Professional Documents

Culture Documents

D 7015 - 04 Rdcwmtu

Uploaded by

Humberto Gutierrez0 ratings0% found this document useful (0 votes)

103 views6 pagesThis designation outlines the procedures for Obtaining Undisturbed Block (cubical and cylindrical) samples of soil. Successful sampling of granular materials requires sufficient cohesion, cementation.

Original Description:

Original Title

D 7015 – 04 ;RDCWMTU_

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis designation outlines the procedures for Obtaining Undisturbed Block (cubical and cylindrical) samples of soil. Successful sampling of granular materials requires sufficient cohesion, cementation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

103 views6 pagesD 7015 - 04 Rdcwmtu

Uploaded by

Humberto GutierrezThis designation outlines the procedures for Obtaining Undisturbed Block (cubical and cylindrical) samples of soil. Successful sampling of granular materials requires sufficient cohesion, cementation.

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 6

Designation: D 7015 04

Standard Practices for

Obtaining Undisturbed Block (Cubical and Cylindrical)

Samples of Soils

1

This standard is issued under the xed designation D 7015; the number immediately following the designation indicates the year of

original adoption or, in the case of revision, the year of last revision. A number in parentheses indicates the year of last reapproval. A

superscript epsilon (e) indicates an editorial change since the last revision or reapproval.

1. Scope

1.1 This designation outlines the procedures for obtaining

undisturbed block (cubical and cylindrical) soil samples.

1.2 Undisturbed block samples are obtained for laboratory

tests to determine the strength, consolidation, permeability, and

other geotechnical engineering or physical properties of the

undisturbed soil.

1.3 Two sampling practices are presented. Practice Acovers

cubical block sampling, while Practice B covers cylindrical

block sampling.

1.4 These practices usually involve test pit excavation and

are limited to relatively shallow depths. Except in the case of

large diameter (that is, >0.75 m) bored shafts of circular

cross-section in unsaturated soils, for depths greater than about

1 to 1

1

2 meters or depths below the water table, the cost and

difficulties of excavating, cribbing, and dewatering generally

make block sampling impractical and uneconomical. For these

conditions, use of a thin-walled push tube soil sampler (Prac-

tice D 1587), a piston-type soil sampler (Practice D 6519), or

Hollow-Stem Auger (D 6151), Dennison, or Pitcher-type soil

core samplers, or freezing the soil and coring may be required.

This practice does not address environmental sampling; consult

Guides D 6169 and D 6232 for information on sampling for

environmental investigations.

1.5 Successful sampling of granular materials requires suf-

cient cohesion, cementation, or apparent cohesion (due to

moisture tension (suction)) of the soil for it to be isolated in a

column shape without undergoing excessive deformations.

Additionally, care must be exercised in the excavation, pres-

ervation and transportation of undisturbed samples (see Prac-

tice D 4220, Group D).

1.6 The values stated in SI units are to be regarded as the

standard. No other units are included in this standard.

1.7 This practice offers a set of instructions for performing

one or more specic operations. This document cannot replace

education or experience and should be used in conjunction

with professional judgment. Not all aspects of this practice may

be applicable in all circumstances. This ASTM standard is not

intended to represent or replace the standard of care by which

the adequacy of a given professional service must be judged,

nor should this document be applied without consideration of

a projects many unique aspects. The word 9Standard9 in the

title of this document means only that the document has been

approved through the ASTM consensus process.

1.8 This standard does not purport to address all of the

safety concerns, if any, associated with its use. It is the

responsibility of the user of this standard to establish appro-

priate safety and health practices and determine the applica-

bility of regulatory requirements prior to use. For specic

hazard statements, see Section 6.

2. Referenced Documents

2.1 ASTM Standards:

2

D 653 Terminology Relating to Soil, Rock, and Contained

Fluids

D 1587 Practice for Thin-Walled Tube Sampling of Soils

for Geotechnical Purposes

D 1785 Specication for Poly (Vinyl Chloride) (PVC) Plas-

tic Pipe, Schedules 40, 80, and 120

D 2488 Practice for Determining Unied Soil Classication

(Visual Method)

D 2937 Test Method for Density of Soils in Place by the

Drive-Cylinder Method

D 3740 Practice for Minimum Requirements for Agencies

Engaged in the Testing and/or Inspection of Soil and Rock

as Used in Engineering Design and Construction

D 4220 Practices for Preserving and Transporting Soil

Samples

D 5434 Guide for Field Logging of Subsurface Explora-

tions of Soil and Rock

D 6151 Practice for Using Hollow-Stem Augers for Geo-

technical Exploration and Soil Sampling

D 6169 Guide for Selection of Soil and Rock Sampling

Devices Used With Drill Rigs for Environmental Investi-

gations

D 6232 Guide for Selection of Sampling Equipment for

1

These practices are under the jurisdiction of ASTM Committee D18 on Soil and

Rock and is the direct responsibility of Subcommittee D18.02 on Sampling and

Related Field Testing for Soil Investigations.

Current edition approved Feb. 1, 2004. Published February 2004.

2

For referenced ASTM standards, visit the ASTM website, www.astm.org, or

contact ASTM Customer Service at service@astm.org. For Annual Book of ASTM

Standards volume information, refer to the standards Document Summary page on

the ASTM website.

1

Copyright ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959, United States.

Waste and Contaminated Media Data Collection Activities

D 6519 Practice for Sampling of Soil Using the Hydrauli-

cally Operated Stationary Piston Sampler

3. Terminology

3.1 DenitionsFor denition of terms in this standard

refer to Terminology D 653.

4. Signicance and Use

4.1 Undisturbed block samples are suitable for laboratory

tests where large-sized samples of undisturbed material are

required or where such sampling is more practical than

conventional tube sampling (Practices D 1587 and D 6519), or

both.

4.2 This method of sampling is advantageous where the soil

to be sampled is near the ground surface. This is the best

available method for obtaining large undisturbed samples of

very stiff and brittle soils, partially cemented soils, and some

soils containing coarse gravel.

4.3 Excavating a column of soil may relieve stresses in the

soil and may result in some expansion of the soil and a

corresponding decrease in its unit weight (density) or increase

in sampling disturbance, or both. Usually the expansion is

small in magnitude because of the shallow depth. Stress

changes alone can cause enough disturbances in some soils to

signicantly alter their engineering properties.

4.4 The chain saw has proved advantageous in sampling

difficult soils, which are blocky, slickensided, or gravelly, or

materials containing alternating layers of hard and soft mate-

rial.

3

The chain saw uses a special carbide-tipped chain.

4

NOTE 1The quality of the result produced by this standard is

dependent on the competence of the personnel performing it, and the

suitability of the equipment and facilities used. Agencies that meet the

criteria of Practice D 3740 are generally considered capable of competent

and objective sampling. Users of this practice are cautioned that compli-

ance with Practice D 3740 does not in itself assure reliable results.

Reliable results depend on many factors; Practice D 3740 provides a

means of evaluating some of those factors.

5. Apparatus

5.1 Excavating and trimming tools are required. This may

include such items as backhoe, pick, shovel, chain saw, trowel,

large and small knives, hacksaw blades, thin wire such as piano

wire. In addition, a sample container having sufficient strength

and rigidity to avoid deformations that could damage the

sample.

5.1.1 The chain for the chain saw is of standard design

except that carbide tips are brazed to the cutting teeth. The

chain saws bar length should be greater than 457 mm.

5.2 For cubical block sampling, a cubical wooden, steel box

or any relatively rigid material that can be assembled into a box

10 mm to 15 mm larger than the sample side dimensions may

be used to contain the cubical block sample during the required

cutting process (see 7.1.8) or transportation or both. Steel

boxes should have some form of protective coating as outlined

in 5.3, unless the soil is to be extruded in less than 3 days. The

box should be fastened using screws, or bolts and nuts

preferable before going to the eld to verify that the parts t

together and can be assembled without vibration of the sample.

Do not use nails or other devices that require hammering to

assemble or dissemble the box.

5.3 For cylindrical block sampling, cylindrical tubes made

of steel or any relatively rigid material may be used to contain

the cylindrical block sample during the required cutting pro-

cess (see 7.2.5) or transportation or both. Steel tubes should

have some form of protective coating, unless the soil is to be

extruded in less than 3 days. The type of coating to be used

may vary depending upon the material to be sampled. Plating

of the tubes or alternate base metals may be specied.

Galvanized tubes are often used when long-term storage is

required. Tubes may be protected with a light coating of

lubricating oil, lacquer, epoxy, TFR uorocarbon, or zinc

oxide. One end of the tube should have a sharpened cutting

edge to assist in cutting the soil. Cylindrical tubes made of

PVC pipe should have a minimum sidewall thickness of no less

than that of a Schedule 80 pipe (Specication D 1785).

NOTE 2Experience with thin-wall push tube sampling of soils (Prac-

tice D 1587) indicates disturbance is minimized when the cutting edge is

about 10 degrees or less. This sharp angle is possible with metal tubes, but

may not be with other materials such as PVC, and a sharp angle may not

be critical to hand trimmed samples.

5.4 Cheesecloth or similar cloth wrapping material.

5.5 Sealing wax, paintbrush, and melting stove or heater.

Use a sealing wax that does not shrink appreciably, does not

permit evaporation from the sample, and does not exhibit

brittle characteristics. Microcrystalline waxes are preferable to

paraffin.

5.6 Shipping containers, packing materials, labels, data

forms, and other necessary supplies. Packing material may be

light, resilient polystyrene plastic, sawdust, or smaller material.

5.7 Fuel for the wax melting stove or heater, and fuel and

lubricating oil for the chain saw.

5.8 Personal protective equipment (PPE) should be consid-

ered when necessary. If a chain saw is used, eye and hearing

protection are necessary. Ahard hat may also be appropriate. A

rst aid kit should be available and a re extinguisher should

also be handy especially where a stove or heater is being used.

6. Hazards

6.1 Warning StatementTrenching and excavation work

presents serious risks, such as slope instability, ventilation,

hearing etc. to all workers involved. All excavations must be

constructed in accordance with applicable OSHA require-

ments.

5

7. Procedure

7.1 Practice ACubical Block Sampling:

7.1.1 At the location where the block sample is to be

obtained level and smooth the ground surface and mark the

3

Tiedemann, D. A., GR-83-8, Undisturbed Block Sampling Using a Chain

Saw, Bureau of Reclamation, Denver, CO, 1983, p. 19.

4

USBR 7100-89, Obtaining Undisturbed Block Samples by the Hand and

Chain Saw Methods, Earth ManualPart 2, Bureau of Reclamation, Denver, CO,

1990, pp. 1079-1083.

5

29 CFR 1926 Labor, Code of Federal Regulations, U.S. Printing office, 1991.

D 7015 04

2

outline of a face of the block. Surface soils containing roots or

other organic matter should be removed.

NOTE 3The size of the sample depends upon its intended use. For

most investigations, a cube about 0.3 m per side, with a mass of about 55

kg, provides sufficient material and can be handled easily.

7.1.2 Carefully excavate a trench around the sample to the

required depth, removing a sufficient amount of material to

provide space in which to work as shown on Fig. 1. If a

backhoe is used to excavate the trench, rst dig out an

oversized column (pedestal) large enough that the soil to be

sampled is not disturbed by the backhoe operation.

NOTE 4Generally, a pedestal 0.9 or 1.2 m on a side and 0.9 to 1.2 m

high is adequate. If the soil is fragile and easily broken, backhoe usage

may be limited to excavation of only two or three sides of the pedestal,

with the remaining side or sides excavated by chain saw and/or by hand

methods. In addition, if the soil is fragile and easily broken, the cylindrical

block sampling procedure (see 7.2) should be considered, provided the

pushing in one continuous motion or drive-cylinder methods are not

used.

7.1.3 Gradually remove excess soil on the sides of the block

using the chain saw and/or hand methods until a pedestal of the

desired size is obtained.

7.1.4 Measure and record the elevation (or depth below the

ground surface) to the top of the sample and depth to water

level if encountered.

7.1.5 Visually classify the soil(s) in the sample based on the

trimmings and exposed surfaces of the block in accordance

with Practice D 2488, and describe the in-place condition of

the soil, such as color, odor, moisture condition, consistency,

cementation and structure. Record the soils classication and

in-place condition on a data sheet, see Section 9. Photographs

of the block location (before and after trimming around the

block) are desirable.

7.1.6 Cover the freshly exposed faces of the sample (ped-

estal) with cheesecloth and paint with melted wax as shown in

Fig. 2. Apply additional layers of cheesecloth and wax to form

a total of three (minimum) layers. Hot wax should not be

poured directly over the sample. If the soil is fragile, apply

cheesecloth and then wax to individual faces of the sample as

they are exposed.

7.1.7 Identify the sample (number, location, elevation, etc.),

and mark the top of sample and the north orientation. A piece

of heavy paper showing this information should be waxed to

the top of the sample and if applicable, add a second copy to

the top of the box containing the block sample, see Section 8.

7.1.8 To remove the cubical block sample, carefully cut or

shear the base of the sample from the underlying soil using a

thin wire such as piano wire if in clayey soils, or with either a

chain saw, shovels, or knives if in other soil types. If the soil is

disturbed easily, a sturdy box with both ends removed should

be placed over the sample, and ll the space between the

sample and the box with packing material and attach the top to

the box with screws, or with bolts and nuts prior to removing

the base of the sample (see Fig. 3).

7.1.9 Carefully tilt the sample on one side. Add appropriate

packing materials to minimize any voids between the box and

sample. Cover the exposed bottom face with at least three

layers of cheesecloth and wax as described in 7.1.6.

7.1.10 Record all necessary information on a data sheet as

specied in Section 9. A copy of a sample data sheet is

included in Appendix X1.

7.2 Practice BCylindrical Block Sampling:

7.2.1 At the location where the cylindrical sample is to be

obtained, level and smooth the ground surface. Surface soils

containing roots or other organic matter should be removed.

Samples may be obtained from the bottom or the side of a test

pit as shown on Fig. 1. Pushing in one continuous motion

without hand trimming can be performed in accordance with

Practice D 1587. Another method for advancing cylindrical

samples by hammer impact is the Drive-Cylinder method (Test

Method D 2937) (see Notes 5 and 6).

7.2.2 Carefully excavate a trench around the sample to the

required depth, removing a sufficient amount of material to

provide space in which to work. If a backhoe is used to

FIG. 1 Procedure for Rectangular Block Sampling FIG. 2 Procedure for Placing Cheesecloth and Wax

D 7015 04

3

excavate the trench, rst dig out an oversized column (pedes-

tal) large enough that the soil to be sampled is not disturbed by

the backhoe operation.

7.2.3 Place the sample container on the surface and gradu-

ally remove excess soil around the perimeter of the container

using a tool like a cutter knife to a diameter several millimeters

larger than the inner diameter of the sampling tube until 5 to 6

mm of soil is exposed.

7.2.4 Gently push down vertically and uniformly to retain

the sample. Repeat the above cutting and pushing procedures

until the surface of the sample extends above the sampling tube

by approximately 3 cm (see Fig. 4).

NOTE 5For soft soil and soils wet of optimum compaction, the tube

can be pushed without any hand trimming using a thin-walled tube as

described in Practice D 1587 or by drive cylinder (Test Method D 2937).

NOTE 6For sensitive, fragile or brittle soils, there could be distur-

bance from pushing or hammering and if disturbance is suspected,

consider using smaller trimming and pushing increments as covered in

7.2.4 .

7.2.5 After lling the sample container, the bottom is

separated from the ground as described in 7.1.8, and the upper

and lower ends of the separated sample are trimmed.

7.2.6 Measure and record the elevation (or depth below the

ground surface) to the top of the sample and depth to water

level, if encountered.

7.2.7 Visually classify soils in the sample in accordance

with Practice D 2488, and describe the in-place condition of

the soil and record information on data sheet, see Section 9.

Photographs of the block location (before and after trimming

around the block) are desirable.

7.2.8 Trim the sample ends ush with the ends of the

cylinder. If the volume and mass of the cylinder is known, the

mass and density of the specimen can be determined. Water

content of the specimen can be determined from the trimmings

and the dry density of sample can be calculated.

7.2.9 Cover the freshly exposed faces of the sample with

cheesecloth and paint with melted wax. Apply additional layers

of cheesecloth and wax to form a total of three (minimum)

layers. Hot wax should not be poured over the sample. If the

exposed faces are fragile, apply cheesecloth and wax to

individual faces as they are exposed. Alternatively, after

measurement, the sample may be sealed with plastic caps and

tape on the ends of the sample.

7.2.10 Identify the sample (number, location, elevation,

etc.), and mark the top of sample and the north orientation. A

piece of heavy paper showing this information should be

waxed to the top of the sample and if applicable, add a second

copy to the top of the box containing the block sample, see

Section 8.

7.2.11 Record all necessary information on a data sheet as

specied in Section 9. A copy of a sample data sheet is

included in Appendix X1.

8. Preparation for Shipment

8.1 Prepare and immediately affix labels or apply markings

as necessary to identify the sample (see Section 7). Top end of

the sample container should be labeled top. Assure that the

markings or labels are adequate to survive transportation and

storage in accordance with Practice D 4220, Group C or D

requirements. For unstable soils, the samples should be trans-

ported and stored in an upright position.

9. Report

9.1 An example of a sample data sheet is included in

Appendix X1.

9.2 Record the information that may be required for prepar-

ing the eld data sheet in general accordance to Guide D 5434.

Record as a minimum the following information (data):

9.2.1 Project information, such as Project No. or name.

9.2.2 Sampling information, such as:

9.2.2.1 General location or referenced to site map,

9.2.2.2 ProcedurePractice A (cubical block sampling) or

Practice B (cylindrical block sampling),

9.2.2.3 Date and time of sampling,

9.2.2.4 Name of sampling personnel and their affiliation and

inspector, as appropriate and

9.2.2.5 Any weather conditions that could affect the sam-

pling process such as raining, snowing, freezing or unusually

hot temperatures, and very windy.

9.2.3 Sample data, such as:

9.2.3.1 Sample number,

9.2.3.2 Depth to top of sample to the nearest 0.2 m or better,

9.2.3.3 Dimensions to the nearest cm or better,

9.2.3.4 Orientation (north arrow on samples top), see 7.1.7

or 7.2.10 and

9.2.3.5 Visual description of the soil(s) contained in the

sample (Practice D 2488) along with the in-place condition of

the soil such as color, odor, moisture condition, consistency

and structure.

9.3 Other data that may be required include:

FIG. 3 Procedure for Placing Box Around R

FIG. 4

D 7015 04

4

9.3.1 Surface elevation or reference to a datum to the

nearest 0.5 m or better, and

9.3.2 Depth of groundwater, if encountered.

10. Keywords

10.1 block sample; block sampling; cylindrical sampling;

geologic investigations; sampling; soil exploration; soil inves-

tigations; subsurface investigations; undisturbed

APPENDIX

(Nonmandatory Information)

X1. EXAMPLE DATA SHEET

FIG. X1.1 Example Data Sheet

D 7015 04

5

ASTM International takes no position respecting the validity of any patent rights asserted in connection with any item mentioned

in this standard. Users of this standard are expressly advised that determination of the validity of any such patent rights, and the risk

of infringement of such rights, are entirely their own responsibility.

This standard is subject to revision at any time by the responsible technical committee and must be reviewed every ve years and

if not revised, either reapproved or withdrawn. Your comments are invited either for revision of this standard or for additional standards

and should be addressed to ASTM International Headquarters. Your comments will receive careful consideration at a meeting of the

responsible technical committee, which you may attend. If you feel that your comments have not received a fair hearing you should

make your views known to the ASTM Committee on Standards, at the address shown below.

This standard is copyrighted by ASTM International, 100 Barr Harbor Drive, PO Box C700, West Conshohocken, PA 19428-2959,

United States. Individual reprints (single or multiple copies) of this standard may be obtained by contacting ASTM at the above

address or at 610-832-9585 (phone), 610-832-9555 (fax), or service@astm.org (e-mail); or through the ASTM website

(www.astm.org).

D 7015 04

6

You might also like

- D 7015 - 04 Rdcwmtu - PDFDocument6 pagesD 7015 - 04 Rdcwmtu - PDFJaneth MendozaNo ratings yet

- ASTM D 2937-00 Standard Test Method For Density of Soil in Place by The Drive-Cylinder MethodDocument5 pagesASTM D 2937-00 Standard Test Method For Density of Soil in Place by The Drive-Cylinder MethodPablo Antonio Valcárcel Vargas100% (1)

- Soil Exploration and Sampling by Auger Borings: Standard Practice ForDocument6 pagesSoil Exploration and Sampling by Auger Borings: Standard Practice ForJailson SilvaNo ratings yet

- D 3213 Â " 91 R97 RDMYMTMTUKVEDocument7 pagesD 3213 Â " 91 R97 RDMYMTMTUKVEJUAN PABLO SILVERIO LUDEÑANo ratings yet

- ASTM D7015 - 07, Obtaining Intact Block (Cubical and Cylindrical) Samples of SoilsDocument6 pagesASTM D7015 - 07, Obtaining Intact Block (Cubical and Cylindrical) Samples of SoilsBárbara RodríguezNo ratings yet

- D 427 - 98 - Rdqyny1sruqDocument5 pagesD 427 - 98 - Rdqyny1sruqgrats_singcoNo ratings yet

- D 3877 - 96 - Rdm4nzctukveDocument6 pagesD 3877 - 96 - Rdm4nzctukvefarageNo ratings yet

- Astm D6519 - 08Document7 pagesAstm D6519 - 08Black GokuNo ratings yet

- Cono de Arena ASTM-D1587-00Document2 pagesCono de Arena ASTM-D1587-00klayalaespolNo ratings yet

- ASTM D4829-08a PDFDocument5 pagesASTM D4829-08a PDFOm BunNo ratings yet

- Astm D3550-01Document5 pagesAstm D3550-01Gerlin BarriosNo ratings yet

- Expansion Index of Soils: Standard Test Method ForDocument6 pagesExpansion Index of Soils: Standard Test Method ForSebastian TamayoNo ratings yet

- Thin-Walled Tube Sampling of Soils For Geotechnical PurposesDocument4 pagesThin-Walled Tube Sampling of Soils For Geotechnical PurposesAnderson de SouzaNo ratings yet

- Soil Density Det. NewDocument15 pagesSoil Density Det. NewPendraSagitaNo ratings yet

- D 6519 - 02-Sampling of Soil Usingthe Hydraulic OperatedStationary Piston SamplerDocument8 pagesD 6519 - 02-Sampling of Soil Usingthe Hydraulic OperatedStationary Piston SamplerJamie MooreNo ratings yet

- D5781 1005608-1Document8 pagesD5781 1005608-1Sidharth SharmaNo ratings yet

- Astm D1452 - 09Document6 pagesAstm D1452 - 09Anna Dewi100% (1)

- D 693 - 03 Rdy5mwDocument3 pagesD 693 - 03 Rdy5mwRufo CascoNo ratings yet

- Moisture-Density (Unit Weight) Relations of Soil-Cement MixturesDocument6 pagesMoisture-Density (Unit Weight) Relations of Soil-Cement Mixturesgrats_singcoNo ratings yet

- Density of Soil in Place by The Drive-Cylinder Method: Standard Test Method ForDocument5 pagesDensity of Soil in Place by The Drive-Cylinder Method: Standard Test Method ForBatNo ratings yet

- Norma Suelos 1Document7 pagesNorma Suelos 1Jesus DiazNo ratings yet

- ASTM D 5784-D 5784M-13-Use of Hollow-Stem Augers For GeoenvironmentalDocument7 pagesASTM D 5784-D 5784M-13-Use of Hollow-Stem Augers For GeoenvironmentalRACHMATNo ratings yet

- Wetting and Drying Compacted Soil-Cement Mixtures: Standard Test Methods ForDocument7 pagesWetting and Drying Compacted Soil-Cement Mixtures: Standard Test Methods Forjimmy AndresNo ratings yet

- D5092 - Design and Installation of Ground Water Monitoring Wells in AquifersDocument14 pagesD5092 - Design and Installation of Ground Water Monitoring Wells in Aquifersmaxuelbestete100% (1)

- D1587!00!2007 Standard Practice For Thin-Walled Tube Sampling of Soils For Geotechnical PurposesDocument4 pagesD1587!00!2007 Standard Practice For Thin-Walled Tube Sampling of Soils For Geotechnical PurposesBobNo ratings yet

- ASTM D 5782-95 Standard Guide For Use of Direct Air-Rotary Drilling For Geoenviromental Exploration and The Installation of Subsurface Water-Quality Monitoring DevicesDocument7 pagesASTM D 5782-95 Standard Guide For Use of Direct Air-Rotary Drilling For Geoenviromental Exploration and The Installation of Subsurface Water-Quality Monitoring DevicesPablo Antonio Valcárcel VargasNo ratings yet

- ASTM D 1633-00 Standard Methods For Compressive Strength of Molded Soil-Cement CylindersDocument4 pagesASTM D 1633-00 Standard Methods For Compressive Strength of Molded Soil-Cement CylindersPablo Antonio Valcárcel VargasNo ratings yet

- D 968-93Document4 pagesD 968-93Thu VoNo ratings yet

- Astm d5873 EsclerometroDocument4 pagesAstm d5873 EsclerometroNabucodonosor1980No ratings yet

- Thin-Walled Tube Sampling of Fine-Grained Soils For Geotechnical PurposesDocument10 pagesThin-Walled Tube Sampling of Fine-Grained Soils For Geotechnical PurposesabualamalNo ratings yet

- D2573-01-2007 Standard Test Method For Field Vane Shear Test in Cohesive SoilDocument8 pagesD2573-01-2007 Standard Test Method For Field Vane Shear Test in Cohesive SoilBobNo ratings yet

- Use of Hollow-Stem Augers For Geoenvironmental Exploration and The Installation of Subsurface Water-Quality Monitoring DevicesDocument7 pagesUse of Hollow-Stem Augers For Geoenvironmental Exploration and The Installation of Subsurface Water-Quality Monitoring DevicesGiancarlo CalleNo ratings yet

- Astm D 5783Document7 pagesAstm D 5783Jorge JiménezNo ratings yet

- D7380 DCPDocument8 pagesD7380 DCPthaynarethNo ratings yet

- D558Document6 pagesD558jimmy AndresNo ratings yet

- Astm D 2488-00 PDFDocument11 pagesAstm D 2488-00 PDFLeandro MachadoNo ratings yet

- Field Vane Shear Test in Saturated Fine-Grained Soils: Standard Test Method ForDocument8 pagesField Vane Shear Test in Saturated Fine-Grained Soils: Standard Test Method ForAlina GheorgheNo ratings yet

- D-6169-98 Selection of Soil and Rock Sampling Devices Used With Drill Rigs For Environmental InvestigationsDocument19 pagesD-6169-98 Selection of Soil and Rock Sampling Devices Used With Drill Rigs For Environmental InvestigationsWaqas Ahmad AbbasiNo ratings yet

- Thin-Walled Tube Sampling of Fine-Grained Soils For Geotechnical PurposesDocument10 pagesThin-Walled Tube Sampling of Fine-Grained Soils For Geotechnical PurposesCarlos CmbbNo ratings yet

- ASTM D1587 Standard Practice For Thin-Walled Tube Sampling of Fine-Grained Soils For Geotechnical PurposeDocument10 pagesASTM D1587 Standard Practice For Thin-Walled Tube Sampling of Fine-Grained Soils For Geotechnical PurposestellaraydanNo ratings yet

- Astm D 3282 - 93 - R 2004Document6 pagesAstm D 3282 - 93 - R 2004anish_am2005No ratings yet

- Sand Equivalent Value of Soils and Fine Aggregate: Standard Test Method ForDocument9 pagesSand Equivalent Value of Soils and Fine Aggregate: Standard Test Method ForNancy Carolina Prieto MartinezNo ratings yet

- D 854 - 00 Rdg1nc1sruq - PDFDocument9 pagesD 854 - 00 Rdg1nc1sruq - PDFLupita CarelyNo ratings yet

- D2321Document11 pagesD2321Timothy McmillanNo ratings yet

- D1883 Red.24524 1Document12 pagesD1883 Red.24524 1Pier ArriagaNo ratings yet

- Astm D2937 10Document6 pagesAstm D2937 10Muqdadaakm2006 RaoofNo ratings yet

- D 427 - 98 Rdqyny1sruq - PDFDocument5 pagesD 427 - 98 Rdqyny1sruq - PDFLupita CarelyNo ratings yet

- D2321-05 Standard Practice For Underground Installation of Thermoplastic Pipe For Sewers and Other Gravity-Flow Applications 1Document11 pagesD2321-05 Standard Practice For Underground Installation of Thermoplastic Pipe For Sewers and Other Gravity-Flow Applications 1RaaannNo ratings yet

- D 4543 - 01 - Preparing Rock Core Specimens and DeterminingDocument5 pagesD 4543 - 01 - Preparing Rock Core Specimens and DeterminingGerald Dueñas EncisoNo ratings yet

- D 2113 - 99 Rdixmtm - PDFDocument20 pagesD 2113 - 99 Rdixmtm - PDFJhony CotaNo ratings yet

- Coiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!From EverandCoiled Tubing Operations at a Glance: What Do You Know About Coiled Tubing Operations!Rating: 5 out of 5 stars5/5 (2)

- Site Safety Handbook for the Petroleum IndustryFrom EverandSite Safety Handbook for the Petroleum IndustryRating: 5 out of 5 stars5/5 (1)

- Corrosion Testing for Metal Finishing: Institute of Metal FinishingFrom EverandCorrosion Testing for Metal Finishing: Institute of Metal FinishingNo ratings yet

- 16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsFrom Everand16th Edition IEE Wiring Regulations: Design and Verification of Electrical InstallationsRating: 4 out of 5 stars4/5 (1)

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- Soil Investigation and Foundation DesignFrom EverandSoil Investigation and Foundation DesignRating: 4.5 out of 5 stars4.5/5 (9)

- Jesús Rubí M.: Fórmulas de Cálculo Diferencial e IntegralDocument0 pagesJesús Rubí M.: Fórmulas de Cálculo Diferencial e IntegralSergio1218No ratings yet

- F 477 - 02 RJQ3NWDocument4 pagesF 477 - 02 RJQ3NWHumberto GutierrezNo ratings yet

- F 438 - 99 Rjqzoc05oqDocument5 pagesF 438 - 99 Rjqzoc05oqHumberto GutierrezNo ratings yet

- D 3517 - 03 Rdm1mtctukveDocument14 pagesD 3517 - 03 Rdm1mtctukveHumberto GutierrezNo ratings yet

- Type PSM Poly (Vinyl Chloride) (PVC) Sewer Pipe and Fittings: Standard Specification ForDocument12 pagesType PSM Poly (Vinyl Chloride) (PVC) Sewer Pipe and Fittings: Standard Specification ForHumberto GutierrezNo ratings yet

- F 409 - 99 Rjqwos05oueDocument16 pagesF 409 - 99 Rjqwos05oueHumberto GutierrezNo ratings yet

- D 5926 - 96 Rdu5mjytukveDocument5 pagesD 5926 - 96 Rdu5mjytukveHumberto GutierrezNo ratings yet

- D 3840 - 99 Rdm4ndatotkDocument9 pagesD 3840 - 99 Rdm4ndatotkHumberto GutierrezNo ratings yet

- D 5319 - 97 R01 RduzmtkDocument4 pagesD 5319 - 97 R01 RduzmtkHumberto GutierrezNo ratings yet

- D 4726 - 02 Rdq3mjyDocument11 pagesD 4726 - 02 Rdq3mjyHumberto GutierrezNo ratings yet

- D 4495 - 98 Rdq0otutukveDocument7 pagesD 4495 - 98 Rdq0otutukveHumberto GutierrezNo ratings yet

- D 3309 - 96a R02 RDMZMDKDocument11 pagesD 3309 - 96a R02 RDMZMDKHumberto GutierrezNo ratings yet

- D 2235 - 96 RdiymzutukveDocument7 pagesD 2235 - 96 RdiymzutukveHumberto GutierrezNo ratings yet

- D 2680 - 95 Rdi2odatotvbDocument8 pagesD 2680 - 95 Rdi2odatotvbHumberto GutierrezNo ratings yet

- D 3035 - 03 RdmwmzutukveDocument8 pagesD 3035 - 03 RdmwmzutukveHumberto GutierrezNo ratings yet

- D 4947 - 00 RDQ5NDCDocument8 pagesD 4947 - 00 RDQ5NDCHumberto GutierrezNo ratings yet

- D 2729 - 96 Rdi3mjktukveDocument6 pagesD 2729 - 96 Rdi3mjktukveHumberto GutierrezNo ratings yet

- D 2657 - 03 Rdi2ntcDocument7 pagesD 2657 - 03 Rdi2ntcHumberto GutierrezNo ratings yet

- D 6246 - 01 RdyyndytmdeDocument10 pagesD 6246 - 01 RdyyndytmdeHumberto GutierrezNo ratings yet

- D 2444 - 99 Rdi0ndqDocument8 pagesD 2444 - 99 Rdi0ndqHumberto GutierrezNo ratings yet

- D 2122 - 98 RdixmjitotgDocument5 pagesD 2122 - 98 RdixmjitotgHumberto GutierrezNo ratings yet

- D 2467 - 02 Rdi0njctmdiDocument8 pagesD 2467 - 02 Rdi0njctmdiHumberto GutierrezNo ratings yet

- D 2105 - 01 - RdixmduDocument6 pagesD 2105 - 01 - RdixmduSwapnil CallaNo ratings yet

- D 6216 - 03 RdyymtyDocument32 pagesD 6216 - 03 RdyymtyHumberto GutierrezNo ratings yet

- D 1694 - 95 R00 Rde2otqDocument4 pagesD 1694 - 95 R00 Rde2otqHumberto GutierrezNo ratings yet

- D 1608 - 98 R03 Rde2mdgDocument6 pagesD 1608 - 98 R03 Rde2mdgHumberto GutierrezNo ratings yet

- D 1527 - 99 Rde1mjctukveDocument11 pagesD 1527 - 99 Rde1mjctukveHumberto GutierrezNo ratings yet

- D 542 - 95 Rdu0mi1sruqDocument5 pagesD 542 - 95 Rdu0mi1sruqHumberto GutierrezNo ratings yet

- D 2914 - 01 Rdi5mtqDocument14 pagesD 2914 - 01 Rdi5mtqHumberto GutierrezNo ratings yet

- D 6941 - 03 Rdy5ndetukveDocument5 pagesD 6941 - 03 Rdy5ndetukveHumberto GutierrezNo ratings yet

- WSH Guidelines for Landscape and Horticulture WorksDocument69 pagesWSH Guidelines for Landscape and Horticulture Workslwin_oo2435No ratings yet

- 12 Volt Bar-Mount Chain Saw Sharpener Owner'S Manual: Item # 141259Document8 pages12 Volt Bar-Mount Chain Saw Sharpener Owner'S Manual: Item # 141259Relyax ColiliNo ratings yet

- How To Sharpen A Chainsaw With A FilDocument8 pagesHow To Sharpen A Chainsaw With A Filjohn louisNo ratings yet

- Husqvarna 345 ManualDocument36 pagesHusqvarna 345 ManualTom FergusonNo ratings yet

- 2011 2012 Machinery SubsidyDocument52 pages2011 2012 Machinery SubsidyFahad AliNo ratings yet

- Stihl Saw Chain IDDocument2 pagesStihl Saw Chain IDcajunhillbilly67% (3)

- Forestry Code FINAL With AmendmentsDocument91 pagesForestry Code FINAL With AmendmentsRose Ann CayabanNo ratings yet

- Module 1 Conduct Pre Horticultural Farm OperationDocument109 pagesModule 1 Conduct Pre Horticultural Farm OperationMEL ANTHONY PALMANo ratings yet

- 2017 FEMA Schedule of Equipment Rates 508 FINALDocument10 pages2017 FEMA Schedule of Equipment Rates 508 FINALFeteneNo ratings yet

- Stihl 044 Instruction ManualDocument54 pagesStihl 044 Instruction ManualSasa Rudan100% (2)

- Mesin Tebang Pokok-ChainsawDocument11 pagesMesin Tebang Pokok-Chainsawnasa_72No ratings yet

- Stihl MS 460 Chainsaw Service Manual PDFDocument94 pagesStihl MS 460 Chainsaw Service Manual PDFBrianCookNo ratings yet

- Chain Saw Cutting Techniques: Tree of KnowledgeDocument3 pagesChain Saw Cutting Techniques: Tree of Knowledgejsmithy456No ratings yet

- NEBOSH IGC-2 PEDESTAL DRILLS HAZARDSDocument7 pagesNEBOSH IGC-2 PEDESTAL DRILLS HAZARDSWafula RobertNo ratings yet

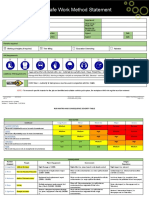

- Safe Work Method StatementDocument7 pagesSafe Work Method StatementInnocent Bhaikwa100% (1)

- Manual Motoserra 235 HusqvarnaDocument464 pagesManual Motoserra 235 HusqvarnaJonas FariaNo ratings yet

- Ms 171Document140 pagesMs 171John DePNo ratings yet

- Husqvarna 240eDocument464 pagesHusqvarna 240enevermore1No ratings yet

- Husqvarna 120 Mark IIDocument332 pagesHusqvarna 120 Mark IIИльдар АхметзяновNo ratings yet

- Machine ToolsDocument67 pagesMachine ToolsmechneedNo ratings yet

- Lubricants Comparision Between BrandsDocument6 pagesLubricants Comparision Between BrandsJen Ekx80% (5)

- OM. 120 Mark II. 2023-07Document448 pagesOM. 120 Mark II. 2023-07Ionuț IonuțNo ratings yet

- Sugihara CatalogueDocument68 pagesSugihara Cataloguezoltan VidakNo ratings yet

- Section III-LIABILITY: Finance Copy - Pre-UseDocument6 pagesSection III-LIABILITY: Finance Copy - Pre-UseyasirNo ratings yet

- Tesmec 1100Document3 pagesTesmec 1100Foromaquinas100% (1)

- Hi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisDocument3 pagesHi Tech Engineering SDN BHD Permit To Work System - Job Hazard AnalysisPHH9834No ratings yet

- STIHL MS 460 ManualDocument124 pagesSTIHL MS 460 ManualScott FullerNo ratings yet

- R. A 9175 - Chainsaw ActDocument4 pagesR. A 9175 - Chainsaw Actruby angelieNo ratings yet

- Chain SawDocument1 pageChain SawFarrukh AhmadNo ratings yet

- Chainsaw ActDocument7 pagesChainsaw ActSarah KellyNo ratings yet