Professional Documents

Culture Documents

Durakol G HM

Uploaded by

pbodoo0 ratings0% found this document useful (0 votes)

311 views3 pageswater proof

Copyright

© © All Rights Reserved

Available Formats

PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentwater proof

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

311 views3 pagesDurakol G HM

Uploaded by

pbodoowater proof

Copyright:

© All Rights Reserved

Available Formats

Download as PDF, TXT or read online from Scribd

You are on page 1of 3

DATA SHEET 11/7/07 10:52 AM Page 1

a.b.e. is an ISO 9001 : 2000 Registered Company.

a.b.e. Construction Chemicals Limited P.O. Box 23053, Isipingo, 4110 7 Wilcox Road, Isipingo, 4133 Tel. (031) 913 5400

TECHNI CAL DATA SHEET

Elastomeric joint sealant SABS 110:1973

DESCRIPTION

durakol G LM is a gun grade two-

component manganese cured medium

modulus polysulphide sealant

complying to SABS 110:1973.

USES

durakol G HM is a sealant used for

sealing expansion joints, stress relief

joints and movement joints in building

and other civil engineering structures,

These include superstructures,

reservoirs and potable water retaining

structures, floors, basements and

subways.

NOTE:

For sewerage treatment and waste

water structures use flexothane G.

FEATURES & BENEFITS

The product is suitable for use in

potable water.

Forms a tough, elastic, rubber-like

seal.

Accommodates continuous and

pronounced cyclic movement in all

planes.

Excellent adhesion to most common

construction materials.

High resistance to ageing and good

resistance to extreme climatic

changes.

Specific primers for porous and non-

porous surfaces ensure excellent

adhesion.

APPLICATION INSTRUCTIONS

JOINT PREPARATION

Thorough preparation of joints is

essential if a satisfactory seal is to be

obtained. For concrete, stone or

masonry substrates, all traces of dust,

laitance, mould oil, any previous

sealant and all other foreign material

must be removed by mechanical

grinding, followed by blowing out with

dry oil-free compressed air. All

substrates must be completely dry.

Suitable back-up material, such as

duracord or durasheet must be used

to adjust sealant depth in the joint to

comply with correct joint geometry.

TYPICAL PHYSICAL PROPERTIES

Form

Two-component

compound. Base and

curing agent has

paste consistency

Colour Grey

M.A.F.

25% butt joints,

50% lap joints

Physical or

chemical change

Chemical cure

Application

temperature

+5 to +35 C

Hardness shore A Gun grade: 20-25

Pot life 2-8 hrs @ 25 C

Setting time

72 hours @ 5 C

36 hours @ 15 C

18 hours @ 25 C

Cure time

8 weeks at 5 C

4 weeks at15 C

2 weeks at25 C

Water immersion

durakol G HM must

be fully cured before

permanent immersion

in water

Chemical

resistance to

occasional spillage

dilute acids, dilute

alkalis, petrol, aviation

fuels, diesel,

kerosene, lubrication

oils, skydrol, white

spirit

Not resistant to

Chlorinated solvents

and oxidizing acids

Biological

resistance

durakol G HM Has

been evaluated in

microbiologically

active situations and

has been shown to

have resistance to

aerobic conditions

Solids content 100%

Density 1,74 kg/litre

Flash points > 65 C

Flammability

Burns but does not

readily support

combustion

duracord is a self releasing material,

but if soft-board is used as the joint

filler, a plastic strip bondbreaker must

be placed on the filler surface before

sealant is applied. The use of bond

breaking tape is not required in

expansion joints where duracord or

durasheet, cellular polyethylene fillers

are used except where a tear off strip

is employed on the durasheet. In this

instance, it is recommended that a

tape be placed over the cut edge of

the durasheet to prevent a

mechanical bond occuring.

Where the sealant is subject to a

hydrostatic head then a 100-200kg/m

density durasheet must be used.

Any expansion joint filler must be

checked to ensure it is tightly packed

and no gaps or voids exist at the base

of the sealing slot before positioning a

bond breaker.

PRIMING OF JOINTS

Porous surfaces must be fully primed

the sides of the joint face, allowing the

solvent to evaporate. The surface

should be touch dry between 30

minutes and 2 hours dependant on

temperature and humidity.

the joint during this time window

otherwise another coat of primer must

be applied.

Note: The use of a bond breaker is not

required in expansion joints containing

duracord or durasheet cellular

polyethylene expansion joint fillers. For

construction or contraction joints a

bond breaker tape or duracord should

be used. Where hydrostatic pressure

exists, only bond breaking tapes must

be used, not foamed back-up strips.

PRIMING

Porous surfaces must be fully primed

with epidermix 326 (twin-pack epoxy

durakol G HM

with epidermix 326 brushed well into

durakol G HM must be introduced into

65002 Rev: 01-05-08

DATA SHEET 11/7/07 10:52 AM Page 1

a.b.e. is an ISO 9001 : 2000 Registered Company.

a.b.e. Construction Chemicals Limited P.O. Box 23053, Isipingo, 4110 7 Wilcox Road, Isipingo, 4133 Tel. (031) 913 5400

TECHNI CAL DATA SHEET

primer) for brush application to

concrete, stone, brickwork, timber and

unglazed edges of ceramic tiles. Brush

well into the faces of the joint, to

ensure complete coverage. Avoid

over-priming resulting in an excess of

primer in the base of the joint or

application beyond faces. The primer

film should be allowed to lose its

solvent (approximately 30 minutes

drying) before sealant is applied.

Primer open time is 4 hours.

If however, the primer is allowed to dry

longer than 6 hours, then the surface

must be re-ground and re-primed.

Non-porous surfaces must be primed

with epidermix 391.

For use on glass and ceramics which

are to be permanently immersed in

water. It is a one part chemically

active, clear liquid for brush or pad

application. One thin coat should be

applied and allowed to dry for 30 to 60

minutes prior to sealant application.

Iron and steel must be protected with

an anti-corrosion primer prior to

sealing.

For estimating purposes allow

approximately 250 ml primer per 6 litre

sealant.

PROTECTION OF ADJACENT

SURFACES

Masking tape applied to areas

adjacent to joint will protect them from

smearing and enable the joints to be

finished to a neat line. The tape should

be applied after the joint has been

prepared, prior to any priming or

sealing operation and removed after all

finishing and tooling operations have

been completed, but before the

sealant has cured.

MIXING

durakol G HM is supplied in a single

container. A cellophane sheet covers

the polysulphide (base). On top of the

cellophane is the plastic container of

activator paste.

To prepare the material for use,

remove the activator and cellophane

sheet. Remove any base adhering to

the cellophane and replace the base in

the container.

Remove the entire activator paste from

its container and add to the base.

Mix the material thoroughly, preferably

with a slow speed drill (not in excess of

250 r/min) fitted with a suitable paddle,

until an even colour, free from streaks,

is obtained.

Periodically scrape the sides and base

of the container with a spatula or small

trowel to ensure complete blending of

components. To obtain a complete mix

will take FIVE TO TEN MINUTES of

mechanical mixing.

If hand mixing is to be carried out, a

minimum period of 15 minutes of

vigorous mixing is required.

Caution: If material is not mixed

thoroughly, its performances will be

impaired.

JOINT GEOMETRY

durakol G HM may be applied to joints

between 6 and 50 mm wide. The width

of the joint should be four times that of

the calculated joint movement. Joints

that are expected to experience

normal cyclic movements should be

designed to an optimum width to depth

ratio of 2:1, subject to the overriding

recommended minimum sealant depth

of:

6 mm for metals, glass and other

non-porous surfaces;

10 mm for all porous surfaces;

20 mm for trafficable joints and

those subject to hydrostatic

pressures.

Joints expected to with stand

hydrostatic or shear forces must have

a width to depth ratio of 1:1.

APPLICATION

Application to primed surfaces can be

by hand or pressure-operated gun or

by trowel or by pouring, according to

the cross-section of the joint to be

filled. It is essential to ensure complete

contact between the sealant and the

joint surfaces.

Tooling of sealant is necessary for

complete air-free filling of voids and to

assist in making contact by wetting the

surfaces to which the sealant is

applied.

The surfaces of the joint should be

smoothed with a clean knife or spatula.

A minimum of surface lubricant such

as dilute detergent solution may be

used to assist the process. Any

masking tape should be removed

immediately after tooling.

CLEANING

All equipment should be cleaned

immediately after use, and before the

material has set, with abe super

brush cleaner followed by washing

with soap and water.

PROTECTION ON COMPLETION

The finished sealant should be

protected from traffic until the sealant

has fully cured. Over-painting of

sealant is not recommended because

of the inability of paint films to accept

movement. However, if definitely

required, trials should be carried out to

determine compatibility.

LIMITATIONS

durakol G HM should not be used in

direct contact with materials containing

pitch or bitumen.

MODEL SPECIFICATION

The sealant shall be durakol G HM, a

two component, high modulus

polysulphide sealant applied in

accordance with the manufacturers

recommendations, abe Construction

Chemicals including the use of

epidermix 391 and epidermix 326

primers where required. The sealant

shall comply with the requirements of

SABS 110, 1973.

PACKAGING

durakol G HM is supplied in 2 litre tins

in cartons of six.

HANDLING & STORAGE

This product has a shelf life of

12 months if kept in a dry cool place in

the original packaging. Note that

higher temperatures may shorten the

shelf life of the product.

HEALTH & SAFETY

durakol G HM is toxic. Always

ventilate the working area well during

application and drying. Avoid flames in

vicinity.

Always wear gloves when working with

the material and avoid excessive

inhalation and skin contact.

If material is splashed in the eye, wash

with copious quantities of clean water

and seek medical attention.

Cured durakol G HM is inert and

harmless.

65002 Rev: 01-05-08

DATA SHEET 11/7/07 10:52 AM Page 1

a.b.e. is an ISO 9001 : 2000 Registered Company.

a.b.e. Construction Chemicals Limited P.O. Box 23053, Isipingo, 4110 7 Wilcox Road, Isipingo, 4133 Tel. (031) 913 5400

TECHNI CAL DATA SHEET

IMPORTANT NOTE

This data sheet is issued as a guide to

the use of the product(s) concerned.

Whilst abe Construction Chemicals

endeavours to ensure that any advice,

recommendation, specification or

information is accurate and correct, the

company cannot - because abe has no

direct or continuous control over where

and how abe products are applied -

accept any liability either directly or

indirectly arising from the use of abe

products, whether or not in accordance

with any advice, specification,

recommendation, or information given

by the company.

FURTHER INFORMATION

Where other products are to be used

in conjunction with this material, the

relevant technical data sheets should

be consulted to determine total

requirements. abe Construction

Chemicals has a wealth of technical

and practical experience built up over

years in the companys pursuit of

excellence in building and construction

technology.

COVERAGE AND GUIDE TO QUANTITIES

Joint size

in mm

Litres per

Metre run

Metre run per

2-litre pack

Metre run per

5-litre pack

5 x 5 0,025 80,00 200,00

5 x 10 0,050 40,00 100,00

10 x 5 0,050 40,00 100,00

10 x 10 0,100 20,00 50,00

15 x 10 0,150 13,00 32,50

20 x 10 0,200 10,00 25,00

20 x 15 0,300 6,70 16,50

20 x 20 0,400 5,00 12,50

25 x 13 0,300 6,20 15,50

40 x 20 0,800 2,50 6,25

50 x 25 1,250 1,60 4,00

500 ml of epidermix 326 to 12 litres of durakol G HM (approximate)

500 ml of epidermix 391 to 20 litres of durakol G HM. (approximate)

These are theoretical yields, no allowance has been made for variation in joint width or wastage,

65002 Rev: 01-05-08

You might also like

- Shaliseal Ps GG: DescriptionDocument3 pagesShaliseal Ps GG: DescriptionVikas Singh ChandelNo ratings yet

- Abrasion-Resistant Epoxy Lining MortarDocument4 pagesAbrasion-Resistant Epoxy Lining MortarBalasubramanian AnanthNo ratings yet

- Masterflex 700 GGDocument3 pagesMasterflex 700 GGHaresh BhavnaniNo ratings yet

- Thioflex 600 Pouring Grade TDSDocument3 pagesThioflex 600 Pouring Grade TDSAhmed NacherNo ratings yet

- ShaliSeal PS PGDocument3 pagesShaliSeal PS PGpoojaNo ratings yet

- Thioflex 600 Gun Grade TDSDocument3 pagesThioflex 600 Gun Grade TDSDevendra100% (1)

- Epoxy Resin Mortar for Concrete ProtectionDocument2 pagesEpoxy Resin Mortar for Concrete ProtectionsudhialakkalNo ratings yet

- Al PUDocument2 pagesAl PUpravi3434No ratings yet

- Fevicol PurDocument3 pagesFevicol PurVenkata ChadaNo ratings yet

- Masterflex 700 PGDocument3 pagesMasterflex 700 PGHaresh BhavnaniNo ratings yet

- BASF MasterSeal M 790 TdsDocument9 pagesBASF MasterSeal M 790 TdsAmar WadoodNo ratings yet

- DR Fixit Pidiseal PS 41G and 42P 112 1Document4 pagesDR Fixit Pidiseal PS 41G and 42P 112 1Avinash GuptaNo ratings yet

- sHOTPATCH 10 v3 PDFDocument2 pagessHOTPATCH 10 v3 PDFAnkita Baban GavadeNo ratings yet

- FL Exothane 27: Polyurethane Construction SealantDocument3 pagesFL Exothane 27: Polyurethane Construction Sealantcremildo maetinhoNo ratings yet

- Proglaze IIDocument3 pagesProglaze IIMohammad ALTAKINo ratings yet

- TDS - Mastertop 300Document3 pagesTDS - Mastertop 300Venkata RaoNo ratings yet

- Rapid Set Tds - NoRestrictionDocument4 pagesRapid Set Tds - NoRestrictionFloorkitNo ratings yet

- 187 NanoGrout EGDocument2 pages187 NanoGrout EGTristan Irvin Asi100% (3)

- Thioflex 600 PDFDocument4 pagesThioflex 600 PDFmilanbrasinaNo ratings yet

- Cmci Cmci: High Flow Epoxy Grout SystemDocument2 pagesCmci Cmci: High Flow Epoxy Grout Systempravi3434No ratings yet

- Kanseal Pu.Document4 pagesKanseal Pu.Sunny SinghNo ratings yet

- Abe DIY BookletDocument89 pagesAbe DIY BookletFrancois-No ratings yet

- TDS - Emaco S88 PlusDocument2 pagesTDS - Emaco S88 PlusVenkata RaoNo ratings yet

- Chemlok 252XDocument4 pagesChemlok 252XHuỳnh TGNo ratings yet

- Euco TopDocument2 pagesEuco Toppravi3434No ratings yet

- 2-Part Polyurethane Sealant for Airport Runways & Concrete JointsDocument2 pages2-Part Polyurethane Sealant for Airport Runways & Concrete JointsjoshepNo ratings yet

- Nitomortar ELDocument4 pagesNitomortar ELmilanbrasinaNo ratings yet

- Protective Concrete Coating GuideDocument3 pagesProtective Concrete Coating GuideTori SmallNo ratings yet

- Sikaflex 11FC - PDS PDFDocument4 pagesSikaflex 11FC - PDS PDFrajeevNo ratings yet

- Thioflex 600Document4 pagesThioflex 600Conifer YuNo ratings yet

- Weather Resistant Crack Filler & SealantDocument2 pagesWeather Resistant Crack Filler & SealantaahtagoNo ratings yet

- Structural Concrete Adhesive Technical Data SheetDocument2 pagesStructural Concrete Adhesive Technical Data SheetBen WalkerNo ratings yet

- SealXtra PS Technical DatasheetDocument2 pagesSealXtra PS Technical DatasheetMichael Kazi100% (2)

- Flexcrete 500: Epoxy Polysulfide Waterproofing CoatingDocument2 pagesFlexcrete 500: Epoxy Polysulfide Waterproofing CoatingSuresh YadavNo ratings yet

- Renderoc HSDocument2 pagesRenderoc HSAdnan JadoonNo ratings yet

- Fugabella Epoxy enDocument6 pagesFugabella Epoxy enKiran Kumar JhaNo ratings yet

- Sonneborn NP2Document4 pagesSonneborn NP2Edward FlynnNo ratings yet

- Flooring CompoundsDocument18 pagesFlooring CompoundsParashuram ChauhanNo ratings yet

- Flexible Pu SealantDocument2 pagesFlexible Pu SealantGi GoNo ratings yet

- Polycoat RbeDocument2 pagesPolycoat RbejovindhaNo ratings yet

- Flexiroof Tds 26-9-10 - NewDocument3 pagesFlexiroof Tds 26-9-10 - Newmiratif19_860027847No ratings yet

- TDS - Mastertop 200Document2 pagesTDS - Mastertop 200Venkata RaoNo ratings yet

- FLORGARD SL self-levelling epoxy flooringDocument3 pagesFLORGARD SL self-levelling epoxy flooringcharibackupNo ratings yet

- Specs Pull Off Cement Plaster General PurposeDocument3 pagesSpecs Pull Off Cement Plaster General PurposeKhan Shahzeb100% (2)

- Datasheet File - Conbextra GPDocument3 pagesDatasheet File - Conbextra GPmuraliNo ratings yet

- High Strength Epoxy Mortar for Manhole RehabilitationDocument1 pageHigh Strength Epoxy Mortar for Manhole Rehabilitationpravi3434No ratings yet

- ShaliTex Sealing CompoundDocument2 pagesShaliTex Sealing CompoundHimagiriNo ratings yet

- Seal FlexDocument2 pagesSeal Flexpravi3434No ratings yet

- TDS - Mastertile 30 - WPMDocument2 pagesTDS - Mastertile 30 - WPMVenkata RaoNo ratings yet

- Nitoseal 220Document4 pagesNitoseal 220Venkata RaoNo ratings yet

- Don't Just Buy Another Product Buy A SOLUTION: Characteristics: CH TitiDocument2 pagesDon't Just Buy Another Product Buy A SOLUTION: Characteristics: CH TitiLion YangNo ratings yet

- Tds - Emaco s88c TDocument2 pagesTds - Emaco s88c TVenkata RaoNo ratings yet

- TDS Pattex BondsealfillDocument5 pagesTDS Pattex BondsealfilldknisNo ratings yet

- Hydroproof: Single Component Acrylic Polymer For Cement Based Waterproof Composite Coating MembraneDocument2 pagesHydroproof: Single Component Acrylic Polymer For Cement Based Waterproof Composite Coating MembraneVenkata Raju KalidindiNo ratings yet

- Sealbond Optimastic PU1K 60 Polyurethane WaterproofingDocument4 pagesSealbond Optimastic PU1K 60 Polyurethane WaterproofingMel GarciaNo ratings yet

- Flo-Grout BP800Document26 pagesFlo-Grout BP800qasim078100% (1)

- Eco-efficient Rendering Mortars: Use of Recycled MaterialsFrom EverandEco-efficient Rendering Mortars: Use of Recycled MaterialsNo ratings yet

- Residential Asphalt Roofing Manual Design and Application Methods 2014 EditionFrom EverandResidential Asphalt Roofing Manual Design and Application Methods 2014 EditionNo ratings yet

- Reinforcing Steel in Slabs On Grade - tcm45-346883Document3 pagesReinforcing Steel in Slabs On Grade - tcm45-346883Ralf SnellNo ratings yet

- CamScanner Scans PDFs QuicklyDocument4 pagesCamScanner Scans PDFs QuicklypbodooNo ratings yet

- 6th Central Pay Commission Salary CalculatorDocument15 pages6th Central Pay Commission Salary Calculatorrakhonde100% (436)

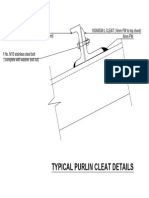

- Typical Purlin Cleat Details for 100x65x8 L Cleat and 76x38x6 RSC PurlinDocument1 pageTypical Purlin Cleat Details for 100x65x8 L Cleat and 76x38x6 RSC PurlinpbodooNo ratings yet

- Connections & Column Base - January 2003Document62 pagesConnections & Column Base - January 2003pbodooNo ratings yet

- Commercial building roof planDocument1 pageCommercial building roof planpbodooNo ratings yet

- (A) Design Parameter: 30 Sin 1 30 Sin 1Document1 page(A) Design Parameter: 30 Sin 1 30 Sin 1pbodooNo ratings yet

- Closed-cell bond breaker and back-up materialDocument2 pagesClosed-cell bond breaker and back-up materialpbodooNo ratings yet

- Block PlanDocument1 pageBlock PlanpbodooNo ratings yet

- Typical Purlin Cleat Details for 100x65x8 L Cleat and 76x38x6 RSC PurlinDocument1 pageTypical Purlin Cleat Details for 100x65x8 L Cleat and 76x38x6 RSC PurlinpbodooNo ratings yet

- Applying UBC97 seismic loads in OrionDocument16 pagesApplying UBC97 seismic loads in Orionpbodoo100% (1)

- Effective Modelling in Fastrak Building DesignerDocument8 pagesEffective Modelling in Fastrak Building Designerpbodoo100% (1)

- TEDDS Manual - January 2006Document80 pagesTEDDS Manual - January 2006pbodooNo ratings yet

- Engineers HandbookDocument561 pagesEngineers Handbookpbodoo100% (3)

- CCL Post Tension Ing Civil 28.04.10Document35 pagesCCL Post Tension Ing Civil 28.04.10Wang JueNo ratings yet

- IntlCP StandardConstructionContractsForm PDFDocument18 pagesIntlCP StandardConstructionContractsForm PDFRahul BaliNo ratings yet

- Typical Purlin Cleat Details for 100x65x8 L Cleat and 76x38x6 RSC PurlinDocument1 pageTypical Purlin Cleat Details for 100x65x8 L Cleat and 76x38x6 RSC PurlinpbodooNo ratings yet

- Standard Training Manual: CSC OrionDocument245 pagesStandard Training Manual: CSC OrionMasaba Solomon63% (8)

- IntlCP StandardConstructionContractsForm PDFDocument18 pagesIntlCP StandardConstructionContractsForm PDFRahul BaliNo ratings yet

- Closed-cell bond breaker and back-up materialDocument2 pagesClosed-cell bond breaker and back-up materialpbodooNo ratings yet

- Conflict Analysis Tools PDFDocument12 pagesConflict Analysis Tools PDFApeuDerrop0% (1)

- Cu Unjieng V MabalacatDocument6 pagesCu Unjieng V MabalacatMp CasNo ratings yet

- Volume Meters Models 962 and 963 Series CDocument8 pagesVolume Meters Models 962 and 963 Series CVictor Edy Facundo DelzoNo ratings yet

- Preparing For 2024: Election Technology and The Battle Against DisinformationDocument13 pagesPreparing For 2024: Election Technology and The Battle Against DisinformationVerified VotingNo ratings yet

- Automatic Transaxle System GuideDocument23 pagesAutomatic Transaxle System GuideChristian Linares AbreuNo ratings yet

- 5 Nighttime Image Enhancement Using A NewDocument7 pages5 Nighttime Image Enhancement Using A NewNithish CenaNo ratings yet

- Final VeganDocument11 pagesFinal Veganapi-314696134No ratings yet

- Ammonium Nitrophosphate Production ProcessDocument133 pagesAmmonium Nitrophosphate Production ProcessHit Busa100% (1)

- Particulars Unit BOQ NO. BOQ QTY: Bill of Quantity Bill of QuantityDocument8 pagesParticulars Unit BOQ NO. BOQ QTY: Bill of Quantity Bill of QuantityAbbasNo ratings yet

- Keyence cv700 - Man2Document232 pagesKeyence cv700 - Man2kamaleon85No ratings yet

- Markard Et Al. (2012) PDFDocument13 pagesMarkard Et Al. (2012) PDFgotrektomNo ratings yet

- Praveen Verma Auto CAD IntershipDocument15 pagesPraveen Verma Auto CAD IntershipPraveen vermaNo ratings yet

- 28 GHZ Millimeter Wave Cellular Communication Measurements For Reflection and Penetration Loss in and Around Buildings in New York CityDocument5 pages28 GHZ Millimeter Wave Cellular Communication Measurements For Reflection and Penetration Loss in and Around Buildings in New York CityJunyi LiNo ratings yet

- Lecture 8 - Life Cycle Inventory Example and SimaPro Intro - S18Document42 pagesLecture 8 - Life Cycle Inventory Example and SimaPro Intro - S18Francisco AraujoNo ratings yet

- Sciencedirect Sciencedirect SciencedirectDocument7 pagesSciencedirect Sciencedirect SciencedirectMohamed Amine NZNo ratings yet

- B. Com II Year Economics Previous Year QuestionsDocument11 pagesB. Com II Year Economics Previous Year QuestionsShashiMohanKotnalaNo ratings yet

- How COVID-19 Affects Corporate Financial Performance and Corporate Valuation in Bangladesh: An Empirical StudyDocument8 pagesHow COVID-19 Affects Corporate Financial Performance and Corporate Valuation in Bangladesh: An Empirical StudyInternational Journal of Innovative Science and Research TechnologyNo ratings yet

- Business-Process Integration: Supply-Chain Management 2.0 (SCM 2.0)Document8 pagesBusiness-Process Integration: Supply-Chain Management 2.0 (SCM 2.0)nidayousafzaiNo ratings yet

- 150 C++ BitsDocument55 pages150 C++ BitsRavi Varma D V SNo ratings yet

- Ahmed (2018)Document9 pagesAhmed (2018)zrancourttremblayNo ratings yet

- Ilogic LinkDocument13 pagesIlogic Linkbekirrrr100% (1)

- Regenerative Braking System: An Efficient Way to Conserve EnergyDocument31 pagesRegenerative Braking System: An Efficient Way to Conserve EnergyPRAVIN KUMAR NNo ratings yet

- Mo Handbook Fbimnci Apr 18, 2019Document296 pagesMo Handbook Fbimnci Apr 18, 2019Prakash Thakulla100% (1)

- The CardiacDocument7 pagesThe CardiacCake ManNo ratings yet

- Online Dispute ResolutionDocument18 pagesOnline Dispute ResolutionMak YabuNo ratings yet

- All India CW Pricelist Wef 01.05.2021Document6 pagesAll India CW Pricelist Wef 01.05.2021Sameer PadhyNo ratings yet

- Assessment Nursing Diagnosis Scientific Rationale Planning Intervention Rationale EvaluationDocument9 pagesAssessment Nursing Diagnosis Scientific Rationale Planning Intervention Rationale Evaluationclydell joyce masiarNo ratings yet

- Ticket Frankfurt Berlin 3076810836Document2 pagesTicket Frankfurt Berlin 3076810836farzad kohestaniNo ratings yet

- GCAF Online Inspector Practice ExamDocument5 pagesGCAF Online Inspector Practice Examcamwills2100% (1)

- Chapter 2 (Teacher)Document19 pagesChapter 2 (Teacher)ajakazNo ratings yet