Professional Documents

Culture Documents

IV.9. Emergency Generator (Less Than 600 KW) - Section 472 - 2014

Uploaded by

Ed CalheOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IV.9. Emergency Generator (Less Than 600 KW) - Section 472 - 2014

Uploaded by

Ed CalheCopyright:

Available Formats

Water & Sewer Standards

EMERGENCY GENERATOR

(LESS THAN 600 KW) SECTION 472

I. GENERAL

I.1. SCOPE OF WORK:

The Contractor shall furnish, install and test a complete, self contained, automatic standby

emergency generator system as specified herein. The self-contained emergency electric

system shall consist of an electric generating unit, which upon interruption of normal power

from transformer, will start automatically and, by an automatic transfer switch, will disconnect

load from normal supply and connect load to emergency generator. Diesel engine driven

electric generator set shall be of the latest commercial type and design with all necessary

switchgear, and controls. Contractor shall furnish and install fuel tank, stainless steel

generator set enclosure, generator foundation and fuel tank foundation and all accessories

necessary for a complete and operable installation. All materials shall be new unless

specifically called for otherwise. Diesel generators supplied under these specifications shall

be provided by Ring Power Corporation and in accordance with the existing contract

purchase agreement (CPA) #11012 dated September 13, 1999 or latest version, between the

JEA and Ring Power. The contractor shall contact David Norse at JEA (904) 665-5501 to

assist with the coordination efforts with the current JEA contract. The Ring Power contract

administrator is Keith R. Moore, Power Generation Sales Manager, (904) 737-7730. Under

this purchase order number, JEA and the contractor shall be entitled to the special rates and

purchase price of equipment and services. The contractor (not JEA) shall pay all cost

associated with the installation of the emergency generator system.

I.2. SHOP DRAWING SUBMITTALS AND ADDITIONAL SUBMITTALS:

The Contractor shall be required to submit a complete shop drawing submittal. Sizing

calculations, signed and sealed by a Florida Registered Professional Electrical Engineer,

shall be submitted with the shop drawings.

I.2.1. Five copies, plus the number of copies the Contractor wishes returned, shall be

submitted to the Engineer for approval.

I.2.2. List of 5 or more operating installations using major components of the same or

similar type equipment furnished for this project.

I.2.3. Name of nearest location of permanent parts supply from which parts may be

obtained in sufficient quantity on a 24 hour basis.

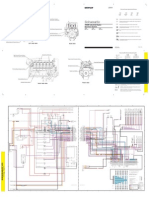

I.2.4. Shop drawings of the generator set, complete power and control wiring

diagrams, foundation requirements, auxiliary equipment required including tanks,

switches, controls, weatherproof enclosure, automatic transfer switch, generator

breaker, wiring and accessories shall be submitted.

I.2.5. Manufacturer's product data describing unit, auxiliary equipment required,

including switches, engine, pump and motor. Include the following:

I.2.5.1. Specifications for fuel

I.2.5.2. Make of engine

I.2.5.3. Number of cylinders

I.2.5.4. Compression ratio

I.2.5.5. Bore, inches

Revised: January 1, 2014 Revised By: KGL Approved By: CFS

EMERGENCY GENERATOR (LESS THAN 600 KW) SECTION 472

IV. 9. - Page 1 of 12

Water & Sewer Standards

I.2.5.6. Stroke, inches

I.2.5.7. Piston displacement, cubic inches

I.2.5.8. Piston speed at rated RPM, feet per minute

I.2.5.9. Make and type of generator

I.2.5.10. Generator electrical rating, KVA

I.2.5.11. Number and type of generator bearings

I.2.5.12. Exciter type and drive

I.2.6. One complete set of operating and maintenance manuals shall be supplied for

the electric set and for auxiliary equipment.

I.2.7. Manufacturer's warranty

I.3. RATING:

Electric set shall be capable of producing rated output for continuous duty at rated generator

RPM when equipped with necessary operating accessories such as air cleaners, lubricating

oil pump, fuel transfer pump, radiator fan, jacket water pump, governor, alternating current

generator and exciter. Unit shall be Delta connected 1800 RPM, 3 phase, 4-wire, 60 cycle,

480 volt standby duty for 480 volt service, or 240 volt standby duty for 240 volt service. Unit

shall be sized to operate two pumps simultaneously, started in sequence unless specified

otherwise. Unit shall be rated such that each pump, upon start-up, will not experience

greater than 20% instantaneous voltage dip, also considering auxiliary power requirements.

Responsibility for sizing generator shall lie with the generator supplier.

I.4. QUALITY ASSURANCE:

I.4.1. Unit shall be the product of a firm regularly engaged in the manufacture of

engines, and a standard model in regular production at the manufacturer's place

of business. Both engine and generator shall be warranted by the same

manufacturer to establish single source responsibility.

I.4.2. Only current units which can be properly maintained and serviced without the

necessity of JEA carrying extensive parts stocks, or being subject to long periods

of interrupted service due to unavailable parts will be considered. Engine-

generator supplier shall maintain a local parts and service facility. Service facility

shall have no less than 60 percent of all engine replacement parts in his stock at

all times.

I.5. WARRANTY AND SERVICE CONTRACT:

I.5.1. Equipment furnished under this section shall be guaranteed against defective

parts and workmanship under terms of the manufacturer's and dealer's standard

warranty for 1 year from date of acceptance of the system and shall include labor

and travel time for necessary repairs at the job site. For JEA funded projects, an

additional 4 years of extended service coverage shall be provided for a total of 5

years of warrantable coverage. Years 2-4 may have an applicable deductible

per failure. Running hours shall not be a limiting factor for the system warranty.

I.5.2. The manufacturer shall provide the services of a factory-trained service

representative to verify the correctness of the Contractor's completed installation;

to check all electronic circuitry and mechanical components to assure their

proper function; to make all necessary measurements in and around the engine

and generator. A minimum of 2 days startup services shall be provided. The

manufacturer shall provide through the Contractor to JEA a written certification

Revised: January 1, 2014 Revised By: KGL Approved By: CFS

EMERGENCY GENERATOR (LESS THAN 600 KW) SECTION 472

IV. 9. - Page 2 of 12

Water & Sewer Standards

that the installation is complete, correct and properly calibrated; by written

notation on the certification the Contractor shall endorse its accuracy.

I.6. PERMITTING OF ABOVEGROUND FUEL STORAGE TANK (LARGER THAN 550

GALLONS):

I.6.1. Prior to construction of an aboveground fuel storage tank, the contractor shall

obtain a copy of the approved construction permit by local regulatory agencies

for the installation of the fuel tank. The contractor shall coordinate with David

Norse (904) 665-5501 of JEA to assist with this effort and DEP notifications in

accordance with state of Florida Guidelines.

II. DIESEL ENGINE

II.1. The Engine generator set shall be as manufactured by Caterpillar, and provided under the

JEA/Ring Power contract specifications.

II.2. Diesel engine shall be vertical or "V" multi-cylinder, full diesel, mechanical injection, heavy

duty type, arranged for direct connection to an alternating current generator, and shall be the

product of a manufacturer regularly engaged in the building of full diesel engines. Engine

shall be a current model which has been in regular production for at least three years.

Engine shall develop sufficient brake horsepower, net at rated RPM, corrected to sea level

barometric pressure (29.92 in. HG) and 110 degrees F, to operate generator continuously at

its rated output with all losses included without undue heating, vibration or wear. Diesel

engine shall be water cooled four cycle compression ignition diesel. The engine exhaust

manifold shall have an expanded metal guard spread sufficiently away from hot parts.

Engine shall meet specifications when operating on No. 2 domestic burner oil.

II.3. Engine shall be designed for automatic-electric starting and shall have battery charger 120 V,

single phase, 10 AMP. It shall be furnished and installed in the engine-generator enclosure.

A wet cell storage battery of not less than 24 volts and of 135 AH capacity to operate engine

starting equipment. Batteries shall be lead acid type complete with cables and rack. Battery

shall be rated in accordance with requirements of engine manufacturer. Batteries shall be

located for easy removal and servicing.

II.4. BHP rating, overall generator efficiency, required auxiliaries, guarantee of fuel consumption,

governor performance and torsional vibration shall be in accordance with manufacturer's

standard published curves and data. Special ratings for a particular application are not

acceptable.

II.5. Engine shall be equipped with an electronic governor capable of 25 percent speed regulation

from no load to full rated load.

II.6. Engine shall be equipped with a pressure lubrication system supplying oil to all surfaces

requiring lubrication. Circulation shall be by a positive displacement pump. Lubrication

system shall include a full flow strainer, oil filter, and an oil cooler of sufficient capacity to

properly cool all lubrication oil circulated.

II.7. Engine shall have an individual mechanical injection pump and injection valve for each

cylinder, any one of which may be removed and replaced from parts stock. Injection pumps

and injection valves shall not require adjustment in service. Fuel injection pumps shall be

positive action, constant-stroke pumps, actuated by a cam driven by gears from the engine

crankshaft.

Revised: January 1, 2014 Revised By: KGL Approved By: CFS

EMERGENCY GENERATOR (LESS THAN 600 KW) SECTION 472

IV. 9. - Page 3 of 12

Water & Sewer Standards

II.7.1. Fuel lines between injection pump and valves shall be heavy seamless tubing;

and, to eliminate irregularity of fuel injections, shall be of the same length for all

cylinders.

II.7.2. Fuel system shall be equipped with replaceable fuel filter elements which may be

easily removed without breaking any fuel line connections or disturbing the fuel

pumps or any other part of the engine. Provide easily serviceable fuel/water

separator/filter ahead of other fuel filters.

II.7.3. All fuel filters shall be conveniently located in one accessible housing, ahead of

injection pumps so that fuel will have been thoroughly filtered before it reaches

the pumps. No screens or filters requiring cleaning or replacement shall be used

in injection pump or injection valve assemblies.

II.7.4. Engine shall be equipped with a built-in gear-type engine-driven fuel transfer

pump, capable of lifting fuel against a head of twelve feet, for supplying fuel

through filters to injection pump at constant pressure.

II.8. Engine shall be provided with suitable safety controls to automatically stop the unit when low

oil pressure, water temperature or engine speed exceeds safe limits. Pilot lights shall be

provided to visually indicate the cause of engine shut down. Pilot lights shall operate off

battery circuit and shall be on engine generator control panel. Provide contacts for remote

engine failure annunciation.

II.9. Engine shall be equipped with radiator and blower fan of sufficient capacity for cooling engine

when diesel electric set is delivering full rated load in an ambient temperature of 125 degrees

F. Air flow restriction from radiator shall not exceed 0.5 inches H20. Engine shall have a

thermostat integral with jacket water circuit to maintain water at proper operating

temperature. Engine shall have a belt driven centrifugal type water circulating pump for

circulating water through cooling system.

II.10. Provide a critical grade type exhaust silencer, manufactured of 304 stainless steel as

specified in this specification.

II.11. Engine shall be provided with an antifreeze solution of 50 percent ethylene glycol, and

suitable unit mounted, thermal circulation type water heater incorporating a thermostatic

switch to maintain engine jacket water at 90 degrees F. in an ambient temperature of 30

degrees F. Heater shall be 1000 watts minimum, single phase, 60 Hertz, and applicable

voltage.

II.12. Furnish a set of spare parts and tools regularly supplied with engine. Include all tools of a

special nature required to properly service engine.

II.13. Provide one or more engine mounted dry type air cleaners of sufficient capacity to protect

working parts of the engine from dust and grit.

III. GENERATOR

III.1. Generator shall be engine-driven, single bearing, continuous duty, salient pole, synchronous

type with amortisseur windings. It shall be of the drip-proof type, entirely self-contained with

only line leads brought out for loading connections. Generator insulation used shall be

NEMA Class F, such that generator life will match that of the prime mover. Generator shall

be designed so all components are accessible with a minimum amount of labor. Both engine

and generator shall be warranted and serviced by same manufacturer. Generator set shall

be Caterpillar.

Revised: January 1, 2014 Revised By: KGL Approved By: CFS

EMERGENCY GENERATOR (LESS THAN 600 KW) SECTION 472

IV. 9. - Page 4 of 12

Water & Sewer Standards

III.2. Generator shall be brushless type, rated at .8PF, three phase, 60 Hertz, 480 volt, or 240 Volt

(if required), delta connected, 4 wire, 1800 RPM.

III.3. Voltage regulator shall be modular construction, replaceable as an assembly and shall

provide regulation for single unit operation within plus or minus 2 percent from rated voltage

at any steady state load between "no load" and "full load."

III.4. Generator shall have static excitation systems which shall incorporate silicon control rectifiers

to provide alternator field excitation. Static shall have capacity to provide 150 percent of

required excitation at rated load and rated voltage. Static excitation system shall incorporate

circuitry to permit voltage build-up from residual magnetism. Field flashing from a separate

source is not acceptable.

III.5. Voltage level, and voltage gain control, shall be provided and easily accessible for normal

operating adjustments. Voltage level control shall have a minimum range of plus or minus 5

percent from rated voltage. Provide voltage adjustment instruction and generator schematic

wiring diagram permanently attached on inside of exciter assembly.

III.6. Generator drive shall be free from critical torsional vibration within the operating speed range.

III.7. Certain applications may require the use of a permanent magnet generator. The generator

supplier, Ring Power, shall be responsible for recommending this type of alternator where

circumstances warrant its use. A separate line item price shall be provided with the original

quotation.

IV. GENERATOR STARTING AND CONTROL PANEL

IV.1. Furnish and install automatic generator starting electronic modular control panel in a metal

enclosure. Starting section shall automatically start engine upon failure of normal source

through starting contacts in automatic transfer switch. Transfer unit shall serve to operate as

follows: Failure of normal supply shall cause its voltage sensitive relay to close a normally

open contact initiating starting cycle of diesel engine. Closing of this contact shall cause

power to be fed to a throttle solenoid, which picks up, opening fuel rack and energizing

starting motor through one of its contacts. As generator voltage approaches normal, relay

coil in the cranking panel shall pick up, opening starting circuit through one of its contacts,

thereby disconnecting starting motor from the rest of the circuit. Lack of oil pressure or over-

temperature of cooling system will cause second relay in cranking panel to be energized, as

normal alternator voltage is approached, causing starting cycle to be terminated immediately.

Should engine fail to start for any reason, a time delay relay in cranking panel limits its

cranking period to 30 seconds. A push-button switch mounted on cranking panel shall allow

engine to be further cranked at the operator's discretion. Resumption of normal power shall

open engine contacts in transfer switch and shall cause engine to shut down after 5 minute

delay.

IV.2. Generator control section shall be 600 volt, with amperage sized to match pump station

service and shall include a 3 pole generator circuit breaker with shunt trip. Shunt trip shall be

actuated by any of the engine safety devices.

IV.3. ENGINE CONTROLS:

IV.3.1. Solid-state, engine control module shall provide the following functions:

IV.3.1.1. Battery DC volts

IV.3.1.2. Coolant temperature

IV.3.1.3. Lube oil pressure

Revised: January 1, 2014 Revised By: KGL Approved By: CFS

EMERGENCY GENERATOR (LESS THAN 600 KW) SECTION 472

IV. 9. - Page 5 of 12

Water & Sewer Standards

IV.3.1.4. Generator set operating hours

IV.3.1.5. Loss of magnetic speed pickup signal

IV.3.2. Automatic/Manual Start-Stop with the following safety shutdowns:

IV.3.2.1. Over-speed protection and indicator

IV.3.2.2. Low lube oil pressure protection and indicator

IV.3.2.3. High coolant temperature protection and indicator

IV.3.2.4. Over-crank protection and indicator

IV.3.2.5. Low coolant level protection

IV.3.3. Engine Control Switch (Three-Position: Stop - Manual - Auto)

IV.3.4. Indicator/ Display Test Switch

IV.3.5. Voltage Adjust Potentiometer (plus 10 percent - 25 percent Range)

IV.4. AC METERING:

IV.4.1. AC Volt Meter

IV.4.2. AC Amp Meter

IV.4.3. Frequency Meter:

NOTE: Ammeter/Voltmeter Phase Selector Switch Four Position (Phase 1,2,3, and Off)

V. THREE CURRENT TRANSFORMERS SIZED TO MATCH THE GENERATOR OUTPUT

CURRENT AUTOMATIC TRANSFER SWITCH

V.1. Provide automatic transfer switch, 3-pole, double throw type, rated 480 volts A.C. amperage

(or 240 Volts A.C. amps if indicated) to match service size as indicated on drawings. Switch

shall be electrically operated, mechanically held type switch. Switch shall be equipped with

full relay protection and shall transfer load to emergency source when one or more of the 3-

phase voltage falls below 85 percent. It shall automatically return load to normal when all

normal line voltages have been restored to 90 percent or more.

V.2. Auto transfer switch shall be equipped with an engine starting contact and with an

emergency lockout relay to prevent switch from closing load on emergency generator until

proper voltage and frequency have been reached. Switch shall be equipped with one time

delay, adjustable from 1/6 to 180 seconds in the engine starting contact circuit to prevent

contact from closing until a predetermined delay has occurred. Switch shall be equipped with

another time delay relay adjustable from 1/6 to 180 seconds which will, after a predetermined

time, allow the emergency generator circuit to remain closed after normal power has been

restored to at least 90 percent voltage. Switch shall be equipped with a time delay, to run

engine for 5 minutes at no load on retransfer to normal power source.

V.3. Provide two additional auxiliary contact switches, 1 normally open and 1 normally closed.

Transfer switch shall be Zenith Model ZTS-D/L, ASCO Series 7000 or Russelectric RMTD

type delayed transition transfer switch with microprocessor controls or JEA pre-approved

equal. Transfer switch shall be enclosed in a weatherproof NEMA 3R stainless steel

enclosure. Auto transfer switch shall be located 3 ft. to 5 ft. from generator pad on the side

opposite from radiator side. Auto transfer switch shall be neatly lined up with utility

disconnects, meter pad, and C.T. if applicable.

Revised: January 1, 2014 Revised By: KGL Approved By: CFS

EMERGENCY GENERATOR (LESS THAN 600 KW) SECTION 472

IV. 9. - Page 6 of 12

Water & Sewer Standards

VI. WEATHERPROOF ENCLOSURE, NON-WALK-IN TYPE (25-200 KW), WALK IN TYPE

250 KW AND ABOVE

VI.1. The complete engine-generator set shall be enclosed in a modular, walk-in type, NEMA-4

stainless steel (304) weatherproof enclosure. The enclosure shall provide 6 ft. minimum

head clearance and 24 inches minimum walk around clearance on sides not including

radiator. The enclosure shall be constructed of removable side panels and end panels. The

top, side and end panels shall be made from 12 gauge stainless steel. All fasteners and

hardware used in construction of the enclosure shall be type 316 stainless steel. The unit

shall have continuous hinged side doors each side and continuous hinged doors at control

end, equipped with key locks for ease of engine maintenance, hold open devices and a three

point latch system. Doors shall be pad lockable and a minimum of 36 inches. There shall be

a stainless steel expanded metal grating or a punched louvered radiator core guard installed

- flush with the enclosure panels in front for the radiator grill, and fixed, punched louvered air

intake ports on the enclosure sides and rear for proper air circulation within the housing.

Provide lifting eyes and spreader bar reinforcement for crane unloading. Provide 3/16 inch

thick "non skid" deck underneath housing. The enclosure shall be constructed as a sound

attenuated style with a maximum dba rating of 86 dba at 15 feet.

VI.2. Battery charger shall be mounted at rear of engine-generator set. Control shall incorporate

equipment as previously specified. Control wire connection between starting and safety

circuits shall be pre-connected before arriving at job site. Minimum of 2 industrial fluorescent

fixtures, light switch, pre-wired distribution circuit, breaker panel, and duplex receptacles shall

be conveniently provided in the enclosure. The light switch and receptacles shall be

provided near generator control panel. Provisions shall be made for mounting batteries and

rack inside the enclosure. The generator breaker, generator control panel, distribution

(lights, jacket water heater, etc.) breaker panel, batteries and accessories shall be enclosed

in the enclosure. Generator Supplier shall provide and install a 240/120V transformer

adequately sized to handle all enclosure loads if service is 480 Volt. Transformer shall feed

off of load side of auto transformer switch.

VI.3. The engine oil and radiator drain lines shall be brought to the outside of the enclosure. A

globe type shut off valve shall be installed in each drain line inside the enclosure for security.

VI.4. Enclosure shall be Phoenix Products, or JEA pre-approved equal.

VII. EXHAUST AND MUFFLER

A critical grade type 304 stainless, exhaust silencer, Maxim or JEA pre-approved equal, shall be

provided and shall be mounted on top of the unit. It shall be secured in position at no less than 4

points. The silencer shall be supported by an angle iron cradle welded to the silencer and bolted to

the angle iron roof support members mounted inside the roof of the enclosure. The silencer shall be

of the side inlet type. The intake of the silencer shall connect to the flexible exhaust connection by

stainless steel pipe. Size as required by engine manufacturer. A flexible stainless steel exhaust

adapter, 18 inch minimum length, shall be furnished for mounting between the engine and silencer.

The flexible exhaust connection as specified shall mount directly on exhaust manifold and shall be

mounted so that no weight is exerted on the manifold at any time. Exhaust silencer enclosure shall

be 304 Stainless Steel with all stainless steel hardware and fasteners.

Revised: January 1, 2014 Revised By: KGL Approved By: CFS

EMERGENCY GENERATOR (LESS THAN 600 KW) SECTION 472

IV. 9. - Page 7 of 12

Water & Sewer Standards

VIII. FUEL SYSTEM

VIII.1. GENERAL:

Each engine-generator unit shall be furnished with a complete fuel system, including engine-

driven fuel pump, fuel filter/separator, engine supply and return line, all stainless steel flexible

connections, manual fire-safe shutoff valves, and solenoid valve. All items shall be suitable

for the specified fuel. The engine-driven fuel pump shall transfer the fuel from the fuel

storage tank to the engine-generator. The fuel system shall be furnished with any equipment

required for the engine to supply or return any unused portion of fuel back to the fuel storage

tank with any level in the tank. Manual fire-safe shutoff valves and a filter/separator shall be

provided on the fuel supply line. The shutoff valve and the filter/separator shall be located

upstream from the flexible connection. All fuel piping shall be schedule 40, 316 stainless

steel (screwed or welded).

VIII.2. FUEL TANK CAPACITY

VIII.2.1. Engine-generators with nominal capacity of 150 kW and less shall be furnished

with a complete fuel system including double wall sub-base type fuel storage

tank unless stated otherwise. The tank shall be UL listed, vented, and shall

normally be used to store the specified petroleum product at atmospheric

pressure. The sub-base fuel storage tank shall have a minimum capacity to

provide 75 hours continuous operation of the engine-generator at 100 percent

capacity, up to 500 gallons maximum capacity. The sub-base tank shall be of

welded steel construction throughout and shall be constructed to permit access

to the electrical stub up area.

VIII.2.2. Engine-generator greater than 150 kW capacity shall be furnished with an above

ground fuel storage tank with a minimum storage capacity to provide 60 hours

continuous operation of the engine-generator at 100 percent load.

IX. ABOVEGROUND FUEL STORAGE TANK

IX.1. GENERAL:

The insulated secondary containment aboveground storage tank system for flammable and

combustible liquids shall be vehicle impact protected and projectile resistant. Tank shall be a

steel tank housed in a double containment concrete vault/tank. The tank shall be

manufactured by ConVault, Inc., Phoenix Products Envirovault or JEA pre-approved

equal.

IX.2. UL/ULC LISTING:

The tank shall be tested to and listed (and carry UL/ULC labels) for the following:

IX.2.1. UL 142, aboveground tanks for flammable and combustible liquids.

IX.2.2. UL 2085, two hour furnace fire test and two hour simulated pool fire test for

insulated tank.

IX.2.3. UL 2085, insulated and protected secondary containment aboveground tanks

for flammable and combustible liquids.

IX.2.4. UL 2085 and UFC SECTION (79-7) APPENDIX #A-II-F-1, ballistic and vehicle

impact test for protected tank.

IX.2.5. UL 2085 Non-Metallic Secondary Containment and Venting by Form of

Construction.

Revised: January 1, 2014 Revised By: KGL Approved By: CFS

EMERGENCY GENERATOR (LESS THAN 600 KW) SECTION 472

IV. 9. - Page 8 of 12

Water & Sewer Standards

IX.2.6. UL CAN/ORD C 142.16, protected aboveground tank assemblies for

flammable and combustible liquids.

IX.2.7. UL CAN/ORD C 142.5, concrete encased aboveground tank assemblies for

flammable and combustible liquids.

IX.2.8. UL CAN/ORD 142.16, the furnace burn requirements for two hour fire rating.

IX.2.9. UL CAN/ORD 142.5, the open (pool) fire testing for two hour flammable liquid

fire test.

IX.2.10. UL CAN/ORD 142.23, aboveground tanks for waste oil.

IX.3. REQUIREMENTS:

IX.3.1. Steel Tank Construction:

IX.3.1.1. Steel tank shall be made of 3/16 inch thick steel. The steel tank

shall hold the liquid fuel. The tank shall be made in accordance with

UL Standard 142 and ULC Standard S601 covering all aspects of

tank fabrication including material specification, fabrication, welding

and testing. The steel tanks exterior shall be coated with primer

paint for protection against corrosion.

IX.3.1.2. At the fabrication shop, the tank shall undergo a 24 hour pressure

test at 5 psig.

IX.3.2. Secondary Containment:

IX.3.2.1. The steel tank shall be wrapped with a minimum of inch thick

Styrofoam (foam) insulation and an impervious barrier of 30 MIL

high density polyethylene membrane (poly). The 30 MIL poly shall

provide containment for a fuel leak through the steel tank. A leak

detector pipe terminating in the secondary containment shall provide

positive-proof that the tank is not leaking.

IX.3.2.2. The 30 MIL poly, shall shield and protect the steel tank exterior from

coming in direct contact with the concrete and thus minimize the

potential of tank external corrosion.

IX.3.3. Concrete Vault:

The tank and secondary containment shall then be encased in a 6 inch thick

reinforced concrete vault. The 6 inches of concrete shall be poured on all sides,

bottom and top of the tank in one step and be monolithic. This process assures

that there are no joints and no heat sinks in the concrete to carry heat from a fire

into the primary containment.

IX.3.4. Coating and Finishing:

The concrete exterior of the tank shall be vacuum coated using a two-part water

based epoxy paint to protect the tank from inclement weather conditions. The

entire pipe fittings and nipples on the tank shall be powder-coated to protect

them from corrosion.

IX.3.5. Overfill Protection:

The tank shall be provided with the following methods to protect against overfill:

(a) direct reading level gauge at the tank which is visible from fill pipe location;

(b) valve located within fill pipe access to close automatically at a specified fill

level; and, (c) audible high level alarm activated by a float switch at a specified fill

level.

Revised: January 1, 2014 Revised By: KGL Approved By: CFS

EMERGENCY GENERATOR (LESS THAN 600 KW) SECTION 472

IV. 9. - Page 9 of 12

Water & Sewer Standards

IX.3.6. Venting:

The tank system shall be furnished with a 2 inch normal vent and an emergency

pressure relief system. The standard emergency relief system furnished with the

tank shall open if the tank pressure exceeds psi. The tank system shall

conform to code requirements and UL/ULC Standards for venting. All vents and

fittings utilized on the fuel tank shall be constructed of stainless steel.

IX.3.7. Support Legs:

Vault shall have concrete support legs of unitized monolithic construction that

provide visual inspection capability.

IX.3.8. Thermal and Corrosion Protection:

The tank construction shall provide thermal insulation to protect against

temperature extremes and corrosion by separating the steel tank from the

concrete. No part of the steel tank shall come in direct contact with concrete or

any other corrosive material.

IX.3.9. Spill Containment:

The tank system shall include a 5 to 15 gallon, stainless steel spill containment

surrounding the fill pipe. The spill container shall be equipped with a normally

closed, hand-operated valve that can be actuated to drain the spilled fuel liquids

into the steel tank.

IX.3.10. Bullet Resistance:

The tank shall withstand bullet resistance tests in compliance with UFC Section

(79-7), Appendix #A-II-F-1.

IX.3.11. Uplift Restraints:

The tank shall be supplied with flood resistant tie-down brackets/hurricane hold-

down restraints.

IX.3.12. Fire Extinguisher and Clean-up Kit:

Portable fire extinguishers must be provided for the suppression of fires in

accordance with NFPA 10 and UFC for high hazard area. Fire extinguisher and

clean-up kit shall be sized and provided by the tank manufacturer. Fire

extinguisher shall be mounted on the exterior of the generator enclosure with 316

stainless steel bracket and fasteners. Clean-up kit shall be similarly mounted

inside the generator enclosure.

IX.3.13. Fuel Piping:

All fuel piping shall be schedule 40, 316 stainless steel with welded socket joints

and brass seat unions at each end connecting the fuel tank to the generator.

There shall not be any pipe bends in the fuel lines. A 316 stainless steel ball

valve shall be installed on supply line at the tank. All tanks 550 gallons or more

shall have installed downstream from the ball valve an adjustable anti-siphon

valve.

IX.3.14. Fuel Tank Monitoring:

All fuel tanks shall have electronic monitoring system that visually displays fuel

level and alarms. Unit must have the capability to be interfaced with the SCAD

system as required.

Revised: January 1, 2014 Revised By: KGL Approved By: CFS

EMERGENCY GENERATOR (LESS THAN 600 KW) SECTION 472

IV. 9. - Page 10 of 12

Water & Sewer Standards

IX.4. INSTALLATION:

IX.4.1. Tank shall be installed as per manufacturers requirements and as per the

drawings. Tank shall be installed by qualified personnel who have been

approved by the manufacturer and who have knowledge of, and possess the

skills and equipment necessary, to install this type of aboveground storage tank

properly and safely. Do not handle or move the tank unless it is empty. Under

no circumstances should a tank containing petroleum product be moved. Do not

drop or drag the tank. After install of tank a two part epoxy touch up paint shall

be applied to all exposed metal. All mounting hardware shall be 316 Stainless

Steel.

IX.4.2. Installation, operation and maintenance of the tank must be carried out in

accordance with the applicable codes and regulations. These aboveground

storage tanks are intended for installation in accordance with NFPA 30, 30A, 31

and UFC Appendix II-F.

IX.5. FOUNDATION:

IX.5.1. The foundation for the tank must be designed (and approved by tank

manufacturer) to support the tank plus the weight of the maximum amount of

product the tank will be storing. The foundation design must also include

provision for draining surface water away from the tank to minimize the risk of

fuel accumulation under the tank from the overfill or spills.

IX.5.2. The tank foundations sub-grade shall be over undisturbed earth or compacted

fill, free of organic material. Provide a minimum 6 inch thick granular sub-grade,

compacted and graded to a level uniform sub-surface prior to the cast slab

placement or pouring of the cast-in-place slab. Surface under the foundation

shall be flat within 1/16 inch per foot. An alternative to pouring the slab in the

field is to purchase a pre-cast slab from the manufacturer.

IX.5.3. The legs of all tanks shall be grouted to provide a uniform load distribution on

legs and foundations.

IX.6. ELECTRICAL:

IX.6.1. Electrical service and fuel piping to the pumps unit shall be installed in

accordance with the requirements of NEC and NFPA and local code

requirements. Fuel piping shall be schedule 10 stainless steel.

IX.6.2. All electrical devices used with or located within 20 feet of the fuel tank shall

conform to NFPA 70 Hazardous Locations. All electric conduits and wiring

connected to the tank shall be explosion proof and in strict accordance with NEC

Class-1, Division 1 or local standards, whichever is stricter.

IX.6.3. An emergency shut-off switch shall be mounted in a location visible from the

dispenser. The switch shall be mounted on a post in a 304 stainless steel NEMA

3R box. The per code switch must be marked as an emergency shut-off switch

and shall be located as indicated on the drawings.

IX.6.4. Electrical grounding is required for flammable liquid fuel tanks. Tanks shall be

provided with two grounding lugs welded to the nipples on tank top.

IX.7. TESTING:

The tank shall be shipped pre-assembled and shop tested. Upon completion of installation,

contractor shall pressure test the primary steel tank to 3 psig. This test shall be performed

Revised: January 1, 2014 Revised By: KGL Approved By: CFS

EMERGENCY GENERATOR (LESS THAN 600 KW) SECTION 472

IV. 9. - Page 11 of 12

Water & Sewer Standards

under the supervision and guidance of the manufacturers representative and in the presence

of the JEAs representative.

IX.8. WARRANTY:

Tank manufacturer shall provide its standard 30 year warranty.

X. TESTS

X.1. Prior to acceptance of the installation, the emergency generator shall be tested at the job site

to show it is free of any defects and will start automatically and be subjected to full load test

at rated capacity at .8 power factor while fully enclosed through the use of dry type load

banks utilized for this purpose.

X.2. The load bank will be capable of definite and precise incremental loading and shall not be

dependent on the generator control instrumentation to read amperage and voltage of each

phase. Rather, the test instrumentation will serve as a check of the generator set meters.

X.3. Salt water brine tanks or those load banks requiring water as a source for cooling are not

acceptable for this purpose and are disallowed and will not be utilized for this test.

X.4. Load bank testing shall be done in the presence of JEA's representative. Testing shall be for

a period of 4 hours under full load and be capable of accepting full block load.

X.5. Prior to acceptance, any defects which become evident during this test shall be corrected at

no additional expense to JEA.

XI. START-UP

On completion of the installation, the initial start-up shall be performed by a factory trained

representative of the engine supplier. At the time of start-up, operating instructions and maintenance

procedures shall be thoroughly explained to the operating personnel. The contractor shall be

responsible for providing a full tank of fuel, at no additional cost to JEA.

XII. PROTECTION AND CLEANING

The Contractor shall provide suitable protection from moisture, dust and construction procedures as

directed by JEA. Maintain protection and generator until acceptance of equipment by JEA. All items

shall be cleaned, touched up as necessary and left in first-class condition.

Revised: January 1, 2014 Revised By: KGL Approved By: CFS

EMERGENCY GENERATOR (LESS THAN 600 KW) SECTION 472

IV. 9. - Page 12 of 12

You might also like

- WOMA Technical Data All Pumps en MedidasDocument11 pagesWOMA Technical Data All Pumps en MedidasEd CalheNo ratings yet

- Whitepaper Fuel SystemsDocument8 pagesWhitepaper Fuel SystemsQaiser Iqbal100% (4)

- 3500B Industrial Engine Electrical System: Left Side View Rear ViewDocument2 pages3500B Industrial Engine Electrical System: Left Side View Rear ViewEd Calhe0% (1)

- CompetitorsDocument4 pagesCompetitorsEd CalheNo ratings yet

- Volvo Prosis 2013 VMDocument2 pagesVolvo Prosis 2013 VMEd CalheNo ratings yet

- Calibrating Pressure GaugesDocument4 pagesCalibrating Pressure GaugesRonny AndalasNo ratings yet

- Brant AgitatorDocument68 pagesBrant AgitatorEd CalheNo ratings yet

- WarrenCATDynoReport2 3508Document11 pagesWarrenCATDynoReport2 3508Ed CalheNo ratings yet

- !rex Roller To Part Book TableDocument1 page!rex Roller To Part Book TableEd Calhe0% (1)

- IADC Dull Bit Grading Chart GuideDocument1 pageIADC Dull Bit Grading Chart GuideanarkasisNo ratings yet

- CompetitorsDocument4 pagesCompetitorsEd CalheNo ratings yet

- JCB JS EXCAVATOR HAMMERS GUIDEDocument1 pageJCB JS EXCAVATOR HAMMERS GUIDEEd CalheNo ratings yet

- 3406Document2 pages3406Ed CalheNo ratings yet

- Datasheet 2494Document1 pageDatasheet 2494Ed CalheNo ratings yet

- System Operation Mechanical Cat 3306 SN EpsDocument37 pagesSystem Operation Mechanical Cat 3306 SN EpsEd Calhe94% (18)

- Testing and Adjusting Cat 3412 SN 3fzDocument21 pagesTesting and Adjusting Cat 3412 SN 3fzEd Calhe100% (11)

- Melco Type F and FC Manual Valve PartsDocument4 pagesMelco Type F and FC Manual Valve PartsEd CalheNo ratings yet

- KG Act 3121269Document24 pagesKG Act 3121269Gustavo KemeñyNo ratings yet

- Grooy D9Awiñg'S: Cam LineDocument1 pageGrooy D9Awiñg'S: Cam LineEd CalheNo ratings yet

- 3 Way Direct Acting Solenoid Valve SV83Document4 pages3 Way Direct Acting Solenoid Valve SV83Ed CalheNo ratings yet

- Item No. Part No. Name of Part Material No. Reqd DescriptionDocument3 pagesItem No. Part No. Name of Part Material No. Reqd DescriptionEd CalheNo ratings yet

- Request for Equipment Repair PartsDocument1 pageRequest for Equipment Repair PartsEd Calhe100% (1)

- Power Swivel Torque ReactionDocument6 pagesPower Swivel Torque ReactionEd CalheNo ratings yet

- 261 267Document7 pages261 267Ed CalheNo ratings yet

- Item No. Part No. Name of Part Material No. Reqd DescriptionDocument3 pagesItem No. Part No. Name of Part Material No. Reqd DescriptionEd CalheNo ratings yet

- Oteco Shear Pin Relief Pressure SettingsDocument1 pageOteco Shear Pin Relief Pressure SettingsEd Calhe100% (1)

- Cylinder Injector Readings ReportDocument9 pagesCylinder Injector Readings ReportEd CalheNo ratings yet

- Strippers JU y JU HDocument5 pagesStrippers JU y JU HEd CalheNo ratings yet

- Top Driven Bowen BarcoDocument65 pagesTop Driven Bowen BarcoingcalderonNo ratings yet

- Westrom Cameron PartsDocument22 pagesWestrom Cameron PartsEd CalheNo ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5784)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- (Artigo) - Non-Oriented Electrical Steel Sheets - D. S. PETROVI PDFDocument9 pages(Artigo) - Non-Oriented Electrical Steel Sheets - D. S. PETROVI PDFcandongueiroNo ratings yet

- Tetrahydrofuran: THF (Disambiguation)Document12 pagesTetrahydrofuran: THF (Disambiguation)Faris NaufalNo ratings yet

- MOBICON Mobile Controller For GSM/GPRS Telemetry: 6ai 16-28di /12doDocument2 pagesMOBICON Mobile Controller For GSM/GPRS Telemetry: 6ai 16-28di /12doĐặng Trung AnhNo ratings yet

- English ThesisDocument112 pagesEnglish ThesisMaria Teresa OndoyNo ratings yet

- Week 2Document11 pagesWeek 2KISHANo ratings yet

- Swiftautoid SA T9680 Black Series 2D Imager Andriod Industrial TabletDocument2 pagesSwiftautoid SA T9680 Black Series 2D Imager Andriod Industrial TabletAirul MutaqinNo ratings yet

- Assignment 2Document6 pagesAssignment 2Umar ZahidNo ratings yet

- Is 15894-2018Document25 pagesIs 15894-2018surender kumarNo ratings yet

- Lec11 Amortized Loans Homework SolutionsDocument3 pagesLec11 Amortized Loans Homework SolutionsJerickson MauricioNo ratings yet

- 100 kWp Rooftop Solar PV Plant Project Report for Ghaziabad FactoryDocument25 pages100 kWp Rooftop Solar PV Plant Project Report for Ghaziabad FactoryvikashNo ratings yet

- Novel Proteinaceous Infectious Particles Cause ScrapieDocument10 pagesNovel Proteinaceous Infectious Particles Cause ScrapieMikey HaveyNo ratings yet

- Movie Recommender System: Shekhar 20BCS9911 Sanya Pawar 20BCS9879 Tushar Mishra 20BCS9962Document27 pagesMovie Recommender System: Shekhar 20BCS9911 Sanya Pawar 20BCS9879 Tushar Mishra 20BCS9962Amrit SinghNo ratings yet

- NX Advanced Simulation坐标系Document12 pagesNX Advanced Simulation坐标系jingyong123No ratings yet

- Lab Report Mass Spring System Omar Nizar2Document31 pagesLab Report Mass Spring System Omar Nizar2Omar MustafaNo ratings yet

- Manriding Tirfor O-MDocument16 pagesManriding Tirfor O-MPhillip FrencilloNo ratings yet

- Blockaura Token 3.1: Serial No. 2022100500012015 Presented by Fairyproof October 5, 2022Document17 pagesBlockaura Token 3.1: Serial No. 2022100500012015 Presented by Fairyproof October 5, 2022shrihari pravinNo ratings yet

- Puppo, F. (2012) - Dalla Vaghezza Del Linguaggio Alla Retorica Forense. Saggio Di Logica GiuridicaDocument3 pagesPuppo, F. (2012) - Dalla Vaghezza Del Linguaggio Alla Retorica Forense. Saggio Di Logica GiuridicaAldunIdhunNo ratings yet

- R Fulltext01Document136 pagesR Fulltext01vhj gbhjNo ratings yet

- Ska611hdgdc (210) (12BB) (2384×1303×35) (680 700)Document2 pagesSka611hdgdc (210) (12BB) (2384×1303×35) (680 700)Marko Maky ZivkovicNo ratings yet

- CBCS StatisticsDocument79 pagesCBCS StatisticsXING XINGNo ratings yet

- Adobe After Effects CS3 Keyboard Shortcuts GuideDocument14 pagesAdobe After Effects CS3 Keyboard Shortcuts GuideBrandon Sirota100% (1)

- Experiment List (FEE)Document5 pagesExperiment List (FEE)bpkeleNo ratings yet

- DMTH505 Measure Theorey and Functional Analysis PDFDocument349 pagesDMTH505 Measure Theorey and Functional Analysis PDFJahir Uddin LaskarNo ratings yet

- Image ReconstructionDocument28 pagesImage ReconstructionRahul PaulNo ratings yet

- SP 5500 V5.1 1.0Document17 pagesSP 5500 V5.1 1.0Rama Tenis CopecNo ratings yet

- 7-3 IP Board Part (SMPS Part) : 7 Block DiagramsDocument8 pages7-3 IP Board Part (SMPS Part) : 7 Block DiagramsSonu KumarNo ratings yet

- 978402applied Math Test Paper - Xi Set 2 - Sem 2Document4 pages978402applied Math Test Paper - Xi Set 2 - Sem 2MehulNo ratings yet

- The Market and Budget ConstraintsDocument8 pagesThe Market and Budget ConstraintsSnehaNo ratings yet

- Tunnel NoiseDocument11 pagesTunnel Noisesylvestrew100% (1)