Professional Documents

Culture Documents

Amaravathi 16 Pointsd

Uploaded by

Sakhamuri Ram'sCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Amaravathi 16 Pointsd

Uploaded by

Sakhamuri Ram'sCopyright:

Available Formats

INDUSTRY PROFILE

India Textile Industry is one of the leading textile industries in the world. Though was

predominantly unorganized industry even a few years back, but the scenario started changing

after the economic liberalization of Indian economy in 1991. The opening up of economy gave

the much-needed thrust to the Indian textile industry, which has now successfully become one of

the largest in the world. India textile industry largely depends upon the textile manufacturing and

export. It also plays a major role in the economy of the country. India earns about 27% of its

total foreign exchange through textile exports. Further, the textile industry of India also

contributes nearly 14% of the total industrial production of the country. It also contributes

around 3% to the GDP of the country. India textile industry is also the largest in the country in

terms of employment generation. It not only generates jobs in its own industry, but also opens up

scopes for the other ancillary sectors. India textile industry currently generates employment to

more than 35 million people. It is also estimated that, the industry will generate 12 million new

jobs by the year 2010.

Various Categories

Indian textile industry can be divided into several segments, some of which can be listed as

below:

Cotton, Silk & Woolen Textiles

Readymade Garments

Hand-crafted Textiles & Jute and Coir

HISTORY:

The oldest cotton fibers and boil fragments, dated from around 5000 B.C., were

discovered in Mexico. In 5000 B.C., the Greek historian Herodotus reported of a

pant that bore fleece cotton has been worn in India and Egypt forever 5000

years. Cotton was grown by Native Americans as early as 1500. In England in the

1700s, it was against the law to import or manufacture fabric made of cotton since

it was a threat to the sheep and wool industry. American colonists were able to

grow lots of cotton, but processing was difficult. It was not until the 1700s that the

cotton industry flourished in the United States.

It was then that Slater, an Englishmen; built the first American Cotton Mill

has improved over the past centuries making cotton growth. These mills converted

cotton fibers into yarn and cloth.In1793 Eli Whitney developed the cotton gin,

which mechanically separates the seed from the lint fiber.

Whitney named his machine a gin, short for the word engine technology

and production much more efficient.

POLICY OF GOVERNMENT OF INDIA TOWARDS COTTON

INDUSTRY:

The Cotton production policies in India historically have been oriented toward

promoting and supporting the textile industry. The Government of India announces

a minimum support price for each variety of seed cotton (kappas) based on

recommendations from the Commission for Agricultural Costs and Prices.

The Government of India is also providing subsidies to the production inputs

of the cotton in the areas of prices. Its sort of a double-edge sword.

Major competitors in industry:

Company name Place

1) Paramount Textiles Mills Pvt. Ltd - Madurai

2) Siva Sankari Mills - Coimbatore

3) PEC Ltd - Delhi

4) Indus Fila Pvt. Ltd - Bangalore

5) Alok Industries - Silvassa

6) R.M. Mohite Textilies - Kolhapur

7) Sachin Textiles - Ichalkaranji

8) Kayaar Exports - Tiruchengode.

9) GTN industries - Hyderabad

10) GTN Enterprises - Kochin

11) Prathibha Syntex - Ahmedabad

12) Mandhana Weaving House - Tarapur

13) Bombay Royan Fashions - Sangli

PROBLEMS

Cotton textile industry is obsessed with many problems. Two main factors which

have wrecked die industry are Government's textile policy and the growth of the

power loom sector.

Power shortage-Textile mills are facing acute shortage of power. Supplies of coal

are difficult to obtain and frequent cuts in electricity and load shedding affect the

industry badly. This leads to loss of man hours, low production and loss in the

mills.

Low productivity of labour-Low productivity is another major problem of cotton

textile industry. On an average an Indian factory worker only handles 380 spindles

and 2 looms as compared to 1,500-2,000 spindles and 30 looms in Japan. If the

productivity of an American worker is taken as 100, the corresponding figure for

U.K. is 51 and for India only 13. Also industrial relations are not very good in the

country. Strikes, layoffs, retrenchments are the common features of many cotton

mills in the country.

SUGGESTIONS;

Tradition in Textiles and long operating experience

Large and growing domestic market

Strong raw material base

Production across entire textile value chain

Stable, low-risk economy, safe for business growth

Easy availability of abundant raw materials like cotton, wool, silk, jute

Widely prevalent social customs

Variety of distinct local culture

Constructive geographic and climatic conditions

ABOUT THE COMPANY:

The founder of Amaravathi Textiles Group who has drawn its future planned

growth. A man whose spirit of dynamism has helped the group to achieve manifold

growth. Thanks to his pioneering vision, the groups operation grew and market

extended. Today Amaravathi Textiles group is a multi-activity group with an

Rs.300crores turnover, comprising divisions with diverse interest in

COTTON

SPINNING

TEXTILE

A Star who shone in all his brilliance and dazzled everyone. With his

visionary leadership abilities and caliber. Unfortunately fate nipped his sparkling

career in the bud. Though short-lived, his visionary dedication continues to guide

the spirit of achievement and enterprise of Amaravathi Textiles across various

activities.

PROMOTERS:

THE BIRTH OF A DREAM

Sri Kandimalla Srinivasa Rao set up a cotton ginning mill in 1984. The operations grew

rapidly to lay solid foundations for giant surging ahead in diverse environments. To the group, the

future is rich in possibilities. A future where the best of minds and men will work. And will have the

most resources to draw upon. Its vision of the future where change will be embraced as the very basis

of opportunity and endeavor.

The managing Director of AMARAVATHI TEXTILES (P) LTD. Relentless pursuit of

perfection is the hallmark of this young and dynamic B.Tech Textiles Graduate.

His rich and professionals experience in the spinning line enabled AMARAVATHI Textiles

Spinning Division to scale new heights. His enterprising zeal and cautious planning have been the

pivotal points in driving the group towards trailblazing progress. Mr. Kandimalla Srinivasa Rao is

committed to labour welfare and his visionary leadership has earned him a wealth of respect among

the employees of AMARAVATHI. Astute professionals by habit, he is forever aiming higher. He is

widely acknowledged as the man who has fostered a can do culture which starts at top and filters

down to every employee at AMARAVATHI TEXTILES. He is powered by just one belief..

Success is a matter of excellence, and not chance.

AIM / VISION / MISSION

Always exploring ways to further the quality and maintain consistency of the product.

Efficient macinery combined with least possible wastages and an eco-friendly manufacturing

process aimed at increasing productivity thereby the organization growth and success

Amaravathi Product: YARN

COTTON

SPINNING

TEXTILE

The Amaravathi collection includes...

Cushion Covers, Throws, Futons, Floor Pillows, Table Cloths, Placemats, Napkins, Table

Runners, Terry Towels, Apron Sets, Tea Towels

Values and policies;

v Promptness in execution.

v Transparency in Business

v Integrity in Negotiation

v Innovation that fuels growth

We care for the environment

Amaravathi is committed to conservation of the environment. Our manufacturing facilities

comply with stringent environmental norms and are equipped for effluent treatment. The

Amaravathi dyeing plant uses reverse osmosis with a multieffect evaporator to qualify as a zero-

discharge unit.

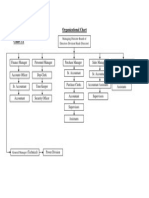

ORGANIZATIONAL STRUCTURE

BOARD OF DIRECTORS

CHAIRMAN & MD

VICE

PRESIDENT

FINANCE

VICE

PRESIDENT

HRD

VICE

PRESIDENT

MARKETING

VICE

PRESIDENT

PRODUCTION

GENERAL

MANAGER

FINANCE

GENERAL

MANAGER

HRD

GENERAL

MANAGER

MARKETING

GENERAL

MANAGER

PRODUCTION

MANAGER

FINANCE

MANAGER

HRD

MANAGER

MARKETING

MANAGER

PRODUCTION

BOARD OF DIRECTORS

K.SrinivasaRao. Director

K.Bhaskar Director

K.Geetha Director

GENERAL MANAGER.

ShriP.Ramesh, D.T.T., B.A.,

ACCOUNTS MANAGER.

ShriN.Veeraiah, B.Com. A.C.A.

BANKERS

State Bank of India, Guntur

State Bank of Mysore, Guntur.

State Bank of Hyderabad, Guntur.

REGISTERED OFFICE

33-263, Kandimalla Road,

Pandaripuram,Chilakaluripet-522616

FACTORY

Martur-522301,

MarturMandal,

Prakasam District, Andhra Pradesh.

Major competitors in company:

Jagadguru textiles

Nsl textiles

Ysr spinning mills

Ml group

STRENGTHS

Vast textile production capacity

Large pool of skilled and cheap work force

Entrepreneurial skills

Efficient multi-fiber raw material manufacturing capacity

Large domestic market

Enormous export potential

Very low import content

Flexible textile manufacturing systems

WEAKNESS

Increased global competition in the post 2005 trade regime under WTO

Imports of cheap textiles from other Asian neighbors

Use of outdated manufacturing technology

Poor supply chain management

Huge unorganized and decentralized sector

High production cost with respect to other Asian competitors

Opportunities

1. Quotas carried on in China after 2005

2. Good political equation with EU and US

3. Improvements in infrastructure and regulations

4. Research and product development

5. Buyers preference for India, after China

6. Understanding buyers need because of language advantage

Threats

1. Rupee appreciation in last few months

2. Trade blocs and partnerships at the exclusion of India

3. Location disadvantage: long transit time to key markets

4. Pricing pressure, following opening up of quotas

5. Enhanced competition from other countries similarly constrained by quotas

You might also like

- Cotton Science and Processing Technology: Gene, Ginning, Garment and Green RecyclingFrom EverandCotton Science and Processing Technology: Gene, Ginning, Garment and Green RecyclingHua WangNo ratings yet

- Mahendra R & TDocument73 pagesMahendra R & THarshith ShettyNo ratings yet

- Cotton IndustryDocument18 pagesCotton IndustrySakhamuri Ram'sNo ratings yet

- CottonDocument17 pagesCottonSakhamuri Ram's100% (1)

- Indian Textile Industry Performance and OpportunitiesDocument44 pagesIndian Textile Industry Performance and OpportunitiesLuminance 2k21No ratings yet

- Inventory Management JapanDocument4 pagesInventory Management JapanSURUCHI KUMARINo ratings yet

- MAP Report For MBADocument57 pagesMAP Report For MBAMaulik TankNo ratings yet

- OS ReportDocument29 pagesOS ReportSuku Thomas SamuelNo ratings yet

- Chapter - 1: Introduction of Textile IndustryDocument68 pagesChapter - 1: Introduction of Textile Industrydeep bajwaNo ratings yet

- Textile Industry Profile and TrendsDocument41 pagesTextile Industry Profile and TrendsArjun100% (1)

- Mudra Project ReportDocument73 pagesMudra Project Reportmit200891No ratings yet

- Textile Industry Internship ReportDocument41 pagesTextile Industry Internship ReportSachin krishna73% (15)

- My ProjectDocument116 pagesMy ProjectLaxmannathsidhNo ratings yet

- Titans of Textile - Weaves 2019Document148 pagesTitans of Textile - Weaves 2019Venkat DevNo ratings yet

- Arvind ReportDocument17 pagesArvind Reportaneri31791100% (1)

- Sengundhar Mills Inplant Training ProjectDocument69 pagesSengundhar Mills Inplant Training ProjectMukesh kannan MahiNo ratings yet

- Ojt ReportDocument33 pagesOjt Reportpandim6477No ratings yet

- Introduction To Textile Industry WaqasDocument80 pagesIntroduction To Textile Industry Waqasghufran-jamsheed-864No ratings yet

- Related TO THE Indian Textile IndustryDocument113 pagesRelated TO THE Indian Textile Industry55dilpreetNo ratings yet

- Strategic Management - Textile Industry (Arvind LTD)Document58 pagesStrategic Management - Textile Industry (Arvind LTD)Diana Aloys82% (17)

- Chapter-1: Involvement of State AgriculturalDocument42 pagesChapter-1: Involvement of State AgriculturalMohankumar MohankumarNo ratings yet

- Aarvee Denims & Exports LTD.: An Industrial Visit Report ONDocument43 pagesAarvee Denims & Exports LTD.: An Industrial Visit Report ONBrijesh PatelNo ratings yet

- Chapter-1: Involvement of State AgriculturalDocument42 pagesChapter-1: Involvement of State AgriculturalMohankumar MohankumarNo ratings yet

- Cotton Mills of IndiaDocument16 pagesCotton Mills of IndiakaviyaNo ratings yet

- 1.1 Introduction To The Study: 1.2 The Present Indian Marketing ScenarioDocument32 pages1.1 Introduction To The Study: 1.2 The Present Indian Marketing ScenarioJohn CenaNo ratings yet

- Final+Report +++Raymond+Chhindwara1 1Document94 pagesFinal+Report +++Raymond+Chhindwara1 1Neeraj Kumar40% (5)

- Saraswati FinalDocument50 pagesSaraswati FinalNaga SudhaNo ratings yet

- Garima 1Document82 pagesGarima 1Parshant GargNo ratings yet

- Gul Ahmed's Strategy in Pakistan's Textile IndustryDocument34 pagesGul Ahmed's Strategy in Pakistan's Textile IndustryShahzeb QureshiNo ratings yet

- Welfare Mittal FinalDocument101 pagesWelfare Mittal FinalAnonymous QrLiISmpFNo ratings yet

- Final DocumentDocument101 pagesFinal DocumentUjjwal SurinNo ratings yet

- Internship ReportDocument32 pagesInternship ReportHimanshu Rajput100% (4)

- Textile Industry in SuratDocument70 pagesTextile Industry in SuratgoswamiakashNo ratings yet

- Theory and Practice of FinancialDocument28 pagesTheory and Practice of FinancialUbaidNo ratings yet

- Internship Report: D.K.Creations Pvt. LTDDocument32 pagesInternship Report: D.K.Creations Pvt. LTDPrasanth SelvarajNo ratings yet

- Financial Statement of Raymond & Bombay DyingDocument18 pagesFinancial Statement of Raymond & Bombay DyingGaurav PoddarNo ratings yet

- Indian Textile Industry OverviewDocument60 pagesIndian Textile Industry OverviewParbrahm SinghNo ratings yet

- Project Report RSWM FinalDocument40 pagesProject Report RSWM Finalomlata_choudhary5061100% (2)

- 1002 Chapter 1 - 2 - 3Document18 pages1002 Chapter 1 - 2 - 3Harichandran KarthikeyanNo ratings yet

- Chapter-I: 1.1 - Introduction To The Textile IndustryDocument148 pagesChapter-I: 1.1 - Introduction To The Textile IndustryGRAMY TRADERS SALEMNo ratings yet

- Final ReportDocument37 pagesFinal ReportRatish RagavNo ratings yet

- KitexDocument57 pagesKitexRijo M EliasNo ratings yet

- An Introduction: Fibers, Yarns & Threads Industry OverviewDocument41 pagesAn Introduction: Fibers, Yarns & Threads Industry OverviewDipak KashyapNo ratings yet

- Textile Industry Internship ReportDocument137 pagesTextile Industry Internship ReportRaghul PrashanthNo ratings yet

- Indian Textile Industry OverviewDocument11 pagesIndian Textile Industry OverviewAnish Sidharth ChekuriNo ratings yet

- Organisational Study of Ikon Exports Garment ManufacturingDocument65 pagesOrganisational Study of Ikon Exports Garment ManufacturingMeena SivasubramanianNo ratings yet

- Navdeep oSWAL FinalDocument54 pagesNavdeep oSWAL FinalLovlesh RubyNo ratings yet

- Masood Textile Mills Internship ReportDocument117 pagesMasood Textile Mills Internship ReportTouqeer Ahmad100% (3)

- Indian Textile Industry SWOT AnalysisDocument20 pagesIndian Textile Industry SWOT AnalysiskurashiNo ratings yet

- Current Facts On Indian Textile Industry: Page - 1Document54 pagesCurrent Facts On Indian Textile Industry: Page - 1bccmehtaNo ratings yet

- Ibis Textiles Directory 2023 SampleDocument13 pagesIbis Textiles Directory 2023 Samplesujan mehtaNo ratings yet

- A Project Report On Reduction of Fabric Faults in Casual Shirting DepartmentDocument23 pagesA Project Report On Reduction of Fabric Faults in Casual Shirting DepartmentranaNo ratings yet

- Pioneer Institute of Professional Studies: SWOT Analysis of Arvind LimitedDocument32 pagesPioneer Institute of Professional Studies: SWOT Analysis of Arvind LimitedAneri PrajapatiNo ratings yet

- Training ProjectDocument89 pagesTraining ProjectR.K.BavathariniNo ratings yet

- Reliance Textiles Marketing StrategyDocument37 pagesReliance Textiles Marketing StrategyM Navneeth Roy100% (1)

- ChapterDocument35 pagesChaptermohamedthayubsm mbastudentNo ratings yet

- Report Training ProgramDocument12 pagesReport Training ProgramSrekanth JeganathanNo ratings yet

- Hijaz Leather Internship ReportDocument55 pagesHijaz Leather Internship ReportMuzammil Motoor90% (21)

- Sustainable Innovations in Textile Chemical ProcessesFrom EverandSustainable Innovations in Textile Chemical ProcessesNo ratings yet

- SpencersDocument12 pagesSpencersSakhamuri Ram'sNo ratings yet

- Ratio Analysis 1012Document74 pagesRatio Analysis 1012Sakhamuri Ram'sNo ratings yet

- Climate defined as weather averaged over 30 yearsDocument4 pagesClimate defined as weather averaged over 30 yearsSakhamuri Ram'sNo ratings yet

- MBA Program VIIT: Performance Appraisal ProcessDocument86 pagesMBA Program VIIT: Performance Appraisal ProcessSakhamuri Ram'sNo ratings yet

- Performance AppraisalDocument85 pagesPerformance AppraisalSakhamuri Ram'sNo ratings yet

- Capital Budgeting CclaDocument50 pagesCapital Budgeting CclaSakhamuri Ram'sNo ratings yet

- Funds Flow Statement Tirumala MilkDocument101 pagesFunds Flow Statement Tirumala MilkSakhamuri Ram's100% (3)

- Capital Budgeting VishakaDocument105 pagesCapital Budgeting VishakaSakhamuri Ram'sNo ratings yet

- Funds Flow StatementDocument101 pagesFunds Flow StatementSakhamuri Ram'sNo ratings yet

- Financial Reports of Devi Sea LTD: Profit & Loss Account For The Year Ended 31St March, 2009Document11 pagesFinancial Reports of Devi Sea LTD: Profit & Loss Account For The Year Ended 31St March, 2009Sakhamuri Ram'sNo ratings yet

- List of The Tables: SL NO NO Title of The Table Page NoDocument9 pagesList of The Tables: SL NO NO Title of The Table Page NoSakhamuri Ram'sNo ratings yet

- Capital Budgeting KarimullaDocument51 pagesCapital Budgeting KarimullaSakhamuri Ram'sNo ratings yet

- "Funds Flow Statement": Eswar College of EngineeringDocument8 pages"Funds Flow Statement": Eswar College of EngineeringSakhamuri Ram'sNo ratings yet

- Capital Budgeting Krishna MurthyDocument54 pagesCapital Budgeting Krishna MurthySakhamuri Ram'sNo ratings yet

- Financial Reports of Devi Sea LTD: Profit & Loss Account For The Year Ended 31St March, 2009Document11 pagesFinancial Reports of Devi Sea LTD: Profit & Loss Account For The Year Ended 31St March, 2009Sakhamuri Ram'sNo ratings yet

- Financial Reports of Devi Sea LTD: Profit & Loss Account For The Year Ended 31St March, 2009Document11 pagesFinancial Reports of Devi Sea LTD: Profit & Loss Account For The Year Ended 31St March, 2009Sakhamuri Ram'sNo ratings yet

- Industry Indan Cotton Textile ProfileDocument30 pagesIndustry Indan Cotton Textile ProfileSakhamuri Ram'sNo ratings yet

- Financial Statement Analysis of Tirumala MilkDocument6 pagesFinancial Statement Analysis of Tirumala MilkSakhamuri Ram'sNo ratings yet

- Master of Business Administration: A Study On Ratio Analysis With Reference To Jocil LimitedDocument97 pagesMaster of Business Administration: A Study On Ratio Analysis With Reference To Jocil LimitedSakhamuri Ram'sNo ratings yet

- VivekDocument24 pagesVivekSakhamuri Ram'sNo ratings yet

- Narasimhulu CR COLLEGE Funds Flow 021Document94 pagesNarasimhulu CR COLLEGE Funds Flow 021Sakhamuri Ram'sNo ratings yet

- Dairy IndustryDocument16 pagesDairy IndustrySakhamuri Ram'sNo ratings yet

- Sreemsbi ResumeDocument4 pagesSreemsbi ResumeSakhamuri Ram'sNo ratings yet

- Industry Indan Cotton Textile ProfileDocument30 pagesIndustry Indan Cotton Textile ProfileSakhamuri Ram'sNo ratings yet

- Sagar Cement PointsDocument16 pagesSagar Cement PointsSakhamuri Ram'sNo ratings yet

- Organizational Chart 3.1 - Management StructureDocument1 pageOrganizational Chart 3.1 - Management StructureSakhamuri Ram'sNo ratings yet

- Employee performance report by monthDocument2 pagesEmployee performance report by monthSakhamuri Ram'sNo ratings yet

- CV For AccountantDocument5 pagesCV For Accountant1053akashNo ratings yet

- Cleaning Wooden Furniture and SurfacesDocument11 pagesCleaning Wooden Furniture and Surfacesjazebel3No ratings yet

- Care LabellingDocument50 pagesCare LabellingJyotirmoy Pal100% (2)

- Bombay Dyeing: History and Products of India's Leading Textile CompanyDocument2 pagesBombay Dyeing: History and Products of India's Leading Textile CompanyVikrant Singh0% (1)

- Traditional Batik Tulis Keraton The Best QualityDocument2 pagesTraditional Batik Tulis Keraton The Best QualityAjeng Sito LarasatiNo ratings yet

- Balance Sheet Analysis of Thirumala Cotton & Agro Products Pvt LtdDocument101 pagesBalance Sheet Analysis of Thirumala Cotton & Agro Products Pvt Ltddurga prasadNo ratings yet

- Pro-Forma Invoice# 343-23 PO 28254 - OrDER# 152992MODFA23 HO23 - Mar 21stDocument2 pagesPro-Forma Invoice# 343-23 PO 28254 - OrDER# 152992MODFA23 HO23 - Mar 21stGabriel BustilloNo ratings yet

- Internship Report: D.K.Creations Pvt. LTDDocument32 pagesInternship Report: D.K.Creations Pvt. LTDPrasanth SelvarajNo ratings yet

- Reebok's Fitness Journey in India and Fraud ScandalDocument26 pagesReebok's Fitness Journey in India and Fraud ScandalHeta Desai100% (1)

- Assam BookDocument52 pagesAssam BookAsh1ScribdNo ratings yet

- Lamodedesignsuit00jobi PDFDocument726 pagesLamodedesignsuit00jobi PDFAnisoaraNeaguNo ratings yet

- Painting in WatercolourDocument192 pagesPainting in Watercolourmr mxyzptlk88% (32)

- Integrated Handloom Canter and GalleryDocument3 pagesIntegrated Handloom Canter and GalleryLeela Krishna100% (1)

- Case Study - Blue FlyDocument17 pagesCase Study - Blue FlyPreetham PrasadNo ratings yet

- Visvesvaraya's Contribution to Garment IndustryDocument91 pagesVisvesvaraya's Contribution to Garment Industrytanmay786No ratings yet

- Luwam Bahta KKDocument7 pagesLuwam Bahta KKKalid AbebeNo ratings yet

- My Idol EntrepreneurDocument3 pagesMy Idol EntrepreneurPuteri Nordiana Mohd AnowarNo ratings yet

- Sarees of Eastern IndiaDocument40 pagesSarees of Eastern IndiaDurga Nareen100% (1)

- Screen Printing Reference GuideDocument3 pagesScreen Printing Reference GuideJerushia GrahamNo ratings yet

- Bhutan-3-Directory v1 m56577569830512215Document19 pagesBhutan-3-Directory v1 m56577569830512215Raman GoyalNo ratings yet

- Ponte Fabric Buyer ListDocument8 pagesPonte Fabric Buyer ListshouravNo ratings yet

- Aditya Birla Group - The Indian Scenerio.: Hindalco-NovelisDocument2 pagesAditya Birla Group - The Indian Scenerio.: Hindalco-NovelisAshish AgarwalNo ratings yet

- A Complete Costing Sheet For A Garment (Women's Skirt)Document3 pagesA Complete Costing Sheet For A Garment (Women's Skirt)OUSMAN SEIDNo ratings yet

- Flexituff ProjectDocument75 pagesFlexituff ProjectSourabh JoshiNo ratings yet

- Sewn Product Engineering-1: Preliminary VisionDocument19 pagesSewn Product Engineering-1: Preliminary Visionmudassar_afzal100% (1)

- Surgical Cotton Manufacturing Business. Absorbent Cotton Roll Production Plant. Absorbent Cotton Wool Manufacturing Project. Medical Cotton.-48297Document62 pagesSurgical Cotton Manufacturing Business. Absorbent Cotton Roll Production Plant. Absorbent Cotton Wool Manufacturing Project. Medical Cotton.-48297umakantNo ratings yet

- Economy in Gupta PeriodDocument2 pagesEconomy in Gupta PeriodEkansh DwivediNo ratings yet

- Project 1Document97 pagesProject 1MEENA VNo ratings yet

- Crochet Earrings Business: A Quantitative Research on Teenagers' Fashion TrendsDocument20 pagesCrochet Earrings Business: A Quantitative Research on Teenagers' Fashion TrendsWends HahaNo ratings yet

- BrotherDocument90 pagesBrotherAgung PraztNo ratings yet