Professional Documents

Culture Documents

Advantages and Disadvantages of Composite Materials - Resin Systems

Uploaded by

Adil Alper CoskunOriginal Description:

Original Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Advantages and Disadvantages of Composite Materials - Resin Systems

Uploaded by

Adil Alper CoskunCopyright:

Available Formats

Care and Repair of Advanced Composites

~

~

Introduction to Composites

together to give the necessary mechanical strength or stiffness to the composite part. Today

this definition usually refers to fibers as reinforcement in a resin matrix, but it can also

include metal-skinned honeycomb panels, for example.

Reinforced concrete is a g~od example of a composite material. The steel and concrete

retain their individual identities in the fmished structure. However, because they work

together, the steel carries the ~nsion loads and the concn;te carries the compression loads.

Although not covered by this bpok, metal and ceramic qmtrix composites are being studied

intensively. Composites in structural applications have the following characteristics:

1.3 Advantages and Disadvantagesof Composites

Composite parts have both advantages and disadvantages when compared to the metal parts

they are being used to replace.

They generally c~>nsist of two or more physically dist,jPctaq4 mechanically separable

D1i!teriab. '. .. , J ,~~,;'"

They are made by mixing the separate materials in such a way as to achieve controlled

and lIniformdispersion of tbe con~titu~!1ts!

j:

j 1.3.1 Advantages of COmposites

J 1. A higher performance for a given weight leads to fuel savings. Excellent strength-to-

weight and stiffness-to-weight ratios can be achieved by composite materials. This is

usually expressed as strength divided by density and stiffness (modulus) divided by

density. These are so-called "specific" strength and "specific" modulus characteristics.

Laminate patterns and ply buildup in a part can be tailored to give the required

mechanical properties in various directions.

I

Mechanical properties of composites are superior to and in sowe cases uniquely differ-

ent from the properties of tbeif constituents. This is clearly seen with glass-reinforced

plastics (GRP). I~ the case of GRP, the epoxy re~iriis11relatively weak, flexible, and

brittle material, and although the glass fibers are strong and stiff, they can be loaded in

tension only as a bare fiber. W~en combined, the resin and fil:>e~ give a strong, stiff

composite with exceUent toughness characteristics.

It is easier to achieve smooth aerodynamic profiles for drag reduction. Complex

double-curvature parts with a smooth surface finish can be made in one manufacturing

operation.

4. Part count is reduced.

5. Pn)(luction cost is reduced. Composites may be made by a wide range of processes.

;~

1.2 History of Composite Materials'

1/

)

v

6. \ Composites offer excellent resistance to corrosion, chemical attack, and outdoor weath-

, ering;however,somechemicalsaredamagingtocomposites(e.g.,paint stripper),and

new types of paint and stripper are being developed to deal with this. Some thermo-

plastics are not very fesist~t to some solvents. Check ~e data sheets for each type.

A composite is, by definition, something made frOJDtWQor more components-in our case

here, a fiber and a resin. Compo~ites are no,tf1new ic:lIW' o~e~ floated down t~e Nile in a

basket made from'papyrus reeds coated with p~~S~'PaJlYI11~ is ~form of paper with a vis-

ible fibrous reinforcement; therefore, it would not hav~ been 4jfftcult to make a waterproof

basket from it. from ancient times, it was known that bricKsWere.stronger if filled with

chopped straw. African "mud" buts were reinforced witJtgras~es and thin sticks. The

Butser Hill farm project shows tJtat woven sticks, bonded with .. mixture of cow dung and

",ud, Wereused to build house w;1llsin England in 1500'B.<::.It would be interesting to

lCnowhow the correct mix ratio for the cow dung cpldthe mud was determined! The lath

and plaster walls in old English houses were a form of composit~. Although the concept is

old, the materials have changed. Carbon, aramid, and glass fibers are very expensive com-

pared to straw, and epoxy resins are costly compared to a mixture of cow dung and mud!

Fortunately, the performance for a given weight is much higher. There also are natural

composites such as wood. The structure of a tree consists of long, strong cellulose fibers

bonded together by a protein-like substance called lignin. The fibers that run up the trunk

and along the branches are thus aligned by nature in the optimum way to resist the stresses

~-experienced from gravity and wind forces. Large radii are provided at the trunk-to-branch

and branch-to-branch joints to reduce stress concentrations at high-load points.

1.3.2 Disadvantages ofComposites

1. Composites are more brittle than wrought metals and thus are more easily damaged.

Cast metals also tend to be brittle.

2. Repair introduces new problems, for the following reasons:

Materials require refrigerated transport and storage and have limited shelf lives.

.

Hot curing is necessary in many cases, requiring special equipment.

Curing either hot or cold takes time. The job is not finished when the last rivet has

been installed.

3. If rivets have been used and must be removed, this presents problems of removal with-

out causing further damage.

4. Repair at the original cure temperature requires tooling and pressure.

2

3

Care and Repair of Advanced Composites

~ ~

Introduction to Composites

5. Composites must be thoroughly cleaned of all contamination before repair.

6. Composites must be dried before repair because all resin matrices and some fibers

absorbmoisture. '

2. No health hazards.

.

3. More closely match fiber performance.

4. Good fire/smoke performance (interiors and fuel tanks and engine parts).

1.3.3 Advantages o/Thermoset Resin Composites

5. Good fatigue performance.

Thermoset resin composites have advantages and disad"antages when compared to thermo-

plastic resin composites. The advantages of thenn<~set reliin composites over thennoplastic

resincomposites includethefollowing: '

I. Thermosets will cure at lower temperatures than most thermoplastics will melt. There-

fore, thermosets can be manufactured at lower temperatures than thermoplast\cs.

6. Primary structure usage.

7. High temperature uses polyetheretherketone (PEEK) 250 to 300C (482 to 572F).

2. 1\vo-part systems can be cured at room temperature, and their cure can be speeded by

heating to approximately 80C (176F). \

3. A range of curing temperatures, particularly with epoxy systems, allows repair at lower

temperatures than the original cure.

8. Commercial applications include helicopter rotor blades, some high-strength interior

parts, and fairing panels on civil aircraft.

9. Future possibility of resin transfer molding (RTM) around reinforcing fiber or use in

conventional application mode (i.e., pre-preg stacking). Single crystal growth versions

could be used for engine parts.

4. Tooling can be used at lower temperatures than with thermoplastics.

5. Chemical resistance is generally good, but check for resistance to any chemicals that

may come into contact with the part. For example, some epoxies are more resistant to

chemicals than others. "

1.3.6 Disadvantages o/Thermoplastlc Resin Composites

1. Cost.

2. New process methods.

3. Long-term fatigue characteristics unknown.

1.3.4 Disadvantages o/Thermoset Resin Composites

1. Slow to process'(cold store/thaw/cure).

4. Temperature to melt for repairs is very high in some cases. This could cause serious

problems for in-situ repairs to primary or secondary structures, especially if being done

near fuel tanks or hydraulic systems.

5. Polyimides suffer microcracking (Ref. 1.1).

2. Relatively low toughness, environmental performance, and strength.

I

~. Can be health hazards.

h. Slowto repair.

1.4 Applications of Composites to Modem Aircraft, Yachts,

Cars, and 1i'ains

1.3.5 Advantages o/Thermoplastlc Resin Composites

1.4.1 Early Aircraft Structures

The advantages of thermoplastic resin composites over thermoset resin composites include

the following:

Early aircraft were composite-based structures because they were' built from wood, which

is a composite material comprising a cellulose/lignin mixture that gives wood its excellent

strength-to-weight performance and properties of resilience and damage resistance. How-

ever, woodis subjecttodeteriorationby moisture-induceddecayandattackfromfungal

growths. By the 1930s, wooden aircraft structures began to be replaced by stressed-skin,

monocoque aluminum alloy structur~s.

1. Thermoplastic resin composites are much tougher than thermosets and offer fast pro-

~. cessing times and good environmental performance, except against certain solvents in

some cases. Again, check each material and its response to each solvent likely to be

encountered.

,

4

5

You might also like

- Introduction-2: Ahmet ErkliğDocument37 pagesIntroduction-2: Ahmet ErkliğSelva KumarNo ratings yet

- Engineered Materials Physical Chemical Properties Macroscopic Microscopic ScaleDocument4 pagesEngineered Materials Physical Chemical Properties Macroscopic Microscopic ScaleStroie AlinaNo ratings yet

- AMP SignedDocument14 pagesAMP SignedYash KadiyaNo ratings yet

- Submitted To: Composite MaterialDocument8 pagesSubmitted To: Composite MaterialMunish DhimanNo ratings yet

- Advanced Composite Materials in Typical Aerospace Applications-LibreDocument10 pagesAdvanced Composite Materials in Typical Aerospace Applications-LibrezaujahaminNo ratings yet

- Composites (Aviation/Aircraft) - ReportDocument57 pagesComposites (Aviation/Aircraft) - ReportChristian100% (2)

- Composite Materials: Advantages and Cost FactorsDocument5 pagesComposite Materials: Advantages and Cost FactorsCoop StElzearNo ratings yet

- 5th (B) ModuleeeDocument26 pages5th (B) ModuleeeHarshitha j gowdaNo ratings yet

- 2-Final Project ReportDocument134 pages2-Final Project ReportAbhimanyu RanaNo ratings yet

- Material For Wind Turbine BladesDocument4 pagesMaterial For Wind Turbine BladesAsif Khan NiaziNo ratings yet

- FRP Sandwich Panel Properties Uses AdvantagesDocument21 pagesFRP Sandwich Panel Properties Uses AdvantagesNaag RajNo ratings yet

- Composite Material-CEQS104-May 2022Document27 pagesComposite Material-CEQS104-May 2022mactessalNo ratings yet

- Thermoplastic Composites - Best Practice GuideDocument49 pagesThermoplastic Composites - Best Practice GuidemanikandapriyaNo ratings yet

- STUDIES ON WEAR BEHAVIOUR OF PMMA-B4C-SiCHYBRIDCOMPOSITEDocument10 pagesSTUDIES ON WEAR BEHAVIOUR OF PMMA-B4C-SiCHYBRIDCOMPOSITESantosh SanchetiNo ratings yet

- Composites (Byprem LataDocument48 pagesComposites (Byprem LatalvvjkhpoggpskjzcpwNo ratings yet

- Referat Case StudyDocument4 pagesReferat Case StudyRazvan BuzilaNo ratings yet

- Lecture 2 Advanced Composites MEC509J2Document14 pagesLecture 2 Advanced Composites MEC509J2Ben MurrayNo ratings yet

- SEMINAR ON JEORI COMPOSITE MATERIALSDocument21 pagesSEMINAR ON JEORI COMPOSITE MATERIALSTarun jajuaNo ratings yet

- High voltage cable accessories design and manufacturingDocument22 pagesHigh voltage cable accessories design and manufacturingMuhAinun16No ratings yet

- CM NotesDocument136 pagesCM NotesFayaz KhanNo ratings yet

- Composite Material GuideDocument34 pagesComposite Material GuideAISHWARYANo ratings yet

- Review of Composite Materials and Applications: M.K.S.SaiDocument7 pagesReview of Composite Materials and Applications: M.K.S.SaiTejas shastrakarNo ratings yet

- Composite Factory1 Dani 3Document9 pagesComposite Factory1 Dani 3abdulber kedirNo ratings yet

- Lecture NotesDocument44 pagesLecture NotesRaj KumarNo ratings yet

- Hybrid CompositeDocument91 pagesHybrid Compositemanoharbyalal100% (3)

- 2023MSEII Handout10Document16 pages2023MSEII Handout10王竣右No ratings yet

- CompositeDocument4 pagesCompositeAshok PradhanNo ratings yet

- Department of Chemical EngineeringDocument7 pagesDepartment of Chemical EngineeringAngelyn de LaraNo ratings yet

- Assignment: Submitted by R.Deepa 116011001503 Ii Yr / Iv SemDocument6 pagesAssignment: Submitted by R.Deepa 116011001503 Ii Yr / Iv SemR. Deepa - ANo ratings yet

- Introduction To Advanced Composite MaterialsDocument47 pagesIntroduction To Advanced Composite MaterialsMr. Naveena B.E.No ratings yet

- UNIT 1 NotesDocument44 pagesUNIT 1 NotesArun KumarNo ratings yet

- Carbon Fiber Reinforced Plastics in Aircraft Construction: C. SoutisDocument6 pagesCarbon Fiber Reinforced Plastics in Aircraft Construction: C. SoutisMizanNo ratings yet

- Carboncarbon Composite Application Areas and LimitationsDocument6 pagesCarboncarbon Composite Application Areas and Limitationsmohan babuNo ratings yet

- Composites REVOLUTIONISE AEDocument3 pagesComposites REVOLUTIONISE AEmachit_xNo ratings yet

- Composite MaterialDocument92 pagesComposite MaterialAparna RNo ratings yet

- High Temperature Insulated Hybrid Yarns for Carbon Fiber CompositesDocument6 pagesHigh Temperature Insulated Hybrid Yarns for Carbon Fiber CompositesHarun VenkateshNo ratings yet

- Basics of Composite Materials GuideDocument47 pagesBasics of Composite Materials Guideandrw1987No ratings yet

- Pap 1263Document10 pagesPap 1263dselva_kumaranNo ratings yet

- PMC MMC CMM FindingsDocument4 pagesPMC MMC CMM Findingssilent spritsNo ratings yet

- Failure Mechanisms in Toughened Epoxy Resins A Review: Amar C. GargDocument45 pagesFailure Mechanisms in Toughened Epoxy Resins A Review: Amar C. GargVansala GanesanNo ratings yet

- 6 Advanced Polymer Composite Propeller BladesDocument12 pages6 Advanced Polymer Composite Propeller BladesThomas MouraNo ratings yet

- The Future of Composites in Gas Turbine EnginesDocument4 pagesThe Future of Composites in Gas Turbine EnginessenthilNo ratings yet

- Mechanical and Water Absorption Behavior of Sisal and Banana Fiber CompositesDocument49 pagesMechanical and Water Absorption Behavior of Sisal and Banana Fiber CompositesKutty AravindNo ratings yet

- CH-3 MachiningDocument16 pagesCH-3 MachiningAbreham DerejeNo ratings yet

- Chapter-4: 4.1 Matrix MaterialsDocument17 pagesChapter-4: 4.1 Matrix MaterialsSasiKumar PetchiappanNo ratings yet

- Project Report.....Document19 pagesProject Report.....Hitesh Parghi100% (2)

- Composite Materials 1Document7 pagesComposite Materials 1Kiruba ShankerNo ratings yet

- Seminar On Composite MaterialsDocument27 pagesSeminar On Composite MaterialsNikhilesh Kadukar100% (3)

- Song 2016Document8 pagesSong 2016AnkushNo ratings yet

- TenCate Chopped Fiber Thermoplastics Compression Molding Technical PaperDocument14 pagesTenCate Chopped Fiber Thermoplastics Compression Molding Technical PaperJohnny 17No ratings yet

- Composite Materials Applicationsxhapter1Document94 pagesComposite Materials Applicationsxhapter1GOUAL SaraNo ratings yet

- Buckling Anaysis of Shell Panel ComponentsDocument55 pagesBuckling Anaysis of Shell Panel Componentsbhukya bhavsinghNo ratings yet

- Fibre Reinforced Cement CompositesDocument51 pagesFibre Reinforced Cement Compositesravi1625100% (1)

- Composite Material Selection For An Aeronautical ComponentDocument16 pagesComposite Material Selection For An Aeronautical ComponentIsrael Alejandro Almaguer AcevedoNo ratings yet

- COMPOSITEDocument19 pagesCOMPOSITEDasrat KumarNo ratings yet

- Composite Materials AyDocument5 pagesComposite Materials Ayardonando123No ratings yet

- Karbon Cam Karşılaştırma 2Document10 pagesKarbon Cam Karşılaştırma 2Hasanmert KaymakNo ratings yet

- Non-Metallic Applications in Oil - Gas IndustryDocument6 pagesNon-Metallic Applications in Oil - Gas IndustryzaheerNo ratings yet

- Self-healing Ceramic Matrix Composites: A MonographFrom EverandSelf-healing Ceramic Matrix Composites: A MonographNo ratings yet

- Advanced Manufacturing ScienceDocument3 pagesAdvanced Manufacturing Sciencemukesh3021No ratings yet

- Trends and Issues of The Cut Flower-372Document27 pagesTrends and Issues of The Cut Flower-372pohzaNo ratings yet

- SCM Group 14 SecBDocument42 pagesSCM Group 14 SecBPrateek ChopraNo ratings yet

- Glass Fiber Properties and UsesDocument14 pagesGlass Fiber Properties and Usesjulio1051No ratings yet

- The A-Z 3D Printing Handbook PDFDocument29 pagesThe A-Z 3D Printing Handbook PDFfranco1600100% (6)

- Om Enterprises, Technochem Industries, Suraj Coats contact detailsDocument3 pagesOm Enterprises, Technochem Industries, Suraj Coats contact detailsAbdul FaheemNo ratings yet

- 7 Product Realization RequirementsDocument10 pages7 Product Realization RequirementsArman Ul Nasar0% (1)

- Aatc Spec 114012Document39 pagesAatc Spec 114012JD100% (1)

- Alkhrdaji - ACI 562 - Design Strength LimintsDocument26 pagesAlkhrdaji - ACI 562 - Design Strength Limintseros100% (1)

- QWDocument10 pagesQWKanokwan MahattanaNo ratings yet

- Tiles ProcessDocument7 pagesTiles Processinkera - HRNo ratings yet

- Pet Market OjooDocument14 pagesPet Market OjooJuan Pablo Fajardo SánchezNo ratings yet

- Nes 747Document252 pagesNes 747Soumya Ranjan Subudhi100% (1)

- Epofine 556 - Finehard 22962Document5 pagesEpofine 556 - Finehard 22962Karishma PrabhuNo ratings yet

- Global Productivity Aggregate DatabaseDocument81 pagesGlobal Productivity Aggregate DatabaseESTEFANIARANGNo ratings yet

- 171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQDocument4 pages171 Gtaw&Smaw Zug Asme (Ade S 5g) WPQMuhammad Fitransyah Syamsuar PutraNo ratings yet

- KELTEC Technolab CECOELDocument40 pagesKELTEC Technolab CECOELEber.CV100% (1)

- Monopolistic Competition: Test ADocument7 pagesMonopolistic Competition: Test Amas_999No ratings yet

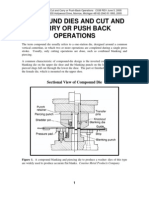

- Compound Die DesignDocument6 pagesCompound Die Designfzulkarnaen_1No ratings yet

- Pemrograman NCDocument3 pagesPemrograman NCPurwadyaziNo ratings yet

- Manholes PolycreteDocument8 pagesManholes PolycreteLuzmin DelaCruzNo ratings yet

- Oil and Gas Production Handbook Ed3x0 - Web - Part11Document2 pagesOil and Gas Production Handbook Ed3x0 - Web - Part11joshua_tan_31No ratings yet

- Ford and World Automobile IndustryDocument6 pagesFord and World Automobile IndustrySahoo SK100% (1)

- C&S Catlogue 90 W INDustrial 9200Document68 pagesC&S Catlogue 90 W INDustrial 9200Abhishek KumarNo ratings yet

- Furnace Startup and Shutdown ProceduresDocument5 pagesFurnace Startup and Shutdown ProceduresaiensyafiqahNo ratings yet

- Drilling Accessories DHOT - Catalog - 11 - 11 - 12 PDFDocument59 pagesDrilling Accessories DHOT - Catalog - 11 - 11 - 12 PDFyacine15100% (3)

- Konvensyen Kesatuan Sekerja 2015 PDFDocument24 pagesKonvensyen Kesatuan Sekerja 2015 PDFKaoru AmaneNo ratings yet

- NEEV IIM Kashipur Schenieder CaseDocument9 pagesNEEV IIM Kashipur Schenieder CaseVuppada Raja Sekhar Reddy100% (1)

- Pipe Welding ProceduresDocument257 pagesPipe Welding ProceduresKhaeril Anwar100% (1)

- Term Paper Mec 208Document20 pagesTerm Paper Mec 208lksingh1987No ratings yet