Professional Documents

Culture Documents

IA - Enthalpy Change Copper Sulfate and Zinc

Uploaded by

annehindenbergCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

IA - Enthalpy Change Copper Sulfate and Zinc

Uploaded by

annehindenbergCopyright:

Available Formats

Anne Hindenberg Chemistry

Internal Assessment

DETERMINTATION OF THE ENTHALPY CHANGE FOR THE

DISCPLACEMENT REACTION BETWEEN ZINC AND COPPER SULFATE

DCP AND CE

Aim: To determine the enthalpy change for the single displacement reaction

between zinc and copper sulphate: Zn (s) + CuSO4 (aq) Cu (s) + ZnSO4 (aq)

Anne Hindenberg Chemistry

Internal Assessment

Page 2 of 9

Contents

Raw Data3

Observations.4

Graph..5

Calculations6-7

Conclusion 8

Evaluation..9

Works Cited.....10

Anne Hindenberg Chemistry

Internal Assessment

Page 3 of 9

Raw Data

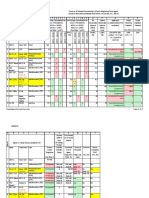

Table 1.0 Table to show raw data collected for temperature increase

Data Recorded

Time/s ( 0.1 s) Temperature (0.5C)

0 20.5

30 20.4

60 20.3

90 20.2

120 20.1

150 20.1

180 ( Zinc Added) 20.1

210 24.9

240 31.7

270 34.2

300 36.0

330 37.0

360 37.3

390 37.2

420 37.3

450 37.2

480 37.1

510 37.0

530 36.9

560 36.8

590 36.6

620 36.4

650 36.3

680 36.1

Anne Hindenberg Chemistry

Internal Assessment

Page 4 of 9

Observations

Before adding the Copper Sulfate and the Zinc Powder together, the copper

sulfate is an electric blue colorless color, whilst the zinc power is a black color.

The Zinc power immediately reacts with the Copper Sulfate solution, which

becomes noticeably warmer. With the zinc being in powder form, the reaction

begins in almost instantaneous with minimal stirring. At the beginning the solution

has a green/blue color. After the zinc has dissolved, it becomes a dark murky

brown/black color. After the solution was removed from the cup, copper (red-

brown) precipitates at the bottom, having been displaced by the zinc.

Graph

Anne Hindenberg Chemistry

Internal Assessment

Page 5 of 9

Figure 2.0 Change in temperature when Zinc powder is added to Copper

sulfate solution

The blue lines are showing the line of best fit to estimate what the maximum

temperature would have been, but as the lid had to be lifted to add the zinc, heat

was lost.

0

5

10

15

20

25

30

35

40

0 60 120 180 240 300 360 420 480 530 590 650

T

e

m

p

e

r

a

t

u

r

e

(

0

.

5

C

)

Time/s ( 0.1 s)

Change of Temperature

Temperature (0.5C)

Anne Hindenberg Chemistry

Internal Assessment

Page 6 of 9

Calculations

Knowing the amount of CuSO as well as its heat capacity, we can calculate the

enthalpy change for this reaction using the formula:

Enthalpy change = - (mass of water x specific heat capacity x temperature

change)

H = m x c x t

Mass of water (g) = volume of copper sulphate solution (cm3)

Mass of water = 25 grams

Specific heat capacity = 4.18 J

Temperature change = 28.9 C (49C 20.1C)

Enthalpy change (Joules) = ( 25 x 4.18 x 28.9) J

1. Molar enthalpy change = Enthalpy change / moles of solute used

2. Enthalpy change = 3020.05 J

3. Moles of solute = (

) (

)

4. Molar enthalpy change =

= 120,802 Joules = 121 kJ mol'

As this reaction is exothermic, i.e. heat is released the enthalpy change is

negative:

H = - 121 kJ mol'

I ended up using the line of best fit (you can see the lines on the graph on page

5) to estimate the change in temperature upon adding the zinc in an ideal

situation, where there would have been no heat loss. The gradient shows the

rate in which the temperature decreases.

We use the best it line to estimate the change in temperature upon adding zinc

in a perfect situation, where no heat would be lost. The gradient shows the rate,

Anne Hindenberg Chemistry

Internal Assessment

Page 7 of 9

at which the temperature decreases. The steep gradient at the time when zinc

was added indicates that the speed of reaction, I.e. change in temperature per

unit time was very high.

To calculating the percentage error (which is the difference between the

theoretical and actual values) with the formula

()

The percentage error which I achieved was =

()

, which is a

reasonably high percentage error. Some of the percentage error could be put

down to

Mass of zinc: 3.0 g 1.7%

Volume of acid: 25 ml 0.4%

Temperature change: 28.9 C 0.2%

Up to 2.3% could be the error of measurement.

The biggest contribution to the experimental error most likely is the heat, which

was lost to the surroundings.

Anne Hindenberg Chemistry

Internal Assessment

Page 8 of 9

Weaknesses and Limitations

The experiment was not repeated and averaged to reduce the impact of

any random errors and to reduce uncertainty.

The interval of readings equal to once every 30 seconds may not be

sufficient to gain enough data - more frequent measurement would have

given a more reliable graph. Some heat was lost to the surroundings and

therefore measured temperature values would not be accurate. This

probably contributed the most to the experimental error being at 44.5%

and therefore would be the biggest weakness of this experiment that

would need to be addressed in particular.

Measurement of 25 ml of copper sulphate had higher uncertainty because

of meniscus measurement uncertainty

Zinc might have had impurities and the styrophome cup might have had

traces of other reactants that introduced random error to the

measurements

Suggestions for improvement

Experiment could be conducted several times and then all the values

averaged to reduce the impact of anomalies and random errors.

Insulations would be useful. Coating and insulating material that would

minimize the heat loss would be useful. Stirring should be done through

the hole. Alternatively, the temperature of the laboratory could be

adjusted, but that is less practical and more difficult to achieve

Zinc should be used in different forms and shapes to investigate how the

shape of the object affects its reactivity. Different concentrations would

give us information on whether concentration of reactants is directly

Anne Hindenberg Chemistry

Internal Assessment

Page 9 of 9

proportional to change in temperature and would be useful for making

predictions about other similar experiments.

Measurement should be taken by the lowest point of the meniscus.

As zinc is provided by the technicians, there is not much that could be

done to ascertain its purity. Possibly wash it is some acis that does not

react with zinc. To prevent traces from other experiments, tubes should be

washed properly before the experiment

You might also like

- IA - Enthalpy of Displacement ReactionDocument5 pagesIA - Enthalpy of Displacement Reaction14nganhc1No ratings yet

- Energetics of Displacement Reaction (ΔH = -219 kJ/molDocument1 pageEnergetics of Displacement Reaction (ΔH = -219 kJ/molnewacademy234100% (2)

- Finding The Enthalpy of The Displacement Reaction of Zinc and Copper Sulfate SolutionDocument2 pagesFinding The Enthalpy of The Displacement Reaction of Zinc and Copper Sulfate SolutionBen Chalmers100% (2)

- IB Chemistry IA Hess's LawDocument4 pagesIB Chemistry IA Hess's LawJason J. Ln75% (4)

- Determining An Enthalpy Change of ReactionDocument7 pagesDetermining An Enthalpy Change of ReactionAntony ProtonotariosNo ratings yet

- Titus John - Enthalpy Prac ReportDocument12 pagesTitus John - Enthalpy Prac Reportapi-295071132No ratings yet

- Reaction of Sodium Thiosulphate and Hydrochloric AcidDocument5 pagesReaction of Sodium Thiosulphate and Hydrochloric Acidapi-373250088% (8)

- WM Chemistry Ia Final Risma RemsudeenDocument12 pagesWM Chemistry Ia Final Risma RemsudeenPriyanshi PeelwanNo ratings yet

- WM Final Chemistry Ia Watermark 1Document12 pagesWM Final Chemistry Ia Watermark 1ppNo ratings yet

- Chemistry IA 3Document10 pagesChemistry IA 3Vanessa TumanggorNo ratings yet

- Chem Practice IADocument9 pagesChem Practice IAnarakhantiNo ratings yet

- Rate of ReactionDocument8 pagesRate of Reactionjason_ngl94No ratings yet

- Chemistry IADocument6 pagesChemistry IAuday agrawal100% (1)

- BIOLOGY Sample IADocument12 pagesBIOLOGY Sample IAVedant SainiNo ratings yet

- LR 1 Electrolysis of Copper SulphateDocument6 pagesLR 1 Electrolysis of Copper SulphateCloud D. LuffyNo ratings yet

- CHem IA Oxalyic AcidDocument5 pagesCHem IA Oxalyic AcidKennard ChiaNo ratings yet

- Measuring The Enthalpy of Combustion of Ethanol IB Chemistry SL Lab ReportDocument7 pagesMeasuring The Enthalpy of Combustion of Ethanol IB Chemistry SL Lab Reportxavier bourret sicotte76% (17)

- How Cooking Temp Affects Kailan CalciumDocument12 pagesHow Cooking Temp Affects Kailan CalciumRona100% (1)

- IA Chemistry 2 Rate of ReactionDocument2 pagesIA Chemistry 2 Rate of ReactionAldo Hamka0% (1)

- Biology Extended Essay Final Draft.Document33 pagesBiology Extended Essay Final Draft.Oliver Hernández100% (1)

- Determination of Enthalpy Between Magnesium and HCLDocument6 pagesDetermination of Enthalpy Between Magnesium and HCLConnor EnglandNo ratings yet

- Catalase in Potato and Hydrogen Peroxide ConcentrationDocument5 pagesCatalase in Potato and Hydrogen Peroxide ConcentrationAdrian Amiranios89% (9)

- Determination of Oxygen Dissolved in Water by WinklerDocument3 pagesDetermination of Oxygen Dissolved in Water by WinklerSazzan NpnNo ratings yet

- Experiment 4 Electrochem CMT555Document10 pagesExperiment 4 Electrochem CMT555Amar Safwan100% (1)

- Heat Solution LabDocument6 pagesHeat Solution LabNicole Graham50% (2)

- IOC S1 TranscriptionDocument4 pagesIOC S1 TranscriptionyunhoNo ratings yet

- Viscosity IA - CHEMDocument4 pagesViscosity IA - CHEMMatthew Cole50% (2)

- Ib Potato Osmolarity LabDocument4 pagesIb Potato Osmolarity LabLuesma Fully (STUDENT)No ratings yet

- Chemistry Internal AssessmentDocument10 pagesChemistry Internal AssessmentFery FekriNo ratings yet

- Esterification: October 27 - 28, 2011Document16 pagesEsterification: October 27 - 28, 2011Misukun67% (3)

- I A Extended Essay Ideas For Ib ChemistryDocument3 pagesI A Extended Essay Ideas For Ib ChemistryAaliyaNo ratings yet

- Chemistry Report On Rate of ReactionDocument6 pagesChemistry Report On Rate of ReactionMatthew Chu80% (5)

- Lab On Transpiration BioDocument8 pagesLab On Transpiration BioNigg100% (1)

- Biology IADocument11 pagesBiology IAAnmolSaxena100% (2)

- Dissolved oxygen estimation by redox titrationDocument2 pagesDissolved oxygen estimation by redox titrationSuet Wan GohNo ratings yet

- Report - Experiment 4Document7 pagesReport - Experiment 4Shirene LiewNo ratings yet

- Yeast Fermentation Rate Peak at 45°CDocument3 pagesYeast Fermentation Rate Peak at 45°CRuifa Huang100% (1)

- Research Article of Equilibrium Constant in Esterification ReactionDocument4 pagesResearch Article of Equilibrium Constant in Esterification ReactionViha Ancillia25% (4)

- Reaction RateDocument19 pagesReaction RateMuhd Hafiz NizamNo ratings yet

- Electrolysis of Copper SulphateDocument3 pagesElectrolysis of Copper Sulphatewscience100% (1)

- Solubility of Some SaltsDocument10 pagesSolubility of Some Saltsken345007No ratings yet

- Analysis of A Commercial Bleach LabDocument7 pagesAnalysis of A Commercial Bleach Labapi-358133276100% (2)

- Measuring The Concentration of Vitamin C in Orange JuiceDocument6 pagesMeasuring The Concentration of Vitamin C in Orange JuiceZe Yu Zhang0% (1)

- IB Chemistry Internal Assessment 2Document18 pagesIB Chemistry Internal Assessment 2beslisevvalNo ratings yet

- Egg Caco3Document6 pagesEgg Caco3Lakshmankumar TjpsNo ratings yet

- Quantitative Electrolysis of CopperDocument12 pagesQuantitative Electrolysis of CopperSyaza Ahmad Jais100% (5)

- Bromine ClockDocument5 pagesBromine ClockOCRChemistrySalters0% (1)

- Fermentation IADocument15 pagesFermentation IAvivek1995vivek100% (1)

- Chemistry IA TopicsDocument1 pageChemistry IA TopicspootisNo ratings yet

- The Rate of Reaction Between Sodium Thiosulphate and Hydrochloric AcidDocument12 pagesThe Rate of Reaction Between Sodium Thiosulphate and Hydrochloric AcidMiriam Barker75% (4)

- Chemistry Sample IADocument11 pagesChemistry Sample IAJulianna Alysha100% (1)

- Biology IA Newdraft!Document16 pagesBiology IA Newdraft!Katherine100% (1)

- J. Lab ReportDocument3 pagesJ. Lab ReportJylla AngwayNo ratings yet

- Chem IA Bonding LabDocument7 pagesChem IA Bonding LabJason YuanNo ratings yet

- Chemistry IADocument17 pagesChemistry IAAlysha SubendranNo ratings yet

- Lab Redox Titration of Fe2 Iron PillsDocument4 pagesLab Redox Titration of Fe2 Iron PillsChristopher Padilla100% (2)

- Lab Report ChemisrtyDocument23 pagesLab Report ChemisrtyWakil NuckchadyNo ratings yet

- Experiment 3 Redox Titration Percent Purity AnalysisDocument5 pagesExperiment 3 Redox Titration Percent Purity AnalysisnanaNo ratings yet

- Determining The Enthalpy Change For A Re PDFDocument4 pagesDetermining The Enthalpy Change For A Re PDFIonNo ratings yet

- 10 TH DeceDocument4 pages10 TH DeceOmaru NimagaNo ratings yet

- The Sun The Sun Is Yellow But My Pee Is Pretty Mellow But The Boys Who Smell It Say Hellooo'Document1 pageThe Sun The Sun Is Yellow But My Pee Is Pretty Mellow But The Boys Who Smell It Say Hellooo'annehindenbergNo ratings yet

- 11.4 - Reproduction IB BiologyDocument3 pages11.4 - Reproduction IB BiologyannehindenbergNo ratings yet

- IOC Breath QuestionsDocument4 pagesIOC Breath QuestionsannehindenbergNo ratings yet

- Spanish VerbsDocument2 pagesSpanish VerbsannehindenbergNo ratings yet

- Galapagos NotesDocument1 pageGalapagos NotesannehindenbergNo ratings yet

- Secret River IOP Presentation - Dick ThornhillDocument5 pagesSecret River IOP Presentation - Dick ThornhillannehindenbergNo ratings yet

- Forced Migration of SyriansDocument8 pagesForced Migration of SyriansannehindenbergNo ratings yet

- Yanmar America publication listing for engine parts, service, and operation manualsDocument602 pagesYanmar America publication listing for engine parts, service, and operation manualsEnrique Murgia50% (2)

- Term Sheet: Original Borrowers) Material Subsidiaries/jurisdiction) )Document16 pagesTerm Sheet: Original Borrowers) Material Subsidiaries/jurisdiction) )spachecofdz0% (1)

- Wacker Neuson RTDocument120 pagesWacker Neuson RTJANUSZ2017100% (4)

- Clean Agent ComparisonDocument9 pagesClean Agent ComparisonJohn ANo ratings yet

- Weir Stability Analysis Report PDFDocument47 pagesWeir Stability Analysis Report PDFSubodh PoudelNo ratings yet

- Introduction To OpmDocument30 pagesIntroduction To OpmNaeem Ul HassanNo ratings yet

- Bluetooth Home Automation Using ArduinoDocument25 pagesBluetooth Home Automation Using ArduinoRabiNo ratings yet

- Periodic ClassificationDocument4 pagesPeriodic ClassificationtusharNo ratings yet

- Ch07 Spread Footings - Geotech Ultimate Limit StatesDocument49 pagesCh07 Spread Footings - Geotech Ultimate Limit StatesVaibhav SharmaNo ratings yet

- BPO UNIT - 5 Types of Securities Mode of Creating Charge Bank Guarantees Basel NormsDocument61 pagesBPO UNIT - 5 Types of Securities Mode of Creating Charge Bank Guarantees Basel NormsDishank JohriNo ratings yet

- Lecture 1: Newton Forward and Backward Interpolation: M R Mishra May 9, 2022Document10 pagesLecture 1: Newton Forward and Backward Interpolation: M R Mishra May 9, 2022MANAS RANJAN MISHRANo ratings yet

- EnerSys Global Leader in Industrial BatteriesDocument32 pagesEnerSys Global Leader in Industrial BatteriesAshredNo ratings yet

- JSA - 0026 Chipping & Granite cutting and lying Work At PB-19Document2 pagesJSA - 0026 Chipping & Granite cutting and lying Work At PB-19Koneti JanardhanaraoNo ratings yet

- Second Law of EntrophyDocument22 pagesSecond Law of EntrophyMia Betia BalmacedaNo ratings yet

- Singer NM37 57manualDocument266 pagesSinger NM37 57manualpaulkoby100% (2)

- Mechanics of Deformable BodiesDocument21 pagesMechanics of Deformable BodiesVarun. hrNo ratings yet

- Exor EPF-1032 DatasheetDocument2 pagesExor EPF-1032 DatasheetElectromateNo ratings yet

- Cold Forging Process TutorialDocument28 pagesCold Forging Process TutorialpanyamnrNo ratings yet

- Spsi RDocument2 pagesSpsi RBrandy ANo ratings yet

- Amana PLE8317W2 Service ManualDocument113 pagesAmana PLE8317W2 Service ManualSchneksNo ratings yet

- Steps To Configure Linux For Oracle 9i Installation: 1. Change Kernel ParametersDocument5 pagesSteps To Configure Linux For Oracle 9i Installation: 1. Change Kernel ParametersruhelanikNo ratings yet

- PCSE_WorkbookDocument70 pagesPCSE_WorkbookWilliam Ribeiro da SilvaNo ratings yet

- Capacity PlanningDocument19 pagesCapacity PlanningfarjadarshadNo ratings yet

- Arduino Guide using MPU-6050 and nRF24L01Document29 pagesArduino Guide using MPU-6050 and nRF24L01usmanNo ratings yet

- AAU5243 DescriptionDocument30 pagesAAU5243 DescriptionWisut MorthaiNo ratings yet

- The Online Medical Booking Store Project ReportDocument4 pagesThe Online Medical Booking Store Project Reportharshal chogle100% (2)

- Bandung Colonial City Revisited Diversity in Housing NeighborhoodDocument6 pagesBandung Colonial City Revisited Diversity in Housing NeighborhoodJimmy IllustratorNo ratings yet

- Micropolar Fluid Flow Near The Stagnation On A Vertical Plate With Prescribed Wall Heat Flux in Presence of Magnetic FieldDocument8 pagesMicropolar Fluid Flow Near The Stagnation On A Vertical Plate With Prescribed Wall Heat Flux in Presence of Magnetic FieldIJBSS,ISSN:2319-2968No ratings yet

- MSDS FluorouracilDocument3 pagesMSDS FluorouracilRita NascimentoNo ratings yet

- Newcomers Guide To The Canadian Job MarketDocument47 pagesNewcomers Guide To The Canadian Job MarketSS NairNo ratings yet