

transient demands.

POWER TRANSFER UNIT

A bidirectional Power Transfer Unit enables the green

system to be powered by the yellow system or vice

versa, without fluid transfer.

The PTU is automatically activated when the

differential pressure between the green and yellow

system is higher than 500 psi (34 bars). When the

engines are shut down, the PTU allows the green system

to be pressurized using the yellow electric pump. The

PTU is inhibited during the first engine start and is

automatically tested at second engine start.

T

M

U

H

Y

D

2

0

1

-

T

0

1

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 4

Mar 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 4

EFFECTIVITY

ALL

THIS PAGE INTENTIONALLY LEFT BLANK

T

M

U

H

Y

D

2

0

1

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 5

Mar 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 5

EFFECTIVITY

ALL

SELF EXAMINATION

Which hydraulic systems are pressurized by an

engine driven pump ?

A - Blue and green.

B - Yellow and blue.

C - Green and yellow.

In normal operation, what is the blue hydraulic

system pressurized by ?

A - The Power Transfer Unit.

B - An engine driven pump.

C - An electric pump.

Is it possible to stow the Ram Air Turbine

in flight ?

A - No.

B - Yes.

T

M

U

H

Y

D

2

0

1

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 6

Mar 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 6

EFFECTIVITY

ALL

29 - HYDRAULIC SYSTEM

29-10-00 SYSTEM CONTROLS

CONTENTS:

Engine 1 Pump

Ram Air Turbine

Blue Electric Pump

Power Transfer Unit

Engine 2 Pump

Yellow Electric Pump

Blue Pump Override

Leak Measurement Valves

T

M

U

H

Y

D

4

0

5

L

E

V

E

L

1

EFFECTIVITY

29-10-00

Page 1

Jun 30/99

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 7

EFFECTIVITY

ALL

SYSTEM CONTROLS

ENGINE 1 PUMP

ENG 1 PUMP pushbutton controls the engine 1 hydraulic

pump.

In normal conditions the engine driven pump 1

pressurizes the green system. When the pushbutton is

set to OFF, the pump operates in the depressurized

mode.

RAM AIR TURBINE

The RAT MAN ON guarded pushbutton permits Ram Air

Turbine deployment at any time.

RAT deployment is automatic in case of failure of main

generators (engines and APU) in flight.

BLUE ELECTRIC PUMP

The blue ELEC PUMP pushbutton controls the blue

electric pump.

With the BLUE ELEC PUMP pushbutton set to AUTO, the

electric pump operates from the moment the first engine

is started until the last engine is shut-down.

When the pushbutton is set to OFF, the pump is

de-energized.

POWER TRANSFER UNIT

The PTU pushbutton controls the arming of the

bidirectional Power Transfer Unit automatic function.

ENGINE 2 PUMP

ENG 2 PUMP pushbutton controls the engine 2 hydraulic

pump.

In normal conditions the engine driven pump 2

pressurizes the yellow system. When the pushbutton is

set to OFF, the pump operates in the depressurized

mode.

YELLOW ELECTRIC PUMP

The yellow ELEC PUMP pushbutton controls the yellow

electric pump.

BLUE PUMP OVERRIDE

For maintenance purposes, the blue hydraulic circuit

can be pressurized by pressing the BLUE PUMP OVRD

pushbutton on the maintenance overhead panel.

On ground, the electric pump operates, provided the

BLUE PUMP OVRD pushbutton has been pressed in and the

ELEC PUMP pushbutton is set to AUTO.

LEAK MEASUREMENT VALVES

A leak measurement valve is positioned in each circuit

upstream of the primary flight controls.

Used for the leakage measurement of each circuit, they

are closed, on ground only, by selecting OFF the leak

measurement valve pushbutton switches on the

maintenance overhead panel.

T

M

U

H

Y

D

4

0

5

-

T

0

1

L

E

V

E

L

1

EFFECTIVITY

29-10-00

Page 2

Jun 30/99

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 8

EFFECTIVITY

ALL

SYSTEM CONTROLS

T

M

U

H

Y

D

4

0

5

-

P

0

1

L

E

V

E

L

1

EFFECTIVITY

29-10-00

Page 3

Jun 30/99

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 9

EFFECTIVITY

ALL

THIS PAGE INTENTIONALLY LEFT BLANK

T

M

U

H

Y

D

4

0

5

L

E

V

E

L

1

EFFECTIVITY

29-10-00

Page 4

Jun 30/99

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 10

EFFECTIVITY

ALL

29 - HYDRAULIC SYSTEM

29-00-00 HYDRAULIC SYSTEM USERS

CONTENTS:

Green, Blue, Yellow users

Priority Valves

T

M

U

H

Y

D

3

0

2

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 1

Mar 31/94

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 11

EFFECTIVITY

ALL

HYDRAULIC SYSTEM USERS

GREEN, BLUE, YELLOW USERS

The three independent hydraulic systems respectively

supply the users indicated on the diagram.

Between these systems, the users are shared in order

to ensure the aircraft control, even if only one

hydraulic system is inoperative.

On the blue hydraulic system, the Constant Speed

Motor/Generator (CSM/G) is used to provide aircraft

electrical power in case of emergency.

PRIORITY VALVES

In the event of low hydraulic pressure, the priority

valves maintain the operation of essential systems by

cutting off hydraulic power to heavy load users.

T

M

U

H

Y

D

3

0

2

-

T

0

1

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 2

Mar 31/94

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 12

EFFECTIVITY

ALL

HYDRAULIC SYSTEM USERS

T

M

U

H

Y

D

3

0

2

-

P

0

1

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 3

Mar 31/94

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 13

EFFECTIVITY

ALL

SELF EXAMINATION

What happens if the hydraulic pressure drops ?

A- The priority valves give priority to the

heavy load users.

B- The priority valves give priority to the

essential systems.

C- The priority valves modulate the pressure

to the users.

T

M

U

H

Y

D

3

0

2

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 4

Mar 31/94

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 14

EFFECTIVITY

ALL

29 - HYDRAULIC SYSTEM

29-00-00 CIRCUIT IDENTIFICATION AND

ROUTING

CONTENTS:

Pipe Routing

Pipe Identification

Component Identification

Connections

Self Examination

T

M

U

H

Y

A

L

0

2

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 1

Oct 31/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 15

EFFECTIVITY

ALL

CIRCUIT IDENTIFICATION AND ROUTING

PIPE ROUTING

The three systems are hydraulically independent.

There are no hydraulic pipes in the passenger cabin

or flight compartment.

T

M

U

H

Y

A

L

0

2

-

T

0

1

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 2

Oct 31/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 16

EFFECTIVITY

ALL

CIRCUIT IDENTIFICATION AND ROUTING

T

M

U

H

Y

A

L

0

2

-

P

0

1

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 3

Oct 31/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 17

EFFECTIVITY

ALL

CIRCUIT IDENTIFICATION AND ROUTING

PIPE IDENTIFICATION

Each pipe is identified by a self-adhesive label which

indicates:

- The part number of the pipe,

- The identification of the pipe as an hydraulic pipe

(black dots, yellow and blue fields) its function and

the direction of the fluid flow.

- An identification of the system comprising a color

code and a number 1, 2 or 3 respectively indicating

the Green, Blue, or Yellow system.

T

M

U

H

Y

A

L

0

2

-

T

0

2

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 4

Oct 31/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 18

EFFECTIVITY

ALL

CIRCUIT IDENTIFICATION AND ROUTING

T

M

U

H

Y

A

L

0

2

-

P

0

2

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 5

Oct 31/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 19

EFFECTIVITY

ALL

CIRCUIT IDENTIFICATION AND ROUTING

COMPONENT IDENTIFICATION

Each hydraulic component is identified by a placard

affixed on the structure near to it, which gives its

Functional Item Number (FIN) and its designation.

T

M

U

H

Y

A

L

0

2

-

T

0

3

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 6

Oct 31/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 20

EFFECTIVITY

ALL

CIRCUIT IDENTIFICATION AND ROUTING

T

M

U

H

Y

A

L

0

2

-

P

0

3

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 7

Oct 31/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 21

EFFECTIVITY

ALL

CIRCUIT IDENTIFICATION AND ROUTING

CONNECTIONS

The most common connections in the hydraulic system

are shown below.

There are two types of connections:

- permanent connections (permaswage).

- removable connections (standard straight or

special fittings).

The manifolds have bobbin type connections for some

components.

The bobbins are equipped with a square seal on the

component side and an o-ring on the manifold side.

T

M

U

H

Y

A

L

0

2

-

T

0

4

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 8

Oct 31/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 22

EFFECTIVITY

ALL

CIRCUIT IDENTIFICATION AND ROUTING

T

M

U

H

Y

A

L

0

2

-

P

0

4

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 9

Oct 31/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 23

EFFECTIVITY

ALL

SELF EXAMINATION

A blue system pipeline is identified by:

A - A blue band and number 1.

B - A blue band and number 3.

C - A blue band and number 2.

T

M

U

H

Y

A

L

0

2

L

E

V

E

L

1

EFFECTIVITY

29-00-00

Page 10

Oct 31/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 24

EFFECTIVITY

ALL

29 - HYDRAULIC SYSTEM

29-30-00 ECAM PAGE PRESENTATION

CONTENTS:

Reservoir Quantity

Reservoir Pressure

Reservoir Overheat

Fire Valve

Engine Driven Pumps

Blue Electric Pump

Yellow Electric Pump

Ram Air Turbine

Power Transfer Unit

System Pressure

System Label

T

M

U

H

Y

D

5

0

1

L

E

V

E

L

1

EFFECTIVITY

29-30-00

Page 1

Jun 30/99

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 25

EFFECTIVITY

ALL

ECAM PAGE PRESENTATION

RESERVOIR QUANTITY

The reservoir quantity indication is green when normal.

It becomes amber at warning level.

RESERVOIR PRESSURE

Reservoir LO AIR PRESS indication appears amber if the

corresponding reservoir air pressure drops below

normal.

RESERVOIR OVERHEAT

Reservoir OVHT indication appears amber if the return

hydraulic fluid temperature is above normal.

FIRE VALVE

The fire valve is green in line when open or not fully

closed and amber cross-line when closed.

T

M

U

H

Y

D

5

0

1

-

T

0

1

L

E

V

E

L

1

EFFECTIVITY

29-30-00

Page 2

Jun 30/99

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 26

EFFECTIVITY

ALL

ECAM PAGE PRESENTATION

T

M

U

H

Y

D

5

0

1

-

P

0

1

L

E

V

E

L

1

EFFECTIVITY

29-30-00

Page 3

Jun 30/99

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 27

EFFECTIVITY

ALL

ECAM PAGE PRESENTATION

T

M

U

H

Y

D

5

0

1

-

P

0

2

L

E

V

E

L

1

EFFECTIVITY

29-30-00

Page 4

Jun 30/99

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 28

EFFECTIVITY

ALL

ECAM PAGE PRESENTATION

T

M

U

H

Y

D

5

0

1

-

P

0

3

L

E

V

E

L

1

EFFECTIVITY

29-30-00

Page 5

Jun 30/99

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 29

EFFECTIVITY

ALL

ECAM PAGE PRESENTATION

POWER TRANSFER UNIT

When PTU is running HYD PTU is displayed green on MEMO

display.

SYSTEM PRESSURE

System pressure indication is normally green. It

becomes amber when the system pressure is too low.

3000 -green: System presure is normal.

1430 -amber: System pressure is too low (pressure below

1450 psi=100 bars).

SYSTEM LABEL

System label is a white word and a green arrow when

the pressure is normal.

Both the word and the arrow are amber when pressure

is too low.

T

M

U

H

Y

D

5

0

1

-

T

0

4

L

E

V

E

L

1

EFFECTIVITY

29-30-00

Page 6

Jun 30/99

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 30

EFFECTIVITY

ALL

ECAM PAGE PRESENTATION

T

M

U

H

Y

D

5

0

1

-

P

0

4

L

E

V

E

L

1

EFFECTIVITY

29-30-00

Page 7

Jun 30/99

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 31

EFFECTIVITY

ALL

THIS PAGE INTENTIONALLY LEFT BLANK

T

M

U

H

Y

D

5

0

1

L

E

V

E

L

1

EFFECTIVITY

29-30-00

Page 8

Jun 30/99

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 32

EFFECTIVITY

ALL

29 - HYDRAULIC POWER

29-00-00 HYDRAULIC SYSTEM WARNINGS

CONTENTS:

Green Reservoir Low Air Pressure

Yellow Reservoir Overheat

Blue Reservoir Low Level

Green Engine Pump Low Pressure

Yellow Electric Pump Low Pressure

Dual System Low Pressure

Ram Air Turbine Fault

Power Transfer Unit Fault

Yellow Electric Pump Overheat

T

M

U

H

Y

D

6

0

2

L

E

V

E

L

3

EFFECTIVITY

29-00-00

Page 1

Jun 30/99

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 33

EFFECTIVITY

ALL

HYDRAULIC SYSTEM WARNINGS

T

M

U

H

Y

D

6

0

2

-

P

0

1

L

E

V

E

L

3

EFFECTIVITY

29-00-00

Page 2

Jun 30/99

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 34

EFFECTIVITY

ALL

HYDRAULIC SYSTEM WARNINGS

T

M

U

H

Y

D

6

0

2

-

P

0

2

L

E

V

E

L

3

EFFECTIVITY

29-00-00

Page 3

Jun 30/99

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 35

EFFECTIVITY

ALL

THIS PAGE INTENTIONALLY LEFT BLANK

T

M

U

H

Y

D

6

0

2

L

E

V

E

L

3

EFFECTIVITY

29-00-00

Page 4

Jun 30/99

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 36

EFFECTIVITY

ALL

29 - HYDRAULIC POWER

29-11-00 GREEN HYDRAULIC SYSTEM D/O

CONTENTS:

Reservoir

Reservoir Pressurization

Fire Valve

Engine Driven Pump

Ground Couplings

Pressure Switch

Power Transfer Unit

High Pressure Manifold

Leak Measurement Manifold

Power Transfer Unit Manifold

Return Manifold

Self Examination

T

M

U

H

Y

D

B

0

3

L

E

V

E

L

3

EFFECTIVITY

29-11-00

Page 1

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 37

EFFECTIVITY

ALL

GREEN HYDRAULIC SYSTEM D/O

Most of the system components are installed in the

main landing gear compartment.

RESERVOIR

The reservoir is equipped with a direct reading gauge,

a quantity indicator and a low level switch for ECAM

indicating and warning.

Normal fill level: 14 l. (3.7 US gal)

Maximum gaugeable level: 18 l. (4.76 US gal)

Low level warning: 3.0 0.4 l. (0.79 0.1 US gal)

RESERVOIR PRESSURIZATION

The reservoir is normally pressurized with air to

prevent cavitation of the pumps.

The reservoir is pressurized to 50 psi (3.43 bar) and

is sealed to hold the pressure when there is no air

supply.

The threshold of the low pressure switch is 22 psi

(1.52bar).

FIRE VALVE

The green system fire valve installed in the left hand

wing, inboard of the pylon, is controlled by ENG 1

FIRE push-button.

When the valve closes it stops the supply of fluid to

the Engine Driven Pump.

ENGINE DRIVEN PUMP

The Engine Driven Pump is attached to the accessory

gearbox. A solenoid valve controlled by the ENG 1 PUMP

push-button selects the pressurized or depressurized

mode.

The Engine Driven Pump cooling and lubricating flow

passes through the case drain filter installed in the

return circuit.

Pump outlet pressure is 3000 psi (206 bar) at zero

flow.

The Engine Driven Pump includes a blocking valve which

isolates the pump from the hydraulic system when the

pump operates in the depressurized mode.

Case drain filter clogging indication: P = 87 8.7 psi

(6 0.6 bar).

GROUND COUPLINGS

The ground service panel consists of two connectors

used to pressurize the green hydraulic system from a

ground cart, a selector valve, two connectors and a

hand pump used for hydraulic reservoir refilling.

T

M

U

H

Y

D

B

0

3

-

T

0

1

L

E

V

E

L

3

EFFECTIVITY

29-11-00

Page 2

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 38

EFFECTIVITY

ALL

GREEN HYDRAULIC SYSTEM D/O

T

M

U

H

Y

D

B

0

3

-

P

0

1

L

E

V

E

L

3

EFFECTIVITY

29-11-00

Page 3

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 39

EFFECTIVITY

ALL

GREEN HYDRAULIC SYSTEM D/O

PRESSURE SWITCH

The pressure switch monitors the Engine Driven Pump

outlet pressure for ECAM indications.

The threshold of pressure switch is 1740 psi (120 bar).

NOTE: A check valve downstream of the pump stops the

fluid flow to the pump if the system is

pressurized by the Power Transfer Unit (PTU).

POWER TRANSFER UNIT

The Power Transfer Unit will run automatically when

the differential pressure between the green and yellow

circuits is greater than 500 psi (34.5 bar).

The PTU is inhibited during the first engine start and

cargo door operation.

HIGH PRESSURE MANIFOLD

PRESSURE SWITCHES

The signals from both pressure switches are sent to

the Flight Control Computers, to the Braking Steering

Control Unit, to the ECAM and to the Flight

Augmentation Computer.

The threshold of the pressure switches is 1450 psi

(99.5 bar).

PRESSURE TRANSDUCER

The pressure transducer provides data for pressure

indication on the ECAM and sends information to ELAC

1 and 2.

LEAK MEASUREMENT VALVE

The leak Measurement valve isolates the flight controls

when the guarded LEAK MEASUREMENT VALVES pushbutton

on the maintenance panel is set to OFF.

HP FILTER

The high pressure filter is equipped with a clogging

indicator.

The clogging indicator operates when the differential

pressure is higher than 87 8.7 psi (6 0.6 bar).

ACCUMULATOR

The accumulator acts as a damper for small changes.

It also makes a supply of fluid available in case of

any demand.

The accumulator is precharged with nitrogen to 1885

psi (130 bar) at 20C. It holds 1.1l (0.29 USgal) of

total volume of fluid when it is full.

SAMPLING VALVE

A sampling valve is provided on the HP manifold.

PRESSURE RELIEF VALVE

The system relief valve connects the high pressure

circuit to the return circuit in case of overpressure.

The relief valve opens at 3436 psi (237 bar) and closes

at 3190 psi (220 bar).

T

M

U

H

Y

D

B

0

3

-

T

0

2

L

E

V

E

L

3

EFFECTIVITY

29-11-00

Page 4

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 40

EFFECTIVITY

ALL

GREEN HYDRAULIC SYSTEM D/O

T

M

U

H

Y

D

B

0

3

-

P

0

2

L

E

V

E

L

3

EFFECTIVITY

29-11-00

Page 5

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 41

EFFECTIVITY

ALL

GREEN HYDRAULIC SYSTEM D/O

LEAK MEASUREMENT MANIFOLD

The leak measurement valve block supplies the flight

controls of the right hand wing, left hand wing and

tail section via three outputs.

Operating a spool valve allows the associated section

to be supplied for leak measurement test.

POWER TRANSFER MANIFOLD

NORMAL BRAKING SELECTOR VALVE

The normal braking selector valve cuts-off the

hydraulic supply to the normal brakes.

SOLENOID VALVE

The solenoid valve installed in the Power Transfer

Unit supply line stops the Power Transfer Unit

operation.

PRIORITY VALVE

The priority valve makes sure that all available

hydraulic pressure is sent to the primary flight

controls if pressure in the system is reduced.

RETURN MANIFOLD

The return manifold comprises:

- one return filter equipped with a clogging

indicator.

- one temperature transmitter which consists of

one temperature switch and two temperature

transducers.

The bypass operates when the differential pressure across

the filter is more than 29 2.35 psi (2 0.16 bar).

Temperature switch and temperature transducers send

data to the ECAM for warnings.

T

M

U

H

Y

D

B

0

3

-

T

0

3

L

E

V

E

L

3

EFFECTIVITY

29-11-00

Page 6

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 42

EFFECTIVITY

ALL

GREEN HYDRAULIC SYSTEM D/O

T

M

U

H

Y

D

B

0

3

-

P

0

3

L

E

V

E

L

3

EFFECTIVITY

29-11-00

Page 7

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 43

EFFECTIVITY

ALL

SELF EXAMINATION

When is the PTU operation inhibited?

A - Never, it cannot be inhibited.

B - Only if an engine failure has been

detected.

C - In case of cargo door operation with the

yellow electric pump.

When is the engine fire shut-off valve closed?

A - Automatically when the engine is shut

down.

B - If the ENG FIRE pushbutton is released

out.

C - Automatically as soon as engine fire is

detected.

T

M

U

H

Y

D

B

0

3

L

E

V

E

L

3

EFFECTIVITY

29-11-00

Page 8

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 44

EFFECTIVITY

ALL

29 - HYDRAULIC POWER

29-12-00 BLUE HYDRAULIC SYSTEM D/O

CONTENTS:

Reservoir

Reservoir Pressurization

Electric Pump

Ram Air Turbine

Pressure Switch

High Pressure Manifold

Leak Measurement Manifold

Return Manifold

Ground Couplings

Self Examination

T

M

U

H

Y

D

C

0

3

L

E

V

E

L

3

EFFECTIVITY

29-12-00

Page 1

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 45

EFFECTIVITY

ALL

BLUE HYDRAULIC SYSTEM D/O

Most of the system components are installed in the

blue hydraulic compartment located in the left hand

belly fairing, forward of the main landing gear

compartment.

RESERVOIR

The reservoir is equipped with a direct reading gauge,

a quantity indicator and a low level switch for ECAM

indicating and warning.

Normal fill level: 6l (1.58 US gal)

Maximum gaugeable level: 8l (2.11 US gal)

Low level warning: between 2.0 and 2.3l (0.52 and 0.6US

gal).

RESERVOIR PRESSURIZATION

The reservoir is normally pressurized with air to

prevent pump cavitation.

The reservoir is pressurized to 50 psi (3.43 bar) and

is sealed to hold the pressure when there is no air

supply.

The threshold of the air pressure switch is 22 psi

(1.52 bar).

ELECTRIC PUMP

With the ELEC PUMP pushbutton set to AUTO, the blue

electric pump will run, if one engine is running, or

BLUE PUMP OVRD pushbutton is set to ON, or Nose Landing

Gear is not compressed and AC power is available from

APU. With the last condition, at touch down a time

delay relay maintains the pump operation for two

minutes after nose landing gear compression.

The pump outlet pressure is 3000 psi (206 bar) at zero

flow.

A temperature switch sends a signal to the ECAM if the

pump body temperature exceeds 165C.

The electric pump cooling and lubricating flow passes

through the case drain filter installed in the return

circuit.

T

M

U

H

Y

D

C

0

3

-

T

0

1

L

E

V

E

L

3

EFFECTIVITY

29-12-00

Page 2

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 46

EFFECTIVITY

ALL

BLUE HYDRAULIC SYSTEM D/O T

M

U

H

Y

D

C

0

3

-

P

0

1

L

E

V

E

L

3

EFFECTIVITY

29-12-00

Page 3

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 47

EFFECTIVITY

ALL

BLUE HYDRAULIC SYSTEM D/O

RAM AIR TURBINE

The Ram Air Turbine (RAT) is deployed automatically

if all AC electrical power sources are lost at speeds

greater than 100Kts, or manually by using either of

the guarded pushbuttons.

PRESSURE SWITCH

The pressure switch monitors the electric pump pressure

for ECAM indications.

The threshold of the pressure switch is 1450 psi (99.5

bar).

A check valve stops the flow of fluid to the electric

pump if the system is pressurized by the RAT.

HIGH PRESSURE MANIFOLD

PRESSURE SWITCHES

The signals from both pressure switches are sent to

the ECAM system and to the Flight Control Computers.

The threshold of the pressure switches is 1450 psi

(99.5 bar).

PRESSURE TRANSDUCER

The pressure transducer provides data for pressure

indication on the ECAM and sends information to ELAC

1 and 2.

LEAK MEASUREMENT VALVE

The leak measurement valve isolates the flight controls

when the guarded LEAK MEASUREMENT VALVES pushbutton

on the maintenance panel is set to OFF.

HP FILTER

The high pressure filter is equipped with a clogging

indicator.

The clogging indicator operates when the differential

pressure is higher than 87 8.7 psi (6 0.6 bar).

ACCUMULATOR

The accumulator acts as a damper for small changes.

It also makes a supply of fluid available in case of

any demand.

The accumulator is precharged with nitrogen to 1885

psi (130 bar) at 20C. It holds 1.1l (0.29 USgal) of

total volume of fluid when it is full.

PRIORITY VALVE

The priority valve makes sure that all available

hydraulic pressure is sent to the primary flight

controls if pressure in the system is reduced.

PRESSURE RELIEF VALVE

The pressure relief valve connects the high pressure

circuit to the return circuit in case of over pressure.

The relief valve opens at 3436 psi (237 bar) and closes

at 3190 psi (220 bar).

SAMPLING VALVE

A sampling valve is provided on the HP Manifold.

T

M

U

H

Y

D

C

0

3

-

T

0

2

L

E

V

E

L

3

EFFECTIVITY

29-12-00

Page 4

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 48

EFFECTIVITY

ALL

BLUE HYDRAULIC SYSTEM D/O T

M

U

H

Y

D

C

0

3

-

P

0

2

L

E

V

E

L

3

EFFECTIVITY

29-12-00

Page 5

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 49

EFFECTIVITY

ALL

BLUE HYDRAULIC SYSTEM D/O

LEAK MEASUREMENT MANIFOLD

The leak measurement valve block supplies the flight

controls of the right hand wing, left hand wing and

tail section via three outputs.

Operating a spool valve allows the associated section

of the flight controls to be supplied for leak

measurement test.

RETURN MANIFOLD

The return manifold comprises:

- one return filter equipped with a clogging

indicator.

- one temperature transmitter which consists of

one temperature switch and two temperature

transducers.

The bypass operates when the differential pressure

across the filter is more than 29 2.35 psi (2 0.16

bar).

Temperature switch and probes send data to the ECAM

for indication and warnings.

GROUND COUPLINGS

On ground it is possible to pressurize the blue

hydraulic system from a ground power unit.

T

M

U

H

Y

D

C

0

3

-

T

0

3

L

E

V

E

L

3

EFFECTIVITY

29-12-00

Page 6

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 50

EFFECTIVITY

ALL

BLUE HYDRAULIC SYSTEM D/O T

M

U

H

Y

D

C

0

3

-

P

0

3

L

E

V

E

L

3

EFFECTIVITY

29-12-00

Page 7

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 51

EFFECTIVITY

ALL

SELF EXAMINATION

When does the electric pump pressurize the blue

system?

A - When the aircraft is on the ground, ELEC

PUMP push-button is set to AUTO and OVRD

(override) push-button is set to ON.

B - When the green and yellow systems are

detected in low pressure configuration.

C - As soon as one engine is running and

OVRD pushbutton is set to ON.

When does the RAT deploy automatically?

A - In flight, if blue hydraulic power is

lost.

B - As soon as two hydraulic power systems

are lost.

C - At speeds greater than 100Kts, if all

electrical power sources are lost.

T

M

U

H

Y

D

C

0

3

L

E

V

E

L

3

EFFECTIVITY

29-12-00

Page 8

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 52

EFFECTIVITY

ALL

29 - HYDRAULIC POWER

29-13-00 YELLOW HYDRAULIC SYSTEM D/O

CONTENTS:

Reservoir

Reservoir Pressurization

Fire Valve

Engine Driven Pump

Ground Couplings

Pressure Switch

Power Transfer Unit

Electric Pump

Hand Pump

High Pressure Manifold

Leak Measurement Manifold

Power Transfer Unit Manifold

Return Manifold

Self Examination

T

M

U

H

Y

D

D

0

4

L

E

V

E

L

3

EFFECTIVITY

29-13-00

Page 1

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 53

EFFECTIVITY

ALL

YELLOW HYDRAULIC SYSTEM D/O

Most of the system components are installed in the

yellow hydraulic compartment, located in the right

hand belly fairing, forward of the main landing gear

compartment.

RESERVOIR

The reservoir is equipped with a direct reading gauge,

a quantity indicator and a low level switch for ECAM

indications and warnings.

Normal fill level: 12 l (3.17 US gal).

Maximum gaugeable level: 18 l (4.76 US gal).

Low level warning: 3 0.4 l (0.79 0.1 US gal).

RESERVOIR PRESSURIZATION

The reservoir is normally pressurized with air to

prevent cavitation of the pumps.

The reservoir is pressurized to 50 psi (3.43 bar) and

is sealed to hold the pressure when there is no air

supply.

The threshold of the air pressure switch is 22 psi

(1.52 bar).

FIRE VALVE

The yellow system fire valve installed in the right

hand wing, inboard of the pylon, is controlled by ENG2

FIRE pushbutton.

When the valve closes it stops the supply of fluid to

the Engine Driven Pump.

ENGINE DRIVEN PUMP

The Engine Driven Pump is attached to the accessory

gearbox. A solenoid valve controlled by the ENG 2 PUMP

pushbutton selects the pressurized or depressurized

mode.

The Engine Driven Pump cooling and lubricating flow

passes through a case drain filter installed in the

return line.

Pump outlet pressure is 3000 psi (206 bar) at zero

flow.

The Engine Driven Pump includes a blocking valve which

isolates the pump from the hydraulic system when the

pump operates in the depressurized mode.

Case drain filter clogging indication: P = 87 8.7

psi (6 0.6 bar).

GROUND COUPLINGS

On the ground it is possible to pressurize the yellow

hydraulic system from a ground power unit.

T

M

U

H

Y

D

D

0

4

-

T

0

1

L

E

V

E

L

3

EFFECTIVITY

29-13-00

Page 2

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 54

EFFECTIVITY

ALL

YELLOW HYDRAULIC SYSTEM D/O

T

M

U

H

Y

D

D

0

4

-

P

0

1

L

E

V

E

L

3

EFFECTIVITY

29-13-00

Page 3

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 55

EFFECTIVITY

ALL

YELLOW HYDRAULIC SYSTEM D/O

PRESSURE SWITCH

A pressure switch monitors the Engine Driven Pump

outlet pressure for ECAM indications.

The threshold of the pressure switch is 1740 psi (120

bar).

NOTE: A check valve downstream of the pump stops the

fluid flow to the pump if the system is

pressurized by the Power Transfer Unit (PTU) or

by the yellow electric pump.

POWER TRANSFER UNIT

The Power Transfer Unit will run automatically when

the differential pressure between the green and yellow

systems is greater than 500 psi (34.5 bar).

The PTU is inhibited during the first engine start and

cargo door operation.

ELECTRIC PUMP

The yellow electric pump runs if the ELEC PUMP

pushbutton is set to ON, or if a cargo door selector

is operated.

The electric pump cooling and lubricating flow passes

through the return filter.

In case of cargo door operation, the PTU is inhibited,

the yellow leak measurement valve is closed and a

signal is sent to SFCC2 to prevent flaps movement.

A check valve downstream of the pump stops the fluid

flow to the pump if the system is pressurized from the

Engine Driven Pump or the PTU.

HAND PUMP

The hand pump is installed on the ground service panel

of the yellow system and is used for manual cargo door

operation only. On ground, when no electrical power

is available, the hand pump can be used to open or

close the cargo doors.

T

M

U

H

Y

D

D

0

4

-

T

0

2

L

E

V

E

L

3

EFFECTIVITY

29-13-00

Page 4

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 56

EFFECTIVITY

ALL

YELLOW HYDRAULIC SYSTEM D/O

T

M

U

H

Y

D

D

0

4

-

P

0

2

L

E

V

E

L

3

EFFECTIVITY

29-13-00

Page 5

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 57

EFFECTIVITY

ALL

YELLOW HYDRAULIC SYSTEM D/O

HIGH PRESSURE MANIFOLD

PRESSURE SWITCHES

The signals from both pressure switches are sent to

the ECAM system, to the Flight Control Computers and

to the Flight Augmentation Computer 2.

The threshold of the pressure switches is 1450 psi

(99.5 bar).

PRESSURE TRANSDUCER

The pressure transducer provides data for pressure

indication on the ECAM and sends information to ELAC

1 and 2.

LEAK MEASUREMENT VALVE

The leak measurement valve isolates the flight controls

when the guarded LEAK MEASUREMENT VALVES pushbutton

on the maintenance panel is set to OFF.

The solenoid valve is automatically closed if the

yellow electric pump is energized by using cargo door

selectors. This is to prevent any movement of the

flight controls.

HP FILTER

The High Pressure filter is equipped with a clogging

indicator.

The clogging indicator operates when the differential

pressure is higher than 87 8.7 psi (6 0.6 bar).

ACCUMULATOR

The accumulator acts as a damper for small changes.

It also makes a supply of fluid available in case of

any demand.

The accumulator is precharged with nitrogen to 1885

psi (130 bar) at 20C. It holds 1.1l (0.29 USgal) of

total volume of fluid when it is full.

SAMPLING VALVE

A sampling valve is provided on the HP manifold.

PRESSURE RELIEF VALVE

The pressure relief valve connects the high pressure

circuit to the return circuit in case of overpressure.

The relief valve opens at 3436 psi (237 bar) and closes

at 3190 psi (220 bar).

T

M

U

H

Y

D

D

0

4

-

T

0

3

L

E

V

E

L

3

EFFECTIVITY

29-13-00

Page 6

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 58

EFFECTIVITY

ALL

YELLOW HYDRAULIC SYSTEM D/O

T

M

U

H

Y

D

D

0

4

-

P

0

3

L

E

V

E

L

3

EFFECTIVITY

29-13-00

Page 7

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 59

EFFECTIVITY

ALL

YELLOW HYDRAULIC SYSTEM D/O

LEAK MEASUREMENT MANIFOLD

The leak measurement valve block supplies the flight

controls of the right hand wing, left hand wing and

tail section via three separate outputs.

Opening a spool valve allows the associated section

of the flight controls to be supplied for leak

measurement test.

PTU MANIFOLD

QUICK DISCONNECT

The quick disconnect is used for maintenance operations

to prevent Power Transfer Unit operation.

PRIORITY VALVE

The priority valve makes sure that all available

hydraulic pressure is sent to the primary flight

controls if pressure in the system is reduced.

SOLENOID VALVE

The solenoid valve, installed in the Power Transfer

Unit supply line, stops the Power Transfer Unit

operation.

RETURN MANIFOLD

The return manifold comprises:

- a return filter equipped with a clogging

indicator.

- a temperature switch and two temperature

transducers.

The bypass operates when the differential pressure across

the filter is more than 29 2.35 psi (2 0.16 bar).

Temperature switch and probes send data to the ECAM

for indication and warnings.

T

M

U

H

Y

D

D

0

4

-

T

0

4

L

E

V

E

L

3

EFFECTIVITY

29-13-00

Page 8

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 60

EFFECTIVITY

ALL

YELLOW HYDRAULIC SYSTEM D/O

T

M

U

H

Y

D

D

0

4

-

P

0

4

L

E

V

E

L

3

EFFECTIVITY

29-13-00

Page 9

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 61

EFFECTIVITY

ALL

SELF EXAMINATION

When is the Engine Driven Pump in the depressurized

mode?

A - When the ENG 2 PUMP pushbutton is set to

OFF.

B - The engine pump cannot be depressurized

as long as the engine is running.

C - The engine pump is automatically

depressurized if the output pressure

drops below 1450 psi.

How can the LH wing be supplied independently

during leak measurement test?

A - By setting the leak measurement valve to

OFF and operating the electric pump

B - By pressurizing the yellow system by

using the PTU.

C - By setting the leak measurement valve to

OFF and manually open the LH wing spool

valve.

What can the hand pump be used for?

A - To pressurize the reservoir.

B - To check the flight controls.

C - To operate the cargo doors.

During which operation is the leak measurement

valve closed automatically?

A - PTU operation.

B - Cargo door operation.

C - Hand pump operation.

T

M

U

H

Y

D

D

0

4

L

E

V

E

L

3

EFFECTIVITY

29-13-00

Page 10

Jul 31/00

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 62

EFFECTIVITY

ALL

29 - HYDRAULIC POWER

29-19-00 LEAKAGE MEASUREMENT SYSTEM

PRESENTATION

CONTENTS:

General

Hydraulic System Test

Full System Test

Component Check

T

M

U

H

Y

D

W

0

1

L

E

V

E

L

3

EFFECTIVITY

29-19-00

Page 1

Oct 31/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 63

EFFECTIVITY

ALL

LEAKAGE MEASUREMENT SYSTEM PRESENTATION

The yellow system has been chosen as an example.

GENERAL

The return flow of a hydraulic system is equal to the

users demand flow plus the permanent internal leakage.

Note: Even with users at neutral, there is a permanent

flow. If the permanent flow is too high the

corresponding system operation will be affected.

The flight controls users are permanently supplied

through Leak Measurement Valves. These valves have to

be closed during leak hydraulic system test.

Internal leakage (full system check) is measured for

each group of users through manually operated shut-off

valves.

HYDRAULIC SYSTEM TEST

To test a complete hydraulic system, a hydraulic ground

cart equipped with a flow meter has to be used to

pressurize the circuit.

Precautions: Before starting the test make sure that

all servocontrols are in their neutral

position and that the spoilers are

retracted. Do not forget to disconnect

the isolation coupling of the PTU to

prevent inadvertent pressurization of

the green system by the PTU.

The internal leakage flow rate is indicated by the

flow meter.

If the flow rate is too high, a full system check has

to be carried out to find out the faulty group of

hydraulic users (RH wing, LH wing, Tail section,

Central section).

T

M

U

H

Y

D

W

0

1

-

T

0

1

L

E

V

E

L

3

EFFECTIVITY

29-19-00

Page 2

Oct 31/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 64

EFFECTIVITY

ALL

T

M

U

H

Y

D

W

0

1

-

P

0

1

L

E

V

E

L

3

LEAKAGE MEASUREMENT SYSTEM PRESENTATION

EFFECTIVITY

29-19-00

Page 3

Oct 31/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 65

EFFECTIVITY

ALL

LEAKAGE MEASUREMENT SYSTEM PRESENTATION

FULL SYSTEM CHECK

Once the hydraulic system is pressurized from the

ground cart, make sure that the ELACs, SECs and

FAC2 are set to ON to supply the hydraulic users.

The Flight Controls surfaces must be kept in the

neutral position.

Note: The internal leakage check has to be done with

the hydraulic fluid at its normal working

temperature.

The full system check is carried out by checking

successively the four sections of the hydraulic system

with the corresponding Leakage Measurement Valve in

the closed position.

The indicated flow must be compared to the theoretical

one and if the flow is over the limit the failed

component belongs to this group of users.

COMPONENT CHECK

Each type of hydraulic component has a maximum

permitted internal leakage limit.

Note: The total leakage of the components within a

section must be less than the permitted maximum

for that section. All together, the total

leakages of the sections must not be more than

the leakage permitted for the complete system.

If the internal leakage is too high, the faulty

component must be identified and replaced.

High leakage rate causes an increase of component

temperature.

If a servocontrol is considered to be faulty, it must

be disconnected and the corresponding hydraulic

section rechecked.

If the internal leakage rate is now within the limits,

the servocontrol is confirmed as defective.

T

M

U

H

Y

D

W

0

1

-

T

0

2

L

E

V

E

L

3

EFFECTIVITY

29-19-00

Page 4

Oct 31/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 66

EFFECTIVITY

ALL

LEAKAGE MEASUREMENT SYSTEM PRESENTATION T

M

U

H

Y

D

W

0

1

-

P

0

2

L

E

V

E

L

3

EFFECTIVITY

29-19-00

Page 5

Oct 31/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 67

EFFECTIVITY

ALL

THIS PAGE LEFT INTENTIONALLY BLANK

T

M

U

H

Y

D

W

0

1

L

E

V

E

L

3

EFFECTIVITY

29-19-00

Page 6

Oct 31/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 68

EFFECTIVITY

ALL

29 - HYDRAULIC POWER

29-14-00 HYDRAULIC RESERVOIR PRESSURIZING

SYSTEM D/O

CONTENTS:

General

Sources

Restrictor

Reservoir Pressurization Unit

Pressure Reducing Valve

Ground Connector

Filter

Water Separator

Reservoir Check Valves

Pressure Gage

Pressure Relief Valve

Manual Depressurization Valve

Self Examination

T

M

U

H

Y

D

E

0

5

L

E

V

E

L

3

EFFECTIVITY

29-14-00

Page 1

Apr 30/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 69

EFFECTIVITY

ALL

HYDRAULIC RESERVOIR PRESSURIZING SYSTEM D/O

GENERAL

An air pressure system is provided to pressurize each

hydraulic reservoir in order to ensure adequate fluid

supply to the pumps.

Each reservoir is pressurized by air at 50 psi (3.5

bar). The system also remains airtight in the event

of pressurization system failure or after engine

shutdown.

SOURCES

The pressure sources are engine 1, via a restrictor

or both engines and the APU, via the pneumatic

manifold. The pressure sources are:

- the engine 1 HP compressor (usual operation).

- the pneumatic system in case of loss of engine1.

- the ground supply.

RESTRICTOR

A restrictor limits the airflow and reduces the

temperature of the high pressure air to a satisfactory

level.

The restrictor also prevents too much bleed air leakage

in case of a leak downstream of the restrictor.

RESERVOIR PRESSURIZATION UNIT

The reservoir pressurization unit (RPU) controls the

pressure of the air supplied to the reservoirs.

PRESSURE REDUCING VALVE

A pressure reducing valve is fitted to the reservoir

pressurization unit.

In normal operation, the delivery pressure of engine

1 has priority over the pressure supply from the

pneumatic manifold.

Pressure reducing valve outlet pressure: 50 psi (3.5

bar).

Two check valves prevent any reverse flow.

GROUND CONNECTOR

Pressurized air from a ground supply cart goes directly

to the reservoir pressurization unit through a ground

connector.

FILTER

A filter fitted with a clogging indicator is installed

in the reservoir pressurization unit to filter the air

from the different supply sources.

WATER SEPARATOR

A water separator is installed on the reservoir

pressurization unit. It makes sure that the air

delivered to the reservoirs is clear of any fluid.

There are two drain valves which prevent freezing of

the water in the RPU.One is an automatic drain valve

which is opened after each engine or APU shutdown, the

other one is a manual self-sealing drain valve.

T

M

U

H

Y

D

E

0

5

-

T

0

1

L

E

V

E

L

3

EFFECTIVITY

29-14-00

Page 2

Apr 30/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 70

EFFECTIVITY

ALL

HYDRAULIC RESERVOIR PRESSURIZING SYSTEM D/O

T

M

U

H

Y

D

E

0

5

-

P

0

1

L

E

V

E

L

3

EFFECTIVITY

29-14-00

Page 3

Apr 30/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 71

EFFECTIVITY

ALL

HYDRAULIC RESERVOIR PRESSURIZING SYSTEM D/O

RESERVOIR CHECK VALVES

Downstream of the reservoir pressurization unit, the

air supply is divided into three flows to supply the

reservoirs through their related check valve. The green

and yellow check valves are installed between the floor

beams above the hydraulic bay and the blue one is

installed in the Aft cargo compartment.

PRESSURE GAGE

An air pressure gage is installed on each hydraulic

reservoir to indicate the actual pressure. LOW AIR

PRESS warning is generated by the pressure switch if

the pressure is less than 22 psi (1.52 bar).

PRESSURE RELIEF VALVE

A pressure relief valve, installed on each reservoir,

relieves pressure to the atmosphere in the event of a

system overpressure.

The threshold of the pressure relief valve is 77 psi

(5.3 bar).

MANUAL DEPRESSURIZATION VALVE

A manual depressurization valve is fitted on each

ground service panel to depressurize each reservoir.

WARNING: When using the manual depressurization valve

put on eye protection and keep away from the

outlet of the valve.

The air can be hot and contain particles of

dust and/or hydraulic fluid.

T

M

U

H

Y

D

E

0

5

-

T

0

1

L

E

V

E

L

3

EFFECTIVITY

29-14-00

Page 4

Apr 30/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 72

EFFECTIVITY

ALL

SELF EXAMINATION

When can the APU pressurize the reservoirs?

A - On ground only

B - In flight only

C - A and B

What are the manual depressurization valves

provided for?

A - Individual reservoir depressurization

B - Depressurization of related hydraulic

circuit

C - Hydraulic system depressurization

What is the purpose of the pressure relief valve?

A - To relieve hydraulic pressure to the

return manifold

B - To relieve excessive air pressure to the

atmosphere

C - To provide overpressure warning to the

ECAM

T

M

U

H

Y

D

E

0

5

L

E

V

E

L

3

EFFECTIVITY

29-14-00

Page 5

Apr 30/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 73

EFFECTIVITY

ALL

THIS PAGE INTENTIONALLY LEFT BLANK

T

M

U

H

Y

D

E

0

5

L

E

V

E

L

3

EFFECTIVITY

29-14-00

Page 6

Apr 30/98

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 74

EFFECTIVITY

ALL

29 - HYDRAULIC POWER

29-16-00 HYDRAULIC RESERVOIR FILLING

PRESENTATION

CONTENTS:

Coupling Socket

Restrictor

Hand Pump

Filter

Reservoir Filling Selector Valve

Reservoir Quantity Indicator

Check Valve

Self Examination

T

M

U

H

Y

D

F

0

1

L

E

V

E

L

2

EFFECTIVITY

29-16-00

Page 1

Jul 31/97

_

A319/A320/A321 TECHNICAL TRAINING MANUAL

29 HYDRAULIC POWER MECHANICS / ELECTRICS & AVIONICS COURSE

U

F

D

4

2

0

0

Page 75

EFFECTIVITY

ALL

HYDRAULIC RESERVOIR FILLING PRESENTATION

COUPLING SOCKET

The coupling socket is used to fill the reservoir from

a pressurized ground hydraulic supply.

The coupling socket includes a check valve.

RESTRICTOR

A restrictor located between the coupling socket and

the reservoir filling selector valve protects the

system against over pressure.

HAND PUMP

The hand pump is used to refill the reservoirs if no

ground cart is available.

The hand pump lever is on the yellow ground service

panel. A specific filling valve including a filter and

a check valve is installed on the hand pump.

FILTER

The filter of the reservoir filling system is equipped

with a clogging indicator.

Note: No bypass possibility on this filter.

RESERVOIR FILLING SELECTOR VALVE

The reservoir filling selector valve directs the

hydraulic fluid from the supply source to the reservoir

of the selected system. Do not depressurize the

hydraulic reservoir to refill it.