Professional Documents

Culture Documents

4 Watt RF Power Amplifier For 2 GHZ - 2

Uploaded by

Krisna GivariOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

4 Watt RF Power Amplifier For 2 GHZ - 2

Uploaded by

Krisna GivariCopyright:

Available Formats

4 Watt RF Power Amplifier for 2 GHz

Overview

This is a redesign of the Motorola MHL19338based 4 watt, 2.0 GHz range amplifier from GBPPR

'Zine, Issue #52. I noticed that when this amplifier module is operating on "outofband"

frequencies, the operation wasn't very stable. This could be attributed to the module's heatsink tab

(ground) to circuit board connections, which need to have a very low inductance path to

ground. This can be difficult to accomplish using standard PC board materials and construction

techniques.

This newer version uses a layout which will eliminate the need for a PC board altogether. The

hybrid power module and its passive supporting components will be mounted, and soldered directly,

to a piece of tin plate (K&S Metal #254), which is then attached to the aluminum heatsink. This

provides both a rugged, physically stable, amplifier base and a low inductance RF ground path.

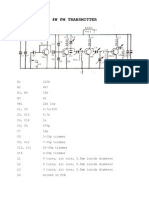

Schematic

29

Pictures & Construction Notes

The aluminum heatsink (left) and the K&S Metal #254 tin sheet.

The aluminum heatsink already has the necessary mounting holes drilled and tapped.

Two #6 stainless steel screws will secure the MHL19338 to the heatsink and tin sheet. Four #8

stainless steel screws with washers will secure the tin sheet to the heatsink.

30

Attach the tin sheet to the heatsink using the proper hardware. Be sure the tin plate fits the heatsink

and that there are no air gaps.

Next, you can attach the MHL19338 to the heatsink. No thermal paste was used, as that can also

lead to RF stability problems. We'll be cooling the MHL19338 using only passive means in this

application. Be sure to not overtighten the MHL19338's mounting screws or you can break the

delicate circuit board inside the module itself.

On the RF output and input pins, solder two rightangle MCX or SMA connectors directly to the tin

sheet, with the RF connector's center pin connected to the MHL19338's respective pin. This

process will require a substantial amount of heat, so use a fairly large solder iron, but try to minimize

the amount of time spent heating the general area.

An optional solder terminal block, with a builtin fuse holder, was added to mount the +28 VDC

power supply connections to.

31

Attach the rest of the passive components.

You can kinda see the two little brown SMT 0.01 F capacitors attached from the MHL19338's V

dd

pins to the ground plane.

The solder terminal strip acts as a common tie point for the +28 VDC power supply lines. The large

diode is for polarity protection. The 1 amp fuse is for current protection.

32

Alternate view.

The two large black round things on the MHL19338's V

dd

power lines are ferrite beads.

33

Construction of the ammo box case for this project.

The +28 VDC power input will come in via two banana jacks with a 0.01 F ceramic bypass

capacitor them at the input.

A panelmounted powerindicated green LED is above that.

The RF input and output will be via two panelmounted N jacks with MCX plug connections.

34

Mounting the amplifer and heatsink like so.

The heatsink should technically be mounted fins up, but this amplifier doesn't get that hot, and the

case it's attached to helps to draw away excess heat.

A copy of the MHL19338 data sheet is included in the case.

35

Outside case overview.

This amplifier will do an easy four watts at around 2 GHz with a 10 mW drive, and will now be much

more stable when operating outofband, even on GPS frequencies! Hehee...

Here is a chart of the RF power output of this particular amplifier when driven with a Micronetics

M35001324 at around +5 dBm. The output RF power was measured on a Bird APM16 RF power

meter using a 5 watt 1.72.2 GHz APM5L slug.

Frequency (MHz) RF Power Output (Watts)

1575 1.3 (L1 GPS)

1650 2.1

1700 2.6

1750 3.0

1800 3.3

1850 3.5

1900 3.7

1950 4.0

2000 3.7

2050 3.5

2100 3.4

2150 3.4

2200 2.4

2250 2.0

2300 1.0 (Ham Band)

2350 0.9

2400 0.8 (Ham Band)

2450 0.5 (Ham Band)

2500 0.1

36

You might also like

- Pages From Pages From Pages1-50 From FAR2XX7 - SvcManDocument50 pagesPages From Pages From Pages1-50 From FAR2XX7 - SvcManornardys PenicheNo ratings yet

- GBPPR 'Zine - Issue #69Document62 pagesGBPPR 'Zine - Issue #69GBPPRNo ratings yet

- 4w FM TransmitterDocument9 pages4w FM TransmitterMantas PauliukonisNo ratings yet

- Philips RF Manual 5th Edition AppendixDocument35 pagesPhilips RF Manual 5th Edition AppendixAnanda KrishnaNo ratings yet

- An-1022 Mechanical and Thermal Considerations in Using RF Linear Hybrid AmplifiersDocument5 pagesAn-1022 Mechanical and Thermal Considerations in Using RF Linear Hybrid AmplifiersEdward YanezNo ratings yet

- An-955 A Cost Effective VHF Amplifier For Land Mobile RadiosDocument8 pagesAn-955 A Cost Effective VHF Amplifier For Land Mobile RadiosEdward YanezNo ratings yet

- A SMT Dual Gate Mosfet Preamplifier For 50 MHZ.: Latest Update 29nov2015Document4 pagesA SMT Dual Gate Mosfet Preamplifier For 50 MHZ.: Latest Update 29nov2015wayan.wandira8122No ratings yet

- Sme35190b Far2x07serDocument514 pagesSme35190b Far2x07serkrupa kumar100% (1)

- The FARA 2 Meter Amplifier ProjectDocument9 pagesThe FARA 2 Meter Amplifier ProjectDhemitz AjaNo ratings yet

- 250mW Mono FM Transmitter KitDocument2 pages250mW Mono FM Transmitter Kitjesus fuentesNo ratings yet

- 250 MW TransmissorDocument2 pages250 MW TransmissorLuis David Cajavilca CutimancoNo ratings yet

- 250 MW TransmissorDocument2 pages250 MW TransmissorLuis David Cajavilca CutimancoNo ratings yet

- GBPPR 'Zine - Issue #6Document58 pagesGBPPR 'Zine - Issue #6GBPPRNo ratings yet

- 8W 144MHz linear amplifierDocument9 pages8W 144MHz linear amplifiersamsularief03No ratings yet

- Low Cost 20MHz Function Generator With MAX038Document10 pagesLow Cost 20MHz Function Generator With MAX038buditux100% (1)

- A600 v2.1 Amplifier Kit Full Assembly InstructionsDocument16 pagesA600 v2.1 Amplifier Kit Full Assembly InstructionsWeishan LiaoNo ratings yet

- GBPPR 'Zine - Issue #94Document66 pagesGBPPR 'Zine - Issue #94GBPPRNo ratings yet

- 450 Watt 6m Amplifier: Chris, G3WOS - July 1993Document10 pages450 Watt 6m Amplifier: Chris, G3WOS - July 1993Adrian DrakesNo ratings yet

- GBPPR 'Zine - Issue #118Document48 pagesGBPPR 'Zine - Issue #118GBPPR100% (1)

- Hall-Effect Latches: FeaturesDocument8 pagesHall-Effect Latches: Featuresjdaudpoto100% (1)

- Provide A Summary of The Components Used in Your Group Traffic Lights Subsystem Schematic by Filling Table 1Document5 pagesProvide A Summary of The Components Used in Your Group Traffic Lights Subsystem Schematic by Filling Table 1Evans MuokiNo ratings yet

- Fara AmplifierDocument5 pagesFara AmplifierDefaultAnomoly100% (1)

- Kit 4. Hobby Power Supply: What To Do If It Does Not WorkDocument2 pagesKit 4. Hobby Power Supply: What To Do If It Does Not WorkChris ThinkerNo ratings yet

- Data Sheet: UHF Push-Pull Power MOS TransistorDocument15 pagesData Sheet: UHF Push-Pull Power MOS Transistoragmnm1962No ratings yet

- LM3886 Gainclone 2x68 Watt Full Amplifier ProjectDocument5 pagesLM3886 Gainclone 2x68 Watt Full Amplifier ProjectJustin AntonioNo ratings yet

- Peter, Your Email Address Malfunctioned. Please Try Again.: Ics and ModulesDocument20 pagesPeter, Your Email Address Malfunctioned. Please Try Again.: Ics and Modulessarantapodarusa4009No ratings yet

- High Power Rfmicrowave Transistors Pallets and AmplifiersDocument6 pagesHigh Power Rfmicrowave Transistors Pallets and AmplifiersItzaNo ratings yet

- Wireless FM TransmitterDocument11 pagesWireless FM Transmitteranon-73153100% (4)

- 4.) - General - Using - of - IGBT - Modules GOOD PDFDocument26 pages4.) - General - Using - of - IGBT - Modules GOOD PDFDoDuyBacNo ratings yet

- Lm3875 ManualDocument26 pagesLm3875 Manualadyo14No ratings yet

- Cascadable Broadband Gaas Mmic Amplifier DC To 6GhzDocument8 pagesCascadable Broadband Gaas Mmic Amplifier DC To 6Ghzrazali1982No ratings yet

- 300 Watt Fet Amp Apt9801Document6 pages300 Watt Fet Amp Apt9801Stephen Dunifer100% (9)

- LG Beko 28cz10rx Service ManualDocument32 pagesLG Beko 28cz10rx Service ManualAlan ScarfidiNo ratings yet

- Directional Coupler PDFDocument7 pagesDirectional Coupler PDFlazarosNo ratings yet

- 3600xxx SSB Mosfet PDFDocument13 pages3600xxx SSB Mosfet PDFricampos08No ratings yet

- LM386 Is A Low Voltage Audio Amplifier and Frequently Used in Battery PoweredDocument10 pagesLM386 Is A Low Voltage Audio Amplifier and Frequently Used in Battery PoweredShivraj BankarNo ratings yet

- Metrobility Twister1580195283Document16 pagesMetrobility Twister1580195283honeyNo ratings yet

- Baofeng BF 888S Low Power Modification For BRIAN 1Document4 pagesBaofeng BF 888S Low Power Modification For BRIAN 1Fidel Atahuichi TorrezNo ratings yet

- Induction Cooker TeardownDocument14 pagesInduction Cooker TeardownNguyễn Hồng DươngNo ratings yet

- FM Ogre - BOM & Build InfoDocument6 pagesFM Ogre - BOM & Build InfoDan LNo ratings yet

- Microcor Transmitter MT-9485-Man Rev NCDocument27 pagesMicrocor Transmitter MT-9485-Man Rev NCfelio ossoNo ratings yet

- Mic 4575Document15 pagesMic 4575JUAN RODRIGUEZNo ratings yet

- RD30HVF1Document8 pagesRD30HVF1David Bohorquez RamosNo ratings yet

- Ak-270 Hex3653 FM Receiver Diy KitDocument13 pagesAk-270 Hex3653 FM Receiver Diy KitOséias Lima VieiraNo ratings yet

- CombinerDocument10 pagesCombiner4z4rbNo ratings yet

- 86 A Grid Dip Oscillator: 1. It Has A Frequency Range of 1.6 To 35.2 MHZ in Four Ranges Using A Set ofDocument7 pages86 A Grid Dip Oscillator: 1. It Has A Frequency Range of 1.6 To 35.2 MHZ in Four Ranges Using A Set ofMauro MarafonNo ratings yet

- 222 MHZ Transverter, Mark 3: Paul Wade W1Ghz ©2020Document27 pages222 MHZ Transverter, Mark 3: Paul Wade W1Ghz ©2020Sharbel AounNo ratings yet

- Gm-300 Service ManualDocument93 pagesGm-300 Service Manualeh2677No ratings yet

- Yaesu FT-101ZD Service ManualDocument193 pagesYaesu FT-101ZD Service ManualYayok S. AnggoroNo ratings yet

- ELECTRICAL SCOPEDocument11 pagesELECTRICAL SCOPESAMEERNo ratings yet

- PWMcircuit 08Document10 pagesPWMcircuit 08kcarringNo ratings yet

- Audio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsFrom EverandAudio IC Projects: A Collection of Useful Circuits Based on Readily Available ChipsNo ratings yet

- Power Supply Projects: A Collection of Innovative and Practical Design ProjectsFrom EverandPower Supply Projects: A Collection of Innovative and Practical Design ProjectsRating: 3 out of 5 stars3/5 (2)

- Radio Frequency Transistors: Principles and Practical ApplicationsFrom EverandRadio Frequency Transistors: Principles and Practical ApplicationsRating: 4 out of 5 stars4/5 (2)

- Semiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsFrom EverandSemiconductor Data Book: Characteristics of approx. 10,000 Transistors, FETs, UJTs, Diodes, Rectifiers, Optical Semiconductors, Triacs and SCRsNo ratings yet

- Diode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesFrom EverandDiode, Transistor & Fet Circuits Manual: Newnes Circuits Manual SeriesRating: 4.5 out of 5 stars4.5/5 (7)

- Radio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142From EverandRadio Shack TRS-80 Expansion Interface: Operator's Manual Catalog Numbers: 26-1140, 26-1141, 26-1142No ratings yet