Professional Documents

Culture Documents

Critical Problems and Recommendations for National Cranberry

Uploaded by

maverick_659Original Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Critical Problems and Recommendations for National Cranberry

Uploaded by

maverick_659Copyright:

Available Formats

1. What are the most critical problems facing National Cranberry that Mr. Schaeffer must address?

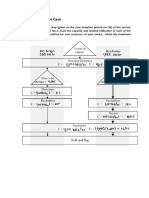

A high level process flow diagram for the plant is as shown below,

As can be seen, there are a few problem areas that needs immediate attention,

a. Installing Light Meter System

b. Reducing unloading wait times

c. Increasing total temporary holding capacity for bins for wet berries

d. Increasing the throughput for Drying

A closer look at data from Exhibit 2 provides some information on the possible root cause of the

truck unloading times.

Regular Plant hours Per Day: 16

Max Wet Processing with Drying capacity @600 bbls/hr: 9,600 bbls/day

Day

Total Deliveries

(scale weight in

bbls.)

Delivered Wet

(%)

Delivered Wet

(scale weight in bbls.)

9/20 16,014 31 4,964

9/21 17,024 39 6,639

9/22 16,550 39 6,455

9/23 18,340 42 7,703

9/24 18,879 41 7,740

9/25 18,257 36 6,573

9/26 17,905 45 8,057

9/27 16,281 42 6,838

9/28 13,343 38 5,070

9/29 18,717 43 8,048

9/30 18,063 59 10,657

10/1 18,018 69 12,432

10/2 15,195 60 9,117

10/3 15,816 60 9,490

10/4 16,536 57 9,426

10/5 17,304 55 9,517

10/6 14,793 46 6,805

10/7 13,862 61 8,456

10/8 11,786 56 6,600

10/9 14,913 54 8,053

As can be seen from the data highlighted above, we can see that we are exceeding or close to

the maximum capacity for Drying for processing wet berries. Thus this could be a potential

bottleneck within the system that could be leading to the filling up of the temporary holding bins,

in turn causing long truck wait times.

All this seems to be adding to the out of control overtime costs currently being seen for the

plant. With more wet berries expected to be processed for next year, the problem may get even

worse leading to more overtime costs.

Overall, it seems that the plant is more geared towards processing dry berries. The plant has

not kept pace with the processing capabilities needed for wet berries even as deliveries for wet

berries have gone up substantially in the last few years.

2. For your numerical analysis, consider a day where 18,000 barrels of berries arrive of which 70%

are wet. Assume that trucks arrive evenly spaced throughout an 11-hour day starting at 7:00

am, and that processing operations (i.e. receiving, dechaffing, milling, etc.) also start at 7:00 am.

Estimate the number of hours the plant must operate to complete the day's work.

Total Berries = 18,000

Wet Berries @70% = 18,000*70% = 12,600

Dry Berries @30% = 18,000*30% = 5,400

Since first set of truck arrives at 0th hour, we will have delivery for 12 hours. Therefore,

throughput for wet berries and dry berries,

wet = 12,600/12 = 1,050 bbl/hr

dry = 5400/12 = 450 bbl/hr

Looking at the process flow for the two operations,

For the dry berries there are no wait times as such processing of dry berries will finish in 12

hours.

Since we have a bottleneck at Drying for the processing of the wet berries, the total processing

times will be much more. In this case,

Makespan =(1050 bbls/hr * 12 hr) / (600 bbls/hr) =21 hours

Thus the plant must operate for 21 hours to finish the days work.

3. When during the day would trucks be waiting? How much truck waiting time would you expect?

Maximum total temporary holding bin capacity for wet berries is 3,200 bbls (3*400 + 250 *8).

wet = 12,600/12 = 1,050 bbl/hr

drying = 600 bbl/hr

INV (drying) = 450 bbl/hr

Truck waiting time would start when the bins for the wet berries will be full.

Truck wait time start = Max Capacity/ INV buildup rate

Truck wait time start = 3,200 bbl/450 bbl/hr = 7.11

If trucks start arriving at 7:00 AM, then the truck wait times would start at around 2:00

PM.

We can also see Inventory buildup as follows,

Time

Bin INV

(Backlog)

INV on

Trucks

# Trucks

Waiting

7:00 0 0 0

As can be seen, the trucks start waiting right after 2:00 PM and the truck queue clears out at

22:40 PM when the Bin INV falls back to maximum capacity of 3200 bbls.

Total truck wait time would be equal to sum of # of trucks waiting each hour. From the table

above, this would be equal to 127 hours.

We can also see that the maximum Inventory of unprocessed wet berries = (1050-600)*12 =

5,400 bbls is at 19:00. That is also the time when the last of the trucks would roll in for the day.

4. Suppose the cost of renting trucks with drivers is $18.00/hour. Based on your analysis, what

recommendations would you make to Mr. Schaeffer?

Option 1: Buying and installing two new dryers

Cost =2*25,000 =$50,000 (This will increase the drying capacity to 1,000 bbl/hr)

Option 2: Converting dry berry holding bins to dry or wet holding bins

We are short in holding wet capacity by 2,200 bbls. Thus we will have to convert a minimum of 9

bins

Cost of converting 9 dry berry holding bins =9*5,000 =$45,000

8:00 450 0 0

9:00 900 0 0

10:00 1350 0 0

11:00 1800 0 0

12:00 2250 0 0

13:00 2700 0 0

14:00 3150 0 0

15:00 3600 400 5

16:00 4050 850 11

17:00 4500 1300 17

18:00 4950 1750 23

19:00 5400 2200 29

20:00 4800 1600 21

21:00 4200 1000 13

22:00 3600 400 5

22:40 3200 0 0

23:00 3000 0 0

0:00 2400 0 0

1:00 1800 0 0

2:00 1200 0 0

3:00 600 0 0

4:00 0 0 0

Option 3: Compensate growers for driver overtime

Cost Total overtime: 12,000 * 2.25*1.5 = $40,500

Cost Driver compensation = 127 * 18 = $2,286

Total Cost =42,786

Even with overtime costs, Option 3 comes out to be cheaper than options 1 & 2.

Another recommendation would be to install the Light Meter System

Plant paid $0.50 on 450,000 bbl. @ 50% over charge and install cost of 10,000,

Savings =0.5*0.5*450,000 10,000 =$102,500

Thus the plant would be saving $102,500 with the Light Meter System

5. Suppose the cost of converting dry berry holding bins so they can store either water-harvested

or dry berries drops to $2,000 per bin. If everything else remains unchanged, how would this

cost reduction affect your recommendations?

With reduced cost of conversion,

Cost of converting 9 dry berry holding bins =9*2,000 =18,000

This is much cheaper than Option 3 as calculated above. Thus, in such a scenario we would

recommend Option 2 and not Option 3.

6. What is the capacity (in bbl. per hour) of receiving plant 1 (RP1)?

Total plant capacity is determined by Separator process @ 1,200 bbl/hr. This assumes

processing Wet berries @600 bbl/hr and Dry berries @600 bbl/hr

You might also like

- NationalCranberryCooperative CaseAnalysisDocument10 pagesNationalCranberryCooperative CaseAnalysisJishnu RoychaudhuriNo ratings yet

- National Cranberry CooperativeDocument14 pagesNational Cranberry CooperativeDenisa A86% (7)

- IDS 532 - National Cranberry Case Study - AnswersDocument4 pagesIDS 532 - National Cranberry Case Study - AnswersVikas Mani TripathiNo ratings yet

- National Cranberry Part IDocument3 pagesNational Cranberry Part IPrateekRaj167% (3)

- National Cranberry Cooperative CaseDocument7 pagesNational Cranberry Cooperative CaseMano Ranjani83% (12)

- 11BM60008 Sec B National Cranberry CooperativeDocument9 pages11BM60008 Sec B National Cranberry CooperativeKunal Verma100% (3)

- National Cranberries CaseDocument7 pagesNational Cranberries CaseHyper Green MindNo ratings yet

- National Cranberry CaseDocument10 pagesNational Cranberry CaseanshumanNo ratings yet

- NCC Awasthi 11BM60071Document8 pagesNCC Awasthi 11BM60071Abhishek AwasthiNo ratings yet

- Case 1 - National Cranberry CooperativeDocument7 pagesCase 1 - National Cranberry Cooperativewhitney100% (1)

- Assignment #1: Merton Truck Company Question 1: What Is The Contribution Toward Fixed Costs If Only Model 101 Is Built?Document9 pagesAssignment #1: Merton Truck Company Question 1: What Is The Contribution Toward Fixed Costs If Only Model 101 Is Built?TerryNo ratings yet

- National Cranberry Case Report Operations ManagementDocument7 pagesNational Cranberry Case Report Operations ManagementKarthik TirupatiNo ratings yet

- National Cranberry Cooperative - 11BM60070Document3 pagesNational Cranberry Cooperative - 11BM60070Neelesh KhattarNo ratings yet

- National Cranberry Cooperative Implements Strategies to Increase Capacity and Reduce CostsDocument11 pagesNational Cranberry Cooperative Implements Strategies to Increase Capacity and Reduce CostsFabiola SE100% (2)

- National Cranberry Cooperative Case AnalysisDocument9 pagesNational Cranberry Cooperative Case AnalysisAudrey Tay100% (3)

- NCC - Case StudyDocument3 pagesNCC - Case StudyDeepika GuptaNo ratings yet

- National Cranberry Case Analysis BottleneckDocument3 pagesNational Cranberry Case Analysis BottleneckHardik SemlaniNo ratings yet

- CranberryDocument4 pagesCranberryharshkhambraNo ratings yet

- National Cranberry Case ReportDocument10 pagesNational Cranberry Case ReportCharles Van Hoorebeke75% (4)

- Answers NCCDocument2 pagesAnswers NCCAmara Khan0% (1)

- National Cranberry HBS Case SolutionDocument9 pagesNational Cranberry HBS Case SolutionSandhya Patil100% (1)

- National Cranberry Cooperative: Operations Management-SCH-MGMT-670Document8 pagesNational Cranberry Cooperative: Operations Management-SCH-MGMT-670Shreyas SatardekarNo ratings yet

- The National Cranberry CooperativeDocument5 pagesThe National Cranberry CooperativeHussein BayramNo ratings yet

- National Cranberry Case Report Operations Management - IDocument9 pagesNational Cranberry Case Report Operations Management - IVikash KumarNo ratings yet

- OM - I National Cranberry CooperationDocument7 pagesOM - I National Cranberry Cooperationamritj100% (1)

- OM-I Assignment - Group 1 - Section A - National Cranberry CooperativeDocument8 pagesOM-I Assignment - Group 1 - Section A - National Cranberry Cooperativeaglakshmanan50% (2)

- National Cranberry Cooperative 1996-1 PDFDocument10 pagesNational Cranberry Cooperative 1996-1 PDFnephielive.cnNo ratings yet

- OPTIMIZED OPERATIONSDocument10 pagesOPTIMIZED OPERATIONSSahil sangwanNo ratings yet

- OM WordDocument3 pagesOM WordpulakitNo ratings yet

- National Cranberry Cooperative SolutionsDocument2 pagesNational Cranberry Cooperative Solutionsjr_gimp83% (6)

- National Cranberry Case SolutionDocument4 pagesNational Cranberry Case SolutionAli Umer MughalNo ratings yet

- National Cranberry CooperativeDocument5 pagesNational Cranberry CooperativeRasheeq RayhanNo ratings yet

- National Cranberry CaseDocument20 pagesNational Cranberry CaseRicardo David Pareja Baquerizo100% (2)

- National Cranberry Cooperations 1996Document15 pagesNational Cranberry Cooperations 1996Mithilesh Singh67% (3)

- NCC CaseDocument13 pagesNCC CaseDaniel FilipeNo ratings yet

- National Cranberry CooperativeDocument15 pagesNational Cranberry CooperativeSaswata Banerjee100% (4)

- Operations Management National Cranberry CaseDocument12 pagesOperations Management National Cranberry CaseKarthik TirupatiNo ratings yet

- Group 1 Donner Company CaseDocument7 pagesGroup 1 Donner Company CaseAjay Kumar100% (1)

- Answers To Old Midterm QsDocument11 pagesAnswers To Old Midterm QsdarshangoshNo ratings yet

- National Cranberry CooperativeDocument3 pagesNational Cranberry CooperativeRasheeq RayhanNo ratings yet

- Littlefield Initial Analysis - Group 1Document4 pagesLittlefield Initial Analysis - Group 1Manjot100% (1)

- Valley Forge Problem SoutionDocument5 pagesValley Forge Problem SoutionSashi Velnati0% (1)

- National Cranberry Cooperative Case AnalysisDocument6 pagesNational Cranberry Cooperative Case AnalysisTeja RaoNo ratings yet

- National Cranberry Cooperative 1981Document10 pagesNational Cranberry Cooperative 1981Nicole Dorado0% (1)

- WAC of Mcleod Motors OperationsDocument8 pagesWAC of Mcleod Motors OperationsMohsin JalilNo ratings yet

- Introduction to Forecasting Methods and Models for OperationsDocument10 pagesIntroduction to Forecasting Methods and Models for OperationsLeland Coontz IV100% (1)

- Littlefield Report #1 - Team MoneyDocument4 pagesLittlefield Report #1 - Team MoneyHaochen Xu100% (1)

- MGMT611 Managing Littlefield TechDocument4 pagesMGMT611 Managing Littlefield Techqiyang84No ratings yet

- Littlefield Simulation Game ReportDocument12 pagesLittlefield Simulation Game ReportSudeep RujNo ratings yet

- OPIM101 - Spring 2010 - R4 SolutionsDocument4 pagesOPIM101 - Spring 2010 - R4 Solutionsjoe91bmwNo ratings yet

- Manzana Insurance Fruitvale Branch - Group 6Document6 pagesManzana Insurance Fruitvale Branch - Group 6Puneet AgarwalNo ratings yet

- 13 American Chemical Corporation - Group 13Document5 pages13 American Chemical Corporation - Group 13Anonymous MpSSPQi0% (1)

- National Cranberry - Section 4 Group 16Document8 pagesNational Cranberry - Section 4 Group 16milwandaNo ratings yet

- NCCDocument5 pagesNCCDeepika GuptaNo ratings yet

- Bacchus, Safraz LE1 - NCCDocument6 pagesBacchus, Safraz LE1 - NCCshaf33zaNo ratings yet

- Xuanyao Zhu, Gao Chao, Anthony Leung, National Cranberry Case Write-UpDocument8 pagesXuanyao Zhu, Gao Chao, Anthony Leung, National Cranberry Case Write-UpJason zhuNo ratings yet

- National Cranberry Cooperative: Revised Apr 09Document16 pagesNational Cranberry Cooperative: Revised Apr 09Varun ChandNo ratings yet

- NCC Case Writeup 2020Document7 pagesNCC Case Writeup 2020rajuNo ratings yet

- National Cranberry Cooperative Reduces Truck Wait TimesDocument16 pagesNational Cranberry Cooperative Reduces Truck Wait TimesNitish Raj SubarnoNo ratings yet

- National Cranberry Cooperative Case Answer 1Document6 pagesNational Cranberry Cooperative Case Answer 1PRITEENo ratings yet

- Annamalai University MBA Financial Management 2nd Year Assignments 2019-20Document4 pagesAnnamalai University MBA Financial Management 2nd Year Assignments 2019-20Senthil KumarNo ratings yet

- Cost-Volume-Profit Analysis: Mcgraw-Hill/IrwinDocument78 pagesCost-Volume-Profit Analysis: Mcgraw-Hill/IrwinSheila Jane Maderse AbraganNo ratings yet

- CH 1 Cost Volume Profit Analysis Absorption CostingDocument21 pagesCH 1 Cost Volume Profit Analysis Absorption CostingNigussie BerhanuNo ratings yet

- IFM Class Examples On ECU and Gold StandardDocument2 pagesIFM Class Examples On ECU and Gold StandardFurukawa YurikoNo ratings yet

- Why Is It Important To Consider Uncertainty When Evaluating Supply Chain DesignDocument3 pagesWhy Is It Important To Consider Uncertainty When Evaluating Supply Chain DesignAkshay_Raja_94150% (2)

- 2nd Quarter First Assessment in Gen. MathDocument3 pages2nd Quarter First Assessment in Gen. MathglaizacoseNo ratings yet

- TCS Recruitment Previous Year Pattern Questions Set-9Document2 pagesTCS Recruitment Previous Year Pattern Questions Set-9QUANT ADDANo ratings yet

- Analyzing Uber's Profitability with Porter's Five ForcesDocument2 pagesAnalyzing Uber's Profitability with Porter's Five ForcesMikey ChuaNo ratings yet

- Accounting 1 Review QuizDocument6 pagesAccounting 1 Review QuizAikalyn MangubatNo ratings yet

- Emory Endeavors in History Vol 3 2010Document125 pagesEmory Endeavors in History Vol 3 2010Maggie PeltierNo ratings yet

- Consumer Attitude Towards Gold OrnamentsDocument34 pagesConsumer Attitude Towards Gold OrnamentsDon Iz BackNo ratings yet

- Data For Giving His Heart More Room: Bruce Springsteen's Private FoundationsDocument63 pagesData For Giving His Heart More Room: Bruce Springsteen's Private FoundationsDavid WilsonNo ratings yet

- 05march 2019 - India - Daily PDFDocument39 pages05march 2019 - India - Daily PDFCoupant CapitalNo ratings yet

- Call Option Binomial Trees ExplainedDocument19 pagesCall Option Binomial Trees ExplainedDhaka SylhetNo ratings yet

- Marketing Rakura TeaDocument19 pagesMarketing Rakura TeaAnonymous G5ScwB50% (2)

- Inventory KPI - SAP TransactionsDocument3 pagesInventory KPI - SAP TransactionsGabrielNo ratings yet

- Chapter Four: Price and Out Put Determination Under Perfect CompetitionDocument49 pagesChapter Four: Price and Out Put Determination Under Perfect Competitioneyob yohannesNo ratings yet

- MMS Derivatives Lec 1Document85 pagesMMS Derivatives Lec 1AzharNo ratings yet

- Module 2c Notes ReceivableDocument35 pagesModule 2c Notes ReceivableChen HaoNo ratings yet

- How EasyJet's Marketing Transformation Drove 134% Revenue GrowthDocument10 pagesHow EasyJet's Marketing Transformation Drove 134% Revenue GrowthAmal HameedNo ratings yet

- Impact of GST on Indian FMCG SectorDocument42 pagesImpact of GST on Indian FMCG SectorManthanNo ratings yet

- ST Small Account Secrets Report FINALDocument33 pagesST Small Account Secrets Report FINALReginald RinggoldNo ratings yet

- 7096 w13 Ms 22Document8 pages7096 w13 Ms 22mstudy123456No ratings yet

- Distribution M1Document22 pagesDistribution M1Charmie EmotinNo ratings yet

- United States v. AMR Corporation, 335 F.3d 1109, 10th Cir. (2003)Document25 pagesUnited States v. AMR Corporation, 335 F.3d 1109, 10th Cir. (2003)Scribd Government DocsNo ratings yet

- CaseStudy-4 v2.0Document7 pagesCaseStudy-4 v2.0Salinda Arjuna LekamgeNo ratings yet

- AssignmentDocument2 pagesAssignmentnavneet26101988No ratings yet

- Budget and B Udgetary C OntrolDocument6 pagesBudget and B Udgetary C OntrolKanika DahiyaNo ratings yet

- Timbangan Elementary School 1 Quarter - 1 Assessment TLE-6 Name: - Score: - Grade/Section: - DateDocument3 pagesTimbangan Elementary School 1 Quarter - 1 Assessment TLE-6 Name: - Score: - Grade/Section: - DateJuraima RashaiNo ratings yet

- Managerial Applications of StatisticsDocument10 pagesManagerial Applications of StatisticsSai Aditya100% (1)