Professional Documents

Culture Documents

Report Project

Uploaded by

Rodriguez Arthurs0 ratings0% found this document useful (0 votes)

199 views53 pagesThis document provides an introduction to the design and engineering of a Cansat project. It discusses that the goal is to design a small satellite that fits inside a 350ml soda can and includes major satellite subsystems like power, sensors, and communication. The Cansat will be launched to altitudes of a few hundred meters and collect data to analyze the mission success or failure. It also provides an overview of some literature on previous Cansat projects and competitions as motivation for the current project.

Original Description:

Project report of sat

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentThis document provides an introduction to the design and engineering of a Cansat project. It discusses that the goal is to design a small satellite that fits inside a 350ml soda can and includes major satellite subsystems like power, sensors, and communication. The Cansat will be launched to altitudes of a few hundred meters and collect data to analyze the mission success or failure. It also provides an overview of some literature on previous Cansat projects and competitions as motivation for the current project.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

199 views53 pagesReport Project

Uploaded by

Rodriguez ArthursThis document provides an introduction to the design and engineering of a Cansat project. It discusses that the goal is to design a small satellite that fits inside a 350ml soda can and includes major satellite subsystems like power, sensors, and communication. The Cansat will be launched to altitudes of a few hundred meters and collect data to analyze the mission success or failure. It also provides an overview of some literature on previous Cansat projects and competitions as motivation for the current project.

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 53

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 1

Chapter 1

Introduction

This Project aims at designing & engineering of a CanSat. In this Project, we are responsible

for designing the CanSat, selecting its mission, integrating the components, testing, preparing

for launch and then analyzing the data. By analyzing the data recorded by the CanSat, we will

investigate the reasons of its success and/or failure.

A CanSat is a simulation of a real satellite, integrated within the volume and shape of a

regular soft drink can. It is small, non-orbiting and with limited complexity, but it is still like a

"satellite" in terms of many of the challenges real satellites faces. No CanSat has ever left the

atmosphere or even orbited the earth.

In November 1998 at the University Space Systems Symposium (USSS) held in Hawaii, Prof.

Bob Twiggs, (Stanford University Space Development Laboratory) suggested the so-called

"CanSat" concept, whereby the entire satellite would adopt the size of a 350-ml can.

All of the components, such as sensors, actuators, and GPS, are housed inside a 350-ml can.

CanSat provides an affordable opportunity for educators and students to acquire basic

knowledge of space engineering and to experience engineering challenges in building a

satellite. The student will be able to design and build a small electronic payload that can fit

inside a standard drink can (350 ml). The CanSats will be launched by a rocket or balloon and

released in the air. Using a parachute, the CanSat will slowly descend back to the ground as it

performs its designated mission (i.e., taking pictures and transmitting telemetry). By analyzing

the data recorded by the CanSat, participants will investigate the reasons of its success and/or

failure.

Objectives

A CanSat is a simulation of a real satellite, integrated within the volume and shape of a soft

drink can. The challenge is to fit all the major subsystems found in a satellite, such as power,

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 2

sensors and a communication system, into this minimal volume. The CanSat is then launched

to an altitude of a few hundred meters by a rocket or dropped from a platform or captive

balloon and its mission begins: to carry out a scientific experiment and achieve a safe landing.

Development of CanSat involves multidisciplinary efforts encompassing mechanical

engineering, material science and also electronics.

CanSats offer a unique opportunity to have a first practical experience of a real space project.

They are responsible for all aspects: designing the CanSat, selecting its mission, integrating

the components, testing, preparing for launch and then analysing the data.

Fig.1. Coke Can sized satellite

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 3

Chapter-2

LITERATURE SURVEY

Introduction

The significance of small satellites is increasing day by day, according to a survey

conducted by Space Works around 250 small satellites shall be launched by year 2020.

Matunaga, S. from Mechanical .Aerospace Engineering, Tokyo Institute of Technology,

Japan had launched a prototype of CanSats, small satellites the size of a soft drink can, on

an amateur rocket in September 1999 (ARLISS: A Rocket Launched International Student

Satellites). He had published an IEEE paper in Aerospace Conference Proceedings, 2000

IEEE on the topic Titech Micro-Satellite Model: Cansat for Sub-Orbital Flight. They

developed four CanSats for ARLISS: CanSat Type1 and Type2 missions are experiments of

two different types of mechanisms for tether applications, CanSat Type3, is a

communications and electronic devices test satellite, and CanSat Type4 is equipped with

CCD camera and transmits video images. The development period is less than 5 months. In

their paper, they have described 4 CanSats missions, subsystem designs including the

ground station and the results of ARLISS experiments.

Principle

The Satellite Development involves of 2 tasks mainly

a) Development of the On Board Computer

b) Development of the Base Station with Graphical User Interface

a) Development of the On Board Computer:

In general the development of the On board Computer is a wide platform which includes

simple processing to complex processing .Based upon our requirement the analysis is

conducted for the kind of the data which is required for our application. After the

finalization of the selection of sensors, the programming logic has to be developed and

scrutinized.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 4

b) Development of the Base Station with Graphical User Interface:

The task of utilization and presentation of the data is a crucial task, the entire work is

justified by its effective and convenient utility. Author Aydemir, M.E.

Department of Electronics Engineering, Turkish Air Force Academy, Istanbul,

Turkey Dursun, R.C. ; Pehlevan, M had published an IEEE paper at the, Recent Advances in

Space Technologies (RAST), 2013 6th International Conference on Ground Station Design

Procedures for CANSAT. He had presented the design and implementation of a PC based

ground station for CANSAT's. However, during the competitions it has been observed that

even thoughthe CANSAT works perfectly, the ground station frequently fails therefore

leading to mission failure. In this study a ground station is developed from scratch using a

high level language (C#) and the procedure is defined briefly. The station is platform-free

therefore it may operate with any CANSAT having different brand microcontrollers. The

users may track several parameters and send control commands simultaneously. The

ground-station is one of the most important aspects of CANSAT trials however, for the

beginners it may be challenging to provide all these features at once. This study defines

many practical aspects of designing ground stations so that more emphasis may be given to

the design of CANSAT hardware and software. The ground station is effective when the

synchronization between the on board computer and the ground station is proper. The

Ground stations which have been developed earlier are found to be ineffective due to the

deficiencyin the satellite communication links between the On Board Computer and

the ground segment. Authors Preindl, B. from Institute of Analysis & Science Computation,

Vienna University of Technology, Vienna, Austria; Mehnen, L. ; Rattay, F. and Nielsen, J.D.

had published an IEEE paper in Satellite and Space Communications, IWSSC 2009.

International Workshop conducted on 9-11 September 2009 on topic titled Design of a

Small Satellite for Performing Measurements in a Ground Station Network. The paper is a

novel design solution based on a small satellite cluster is going to be proposed to offer

quality assurance for the ground segment in both sending and receiving directions in

multiple amateur frequency bands based on high-accurate error rate information.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 5

Chapter 3

Motivation

1. CanSat has been developed by some students participating in international competitions

but not locally used for different applications such as atmospheric weather studies. IIIT-H,

very ably led by Prof. KS Rajan, comprised of nine undergraduate students from the

electronics and communications engineering (ECE) developed a CanSat for a competition.

The team worked for the last six months on various aspects of the design, fabrication, and

testing of the micro-satellite - IIIT-Hs CanSat - to compete with some of the best teams

from around the world.

2. In 1998, about 50 students and faculties from 12 universities from the United States and

Japan met at a symposium held in Hawaii. It was the first "University Space Systems

Symposium". Here, Bob Twiggs, professor emeritus at the Stanford University, proposed

the initial idea of what later would become the nanosatellite projects. That idea was to

launch a structure of the size of a soda can into space. Its volume should be around 350

milliliters and the mass, about 500 grams. This led to a project that began in 1999 called

ARLISS, involving mostly American and Japanese Universities, carrying out the first

launch on September, 11th of that year and continuing each year without interruption. The

initial idea, still prevalent today, was to launch 3 satellites of 350 milliliters, or a satellite

of greater volume. The means would be a rocket capable of moving 1.8 kilos and of

ascending to 4000 meters, opening the door to low cost space flights -about $400. In 2000

the missions were very different: for instance, calculating the opening of a landing system

using data provided by the barometer or making use of a differential GPS system. The

project came to a more complex situation in 2001 when the ComeBack category was

added, according to which the satellite should be directed to a particular target. This

mission was very successful and in 2002 students of Space Robotics Lab of the Tohoku

University went up to 45 meters from the target and in 2006 this figure dropped to 6

meters. Interest in this type of satellites has been growing and spreading. In 2003 the

University of Tokyo placed into orbit two satellites CubeSat, satellites of a size slightly

larger than the CanSats, and cube shaped. In recent years, several competitions have been

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 6

developed following the same concept proposed by Prof. Bob Twiggs and reflected in

ARLISS both national and internationally.

Methodology :

Month 1 Material Acquisition, System Engineering

Month 2-4 CAD modelling / Analysis

Month 5 Module Integration,

Month 6 System Testing

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 7

CHAPTER-4

CANSAT DESIGN

CAD Modelling:

Three concepts were evaluated in preparation for the project: a parachute control system, a

parachute control system and a glider approach. Given the lack of availability of appropriate

skills required developing a glider, and because a parachute is far less susceptible to

interference from the wind when compared to a parachute the parachute approach was

chosen. Acrylics material is chosen for the on-board system Key mechanical components

were identified as:

The main parts of the on-board computer are:

Predrilled Main board for mounting circuit boards.

Angle bracket for attaching a parachute.

Computer board with processor and connectors for sensors and communications.

Programmable processor that can be programmed in BASIC Software.

Serial interface connector for host PC communications.

Sensor board with a pressure and temperature sensor.

As construction of parachute requires a person who is skilled at sewing, it was decided that

one should be purchased. A strong on-board construction was considered vital to successful

recover of the Small Satellite, as even with a parachute it would descend at a high speed. The

Small Satellite was thus built around a Perspex chassis (providing support for circuits,

sensors, the battery) housing made out of acrylics providing protection on impact. Out of Four

Designs made, best suitable design is selected for On-board Computer as shown below.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 8

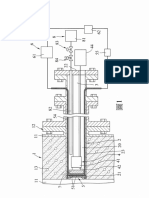

Fig, 4.1.1 Final CAD Design of the On-board Computer

Fig. 4.1.2 All View of the Final on-board System

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 9

Fig. 4.1.3 Drafting of the Final on-board system

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 10

Fig. 4.2.1 Cad Design of on-board system (Chamfered end) (Difficult to Fabricate with Laser)

Fig. 4.2.2 Cad Design of on-board system (Chamfered end) (Difficult to Fabricate with Laser)

Fig. 4.2.1 Cad Design of on-board system (with Cut out section) (Not good for Electronic

Circuits)

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 11

CHAPTER-5

Structural Analysis

FEA Analysis:

FEA section for static structural analysis.

Problem specification:

In static structural analysis we are interested in the total deformation, Von Misses stress which

is also known as equivalent stress, shear stress and stress intensity induced in the skin

structure of the wing. Pre-Analysis and Start-Up Open ANSYS Workbench We are ready to

do a simulation in ANSYS Workbench. Open ANSYS Workbench by going to Start >

ANSYS > Workbench. This will open the start-up screen seen as seen below

Fig 5.1.1 Ansys 15 Workbench

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 12

Material Property :

The material we have chosen is Acrylic material which consist of

Density = 1.19gcm^-3

Youngs Modulus (E) = 2800 Mpa

Poission Ratio = 0.35

Ultimate Tensile Stress = 70 Mpa

Tensile yield stress = 69 Mpa

Compressive yield stress = 124 Mpa

Tensile ultimate strength = 690 Mpa

Compressive ultimate Strength = 1240 Mpa

Factor of Safety = 10

For the given input in the Ansys 14.5 it gives the various von mises stress and strain for the

applied force.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 13

Fixed Support

To begin, we need to tell ANSYS what kind of simulation we are doing. If you look to the left

of the start-up window, you will see the Toolbox Window. Take a look through the different

selections. Because we are only doing a force loading, we will be doing a Static Structural

simulation. Load the Static Structural tool box by dragging and dropping it into the Project

Schematic.

Fig. 5.1.2 Tool Box Window

Name the Project Wing structure by doubling clicking {Static Structural (ANSYS)}}

underneath the project schematic.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 14

Geometry

In Workbench in the Project Schematic window, go to File > Import. In the Import window

that opens, change the file type (next to the File Name text box) to Geometry File. Select the

downloaded geometry file and press Open. The geometry should now be in the project

schematic, as shown below.

Fig. 5.1.3 Geometrical Design

Generate the Geometry Next; we will open the file to generate the geometry. Double click the

imported geometry to open the Design Modeller. When the Design Modeller opens, a pop up

window will ask us for the default units of measurement for the geometry. Select Meter and

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 15

then press OK. After you select the units, you will notice the Graphics window is empty. We

will fix this soon. First, click on in the Outline window. In the Details window, change

Operation from Add Material to Add Frozen. Finally, generate the part by clicking once you

press, the imported geometry should show in the Graphics window.

Mesh

Initial Setup Close the Design Modeler if you haven't already, and open ANSYS Mechanical

by double clicking When ANSYS Mechanical opens, notice that there is a question mark next

to Geometry in the Project Outline - this means that there is something missing in this section.

Expand Geometry, expand Part and select Outer Surface.

Notice that Thickness is highlighted as it does not have a value specified. We will specify a

thickness so the geometry will mesh correctly. For the Outer Surface, enter 1e-2 next to

Thickness. Repeat with the value of 3e-2 for Spar to thickness.

Body Sizing

For this geometry, we will be using a body sizing. Click on Mesh in the Project Outline

window to open up the Meshing Menu in the menu bar. To create a new sizing, go to Mesh

Control > Sizing. Next, we need to select the geometry that the sizing will affect. We want to

select the entire geometry.

Mapped Face Meshing

To apply a mapped face meshing, first click on Mesh in the Outline window. This will bring

up the Meshing Menu Bar at the top of the screen. Next, select Mesh Control > Mapped Face

Meshing. Select the 2 faces of the mesh by holding down the left mouse button and dragging

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 16

over the entire geometry. In the Details window, click Geometry > Apply - it should say 2

faces are selected.

Fig. 5.1.5 Imported Mesh Geometry in Ansys Software

In the Setup Menu, select Supports > Fixed Supports. Make sure the Edge Selection Filter is

selected, hold down Ctrl, and left mouse click the upper and lower edges of the airfoil you are

looking at. In the details window, select Geometry > Apply.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 17

Fig.5.1.6 Applied Load

Solution Deformation

To add deformation to the solution, first click to add the solution sub menu to menu bar. Now

in the solution sub menu click Deformation>Total to add the total deformation to the solution.

It should appear in the outline tree.

Equivalent Stress

In the solution sub mean, select Stress > Equivalent (von-Mises). In the details pane, ensure

Geometry is set to All Bodies.

Shear Stress

In the solution sub mean, select Stress > shear stress. In the details pane, ensure Orientations

is set to X axis and Geometry is set to All Bodies. Rename the Stress to Stress XX by right

clicking Shear Stress in the Outline window and selecting Rename.

Stress intensity

In the solution sub mean, select Stress > shear intensity. In the detail pane, ensure Geometry is

set to All Bodies. We are ready to solve the Simulation Press

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 18

Fig. 5.1.7 Elastic Strain for the Applied Load

Fig. 5.1.8 Von-mises Stress for the applied Load

Fig. 5.1.9 Total Deformation for the applied Load

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 19

Fig. 5.1.10 Total Directional Deformation (X-Axis) for the applied Load

Fig. 5.1.11 Total Directional Deformation (Y-Axis) for the applied Load

So Acrylic plastic can withstand certain amount of load with low weight ratio during the

parachute drop. So we have chosen the acrylic material for on-board system.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 20

Chapter-6

Hardware

The block diagram gives us the layout of the hardware connections of the Small Satellite.

Fig.6.1. Block Diagram of hardware

i. Arduino

Arduino is a single-board microcontroller to make the usage of electronics, in multidisciplinary

projects, more accessible. The hardware consists of an open-source hardware board designed

around an 8-bit AtmelAVR microcontroller or a 32-bit Atmel ARM. The software consists of a

standard programming language compiler and a boot loader that executes on the microcontroller.

The convenience of the Arduino board is its connection methodology where the CPU board to be

connected to a variety of interchangeable add-on modules known as shields. Some shields

communicate with the Arduino board directly over various pins, but many shields are

individually addressable via an ICserial bus, allowing many shields to be stacked and used in

parallel. Official Arduinos have used the mega AVR series of chips, specifically the ATmega8,

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 21

ATmega168, ATmega328, ATmega1280, and ATmega2560. A handful of other processors have

been used by Arduino compatibles. Most boards include a 5 volt linear regulator and a 16 MHz

crystal oscillator (or ceramic resonator in some variants), although some designs such as the

LilyPad run at 8 MHz and dispense with the on-board voltage regulator due to specific form-

factor restrictions. An Arduino's microcontroller is also pre-programmed with a boot loader that

simplifies uploading of programs to the on-chip flash memory, compared with other devices that

typically need an external programmer.

At a conceptual level, when using the Arduino software stack, all boards are programmed over

an RS-232 serial connection, but the way this is implemented varies by hardware version. Serial

Arduino boards contain a level shifter circuit to convert between RS-232-level and TTL-level

signals. Current Arduino boards are programmed via USB, implemented using USB-to-serial

adapter chips such as the FTDI FT232. Some variants, such as the Arduino Mini and the

unofficial Boarduino, use a detachable USB-to-serial adapter board or cable, Bluetooth or other

methods. (When used with traditional microcontroller tools instead of the Arduino IDE, standard

AVR ISP programming is used).

The Arduino Nano, and Arduino-compatible Bare Bones Board and Boarduino boards may

provide male header pins on the underside of the board to be plugged into solder less

breadboards.

There are many Arduino-compatible and Arduino-derived boards. Some are functionally

equivalent to an Arduino and may be used interchangeably. Many are the basic Arduino with the

addition of commonplace output drivers, often for use in school-level education to simplify the

construction of buggies and small robots. Others are electrically equivalent but change the form

factor, sometimes permitting the continued use of Shields, sometimes not. Some variants use

completely different processors, with varying levels of compatibility.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 22

Fig. 6.1.2.Arduino Controller Board

The Arduino Uno is a microcontroller board based on the ATmega328. It has 14 digital

input/output pins (of which 6 can be used as PWM outputs), 6 analog inputs, a 16 MHz ceramic

resonator, a USB connection, a power jack, an ICSP header, and a reset button. It contains

everything needed to support the microcontroller; simply connect it to a computer with a USB

cable or power it with an AC-to-DC adapter or battery to get started.

The Uno differs from all preceding boards in that it does not use the FTDI USB-to-serial driver

chip. Instead, it features the Atmega16U2 (Atmega8U2 up to version R2) programmed as a

USB-to-serial converter. The Arduino Uno board has a resistor pulling the 8U2 HWB line to

ground, making it easier to put into DFUmode.

The board has the following new features:

1.0 pinout added SDA and SCL pins that are near to the AREF pin and two other new

pins placed near to the RESET pin, the IOREF that allow the shields to adapt to the

voltage provided from the board. In future, shields will be compatible with both the board

that uses the AVR, which operates with 5V and with the Arduino Due that operates with

3.3V. The second one is a not connected pin that is reserved for future purposes.

Stronger RESET circuit.

Atmega 16U2 replace the 8U2.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 23

"Uno" means one in Italian and is named to mark the upcoming release of Arduino 1.0. The Uno

and version 1.0 will be the reference versions of Arduino, moving forward. The Uno is the latest

in a series of USB Arduino boards, and the reference model for the Arduino platform; for a

comparison with previous versions, see the index of Arduino boards.

Technical Specification

Microcontroller ATmega328

Operating Voltage 5V

Input Voltage (recommended) 7-12V

Input Voltage (limits) 6-20V

Digital I/O Pins 14 (of which 6 provide PWM output)

Analog Input Pins 6

DC Current per I/O Pin 40 mA

DC Current for 3.3V Pin 50 mA

Flash Memory 32 KB (ATmega328) of which 0.5 KB used by bootloader

SRAM 2 KB (ATmega328)

EEPROM 1 KB (ATmega328)

Clock Speed 16 MHz

The Arduino reference design can use an Atmega8, 168, or 328, Current models use an

ATmega328, but an Atmega8 is shown in the schematic for reference. The pin configuration is

identical on all three processors.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 24

Power

The Arduino Uno can be powered via the USB connection or with an external power supply. The

power source is selected automatically.

External (non-USB) power can come either from an AC-to-DC adapter (wall-wart) or battery.

The adapter can be connected by plugging a 2.1mm center-positive plug into the board's power

jack. Leads from a battery can be inserted in the Gnd and Vin pin headers of the POWER

connector.

The board can operate on an external supply of 6 to 20 volts. If supplied with less than 7V,

however, the 5V pin may supply less than five volts and the board may be unstable. If using

more than 12V, the voltage regulator may overheat and damage the board. The recommended

range is 7 to 12 volts.

The power pins are as follows:

VIN. The input voltage to the Arduino board when it's using an external power source

(as opposed to 5 volts from the USB connection or other regulated power source).

Voltage can be supplied through this pin, or, if supplying voltage via the power jack,

access it through this pin.

5V.This pin outputs a regulated 5V from the regulator on the board. The board can be

supplied with power either from the DC power jack (7 - 12V), the USB connector (5V),

or the VIN pin of the board (7-12V). Supplying voltage via the 5V or 3.3V pins bypasses

the regulator, and can damage the board.

3V3. A 3.3 volt supply generated by the on-board regulator. Maximum current draw is

50 mA.

GND. Ground pins.

IOREF. This pin on the Arduino board provides the voltage reference with which the

microcontroller operates. A properly configured shield can read the IOREF pin voltage

and select the appropriate power source or enable voltage translators on the outputs for

working with the 5V or 3.3V.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 25

Memory

The ATmega328 has 32 KB (with 0.5 KB used for the bootloader). It also has 2 KB of SRAM

and 1 KB of EEPROM (which can be read and written with the EEPROM library).

Input and Output

Each of the 14 digital pins on the Uno can be used as an input or output, using pinMode(),

digitalWrite(), and digitalRead() functions. They operate at 5 volts. Each pin can provide or

receive a maximum of 40 mA and has an internal pull-up resistor (disconnected by default) of

20-50 kOhms. In addition, some pins have specialized functions:

Serial: 0 (RX) and 1 (TX). Used to receive (RX) and transmit (TX) TTL serial data.

These pins are connected to the corresponding pins of the ATmega8U2 USB-to-TTL

Serial chip.

External Interrupts: 2 and 3. These pins can be configured to trigger an interrupt

on a low value, a rising or falling edge, or a change in value.

PWM: 3, 5, 6, 9, 10, and 11. Provide 8-bit PWM output with the analogWrite()

function.

SPI: 10 (SS), 11 (MOSI), 12 (MISO), 13 (SCK). These pins support SPI

communication using the SPI library.

LED: 13. There is a built-in LED connected to digital pin 13. When the pin is HIGH value,

the LED is on, when the pin is LOW, it's off.

The Uno has 6 analog inputs, labelled A0 through A5, each of which provide 10 bits of

resolution (i.e. 1024 different values). By default they measure from ground to 5 volts, though it

is possible to change the upper end of their range using the AREF pin and the analogReference()

function. Additionally, some pins have specialized functionality:

TWI: A4 or SDA pin and A5 or SCL pin. Support TWI communication using

the Wire library.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 26

There are a couple of other pins on the board:

AREF. Reference voltage for the analog inputs. Used with analog Reference().

Reset. Bring this line LOW to reset the microcontroller. Typically used to add a reset

button to shields which block the one on the board.

See also the mapping between Arduino pins and ATmega328 ports. The mapping for the

Atmega8, 168, and 328 is identical.

Communication

The Arduino Uno has a number of facilities for communicating with a computer, another

Arduino, or other microcontrollers. The ATmega328 provides UART TTL (5V) serial

communication, which is available on digital pins 0 (RX) and 1 (TX). An ATmega16U2 on the

board channels this serial communication over USB and appears as a virtual com port to

software on the computer. The '16U2 firmware uses the standard USB COM drivers and no

external driver is needed. However, on Windows, an .inf file is required. The Arduino software

includes a serial monitor which allows simple textual data to be sent to and from the Arduino

board. The RX and TX LEDs on the board will flash when data is being transmitted via the

USB-to-serial chip and USB connection to the computer (but not for serial communication on

pins 0 and 1).

A Software Serial library allows for serial communication on any of the Uno's digital pins.

The ATmega328 also supports I2C (TWI) and SPI communication. The Arduino software

includes a Wire library to simplify use of the I2C bus.

Programming

The Arduino Uno can be programmed with the Arduino software (download). Select Arduino

Uno from the Tools > Board menu (according to the microcontroller on your board).

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 27

The ATmega328 on the Arduino Uno comes pre-burned with a bootloader that allows you to

upload new code to it without the use of an external hardware programmer. It communicates

using the original STK500 protocol (reference, C header files).

The bootloader can be bypassed and the microcontroller can be programmed through the ICSP

(In-Circuit Serial Programming) header.

The ATmega16U2/8U2 is loaded with a DFU bootloader, which can be activated by:

On Rev1 boards: connecting the solder jumper on the back of the board and then resetting

the 8U2.

On Rev2 or later boards: there is a resistor that pulling the 8U2/16U2 HWB line to

ground, making it easier to put into DFU mode.

The Atmel's FLIP software (Windows) or the DFU programmer (Mac OS X and Linux) can be

used to load a new firmware. The ISP header with an external programmer (overwriting the DFU

bootloader).

Automatic (Software) Reset

Rather than requiring a physical press of the reset button before an upload, the Arduino Uno is

designed in a way that allows it to be reset by software running on a connected computer. One of

the hardware flow control lines (DTR) of the ATmega8U2/16U2 is connected to the reset line of

the ATmega328 via a 100 nanofarad capacitor. When this line is asserted (taken low), the reset

line drops long enough to reset the chip. The Arduino software uses this capability to allow you

to upload code by simply pressing the upload button in the Arduino environment. This means

that the bootloader can have a shorter timeout, as the lowering of DTR can be well-coordinated

with the start of the upload.

This setup has other implications. When the Uno is connected to either a computer running Mac

OS X or Linux, it resets each time a connection is made to it from software (via USB). For the

following half-second or so, the bootloader is running on the Uno. While it is programmed to

ignore malformed data (i.e. anything besides an upload of new code), it will intercept the first

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 28

few bytes of data sent to the board after a connection is opened. If a sketch running on the board

receives one-time configuration or other data when it first starts, make sure that the software with

which it communicates waits a second after opening the connection and before sending this data.

The Uno contains a trace that can be cut to disable the auto-reset. The pads on either side of the

trace can be soldered together to re-enable it. It's labelled "RESET-EN".

USB Overcurrent Protection

The Arduino Uno has a resettable polyfuse that protects your computer's USB ports from shorts

and overcurrent. Although most computers provide their own internal protection, the fuse

provides an extra layer of protection. If more than 500 mA is applied to the USB port, the fuse

will automatically break the connection until the short or overload is removed.

Physical Characteristics

The maximum length and width of the Uno PCB are 2.7 and 2.1 inches respectively, with the

USB connector and power jack extending beyond the former dimension. Four screw holes allow

the board to be attached to a surface or case.

ii. GPS Module

The Global Positioning System (GPS) is a space-based satellite navigation system that provides

location and time information in all weather conditions, anywhere on or near the Earth where

there is an unobstructed line of sight to four or more GPS satellites. The data is sent out on the

serial port at an interval called update rate. The GPS receivers output NMEA data. The NMEA

(National Marine Electronics Association) standard is formatted in lines of data called sentences.

Each sentence contains various bits of data organized in comma delimited format (i.e. data

separated by commas). The 3 NMEA data lines which are continuously received are GPRMC,

GPGGA and GPGSA.

For example if one set of data stream is

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 29

$GPRMC,235316.000,A,4003.9040,N,10512.5792,W,0.09,144.75,141112,,*19

$GPGGA,235317.000,4003.9039,N,10512.5793,W,1,08,1.6,1577.9,M,-20.7,M,,0000*5F

$GPGSA,A,3,22,18,21,06,03,09,24,15,,,,,2.5,1.6,1.9*3E

The GPGGA sentence contains the follow:

Time: 235317.000 is 23:53 and 17.000 seconds in Greenwich mean time

Longitude: 4003.9040 N is latitude in degrees. decimal minutes, north

Latitude: 10512.5792 W is longitude in degrees. decimal minutes, west

Number of satellites seen: 08

Altitude: 1577 meters

Fig. 6.2.2 GPS Module

iii. Wireless Module

An RF(Radio Frequency) module is used to transmit and/or receive radio signals from the robot

to the base station. The telemetry system used is designed as an open source Xbee replacement

radio set, offering a lower price, longer range (approx one mile) and superior performance to

Xbee radios. Its workable frequency is 915 MHz and it has serial board connection for the air

and USB connection for the ground.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 30

The system provides a full-duplex link using HopeRF's HM-TRP modules running custom, open

source firmware. Interface to the module is via standard 5V-tolerant TTL serial / FTDI USB

serial.

The SiK firmware includes a bootloader that permits radio firmware upgrades over the serial

interface, and radio firmware with configurable parameters. Firmware upgrades and

configuration are fully supported in the APM Mission Planner. Configuration is also possible

through the 3DR Radio configurator and AT commands.

Hardware features and specifications

Very small size

Light weight (under 4 grams without antenna)

Available in 900MHz or 433MHz variants

Receiver sensitivity to -121 dBm

Transmit power up to 20dBm (100mW)

Transparent serial link

Air data rates up to 250kbps

Range of approx. 1 mile

MAVLink protocol framing and status reporting

Frequency hopping spread spectrum (FHSS)

Adaptive time division multiplexing (TDM)

Support for LBT and AFA

Configurable duty cycle

Built in error correcting code (can correct up to 25% data bit errors)

Demonstrated range of several kilo meters with a small Omni antenna

Can be used with a bi-directional amplifier for even more range

Open source firmware

AT commands for radio configuration

RT commands for remote radio configuration

Adaptive flow control when used with APM

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 31

Based on the HopeRF HM-TRP radio module, featuring an SiLabs Si1000 RF

microcontroller

Fig. 6.2.3 TTL Telemetry Module

iv. Pressure Sensor

A pressure sensor measures pressure, typically of gases or liquids. A pressure sensor usually acts

as a transducer; it generates a signal as a function of the pressure imposed. For the purposes of

this, such a signal is electrical. The pressure sensor we are using is an absolute pressure sensor.

The pressure sensor we are using is BMP085 manufactured by BOSCH. The BMP085 is

designed such that it can be connected directly to the microcontroller using I2C bus. The

pressure sensor is based on piezo-resistive technology for EMC robustness, high accuracy and

linearity as well as long term stability.

Technical Specifications:

Pressure Range: 300 - 1100hPa (+9000m to -500m above sea level)

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 32

Supply voltage: 1.8 3.6 V (V DDA)

1.62 V 3.6 V (V DDD)

LCC8 package: Robust, ceramic lead-less chip carrier (LCC) package

Small footprint: 5.0mm x 5.0mm

Super-flat: 1.2mm height

Low power: 5 micro A at 1 sample / sec. in standard mode

Low noise: 0.06hPa (0.5) in ultra-low power mode

0.03hPa (0.25) ultra-high resolution mode

Down to 0.1 micro m (rma noise) possible

Temperature measurement included

I2C interface

Fully calibrated

Pb-free, halogen-free and RoHS compliant,

MSL 1

Fig. 6.2.4 Pressure sensor & Pin Diagram

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 33

Pin No. Name Function Type

1 GND Ground Power

2 EOC End of Conversion Digital output

3 V

DDA

Power supply Power

4 V

DDD

Digital Power Supply Power

5 NC no Internal connection -

6 SCL I2C serial bus clock input Digital input

7 SDA I2C serial bus data Digital bi-directional

8 XCLR Master clear (low active) input Digital input

Fig. 6.2.5 Connection Methodology

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 34

v. Humidity & Temperature Sensor

Temperature sensors are devices used to measure the temperature of a medium. A humidity

sensor is a device used to measure the humidity of air or any gas in a given area. It can be used in

both indoors and outdoors.

The module being utilized is DHT22. DHT22 output calibrated digital signal. It utilizes

exclusive digital-signal-collecting technique and humidity sensing technology, assuring its

reliability and stability. Its sensing elements are connected with 8-bit single-chip computer.

This model is temperature compensated and calibrated in accurate calibration chamber and the

calibration-coefficient is saved in type of programme in OTP memory, when the sensor is

detecting, it will cite coefficient from memory.

Fig. 6.2.6 Sensor & Pin diagram

Pin Specification

Pin No. Function

1 VDD-power supply

2 DATA-signal

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 35

Technical Specification

Model DHT11

Power supply 3.3-6V DC

Output signal digital signal via single-bus

Sensing element Polymer capacitor

Operating range humidity 0-100%RH; temperature -40~80Celsius

Accuracy humidity +-2%RH(Max +-5%RH); temperature <+-0.5Celsius

Resolution or sensitivity humidity 0.1%RH; temperature 0.1Celsius

Repeatability humidity +-1%RH; temperature +-0.2Celsius

Humidity hysteresis +-0.3%RH

Long-term Stability +-0.5%RH/year

Sensing period Average: 2s

Interchange ability fully interchangeable

Dimensions small size 14*18*5.5mm; big size 22*28*5mm

vi. Accelerometer

An accelerometer is a device that measures proper acceleration. The proper acceleration

measured by an accelerometer is not necessarily the coordinate acceleration (rate of change of

velocity). Instead, the accelerometer sees the acceleration associated with the phenomenon of

weight experienced by any test mass at rest in the frame of reference of the accelerometer device.

For example, an accelerometer at rest on the surface of the earth will measure an acceleration g=

9.81 m/s

2

straight upwards, due to its weight. By contrast, accelerometers in free fall or at rest in

3 NULL

4 GND

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 36

outer space will measure zero. Another term for the type of acceleration that accelerometers can

measure is g-force acceleration.

Accelerometers have multiple applications in industry and science. Highly sensitive

accelerometers are components of inertial navigation systems for aircraft and missiles.

Accelerometers are used to detect and monitor vibration in rotating machinery. Accelerometers

are used in tablet computers and digital cameras so that images on screens are always displayed

upright.

Single- and multi-axis models of accelerometer are available to detect magnitude and direction

of the proper acceleration (or g-force), as a vector quantity, and can be used to sense orientation

(because direction of weight changes), coordinate acceleration (so long as it produces g-force or

a change in g-force), vibration, shock, and falling in a resistive medium (a case where the proper

acceleration changes, since it starts at zero, then increases). Micro machined accelerometers are

increasingly present in portable electronic devices and video game controllers, to detect the

position of the device or provide for game input.

Pairs of accelerometers extended over a region of space can be used to detect differences

(gradients) in the proper accelerations of frames of references associated with those points. These

devices are called gravity gradiometers, as they measure gradients in the gravitational field. Such

pairs of accelerometers in theory may also be able to detect gravitational waves.

Fig.6.2.7 Accelerometer & Pin diagram

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 37

Pin Specification

The ADXL335 is a complete 3-axis acceleration measurement system. The ADXL335 has a

measurement range of 3 g mini-mum. It contains a poly silicon surface-micro machined sensor

and signal conditioning circuitry to implement an open-loop acceleration measurement

Pin No. Mnemonic Description

1 NC No Connect

2 ST Self-Test

3 COM Common

4 NC No Connect

5 COM Common

6 COM Common

7 COM Common

8 Z OUT Z Channel Output

9 NC No Connect

10 Y OUT Y Channel Output

11 NC No Connect

12 X OUT X Channel Output

13 NC No Connect

14 Vs Supply Voltage (1.8V to 3.6V )

15 Vs Supply Voltage (1.8V to 3.6V )

16 NC No Connect

EP Exposed Pad Not internally connected. Solder for mechanical integrity

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 38

architecture. The output signals are analog voltages that are proportional to acceleration. The

accelerometer can measure the static acceleration of gravity in tilt-sensing applications as well as

dynamic acceleration resulting from motion, shock, or vibration.

The sensor is a polysilicon surface-micro machined structure built on top of a silicon wafer.

Polysilicon springs suspend the structure over the surface of the wafer and provide a resistance

against acceleration forces. Deflection of the structure is measured using a differential capacitor

that consists of independent fixed plates and plates attached to the moving mass. The fixed plates

are driven by 180 out-of-phase square waves. Acceleration deflects the moving mass and

unbalances the differential capacitor resulting in a sensor output whose amplitude is proportional

to acceleration. Phase-sensitive demodulation techniques are then used to determine the

magnitude and direction of the acceleration.

Technical Specification

3-axis sensing

Small, low profile package

4 mm 4 mm 1.45 mm LFCSP

Low power : 350 A (typical)

Single-supply operation: 1.8 V to 3.6 V

10,000 g shock survival

Excellent temperature stability

BW adjustment with a single capacitor per axis

RoHS/WEEE lead-free compliant

Fig.6.2.8 Axes of Acceleration Sensitivity

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 39

vii. Camera Module

The Camera Module consists of a pin hole lens which captures the data and stores the data into

the micro SD memory card. This can be retrieved later and when the memory card is connected

to the PC then the video of the entire travel of the satellite can be seen.

Fig. 6.2.9 Camera Module

viii. Hardware Assembly Procedure

1. Cut the male pin connector header in to the following lengths: - 6 pins (H1) - 10 pins

(H2) - 8 pins (H3) - 8 pins (H4)

2. Insert the connector headers into the Arduino board with the short end up.

3. Mount the shield board on top of the Arduino Uno.

4. Solder all the pins on the top of the circuit board and then remove it from the Arduino

Uno. Make sure not to heat the pins to long while soldering. To long exposure to heat

might damage the Arduino board.

5. Cut out two lengths of 4-pin connector header and one length of 2-pin connector header.

Place them on the top of the shield board and solder them on the bottom as shown on the

illustration.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 40

6. The green female connector header allows us to easily connect and disconnect the radio

for programming. Place the connectors on top of the board and solder them on the

bottom.

7. Solder the data logger onto the shield board using a 6-pin connector header. Use the short

end of the connector downwards trough the shield board. It is recommended to use some

hot glue in between the board and the logger to support the logger. If not supported it

may easily brake off or damage the soldering points.

8. Use two lengths of 5 pin male connector header and solder the accelerometer onto the

shield board at the U1-possition. Make sure to put the sensor the correct way. The black

IC-chip on the sensor should be pointing upwards. Also note that two of the solder pads

both on the shield board and the sensor have a square shape instead of a circle shape.

These squares should be aligned.

9. Put the pressure sensor onto the shield board and solder it on the bottom side.

10. Continue by soldering the 75 Ohms resistor to the R2 position, the 1uP capacitor to C1

position and the temperature IC sensor (LM35DZ) to T1 position. The temperature

sensors orientation is labelled with at drawing on the board. The capacitors orientation is

labelled with a plus sign (+) on the board. The positive pin on the capacitor is the longest

pin. The negative pin is also marked on the side of the capacitor.

11. Solder a 2-pin male connector header to one of the radios. These pins will only be used

as support to reduce the strain on the radio connector. Mount the radio to the shield

board. Solder the battery connector to the shield board

ix. Software Installation

The Software for writing the program and compiling the program for the Arduino is provided by

Arduino.

Steps for obtaining the software

Goto arduino.cc/en/Main/Software and download the latest version

Click on the downloaded zip-file

Extract the contents to folder on your computer, for example C:/Program

files/Arduino.

The content will then be put in a subfolder of this location

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 41

Connect the board

The Arduino Uno automatically draws power from either the USB connection to the computer or

an external power supply. Connect the Arduino board to the computer using the USB cable. The

green power LED (labelled PWR) should go on.

Install drivers

Installing drivers for the Arduino Uno with Windows 7, Vista or XP

Plug in the board and wait for Windows to begin its driver installation process. On some

computers the drivers will install automatically. If not, follow the steps below.

Click on the Start Menu, and open up the Control Panel.

While in the Control Panel, navigate to System and Security. Next, open the Device

Manager which you will find under System.

Look under Ports (COM & LPT). You should see an open port named "Arduino UNO

(COMxx)" In some cases you wont find Arduino Uno, instead you will find

Unknown device at the top.

Right click on the "Arduino UNO (COMxx)" port and choose the "Update Driver

Software" option.

Next, choose the "Browse my computer for Driver software" option.

Finally, navigate to and select the Arduino Uno's driver file, named "ArduinoUNO.inf",

located in the "Drivers" folder of the Arduino Software download (not the "FTDI USB

Drivers" subdirectory).

Windows will finish up the driver installation from there.

Launch the Arduino application

Double-click the Arduino application in the folder where you extracted it. To find this

application easier you can also make a shortcut to the desktop.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 42

Opening an example code

Open the example code by: File Open The CanSat DVD Code

TestArduino.ino. You will get a message to create a sketch folder, and move the file. This will

make a copy of the .ino file

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 43

Selecting the board

Select the entry in the Tools Board menu that corresponds to the presently used Arduino.

Selecting the serial port

Select the serial device of the Arduino board from the Tools Serial Port menu. This is likely

to be COM3 or higher (COM1 and COM2 are usually reserved for hardware serial ports). To

find out, the Arduino board has to be disconnected and re-opened; the entry that disappears

should be the Arduino board. Reconnect the board and select that serial port.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 44

Uploading the program

Click the "Upload" button in the environment. After few seconds the RX and TX LEDs on the

board flashing. If the upload is successful, the message "Done uploading." will appear in the

status bar.

Read data

Open the serial monitor to look at the data that is coming from the Arduino Uno board. This

opens a new window which is called after the current COM-port being used. A text string from

the serial prints which have been set in the code will be received.

Testing the Arduino Uno board

To verify whether the right data is being received, each channel should be set to ground and

power. A wire should be plugged in the analogue connectors and power connectors on the

Arduino Uno.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 45

Connect one end of the wire in A0 on the board

Connect the other end in GND

Now should Analog0 show 0

Move the wire from GND to 5V

Now should Analog0 show 5

Move the wire from 5V to 3.3V

Now should Analog0 show 3.3

Repeat the cycle with A1

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 46

Chapter-7

GROUND STATION

For CANSATs the design of ground station GUI is one of the most important parts and

in this section a design is mentioned briefly. For this study, many programming

languages and development platforms like MATLAB, Java and LabView are researched

and examined. C# programming language and Visual Studio -as a development platform-

are chosen for design of the ground station GUI, because C# is an advanced, object-

oriented high level programming language and Visual Studio is a user-friendly

development platform. In addition to these features, there are many advantages of using

C# programming language for beginners and some of them are:

It comes with a large framework of pre-developed components (also called as .Net

Framework),

It is full of features that make development faster and easier, usually at the cost of

flexibility and/or runtime performance,

It is much cleaner and has easier to use syntax,

The ability of using advanced and easy interface provided with Visual Studio.

It is freeware for small-sized applications.

A. Received Data Format

The hardware sends data in a string as :

$,40.968788,28.842109,4,20680,0,100089,27.89,99999

Next the GUI changes data format with using this code:

string[ ] parsedBuffer = new string[32];

parsedBuffer = buffer.Split(new char[1] { ',' });

Latitude = Convert.ToDouble(parsedBuffer[1]);

Longitude = Convert.ToDouble(parsedBuffer[2]);

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 47

Satellites = Convert.ToInt16(parsedBuffer[3]);

UTC = (parsedBuffer[4]);

Speed = Convert.ToDouble(parsedBuffer[5]);

Temperature = Convert.ToDouble(parsedBuffer[6]);

Pressure = Convert.ToInt32(parsedBuffer[7]);

Atm = Convert.ToDouble(parsedBuffer[8]);

BarometerAltitude=Convert.ToDouble(parsedBuffer[9]);

Pressure and temperature data is provided from a digital pressure sensor, because of the

ambient pressure drift, it needs to be adjusted for actual pressure value.

B. GUI Layout

GUI layout consists of conrol panel, warning screen, serial port panel, graphs and map (Fig.). Every

value is displayed as string. Also changes of temperature, speed, pressure and altitude temperature

with respect to time are shown .

The GUI provides serial port of com, baud and parity selections. The user first has to select

serial port properties to run the GUI. Then the program detects serial port properties then if

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 48

there is any problem, the GUI does not run and show problem on the warning screen. If the

serial port properties are available, GUI starts to run (Fig).

Fig.7.1 The Serial Port Interface

CANSAT location is shown on the world map with using latitude and longitude data. If ground

station connects internet, CANSAT location is shown in real time. Also the user can select

different map type from options tab. So the user can use the different maps for different aims.

Moreover, map depth of focus can be adjusted with using mouse and scale tab which is near the

map or select the auto map option. If CANSAT connection is broken, new latitude and longitude

data are the last data which was received (Fig.7.1.2).

Fig.7.1.2 The Map

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 49

GUI has the correction options for example, if there is adjust offset problem about

temperature, barometric altitude, pressure or speed values, the user can adjust it with using

offset tab. All values are shown as string also temperature, barometric altitude, pressure and

speed values are plot tables concurrently. The tables auto scale. If the user would like to use

auto scale property, GUI automatically adjusts scale to value range, so the user can see the

value changes easily. For example, if change is getting smaller, scale gets narrow, so the user

can notice the instantaneous small changes.

Fig.7.1.3The tables and offsets

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 50

C. Ground Station Flow Scheme

Serial port must be available for starting GUI. The program searches every serial port and the

user selects available port and GUI starts (Fig. 11). First, GUI receives string data from

CANSAT and parses it which is separated with commas. Every date covers to integer, double,

float and string syntax. Finally, graphics are drawn

Fig.7.4 The Ground Station Flowchart

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 51

Chapter-8

CONCLUSION

The development of the Small Satellite includes 3 vital steps:

1. Design a CAD model for the external body of the satellite and perform design iterations

of the CAD model, conduct the stress analysis for the body made and make respective

corrections.

2. Fabricating the sensors, GPS, radio transceiver along with the Arduino board,

programming and compiling the on-board computer.

3. Develop an algorithm for the Graphical User Interface which is to be developed and

interfacing the On board computer with GUI.

We have designed the CAD model of the body of the Satellite, performed the stress analysis

and written the program for the Arduino Controller Board.

We have to perform the fabrication of the electronic components along with the Controller

and develop the GUI in the Visual Basic Platform and interface the On-Board Computer

along with the GUI.

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 52

REFERENCE

Authors SaburoMAlzTNAGA , Keisuke Yoshiharpi, Yoshiki SUGIURA- Masato SEKIGUCHI,

HirotakaSAWADA,Shingo TSURUMI, Koji NAKAYA, Makoto MORI, KyoichiU,

NaohideMAEDA and Osamu MORI of Mechano-Aerospace Engineering, Tokyo Institute of

Technology, Tokyo 152-8552, Japan had published an IEEE paper on the topic Titech Micro-

Satellite Model:CanSat for Sub-orbital Flight.

Authors Jack K. Kreng, Michelle M. Ardeshiri, Oscar C. Barbosa, and Yogi Y. Krikorian from

The Aerospace Corporation, Communication Systems Engineering Department, Los Angeles,

California had presented an IEEE paper on the Telemetry, Tracking, and Commanding (TT&C)

Link Considerations for a LEO Sat123

Authors M. HosseinSharifi, Senior Member, IEEE from M/A-COM Telecommunications, Inc.

Germantown and MahammedArozullah Dept. of Electrical Engineering from The Catholic

University of America Washington had published an IEEE paper on A Centralized Multiple

Satellite Network For Real Time Global Space, Land, And Mobile Communications.

The authors Bastian Preindl from Institute of Analysis and Scientific Computing Vienna

University of Technology, Austria; Lars Mehnen from Institute for Biomedical Engineering FH

Technikum Wien, Austria; Frank Rattay from Institute of Analysis and Scientific Computing,

Vienna University of Technology, Austria and Jens Dalsgaard Nielsen from Section of

Automation and Control Aalborg University, Denmark had written an IEEE paper on Design of

a Small Satellite for PerformingMeasurements in a Ground Station Network

The CHASQUI team members from the J. Martn 1 Center for Technological Information and

Communications, National University of Engineering (UNI), Lima, Peru; Canales R. from

German Aerospace Center (DLR), German Space Operations Center, Germany and Glen

Rodriguez from the Technical Consultants to the National University of Engineering had

published an IEEE paper on the topic Design of a Peruvian Small Satellite Network

Design & Engineering of a Cansat

Nagarjuna College of Engineering & Technology Page 53

Authors ChetanAngadi Team Leader, Project STUDSAT Department of Electronics &

Communication Engineering NitteMeenakshi Institute of Technology Affiliated to the

Visveswaraya Technological University, Karnataka, India; ZhoraManjiyani, Core Leader,

Payload; Chetan Dixit, Core Leader, Project & Finance Management; Vigneswaran K, Avinash

G.S, Prithvi Raj Narendra, Core Leader, Command & Data-Handling.

Shwetha Prasad, Core Leader, Communication System; Harish Ramavaram&Mamatha R.M,

ADCS.Karthik G, Arpan H.V, Sharath A.H, SashiKiran P, Core Leaders, Structure and

Visweswaran K, Core Leader, Ground Station had jointly published an IEEE project on

STUDSAT: Indias First Student Pico-Satellite Project.

Author Stileyrnan SOYER from Istanbul Technical University,Istanbul, TURKEY had published

an IEE paper on the topic Small Space Can: CanSat

Authors Mustafa EmreAydemir from the Department of Electronics Engineering, Turkish Air

Force Academy, Istanbul, Turkey; Mansur Celebi from the Department of Aerospace

Engineering, Turkish Air Force Academy, Istanbul, Turkey; Serdar Ay from the Department of

Aerospace Engineering, Turkish Air Force Academy,Istanbul, Turkey; Esau VincenteVivas of

Mexico University NacionalAutonoma de Mexico, Mexico; FredyCalleBustinza from Peru

Universidad Nacional de Ingenieria, Peru; and Dan Phan from Vietnam Space Tech Institute of

Vietnam, Vietnam had published an IEEE paper on Design and Implementation of a Rover-

Back CANSAT

Authors Mustafa EmreAydemir, Raif Can Dursun from the Turkish Air Force Academy,

Department of Electronics Engineering, Istanbul, Turkey; and MiracPehlevan from the Turkish

Air Force Academy, Department of Computer Engineering, Istanbul, Turkey had publishe an

IEEE paper on the topic GROUND STATION DESIGN PROCEDURES FOR CANSAT

You might also like

- An Overview of Small Satellites in Remote SensingDocument54 pagesAn Overview of Small Satellites in Remote SensingJohannNo ratings yet

- Prototype of Cansat With Auto-Gyro Payload For Small Satellite EducationDocument7 pagesPrototype of Cansat With Auto-Gyro Payload For Small Satellite EducationPusapati Saketh Varma ed21b048No ratings yet

- NANO SATELLITES: An Overview of Components, Applications and AdvantagesDocument15 pagesNANO SATELLITES: An Overview of Components, Applications and AdvantagesDharni ShahNo ratings yet

- Research Paper Satellite CommunicationDocument8 pagesResearch Paper Satellite Communicationcamhwq6m100% (1)

- IAC 19, A7,1,5, x49711Document15 pagesIAC 19, A7,1,5, x49711pacoNo ratings yet

- Acta Astronautica: SciencedirectDocument14 pagesActa Astronautica: SciencedirectRobinson 10K10No ratings yet

- Satellite Research PaperDocument4 pagesSatellite Research Paperwonopwwgf100% (1)

- Antennas For Small Satellite ApplicationsDocument13 pagesAntennas For Small Satellite ApplicationsMr. MERLIN GILBERT RAJ S 1154No ratings yet

- Computation 11 00182 v2Document31 pagesComputation 11 00182 v2Roberto Carlos FvtureNo ratings yet

- Research Paper On SatelliteDocument8 pagesResearch Paper On Satellitehubegynowig3100% (1)

- Toward Space-Based Wireless Sensor NetworksDocument21 pagesToward Space-Based Wireless Sensor NetworksAhmed El ShafieNo ratings yet

- Tim Girard Resume 8 2013Document3 pagesTim Girard Resume 8 2013sundar_subash25No ratings yet

- Static and Random Vibration Analyses of A University Cubesat ProjectDocument13 pagesStatic and Random Vibration Analyses of A University Cubesat ProjectShoaib IqbalNo ratings yet

- Assan LI: Academic RecordDocument4 pagesAssan LI: Academic Recordilyas muhammadNo ratings yet

- Lessons Learned of Nspo'S Picosatellite Mission: Yamsat - 1A, 1B & 1CDocument13 pagesLessons Learned of Nspo'S Picosatellite Mission: Yamsat - 1A, 1B & 1CSai Swaroop MandalNo ratings yet

- Inflatable Antenna Technology With Preliminary ShuDocument7 pagesInflatable Antenna Technology With Preliminary ShudivyaNo ratings yet

- eDocument18 pageseSapto Adi NugrohoNo ratings yet

- Misión 2-IAC2010-S16-1-Nanosatellite-tracking-F-PranajayaDocument9 pagesMisión 2-IAC2010-S16-1-Nanosatellite-tracking-F-Pranajayayubrany gonzalezNo ratings yet

- Vaishnavi Narayanan: EducationDocument2 pagesVaishnavi Narayanan: Educationvaishnavi narayananNo ratings yet

- SathyabamaSat - DetailsDocument3 pagesSathyabamaSat - DetailsGrow LiveNo ratings yet

- Araslan-System Eng and Design-Ssd2020-PDocument247 pagesAraslan-System Eng and Design-Ssd2020-PMim Alperen YarenNo ratings yet

- Science Missions Using CubeSatsDocument19 pagesScience Missions Using CubeSatsluizfelipe94No ratings yet

- Aas18 681Document15 pagesAas18 681Kamel KerroucheNo ratings yet

- University Small Satellite Program - Anusat: K. Thyagarajan, J.P. Gupta, Dr. P.S. Goel, Prof. K. JayaramanDocument5 pagesUniversity Small Satellite Program - Anusat: K. Thyagarajan, J.P. Gupta, Dr. P.S. Goel, Prof. K. JayaramankpreddypadiraNo ratings yet

- Introducing SOST An Ultra-Low-Cost Star Tracker Concept Based On A Raspberry Pi and Open-Source Astronomy SoftwareDocument15 pagesIntroducing SOST An Ultra-Low-Cost Star Tracker Concept Based On A Raspberry Pi and Open-Source Astronomy SoftwareGichuru MuthomiNo ratings yet

- Hassan 2019 IOP Conf. Ser. Mater. Sci. Eng. 610 012035Document14 pagesHassan 2019 IOP Conf. Ser. Mater. Sci. Eng. 610 012035mohammad1jamalNo ratings yet

- Hishmeh 2009Document15 pagesHishmeh 2009Andrei Toma StoicaNo ratings yet

- Roadmapwkshp LessardDocument2 pagesRoadmapwkshp LessardIset LabNo ratings yet

- Design of Flight Software For The KySat CubeSat BusDocument15 pagesDesign of Flight Software For The KySat CubeSat BusAndrei Toma StoicaNo ratings yet

- Cubesat Project: Experience Gained and Design Methodology Adopted For A Low-Cost Electrical Power SystemDocument24 pagesCubesat Project: Experience Gained and Design Methodology Adopted For A Low-Cost Electrical Power SystemRaed HossainNo ratings yet

- PHD Thesis Satellite CommunicationDocument5 pagesPHD Thesis Satellite CommunicationHelpWritingPapersSalem100% (2)

- Aas18 681Document15 pagesAas18 681Maman de AnisNo ratings yet

- Lochie Ferrier's ResumeDocument1 pageLochie Ferrier's ResumeLochie FerrierNo ratings yet

- Clasificarea SatelitilorDocument45 pagesClasificarea SatelitilorVictoria LevinteNo ratings yet

- Applsci 11 02659 v2Document21 pagesApplsci 11 02659 v2Cristian BandilaNo ratings yet

- A Pico-Satellite Assembled and Tested Du PDFDocument9 pagesA Pico-Satellite Assembled and Tested Du PDFJorge MarioNo ratings yet

- ESA Wireless Working Group Advances Spacecraft Data HandlingDocument16 pagesESA Wireless Working Group Advances Spacecraft Data HandlingnicolasNo ratings yet

- A Framework For Robust and Flexible Ground StationDocument21 pagesA Framework For Robust and Flexible Ground StationLeila BachiriNo ratings yet

- Keplers Orbits (Aerospace)Document3 pagesKeplers Orbits (Aerospace)valNo ratings yet

- Class Activity Lecture NoteDocument18 pagesClass Activity Lecture NoteBora MenekşeNo ratings yet

- SRMSAT-2 Mission to Study Lunar ScienceDocument282 pagesSRMSAT-2 Mission to Study Lunar SciencePranav CVNo ratings yet

- SDNX Cansat NepalDocument3 pagesSDNX Cansat NepalSagar aryalNo ratings yet

- Annual 2011-12: - Massachusetts Institute of TechnologyDocument78 pagesAnnual 2011-12: - Massachusetts Institute of TechnologyLc RangaNo ratings yet

- Proyectos NASA-AMESDocument17 pagesProyectos NASA-AMESLuis MonsanNo ratings yet

- NASA Internship Guide: 15 Project OptionsDocument17 pagesNASA Internship Guide: 15 Project OptionsLuceroSeguraJuárezNo ratings yet

- Approaches and Solutions For Martian Spacesuit Design: September 2017Document16 pagesApproaches and Solutions For Martian Spacesuit Design: September 2017Aryan TomarNo ratings yet

- An Architecture For Self-Fabricating Space SystemsDocument17 pagesAn Architecture For Self-Fabricating Space SystemsWalfarid LimbongNo ratings yet

- RvsatDocument14 pagesRvsatAbyan RaidhNo ratings yet

- ICESCO's 3rd International Model Satellite (Cansat) Training Workshop & Aerospace SymposiumDocument20 pagesICESCO's 3rd International Model Satellite (Cansat) Training Workshop & Aerospace SymposiumshaomahirNo ratings yet

- Research Paper On Satellite RadioDocument6 pagesResearch Paper On Satellite Radioefdwvgt4100% (3)

- Australia & Korea Joint Venture: Cooperative Research Centre For Satellite Systems Number 83, June 1999Document12 pagesAustralia & Korea Joint Venture: Cooperative Research Centre For Satellite Systems Number 83, June 1999Zoe Ellen BrainNo ratings yet

- Yarce 2017 J. Phys. Conf. Ser. 850 012019Document11 pagesYarce 2017 J. Phys. Conf. Ser. 850 012019botametunosegaNo ratings yet

- 716074main Short 2011 PhI Printable SpacecraftDocument52 pages716074main Short 2011 PhI Printable SpacecraftYiechin NgNo ratings yet

- Delivery of Colloid Micro-Newton Thrusters For The Space Technology 7 MissionDocument15 pagesDelivery of Colloid Micro-Newton Thrusters For The Space Technology 7 MissionJohn DoeNo ratings yet

- The Evolution and Promise of Robotic In-Space ServicingDocument6 pagesThe Evolution and Promise of Robotic In-Space ServicingSushil GautamNo ratings yet

- EyasSAT: A Hands-On Space Systems Engineering ExperienceDocument16 pagesEyasSAT: A Hands-On Space Systems Engineering ExperienceEmre ErgeneNo ratings yet

- A CubeSat Constellation For Integrated Earth Observationand Marine - Air Traffic MonitoringmainDocument13 pagesA CubeSat Constellation For Integrated Earth Observationand Marine - Air Traffic MonitoringmainJuan Antonio SanchezNo ratings yet

- Thermal Design Analysis and Test Validation of Turksat-3USat SatelliteDocument15 pagesThermal Design Analysis and Test Validation of Turksat-3USat SatelliteputrastevanofyNo ratings yet

- Combustion and Flame: Kyung Ju Kim, Myung Hoon Cho, Soo Hyung KimDocument9 pagesCombustion and Flame: Kyung Ju Kim, Myung Hoon Cho, Soo Hyung KimRodriguez ArthursNo ratings yet

- National Cheng Kung University student examines causes and impacts of landslides in IndiaDocument17 pagesNational Cheng Kung University student examines causes and impacts of landslides in IndiaRodriguez ArthursNo ratings yet

- Mems Report JournalDocument4 pagesMems Report JournalRodriguez ArthursNo ratings yet

- Implementation of A Skating Motion On A Spider Robot: Bachelor ThesisDocument55 pagesImplementation of A Skating Motion On A Spider Robot: Bachelor ThesisRodriguez ArthursNo ratings yet

- Volume 3 Issue 9 Paper 1Document21 pagesVolume 3 Issue 9 Paper 1Rodriguez ArthursNo ratings yet

- Optimization CrankShaft MechanismDocument22 pagesOptimization CrankShaft MechanismLakshman ReddyNo ratings yet

- Automobile Crank ShaftDocument8 pagesAutomobile Crank ShaftRodriguez ArthursNo ratings yet

- SP19416圖式20161104Document3 pagesSP19416圖式20161104Rodriguez ArthursNo ratings yet

- Mos Fabrication Content BsDocument11 pagesMos Fabrication Content BsarumugamNo ratings yet

- Polyjet Materials Data SheetDocument2 pagesPolyjet Materials Data SheetRodriguez ArthursNo ratings yet

- Aiaa 2010 1018Document11 pagesAiaa 2010 1018Rodriguez ArthursNo ratings yet

- Solar Power Pesticides SprayerDocument4 pagesSolar Power Pesticides SprayerRodriguez Arthurs100% (1)

- A356.0 Alloy DetailDocument2 pagesA356.0 Alloy DetailAdrian LimantoNo ratings yet

- 3D Printing TechnologyDocument5 pages3D Printing Technologyvasu088No ratings yet

- Ijsetr Vol 3 Issue 5 1453 1457Document5 pagesIjsetr Vol 3 Issue 5 1453 1457Rodriguez ArthursNo ratings yet

- Nafems Conference BroucherDocument4 pagesNafems Conference BroucherRodriguez ArthursNo ratings yet

- Design Optimization TutorialDocument13 pagesDesign Optimization TutorialRodriguez ArthursNo ratings yet

- Access Global Online Research Ag ResourcesDocument2 pagesAccess Global Online Research Ag ResourcesRodriguez ArthursNo ratings yet

- FIBER OPTICS Workshop BrouchureDocument15 pagesFIBER OPTICS Workshop BrouchureRodriguez ArthursNo ratings yet

- LS-PrePost Forming Aug1stDocument240 pagesLS-PrePost Forming Aug1stRodriguez ArthursNo ratings yet

- Skill Development Program for Employability EnhancementDocument15 pagesSkill Development Program for Employability EnhancementRodriguez ArthursNo ratings yet

- V Tail MAV ReportDocument46 pagesV Tail MAV ReportRodriguez ArthursNo ratings yet

- UAV Design TrainingDocument17 pagesUAV Design TrainingPritam AshutoshNo ratings yet

- CAEA v145 Update ACTDocument22 pagesCAEA v145 Update ACTRodriguez ArthursNo ratings yet

- NAL Workshop April8 VeenaDocument37 pagesNAL Workshop April8 VeenaRodriguez ArthursNo ratings yet

- ABAQUS Tutorial Schedule and Access InfoDocument2 pagesABAQUS Tutorial Schedule and Access InfoAmit RajputNo ratings yet

- Trends in Aerospace EngineeringDocument21 pagesTrends in Aerospace EngineeringRodriguez ArthursNo ratings yet

- XFLR5 Tut v1Document40 pagesXFLR5 Tut v1spandaglis0% (1)

- Ramesh S TalkDocument21 pagesRamesh S TalkRodriguez ArthursNo ratings yet

- Iowa State Univeristy: CansatDocument37 pagesIowa State Univeristy: CansatisucansatNo ratings yet

- Cansat2018 5278 PDRDocument146 pagesCansat2018 5278 PDRiguanajazzNo ratings yet

- Cansat Proposal ReportDocument2 pagesCansat Proposal ReportJalla123No ratings yet

- Cansat2022 1078 PDR v01Document179 pagesCansat2022 1078 PDR v01Francisco SanchezNo ratings yet

- Cansat - Malaysian Plan: Malaysia National Space Agency (Angkasa)Document24 pagesCansat - Malaysian Plan: Malaysia National Space Agency (Angkasa)jjaavvmmNo ratings yet