Professional Documents

Culture Documents

Monomer Env Impact Study

Uploaded by

nikhaarjCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Monomer Env Impact Study

Uploaded by

nikhaarjCopyright:

Available Formats

Environmental

Impact

Assessment for

Monomer

Chemical Ind.

Pvt. Ltd.

(Unit II)

Synthetic Dye & dye

Intermediate

Prepared By :

M/s. Sadekar Enviro Engineers

Pvt. Ltd.

Pre Mansoon data (Feb 2011- May 2011)

Revised By

M/s Monomer Chemicals Industries

Pvt. Ltd.

(Unit No - II)

Plot No. K-4, Additional Ambernath MIDC,

Anandnagar, Ambernath (E),

Dist. : Thane

May - 2012

Revised

After 54

th

Meeting

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

1

CONTENTS

1.THEPROJECT....................................................................................................................................................4

1.1FACILITIESATPROJECTSITE .................................................................................................................................4

1.2MANUFACTURINGPROCESSDYES.......................................................................................................................8

1.3FASTBLUEBBASE ................................................................................................................................................8

1.4PHTHALOGENBLUEIBN.......................................................................................................................................8

1.5REACTIVEDYES: ...................................................................................................................................................9

1.6VATDYES..............................................................................................................................................................9

2ENVIRONMENTALIMPACTASSESSMENT ........................................................................................................23

2.1ENVIRONMENTALIMPACTASSESSMENT ......................................................................................................................23

2.2AIRENVIRONMENT .................................................................................................................................................24

2.3NOISEENVIRONMENT .............................................................................................................................................24

2.4WATERENVIRONMENT............................................................................................................................................25

2.5LANDENVIRONMENT ..............................................................................................................................................25

2.6BIOLOGICALENVIRONMENT......................................................................................................................................25

2.7SOCIOECONOMIC&HEATHENVIRONMENT................................................................................................................25

3.BASELINEENVIRONMENTALSTATUSANDIDENTIFICATIONOFIMPACTS.......................................................28

3.1AIRENVIRONMENT .................................................................................................................................................28

3.2 NOISE ENVIRONMENT.......................................................................................................................................39

3.3WATERENVIRONMENT............................................................................................................................................42

3.4LANDENVIRONNENT ...............................................................................................................................................61

3.5ECOLOGICAL&BIOLOGICALENVIRONMENT .................................................................................................................80

3.6SOCIOECONOMICENVIRONMENT ...........................................................................................................................101

4.PREDICTIONOFIMPACTS ............................................................................................................................110

4.1 AIRENVIRONMENT........................................................................................................................................110

4.2 NOISEENVIRONMENT ....................................................................................................................................112

4.3 WATERENVIRONMENT ..................................................................................................................................115

4.4 LANDENVIRONMENT.....................................................................................................................................115

4.5BIOLOGICALENVIRONMENT....................................................................................................................................116

4.6SOCIOECONOMICENVIRONMENT ...........................................................................................................................116

5.ENVIRONMENTALIMPACTSTATEMENT........................................................................................................124

6.ENVIRONMENTALMANAGEMENTPLAN......................................................................................................127

7RISKASSESSMENTANDDISASTERMANAGEMENTPLAN...............................................................................151

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

2

7.1RISKASSESSMENT.................................................................................................................................................151

7.2DISASTERMANAGEMENTPLAN.......................................................................................................................177

8.MATERIALSAFETYDATASHEETLIST ............................................................................................................187

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

3

C

C

H

H

A

A

P

P

T

T

E

E

R

R

I

I

T

T

H

H

E

E

P

P

R

R

O

O

J

J

E

E

C

C

T

T

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

4

1.THEPROJECT

M/s. Monomer Chemical Industries Pvt. Ltd. (Unit 2), Ambernath has been

proposed New Dye Intermediate Manufacturing plant. The main product of the

proposed project is Synthetic Organic Dyes & Dye Intermediates. Capacity of proposed

manufacturing project is 2100 MT/ Annum. The MIDC Plot No. K-4, owned by M/s.

Kashya Textile Ltd. has been purchased by Monomer with ready setup inclusive of

factory building, water supply, electricity supply drainage facility etc.

The capital investment of proposed project is Rs. 8.0 Crore. The project details at

a glance were furnished in Table 1.1 & 1.2.

1.1FACILITIESATPROJECTSITE

The plant have wide facilities like gate house, Quality control lab, Dispatch

center, Utility and change Room, Raw material store (chem.), Engg. Workshop, Scrap

Yard Store Area, Kitchen (Canteen), Cooling tower, Boiler, Over head water storage

tank, Production Building, Office, Packaging Room & Finished Products store room,

Hazardous waste storage area, Effluent Treatment Plant, Waste water analysis lab. The

overall plot plan is shown in Fig. 1.1 .

The details of all equipment & Area distribution are shown in Table 1.3 & Table

1.4. The industry has good employment facility. The details of employment are shown

in Table 1.5 & Table 1.6.

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

5

SITE PHOTOGRAPH OF PROPOSED PROJECT

(EXISTING STUCTURE OF KASHA TEXTILE)

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

6

SITE PHOTOGRAPH OF PROPOSED PROJECT

(EXISTING STUCTURE OF KASHA TEXTILE)

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

7

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

8

1.2MANUFACTURINGPROCESSDYES

1.3FASTBLUEBBASE

1. Add ONA to the mixture of methanol, caustic and dichlone in 2-3 hours.

Maintain the reaction mass for 6 hrs. Then add formaldehyde in 5 hrs and

maintain. Filter methanol layer to obtain wet cake. Recover methanol by

distillation and use for next batches

2. Add the resultant wet cake to the mixture of cold dilute sulphurinc acid and thio

urea. Stir for 1 hr to complete the reaction. Isolate the product by HCL and salt.

Filter isolated product to get wet cake

3. Neutralise the wet cake with soda ash. Filter and wash. Dry and blend to obtain

Fast Blue B Base.

1.4PHTHALOGENBLUEIBN

Stage I: (A) Metal Phthalocyanines

Nitrobenzene solvent is charged in a vessel, it is dried for 2 hrs to remove traces

of water. Then phtahlic anhydride is charged along with carbamide . The metal

salt is then charged along with ammonium chloride and heated upto 175 degrees

centigrade. After the reaction. Solvent is recovered and the crude dry material is

obtained. This crude is then purified by treating with sulphuric acid 5 % at 90

o

C, filtered and washed acid free, dried and pulverized and CoPC obtained is

used for next stage-II

Stage II: (B) Phthalogen Blue IBN (Final Product)

The CoPC is chlorinated with Cl

2

gas in presence of ODCB at room tempreture.

After completion of reaction the unreacted Cl2 gas is scrubbed in scrubber by

circulating alkaline water. The above reaction mass is aminated with amine in

presence of methanol as solvent at room temperature. After completion of

reaction, recover the solvent by simple distillation. After recovery of methanol

the reaction mass is cooled to 25 degrees centigrade, filtered and centrifuged. The

filter is collected in storage receiver and recycled for further batches. Solid

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

9

product loaded to tray dryer after and pulverizing the material is sent for testing,

standardization tone adjustment, dilution etc and packaging for dispatch

1.5REACTIVEDYES:

The base of dye is formed by diazotization of amino compound with hydrochloric

acid & Sodium Nitrite at 0-5 C .Then above diazo compound is coupled with

another suitable compound in solution form at neutral PII.

The base is then first condensed with cynuric Chloride and then with alkaline amine

compound at neutral pH and 40 C 45 C temperature. The final dye in solution

formed is then clarified through filter press to remove insoluble objects if any, the

clear dye liquid of neutral pH is taken for spray drying and dried at suitable

temperature. The powder dye obtained is then standardized for shade, strength and

tone against standard product in blender or ball mill.

The finished products is then discharged

1.6VATDYES

Vat dyes are having high all round fastness properties when applied to cellulose

fibers. They are marked in a range of physical forms such as ultra cone, powder and

micro disperse. They are supplied in water insoluble form. We have imported vat

dyes crude, crude means highly concentrated. This crude dyestuff is mixed with

required quantity of dispersing agent (Sodium Lignin Sulphonate- Borresperse 3 A).

Together with Naphthalene sulphonate & sequesting agent for & hours to get

smooth homogeneous suspense. This suspension is then sand milled using galss

beads for particle size reduction.

After achieving required size the slurry is sieved & standardized using Napthalene

sulphonates for necessary shade & strength.

The standardized slurry is finally spray dried & packed as finished goods.

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

10

Detail of Proposed Solvent Recovery System :

Process Detail :

The solvents will be recover and reuse for the process. The fixed volume of Spent

solvent shall be charge into the SS reactor for recovery and heated, to distil out

collected in receiver. The residue left in the reactor shall be drain in open HDPE

drum. The small quantity of solid waste material (Tar Type material) may be float

on top surface and which will be taken out and collected in drums /containers. The

washing effluent shall be drain to E.T.P. for further treatment & the solid wastes are

shall be dispose through CHWTSDF.

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

11

Schematic Enclosed:

S.S Reactor

Residue

H.D.P.EDrum

LiquidWaste(i.eWater)

Condenser

S.SReceiver

Recovered

Solvents

Spent

Solvent

Solidwaste

Reflux

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

12

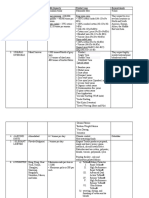

TABLE: 1.1 : PRODUCT MANUFACTURED IN PROPOSED PROJECT

Sr. No Name of Product

Proposed Production

Capacity

1

Synthetic Organic Dyes &

Intermediates

2100 MT/Annum

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

13

TABLE 1.2 : RAW MATERIAL USED IN PROPOSED PROJECT

SYNTHETIC ORGANIC DYES & INTERMEDIATES = 2100 MT/A

Sr. No.

List Of The Raw Materials Used At

All Stages Of Manufacture

Raw Material Utilization

(MT/Annum) for Full

Consumption Capacity

1 NMJ Acid 25

2 S.Tobias Acid 35

3 Caustic Soda (Flakes) 40

4 Hydrochloric Acid 90

5 Sodium Nitrite 60

6 Acetic Anhydride 25

7 Soda Ash 120

8 Salt Fine 250

9 Cynuric Chloride 30

10 Liquor Ammonia 30

11 Sulphamic Acid 1

12 Vinyl Sulphone Ester 145

13 S.P.C.P. 150

14 H. Acid 10

15 Orthanilic Acid 3

16 O. T. Liquid 1.5

17 MPDSA 6

18 DASDA 2

19 Sodium Bi Carbonate 10

20 K.Acid 10

21 MUA 5

22 Oil H.S. 2

23 BDSA 1

24 Metanilic Acid 10

25 MOP 15

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

14

Sr. No.

List Of The Raw Materials Used At

All Stages Of Manufacture

Raw Material Utilization

(MT/Annum) for Full

Consumption Capacity

26 Octanol 4

27 Tobias Acid 20

28 5-Sulpho Anthanilic Acid 3

29 C. Acid 2

30 Hydrogen Peroxide 1

31 P.P.D. 1

32 Potassium Carbonate 1

33 Caustic Potash 1

34 Dispersing Agent 3

35 Ferros Sulphate 10

36 Lime Powder 20

37 Carbon Black 2

38 Antidust Oil 5

39 Sodium Sulphate 120

40 Sulphuric Acid 25

41 Sodium Acetate 12

42 MPDDSA 15

43 2 Ethyl Pyridone 10

44 Sulphanilic Acid 10

45 Gamma Acid 1

46 J.Acid 15

47 Resorcinaol 1

48 OAVS 2

49 Copper Sulphate 1

50 SPMP 1

51 B - Naphthol 10

52 Pig. Red Cerise 1.5

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

15

Sr. No.

List Of The Raw Materials Used At

All Stages Of Manufacture

Raw Material Utilization

(MT/Annum) for Full

Consumption Capacity

53 Alpha Blue/Heuco Blue 3

54 Yellow 12 2

55 CPC Green 2

56 Orange G (13) 1

57 4.5 Mole 1

58 MEG - 6

59 Syntho D Foam (Defoamer) 1

60 Dynol SP 20 2

61 9.5 mole (fn 136) 3

62 DMAPA 90

63 STPP 2

64 Ortho Nitro Anisol 145

65 Formaldehyde 80

66 Dichlone 5

67 Thio Urea 5

68 Cobalt Sulphate 120

69 Phthalic Anhydride 105

70 Nitro Benzene 50

71 Methanol 90

72 ODCB 20

73 Carbamide 150

74 Styrene Acrylate 25

75 Chlorine gas 12

76 Cobalt Metal 25

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

16

TABLE: 1.3 : LIST OF EQUIPMENT FOR PROPOSED PROJECT

SR. No. PARTICULARS Nos.

1. Glass Line Reactor - 1 1

2. Glass line Reactor - 2

(with scrubbing system)

1

3. MSLR Reactor 1

4. S.S. Reactor with distillation set up 1

5. RVD -1 with distillation setup 1

6. RVD 2 with distillation setup 1

7. S.S. reactor with distillation Column 1

8. S.S. Reactor 1

9. PP FRP tank - 1 1

10. PP FRP tank 2 1

11. Filter notch 1

12. Centrifuge 48 S.S. 1

13. Centrifuge 48 MSEP 1

14. Centrifuge 24 S.S. 1

15. SFD 1

16. FBD 1

17. Blender 5 Kl 1

18. Blender 1 KL 1

19. Multimill 1

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

17

20. Tray Dryer 1

21. Filter Press 1

22. Sand mill 1

23. Sigma mixture 1

24. Vacuum pump 1

25. Transferring pump 4

26. Filtration Pump 2

27. Boiler 1

28. Thermopack 2

29. Air Compressor 2

30. Storage Tanks

i. LDO 10 KL 2

ii H2SO4 10 KL 1

iii Nitrobenzene 5 KL 1

iv ODC B- 5 KL 1

v Formaldehyde 5 KL 1

vi Methanol 12 KL 1

31. D.G. Set 160 KVA 1

32. D.G. Set 15 KVA 1

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

18

Table: 1.4 : SITE DISTRIBUTION IN AROUND 16135 SQ. MTR. AREA

PLANT

SR. No. PARTICULARS AREA Mt Sq.

1.

Total Area of Plot 16135.00

2.

Total Built up Area 6041.00

3. Total Ground Area

5694.00

4. Total Office Area

5.

Total Factory Area

5117.00

6.

Green Belt 5324.00

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

19

TABLE: 1.5 : TOTAL EMPLOYMENT IN MONOMER CHEMICAL

INDUSTRIES PVT. LTD., FOR PROPOSED PLANT

Sr. No Designation No. Of Employees

1 Works Manager 1

2 Production Manager 1

3 Production Chemist 3

4 Supervisors 4

5 Plant Operators 5

6 Engineering Services & Personnel

i Engineers 1

ii Supervisor 2

iii Wireman 3

iv Filter 3

7 R & D Manager 1

8 R & D chemist 2

9 QC Manager 1

10 QC Chemist + ETP Chemist 3

11 Store In charge 1

12 Administrative office 5

Total 36 Nos.

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

20

TABLE: 1.6 : CONTRACTOR SERVICES IN MONOMER CHEMICAL

INDUSTRIES PVT. LTD., FOR PROPOSED PLANT.

Sr. No. Department

No. Of Person for Proposed

Plant

1. Workers 20

2. Security 6

3. Horticulture 1

4. House Keeping 2

5. Canteen 1

6. Operation & ETP 4

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

21

FIG. NO. 1.1 : PLOT PLAN

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

22

C

C

H

H

A

A

P

P

T

T

E

E

R

R

I

I

I

I

E

E

N

N

V

V

I

I

R

R

O

O

N

N

M

M

E

E

N

N

T

T

A

A

L

L

I

I

M

M

P

P

A

A

C

C

T

T

A

A

S

S

S

S

E

E

S

S

S

S

M

M

E

E

N

N

T

T

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

23

2ENVIRONMENTALIMPACTASSESSMENT

2.1EnvironmentalImpactAssessment

As per the provision of EIA Notification No. S. O. 1533 (E) dated 14.09.2006

amended on January 19, 2009 the proposed project of M/s. Monomer Chemical

Industries Pvt. Ltd (Unit 2 ) come under Category B of 5 (f). As per the notification the

proposed developments cannot be undertaken under it is accorded environmental

clearance by the authority in accordance with the procedure specified in this

notification. The procedure includes environmental impact assessment (EIA) report and

environmental management plan needs to be submitted. Accordingly, this EIA report

has been prepared with main objective of getting environmental clearances for the

Synthetic Organic Dyes & Dye Intermediates manufacturing industry. The study also

projected environmental impact driven by the activity on regional environmental

quality.

M/s. Monomer Chemical Industries Pvt. Ltd. (Unit 2)., Plot no. K 4, Knitwear

Complex, Additional MIDC area, Anandnagar, Ambernath. Dist: Thane retained

Sadekar Enviro Engineers Pvt. Ltd. Thane to conduct Environmental Impact

Assessment (EIA) study based on one season primary environmental quality data,

environmental impact statement based on the identification, prediction and evaluation

of impact & environmental management plan.

Objectives:

The objectives of EIA study are

Assessment of the present status of air, noise, water, land, biological and

socio- economic components of environment including parameters of human

interest in the study area of 10 km radial distance around project site.

Identification of potential impacts on various environmental components

due to activities envisaged during construction and operation phases of the

project development

Predication of project specific impacts on the major environment components

using appropriate mathematical/simulate models

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

24

Preparation of environment impact statement based on the identification,

prediction and evaluation of impacts

Delineation of environmental management plan (EMP) outlining prevention

and control strategies for minimizing adverse impacts of the project

Formulation of environmental quality monitoring program for construction

and operational phases to be pursued by the project proponent.

Environmental Component Wise Activities for the Study

2.2AirEnvironment

Ambient Air Quality monitoring to measure levels of PM

2.5

, PM

10

, SO

2

&

NOx

Collection of surface meteorological data, viz wind speed, wind direction,

relative humidity, temperature and cloud cover.

Identification and quantification of potential emission sources from industrial

source.

Prediction of ground level concentration (GLCs) of air pollutants through

appropriate air quality model incorporating the requirements specified in the

publication of central pollution control Board Assessment of impact in Air

Environment Guidelines for conducting Air quality Modeling.

Evaluation of the adequacy of proposed pollution control measures to meet

air quality emission standard.

Recommendation of air pollution mitigation measures.

2.3NoiseEnvironment

Measurement of noise levels in residential, commercial and industrial zones

in the study area

Prediction of impacts due to increase in noise levels arising out of the

proposed project

Evaluation of noise pollution control measures

Recommendations on noise mitigation measures.

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

25

2.4WaterEnvironment

Study of ground water (dug wells / tube wells) and surface water resources

with respect to their quantity & quality

Estimation of water requirement for the proposed project and its effect on

water demand vis--vis regional water balance

Evaluation of waste water treatment plant & suggest modifications or

additional recommendations, if any

Prediction of impacts on quality of receiving environmental system due to

disposal of treated waste water.

2.5LandEnvironment

Studies on soil characteristics in the study area

Characterization of solid/hazardous wastes to be generated due to the project

Delineation of environmentally compatible management options for

handling, storage and disposal of solid/hazardous wastes.

2.6BiologicalEnvironment

Collection of information on flora and fauna in the study area and

identification of endangered species.

Identification of ecologically sensitive areas such as biosphere reserves,

wildlife sanctuary, national park etc. near project site.

Assessment of impact on endemic and sore/endangered plant species due to

proposed project.

Design of greenbelt and identification of suitable native plant species.

2.7Socioeconomic&HeathEnvironment

Collection of baseline data on the socio-economic profile of the study area.

Collections of information on cultural and aesthetic attributes in the study are

including places of historical / archaeological importance.

Projection of anticipated changes due to the proposed project and delineation

of measures to minimize the impacts.

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

26

Assessment of economic benefits to community and environment arising out

of the proposed project.

Due to the proposed project the employment will increase which will help to

increase the standard of living of surrounding people. Socio- Economic

activities such as medical camps, note book distribution to school childrens

etc. shall be done on regular basis.

Prediction of impacts

Identification, quantification and evaluation of impact due to the proposed

developments through standard modeling studies.

Prediction and evaluation of impacts due to increase in pollutant load on

impacts on land and air quality.

Assessment of benefits of human interest due to the proposed activity.

Environmental Management Plan

Environmental Management Plan (EMP) will be drawn after identifying,

predicting and evaluating the significant impacts on each component of the

environment.

EMP will be delineated incorporating control technologies, safe guards etc for

mitigation of adverse impacts with due consideration to their cost

effectiveness

The post project monitoring should be undertaken with recourse to

continuous online environmental audit.

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

27

C

C

H

H

A

A

P

P

T

T

E

E

R

R

I

I

I

I

I

I

B

B

A

A

S

S

E

E

L

L

I

I

N

N

E

E

E

E

N

N

V

V

I

I

R

R

O

O

N

N

M

M

E

E

N

N

T

T

A

A

L

L

S

S

T

T

A

A

T

T

U

U

S

S

A

A

N

N

D

D

I

I

D

D

E

E

N

N

T

T

I

I

F

F

I

I

C

C

A

A

T

T

I

I

O

O

N

N

O

O

F

F

I

I

M

M

P

P

A

A

C

C

T

T

S

S

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

28

3.BASELINEENVIRONMENTALSTATUSANDIDENTIFICATIONOF

IMPACTS

3.1AirEnvironment

The baseline air quality status forms the basis for the assessment of air quality

impacts due to the proposed development activity. Baseline air quality status can be

generated through a well designed air quality monitoring activity. Baseline status

studies of air environment were carried out through reconnaissance survey followed

by air quality surveillance program and micro-meteorological data collection. Micro-

meteorological data is used in the interpretation of baseline status and for studying

air pollution dispersion pattern and prediction of impacts.

3.1.1 Design of ambient air quality monitoring network:

The following criteria were taken into account in designing the ambient air

quality-monitoring network.

Topography/terrain of the study area

Populated areas within the region

Prediction of max concentration & distances of their likely occurrences under

prevailing micro-meteorological conditions

Representation of regional background

Representation of valid cross sectional distribution in down wind direction

Historical wind rose to understand the wind pattern in the area.

Reconnaissance

Reconnaissance survey was undertaken within the study area to collect

information regarding topography of the study area, meteorological features of the area

and other features relevant to the air environment. Reconnaissance survey enables the

selection of sampling sites and design of air quality monitoring network. The criteria

pollutants like PM

2.5, ,

PM

10

, SO

2

and NOx were identified to assess the existing air quality

in the impact zone. The study was conducted for summer season (March 2011 May

2011).

The location of the plant is spread over on area of 16135 sq. mt., at Ambernath,

Thane. The study area was 10 km radial distance from the proposed plant site. The

identified impact zone is covered by wasteland, market places, and other rurally

inhabited localities. Within the study area there are some other big and small industries.

Perrigo API India Limited, Watson Pharma Pvt. Ltd. are the industry prevalent in the

area. Seven ambient air quality- monitoring sites were selected based on the ambient air

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

29

quality monitoring network design. The distance and bearing of these locations with

respect to the plant site are given in Table 3.1.1 and indicated in Figure 3.1.1.

Methodology for Ambient Air Quality Monitoring

3.1.1.1 The ambient air quality monitoring was carried out in accordance with

guidelines of Central Pollution Control Board (CPCB) and National Ambient Air

Quality Standards (NAAQS) of CPCB dated 18

th

November 2009. Ambient Air

Quality Monitoring (AAQM) was carried out at 7 locations in summer season

considering the criticality of the region.

3.1.1.2 AAQM locations were monitored on 24 hourly average basis for two days in a week as

per guidelines of CPCB and NAAQS. AAQM was carried out at 7 number of locations,

as per presented in CPCB guideline to determine a finer cross-sectional distribution of

air pollution in an industrial developed region.

3.1.1.3 The conventional and project specific parameters such as s particulate matter (PM

2.5,

PM

10

), Sulphur Dioxide (SO

2

) and Oxides of Nitrogen (NOx) are monitored. The

sampling location with high volume sampler is shown in Figure 3.1.2.

3.1.1.4 The values for monitored concentrations of various pollutants at all the

monitoring location were processed for different statistical parameters like

arithmetic mean, standard deviation, minimum concentration, maximum

concentration and percentile values. The existing baseline levels in summer

season with respect to PM

2.5

, PM

10

, SO

2

, NOx, are expressed in terms of various

statistical parameters the 98

th

percentile concentration have been compared with

stipulated standards of CPCB as per the National Ambient Air Quality

Standards.

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

30

3.1.2 Micro-Meteorology of the Area

3.1.2.1 The study of micro-meteorological conditions of a particular region is of utmost

importance to understand the variations in ambient air quality status in that

region. The prevailing micrometeorology at project site plays a crucial role in

transport and dispersion of air pollutants. The persistence of the predominant

wind direction and wind speed at the project site will decide the direction and

extent of the air pollution impact zone. The principal variables, which affect the

micrometeorology, are horizontal transport and dispersion (average wind speed

and directions), convective transport and vertical mixing (atmospheric stability)

and also topography of the area towards local influences.

3.1.2.2 Climatological Tables of Observatories in India (1951-1980), published by the

India Meteorological Department, were used to obtain historical data for the

region. Ambernath is the nearest weather observatory to the project site.

Temperature varied in the range of 28.89

o

C 31.11

o

C. Annual rainfall varied in

the range of 1850 2130 mm with normal annual rainfall of 1967 mm. The annual

average of rainy days (rainfall above 282.1 mm in a day) was 46.8. The annual

average wind speed was 7.2 km/h. Seasonal variation in predominant wind

direction was not observed at Ambernath. Winds from the E-W were

predominant in the winter and the summer season.

3.1.2.3 The months of March, April and May are considered to be representative of

summer season. Monthly mean relative humidity was in the range of 38 - 79% in

the summer season. Wind predominantly blows from E-W sector in summer

season. Wind speed remains in the range of 7.2 km/h for most of the days and a

cloudless sky is observed for 80-85% of the duration during the summer season.

The meteorological data is collected and processed to draw wind-rose as shown

in Fig. 3.1.3. The daily (00-24 hrs) wind-rose in the project region shows the

predominant winds during study period were from E-W sector with

predominant wind 23.91%. There are no significant variations in wind

speed/wind directions. However the wind speed during daytime was relatively

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

31

higher compared to night time. The calm condition was observed for 17 %

during study period.

3.1.3 Base line Air Quality Status

The concentration data were processed for different statistical parameters the base

line levels of PM

2.5

, PM

10

, SO

2

and NO

x

are presented in Tables 3.1.1 to 3.1.8.

Particulate Matter (PM

2.5

Micron): The average PM

2.5

concentrations at different

location varied between 28 - 58 g/m

3

(Table 3.1.2). The 98

th

percentile value at

all the locations was found to be in the range of 34.38 - 42.38 g/m

3

(Table 3.1.3).

The highest PM

2.5

concentration was observed at South Haji Malang Village

area. The 98

th

percentile value in the study area is less than the CPCB stipulated

standard.

Particulate Matter (PM

10

Micron): The average PM

10

concentrations at different

locations varied between 58 to 94 g/m

3

(Table 3.1.2). The 98

th

percentile value

at all the locations was found to be in the range of 75.30 to 93.72 g/m

3

(Table

3.1.3). Its highest PM

10

concentration was observed at South Haji Malang

Village area. The 98

th

percentile value in the study area is less than the CPCB

stipulated standard.

Sulphur Dioxide (SO

2

): The average SO

2

concentrations at different locations

varied between 3.60 8.20 g/m

3

(Table 3.1.2). The 98

th

percentile value at all

the locations was found to be in the range 5.90 8.16 g/m

3

(Table 3.1.3). The

highest SO

2

concentration was observed at East, Caramel Convent School area.

The 98

th

percentile value in the study area is very much less than the CPCB

stipulated standard.

Oxides of Nitrogen (NOx): The average NOx concentrations at different

locations varied between 8.50 18.10 g/m

3

(Table 3.1.2). The 98

th

percentile

value at all the locations was found to be in the range of 16.12 17.86 g/m

3

(Table 3.1.3). The highest NOx concentration was observed at East, Caramel

Convent School area. The 98

th

percentile value in the study area is less than the

CPCB stipulated standard.

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

32

3.1.4 Stack Emissions/ Process Emissions

3.1.4.1 The stack emission sources from proposed activity can be categorized into i)

boilers/heaters/furnaces and ii) diesel generators. The details such as stack

height, stack top inside diameter and flue gas temperature were summerised in

Table 3.1.4.

3.1.4.2 Major fuel burning emission sources include 1 stacks of DG (160 KVA), 1 stack of

Boiler & Thermopac (combined).

3.1.4.3 All the process reactors will be connected to scrubbing system. Alkali scrubber

will be provided to take care of acid fumes & other toxic gases. The caustic media

will be regularly checked & maintained properly to scrub the acid mist. The

scrub solution will be used in process.

3.1.4.4 Monitoring will be regularly undertaken by third party. Details of stacks are

presented in Table 3.1.4

DESIGN DETAILS OF AIR POLLUTION CONTROL SYSTEM:-

A) BOILER

Sr. No. PARAMETER CAPACITY

1 Equipment capacity 850 kg/hr

2 Fuel LDO

3 Fuel Consumption 1400 kg/day

4 Gas Quantity 800 1200 Nm

3

/hr

5 Inlet Gas Temperature 120 160

0

C

6 Outlet Gas Temperature 80 90

0

C

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

33

B) THERMOPACK

Sr. No. Parameter Capacity

1 Equipment capacity 2 Lac. K. Cal.

2 Fuel LDO

3 Fuel Consumption 500 kg/day

4 Gas Quantity 800 1200 Nm

3

/hr

5 Inlet Gas Temperature 120 160

0

C

6 Outlet Gas Temperature 80-90

0

C

C) SCRUBBER (WATER & ALKALY)

Sr. No. Parameter Capacity

1 Equipment capacity 200 M

3

/Min

2 Media used Alkaly & Water

3 Alkali Consumption 10 15 kg/day

4 Gas Quantity 200 Nm

3

/hr

5 Inlet Gas Temperature 50 - 55

0

C

6 Outlet Gas Temperature 40 45

0

C

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

34

Table 3.1.1 : Details of Ambient Air Quality Monitoring Stations

w.r.t. Monomer Chemicals

Sr. No.

Sampling Location

Direction Dist. (Km)

1. Location 1 South-Haji malang Village S 3

2. Location 2 West- Near GIP Railway DAM W 3

3. Location 3

West- North- Rangoli Garden

Restaurant

WN 3

4. Location 4 East , Caramel Convent School E 3

5. Location 5 Proposed Site

Propose

site

0

6. Location 6

Training Institute At Jambhul

gaon

EN 5

7. Location 7 Gurukul school SE 5

a.g.l : above ground level

Table 3.1.2 : Ambient Air Quality Status (Summer Season)

Unit: g/m

3 ,

Avg.: 24 hours

PM2.5 PM10 SO2 NOx Sr.

No.

Sampling

Location

(g/m3) (g/m3) (g/m3) (g/m3)

1 Location 1 42.38 (32-58) 81.13 (71-94) 4.88 (3.6-7) 11.65 (9.3-16.6)

2 Location 2 38.63 (30-52) 74.25 (64-88) 4.70 (3.60-7.20) 12.39 (10.10 16.50)

3 Location 3 34.38 (28-40) 68.38 (58-78) 4.84 (3.60-7.10) 11.53 (8.50-16.20)

4 Location 4 36 (31-46) 74.50 (60-91) 5.70 (4.20-8.0) 13.21 (10.70-18.10)

5 Location 5 34.38 (29 - 42) 68.63 (63-76) 5.66 (4.10-8.20) 12.65 (10.30-18.10)

6 Location 6 40.46 (32-58) 80.36 (71-94) 4.38 (3.6-7) 11.5 (9.3-16.6)

7 Location 7 38.6 (30-52) 74.5 (64-88) 4.50 (3.60-7.20) 12.9 (10.10 16.50)

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

35

Table 3.1.3: AMBIENT AIR QUALITY STATUS (Summer Season) 98th Percentile

Unit: g/m

3,

Avg.: 24 hours

Pollutant

Arithmetic Man

(g/m3)

98th Percentile

(g/m3)

Ambient Air Quality

Standards of CPCB

(g/m3)

PM

2.5

28-58 34.38 42.38 60

PM

10

58 94 75.30 93.72 100

SO

2

3.60 -8.20 5.90 8.16 80

NO

X

8.50 -18.10 16.12. 17.8 80

Table 3.1.4 : Stack Details

Stack

No

Stack Identification

Stack

Height

(m)

Stack top

inside dia.

(m)

Stack

gas exit

temp

(

O

K)

Volumetric

flow rate;

(m

3

/h) NTP

Type of

Fuel

1. DG (160 KVA) (S1) 5.0 0.300 125-190 300-500 H.S.D

2.

Boiler &

Thermopack

(Combined))

32.0 0.450 120 140 1100-1200 LDO

3. Scrubber 12.0 0.275 40 -45 180-250 -

Fuel: H.S.D. High Speed Diesel,

LDO - Light Diesel Oil,

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

36

Fig 3.1.1 Ambient Air Sampling Locations in Study Area

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

37

Fig 3.1.2 High Volume Sampler for Ambient Air Sampling At Study Location

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

38

Fig 3.1.3 Wind Roses for Summer Season

Conclusion

Proposedprojectwillhaveoneboiler&Thermopackassourceofairpollutionemission.SO

2

emission

fromtheseunitswillhave64kg/daywhichlessthan126kg/day(GiveninConsenttoEstablish)

TheAmbientmonitoringresultswithin10KMstudyareafoundwellwithinlimitasperNAAQstandard

exceptPM10whichisnearertotheprescribedlimit,henceprecautiontobetakenfromproposed

activitytominimizetheSMPemissions&continuousmonitoringshouldbecarriedoutasperCPCB

guideline(refTable3.1.3).TocontroltheSPMlevelgreenbeltdevelopmentalsoproposedaroundthe

peripheryofunit.

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

39

ProposedprojectwillnothavePM

10

emissionsothatbaselinedata(PM1075.393g/m

3

(98%)willnot

affect.

3.2 Noise Environment

3.1.5 Reconnaissance

The reconnaissance was conducted with a view to establish the baseline status of

environment with respect to noise levels in the study area surrounding villages and

other centrals of human activities. The objective of noise quality survey is to assess

the impact of noise generated due to proposed development consisting of processing

unit, generators, and compressors etc. on the surrounding environment. The

background noise levels were estimated for identification and characterization of

noise sources noise levels within the study area in the villages and at sensitive

receptors were measured.

3.1.6 Background Noise Level Source

Background noise levels were monitored at 7 locations in the study area. Locations

for monitoring of ambient noise levels are shown in Fig. 3.2.1. Noise levels were

measured using precision integrated sound level meter for movement of vehicles,

loading unloading operations, also contributed to noise levels. Background noise

levels measured in number of village at differed times and locations are summarized

in Table 3.2.1.

The noise levels in residential area varied from 42.8 to 54.9 dB(A) in day and 25.6 to

45.6 dB(A) in night.

The noise levels in sensitive area varied from 38.2 to 49.2 dB(A) in day and 17.1 to

39.5 dB(A) in night.

The noise levels in Commercial area/ Highway varied from 59.3 to 67.5 dB(A) in

day and 41.5 to 53.9 dB(A) in night.

The noise levels near surrounding Industries of Monomer Chemical Industries Pvt.

Ltd. varied from 66.7 to 78.8 dB(A) in day and 48.3 to 67.3 dB(A) in night.

Ambient Noise quality status are summarized in Table 3.2.2

3.1.7 Sources of noise

Noise sources at proposed plant site mostly are other industrial activities & wind

blow, vehicular movement. However the noise generated by these vehicles was

found to be insignificant.

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

40

Table 3.2.1: Details of Ambient Noise Monitoring Stations

Sr. No. Sampling Location Noise Levels dB(A)

Day Night

1 South-Haji malang Village 48.0 45.0

2 West- Near GIP Railway DAM 47.9 35.3

3 West- North- Rangoli Garden Restaurant 44.6 36.5

4 East , Caramel Convent School 49.0 39.4

5 Proposed Site 51.0 40.20

6 Training Institute At Jambhul gaon 53.6 41.8

7 Gurukul school 50.5 40.3

Table 3.2.2 : Ambient Noise Quality Status in Summer Season

Unit : g/m

3

Avg.:24 hours

Location Category

Day dB(A)

Night dB(A)

Ambient Noise Quality

Standards of CPCB

Location Category (6 am to 9

pm)

(9 pm to 6 am) Day

dB(A)

Night dB(A)

Residential area 42.8 54.9 25.6 45.6 55 45

Sensitive area 38.2 49.2 17.1 39.5 50 40

Commercial/Highway 59.9 67.5 41.5 53.9 65 55

Industrial area 66.7 78.8 48.3 67.3 75 70

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

41

FIG3.2.1AMBIENTNOISESAMPLINGLOCATIONSINSTUDYAREA

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

42

3.3WaterEnvironment

3.3.1 Reconnaissance

3.3.1.1 A reconnaissance was undertaken to identify sampling locations to

establish baseline status of ground water and surface water quality in

the study area during March 2011 to May 2011. The major sources of

drinking water in these villages from MIDC.

3.3.1.2 Chikloli Dam & GIP Railway Dam is the major source of surface water.

3.3.2 Water Quality survey

3.3.2.1 Upstream and downstream samples were collected for sampling

.Sampling locations chosen for water quality study were shown in

Figure 3.3.1 and Table 3.3.1. On site sampling collection and chemical

fixation for various parameters including plankton study are done at

locations only.

3.3.2.2 Water samples were analyzed for physico-chemical characteristics,

nutrients, organic parameter, heavy metals, and bacteriological

parameters as per standard methods (APHA 2005) Decision on the

analytical data is presented in the following sections.

3.3.3 Water Quality Status

3.3.3.1 Physical Parameters

The data on physical characteristics comprising pH, temperature,

turbidity, total dissolved solids, total suspended solids and

conductivity for surface and ground water are presented in Table

3.3.2. Surface water quality indicates that it has pH in the range of 6.8

to 7.0, turbidity 1 to 4 NTU, suspended solids 50 to 60 mg/lit, total

dissolved solids in the range of 60 to 80 mg/l and conductivity in the

range of 180 to 210 S/cm. The ground water quality showing pH 6.8

to 7.2, turbidity <1 to 2.0 NTU, suspended solids <1 to 10.0 mg/l,

dissolved solids was 40 to 60 mg/l and conductivity in the range of 100

to 180 S/cm. (Table 3.3.2)

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

43

3.3.3.2 Inorganic Parameters

Inorganic parameters of surface and ground water viz, alkalinity total

hardness, calcium hardness, chloride, sulphate, sodium and potassium

are given in Table 3.3.3. The surface water samples exhibited alkalinity

in the range of 40 to 60 mg/l, total hardness 80 to 100 mg/l, calcium

hardness 60 to 70 mg/l and the concentrations of chloride, sulphate,

sodium and potassium 30 to 45 mg/l, 1.0 to 3.0 mg/l, 100 to 180 mg/l,

and 40 to75 mg/l, respectively. The ground water samples exhibited

alkalinity in the range of 10 to 30 mg/l, total hardness 37 to 190 mg/l,

calcium hardness 10 to 60 mg/l and the concentrations of chloride,

sulphate, sodium and potassium 10 to 50 mg/l, 10 to 50 mg/l, 1 to 25

mg/l, and 1 to 10 mg/l, respectively in ground water samples.

3.3.3.3 Nutrients and Organic Parameters

Water sample from surface and ground water sources are analysed for nitrate

total phosphate, dissolved oxygen, chemical oxygen demand, oil & grease.

The results of these parameters for surface and ground water sources are

summarized in Table 3.3.4.

Surface water concentrations of nitrate and phosphate were found in the

range of 1.0 to 1.3 mg/l and 0.01 to 0.02 mg/l respectively. The dissolved

oxygen and chemical oxygen demand were in the range of 3.0 to 4.0 mg/l

and 10 to 20 mg/l respectively. Biochemical Oxygen Demand were found in

the range of 2to 4 mg/l in all samples, oil & grease were not detected and

hydrocarbon was not detectable in all samples. Concentrations of nitrate,

total phosphate, dissolved oxygen, chemicals oxygen demand in the ground

water samples were observed in the ranges of 0.1 to 2.0 mg/l, 0.01 to 0.02

mg/l, 3.7 to 6.1 mg/l, 5 to 25 mg/l respectively. The level of oil & grease and

hydrocarbon were not detectable in all samples.

3.3.3.4 Heavy Metals

The heavy metal concentration in surface water and ground water samples

are given in Table 3.3.5. The surface water analysis for Heavy metal

representing Cd, Cr, Pb, was found below detectable limit. Fe, As, Co, as 0.03

mg/l, 0.01 mg/l, and 0.05 mg/l, respectively and Zn and Mn were found in

the range 0.04 to 0.06 mg/l, 0.03 to 0.10 mg/l respectively. In ground water

sample, concentration of Mo, Pb was not detected at any location, Co and

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

44

Mn, found in very few locations and as a maximum concentrations of 0.08

mg/l and 0.09 mg/l respectively. (Table 3.3.5)

3.3.3.5 Bacteriological Characteristics

The surface and ground water samples with reference to dug wells were

analyzed for estimating total & fecal coliform using membrane filtration

technique. The bacteriological characteristics of surface as well as ground

water sources are presented in Table 3.3.6.

Surface water samples showed the total coliform counts absent and fecal

coliform counts were absent at upstream / downstream of Chikloli Dam. In

ground water samples, the total coliform counts absent & fecal coliform were

not detectable in ground water representing bacteria uncontaminated water

resource.

3.3.4 Water Requirement

The water requirement of Monomer Chemicals Pvt. Ltd. will be 111.00

m

3

/day. The water is required for process washings, boiler, cooling tower

makeup, services, fire water and domestic purposes. The Water

requirement will be fulfilled by MIDC.

Raw water will be received in the factory premises having a combined

storage capacity of 100 CMD. At storage it is dosed with hypochlorite

solution and pumped into over head tank. From over head tank water

goes to plant by gravity and at outlet, again hypochlorite is dosed using

auto-dosing pump. It is then processed through the sandbag filter before

going to plant.

3.3.5 Wastewater Generation Sources

The major sources of wastewater generation from plant include wash

water, filter press washing etc. The schematic of wastewater treatment

plant is shown in Fig. 3.3.5. The wastewater generation from the plant

and prediction for proposed plant is given in Table 3.3.7.

The effluent samples from unit I of M/s. Monomer Chemical Industries

Pvt. Ltd. have been collected & treatability study carried out on

wastewater. The results are presented in the Table 3.3.8 to 3.3.9.

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

45

3.3.6 Wastewater Disposal

M/s. Monomer Chemical Industries Pvt. Ltd. has been granted consent to

establish by MPCB. An underground pipeline of 8 diameter and 0.15 km

long will be provided to discharge treated wastewater in CETP. A diffuser

will be provided at the end of pipeline for proper diffusion. The pipeline

can carry maximum wastewater to the tune of 90 m

3

/day.

Table 3.3.1: Water Quality Sampling Locations

Sr. No. Sampling Location

Surface Water River/Dam

Chikloli Dam (upstream) (1.0 km from Monomer)

Chikloli Dam (downstream) (1.0 km from Monomer)

GIP Rail Way DAM (2.0 km from Monomer)

Ground Water

South-Haji malang Village

West- Near GIP Railway DAM

West- North- Rangoli Garden Restaurant

East , Caramel Convent School

Proposed Site

Training Institute At Jambhul gaon

Gurukul school

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

46

Table 3.3.2: Water Quality Physical Parameters

Sr.

No.

Sampling

Location

pH

Temperature

(

O

C)

Conductivity

(S/cm)

Total

Suspended

Solids

(mg/l)

Total

dissolved

solids

(mg/l)

Turbidity

(NTU)

Surface Water River & Pond

1.

ChikloliDam

(upstream)

(1.0kmfrom

Monomer)

6.9 30 181 57 63 2.3

2.

ChikloliDam

(downstream)

(1.0kmfrom

Monomer)

7.0 30 195 52 65 3.2

3.

GIPRailWay

DAM(2.0km

fromMonomer)

6.8 30 201 50 72 2.0

Ground Water

4.

South-Haji

malang Village

7.2 28 104 2.5 43 0.76

5.

West- Near GIP

Railway DAM

7.1 30 110 4.8 48 2.0

6.

West- North-

Rangoli Garden

Restaurant

7.0 28 115 1.8 33 <1

7.

East , Caramel

Convent School

7.1 28 130 8.3 46 <1

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

47

8.

Proposed Site 6.9 30 126 4.1 52 <1

9.

Training

Institute At

Jambhul gaon

7.0 24 176 5.0 56 <1

10.

Gurukul resort 7.1 32 134 4.1 47 <1

Note: - Sample collected & Analysed by Sadekar Enviro Engineers Pvt. Ltd.

Table 3.3.3: Water Quality Inorganic Parameters

Total

alkalinity

Total

hardness

Ca

hardness

Cl SO

4

Na K Ni

Sr.

No.

Sampling

Location

(as CaCO3) (mg/l) (mg/l)

Surface Water River & Pond

1.

Chikloli Dam

(upstream)

(1.0 km from

Monomer)

42 97 70 37 1.3 33 53 ND

2

Chikloli Dam

(downstream

)

(1.0 km from

Monomer)

60 92 65 34 1.7 46 48 ND

3

GIP Rail

Way DAM

(2.0 km from

Monomer)

57 81 62 45 2.6 42 73 ND

Ground Water

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

48

4

South-Haji

malang

Village

28 75 19 18 9 4.2 0.27 ND

5

West- Near

GIP Railway

DAM

13 69 40 20 32 20 4.9 ND

6

West- North-

Rangoli

Garden

Restaurant

25 105 58 19 14 15 2 ND

7

East ,

Caramel

Convent

School

19 88 34 21 12 19 4 ND

8

Proposed

Site

23 65 35 35 27 14 17 ND

9

Training

Institute At

Jambhul

gaon

16 85 38 25 29 16 5.8 ND

10

Gurukul

school

17 37 34 27 35 19 6.0 ND

Note: - Sample collected & Analysed by Sadekar Enviro Engineers Pvt. Ltd.

ND:- Not Detected

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

49

DetectableLimitofLamp:Ni0.02mg/lit.Table3.3.4;WaterQualityNutrient,DemandandOrganic

Parameters

Nitrate

as N

Total

Phosphate

Dissolved

oxygen

Chemical

oxygen

demand

Biochemical

oxygen

demand

Oil

and

Grease

Hydro

-

carbo

ns

Sr.

No.

Sampling

Location

(mg/l) (g/l)

Surface Water River & Pond

1.

ChikloliDam

(upstream)

(1.0kmfrom

Monomer)

1.0 0.01 4.0 12 2.4 ND ND

2.

ChikloliDam

(downstream)

(1.0kmfrom

Monomer)

1.3 0.02 3.0 16 3.6 ND ND

3.

GIPRailWay

DAM(2.0km

fromMonomer)

1.1 0.02 3.7 11 2.8 ND ND

Ground Water

4.

South-Haji

malang

Village

0.3 0.01 6.1 5 1.5 ND ND

5.

West- Near

GIP

Railway

DAM

1.0 0.02 5.6 12 3.7 ND ND

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

50

6. West-

North-

Rangoli

Garden

Restaurant

0.3 0.01 4.8 20 6 ND ND

7. East ,

Caramel

Convent

School

0.4 0.02 3.9 18 5.7 ND ND

8. Proposed

Site

1.8 0.02 5.5 24 7.9 ND ND

9. Training

Institute At

Jambhul

gaon

0.6 0.01 4.5 20 7.0 ND ND

10. Gurukul

school

0.5 0.02 3.7 18 5.7 ND ND

Note: - Note: - Sample collected & Analysed by Sadekar Enviro Engineeers Pvt. Ltd.

ND - Not Detectable

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

51

Table 3.3.5: Water Quality Heavy Metals

Cd Cr Cu Pb Fe Mn Zn As Co Mo

Sr.

No.

Sampling

Location

(mg/l)

Surface Water River & Pond

1.

ChikloliDam

(upstream)

(1.0kmfrom

Monomer)

ND ND ND ND 0.02 0.1 0.06 0.01 0.05 ND

2.

ChikloliDam

(downstream)

(1.0kmfrom

Monomer)

ND ND ND ND 0.03 0.1 0.05 0.01 0.04 ND

3.

GIPRailWay

DAM(3.0km

fromMonomer)

ND ND Traces ND 0.04 0.03 0.04 0.01 0.07 ND

Ground Water

4.

South-Haji

malang Village

ND ND ND ND 0.02 0.03 0.07 0.01 0.07 ND

5.

West- Near

GIP Railway

DAM

ND ND Traces ND 1.3 0.04 0.2 0.01 0.05 ND

6.

West- North-

Rangoli

Garden

Restaurant

ND ND ND ND 0.06 0.02 ND 0.01 ND ND

7.

East , Caramel

Convent

School

ND ND ND ND 0.26 0.09 ND ND ND ND

8. Proposed Site ND ND 0.02 ND 0.31 ND 0.06 ND ND ND

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

52

9.

Training

Institute At

Jambhul gaon

ND ND Traces ND 1.3 0.04 0.2 0.01 0.05 ND

10.

Gurukul

school

ND ND ND ND 0.06 0.02 ND 0.01 ND ND

Note: - Sample collected & Analysed by Sadekar Enviro Engineers Pvt. Ltd.

ND - Not Detectable

Detectable Limit of AAS Lamp :- Cd - 0.002, Cr - 0.1, Cu- 0.01, Pb-0.05, Fe- 0.02,

Mn- 0.01, Zn-0.005, As-0.005, Co- 0.03, Mo- 0.05 (Parameters Measured in Mg/ lit.)

Table 3.3.6: Water Quality Bacteriological Parameter

Total Faecal

Coliform Sr. No. Sampling Location

CFU 100 ml

Surface Water River & Pond

1.

Chikloli Dam (upstream )

Absent ND

2.

Chikloli Dam (Downstream )

Absent ND

3.

GIP Rail way DAM

Absent ND

Ground Water

4.

South-Haji malang Village

Absent ND

5.

West- Near GIP Railway DAM

Absent ND

6.

West- North- Rangoli Garden Restaurant

Absent ND

7.

East , Caramel Convent School

Absent ND

8.

Proposed Site

Absent ND

9.

Training Institute At Jambhul gaon

Absent ND

10.

Gurukul School

Absent ND

Note: - Sample collected & Analysed by Sadekar Enviro Engineers Pvt. Ltd.

ND - Not Detectable

Table 3.3.7: Water Requirement & Waste Water Generation

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

53

WATER EFFLUENT

PHASE

Consumption

(CMD)

Losses

(CMD)

Domestic

(CMD)

Industrial

(CMD)

Domestic 15 5 10 Nil

Industrial

Process/

Washing

80 + 20 (from ETP) Nil Nil 80

Cooling 6 6 Nil Nil

Gardening 10 10 Nil Nil

Total

111 21 10 80

Treated effluent discharge line

connected to CETP.

Table 3.3.8: Treatability Study on Effluent by developing pilot plant (From Monomer

Unit I)

Parameters Raw

Effluent

After Primary

Treatment &

Ozonation

After

Secondary

Treatment

After Tertiary

Treatment

pH 3.2 7.0 7.0 7.0

COD 3800 1520 152 141

BOD 1100 445 47 38

TDS 2851 1140 113 106

O&G 15 6 0.6 0.5

Specific Parameters

Colour 634 380 266 186

Chlorides 1032 413 41 38

Sulphate 1540 616 62 58

TAN 134 54 5.5 5.1

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

54

Note:- Except pH Value & Color All parameters are measured in mg/ lits. Colour

Measured At Hz.

Table 3.3.9: Quality Of effluent after Treatment

Standards

Sr.

No.

Parameter

Observed

values

Environment

Protection

[amendments]

rules 1996

CPCB standards

(water consent)

1. pH 7.0 5.5-9.0 6.5-8.5

2. Oil & grease 0.5 10 < 10

3. Total Dissolved Solids 106 NS NS

4. BOD (3 days 27

o

C) 38 100 < 100

5. COD 141 250 < 250

All parameters except pH are expressed in mg/l

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

55

Fig3.3.1WaterQualitySamplingLocationsinStudyArea

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

56

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

57

Fig 3.3.2 Effluent Treatment Plant

Table 3.3.10: Technical specifications

EFFLUENT TREATMENT PLANT

Sr.

No.

Unit Dimensions Qty

Electro-

mechanical/

R.C.C.

1.

Oil & Grease Trap

3.5 m x 1.5 m x 1.5 m 1 No. RCC

2.

Oil skimmer

Cap: 10 litr/hr

1 No. Mechanical

3.

Collection cum

Neutralization Tank

4.5 m x 4.5 m x 3.0 m

each

2 Nos. RCC

4.

Air Blower for Eq. / N.

Tank

Cap. : 100 M

3

/hr

Pressure: 0.45

kg/cm

2

Motor : 5 H.P

2 Nos. Mechanical

5.

Chemical Preparation

System

1.3 m x 1.3 m x 1.3 m

each

2 Nos. RCC

6.

Agitator for chemical

preparation

100 RPM. S.S. 304 shaft

& M.S. mounting with

FRP coating.

2 Nos. Mechanical

7.

Coarse Bubble diffuse

Aeration system for

collection

Cum Equalization Tank

(6 + 6 nos.), HDPE &

EPDM

2 Nos. Mechanical

8. Electrostatic Precipitator 2.5m

3

/Hr flow rate 1 System Instrument

9. Effluent Transfer Pump

M.O.C. : P.P/S.S.

Cap : 5 m

3

/hr

Motor : 2.0 H.P.

2 Nos. Mechanical

10.

Primary Settling Tank with

F.M.

3.25 m x 3.25 m x 3.5 m

each

1 No. RCC

11. Agitator for flash mixer

100 RPM., S.S. 304 shaft

& M.S. mounting with

FRP coating

2 Nos. Mechanical

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

58

Sr.

No.

Unit Dimensions Qty

Electro-

mechanical/

R.C.C.

12. Carbon Treatment Tank

3.25 m x 3.25 m x 3.0 m

each

1 Nos RCC

13.

Aeration System for

mixing purpose

MOC : S.S. 304

Size : 1"

2 Nos Mechanical

14. Filter press Feed Pump

M.O.C.: C.I/S.S.

Cap : 5 m

3

/hr

Head : 30 mtr

Motor : 5.0 H.P.

6 Nos Mechanical

15. Sludge Tank

2.0 m x 2.0 m x 1.5 m

1 No RCC

16.

Filter Press (P.P Recess

Type F.P.)

800 x 800 mm

2 Nos Mechanical

17. Oxidation Tank

4.5 m x 4.5 m x 2.5 m

each

1 No RCC

18.

Circulation

Pump/Transfer pumps

Motor : 2.0 H.P

Make : Kirloskar

Head : 20 mtr

2 Nos Mechanical

19. Ozonator

Cap.:800 gm O

3

generation/hr

1 No Instrument

20. Bio- reactor

6.0 m x 12.0 m x 4.5 m

1 No. RCC

21. Clarifier Tank

3.5 Mt. & ht. 2.5 mtr.

2 Nos. RCC

22.

Mechanism for clarifier

Tank

3.5 M. & ht. 2.5 mt., 5

RPH

1 No. Mechanical

23.

Air Blower for Bio- reactor

-I

Cap : 350 m

3

/hr

Motor : 15 H.P.

each

2 Nos. Mechanical

24.

Fine Bubble Membrane

Diffuse Aeration system

for Bio- Reactors I & II

Size: 67 mm & 2000

mm

80 + 40

Nos.

Mechanical

25. Return Sludge Pumps

Cap : 3 M

3

/hr.

2 Nos. Mechanical

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

59

Sr.

No.

Unit Dimensions Qty

Electro-

mechanical/

R.C.C.

26. Polishing Tank

2.5 m x 2.5 m x 1.8 m

1 No. RCC

27. Sludge Drying Beds

3.0 m x 3.0 m x 1.0 m

each

2 Nos. RCC

28. Filter feed pump

Cap : 5 m

3

/hr.

head : 30 mtr.

2 Nos. Mechanical

29. Shelter for Air Blower

10 x 8

1 No. RCC

30. Pressure sand filter

800 mm & ht. 1250

mm

1 No. Mechanical

31. Activated carbon filter

800 mm & ht. 1250

mm

1 No. Mechanical

32.

Interconnecting piping

with in battery limit.

90mm, 63mm, 50mm

OD

1 lot Piping

33. Electrical/control panel

M.S. with powder

coated, compartmental

,main switch,

one volt meters &

ameters for each switch,

Internal wiring, main

switch, RYB lamps,

Energy meter

1 No. Electrical

34. Misc. items

Safety railing ladders

for all tanks, painting

with two coats oil paint

for M.S. structure

& snocem painting for

civil structure.

Lot Misc.

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

60

Figure 3.3.3 Scrubber system

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

61

3.4LandEnvironnent

3.3.7 Reconnaissance

3.3.7.1 A reconnaissance was undertaken to identify sampling locations to

establish baseline status of soil quality in the study area. The area

comes under Coastal plain. Soils are mostly brownish black soil.

3.3.7.2 The study area primarily industrial area. The water table in the delta

region is maximum depth of water level being >1.5 mt below the

ground level.

3.3.7.3 The region is characterized by coastal climate with moderate

temperature and high relative humidity. Average annual rainfall

recorded in the region is 3200 mm, which is received due to southwest

monsoon during June to September. The daily average temperature is

27.6

0

C. The mean speed of wind is around 8.7 Kmph at a maximum

temp of 38.5

0

C.

Topography and Geological Characteristics

The rock formations in the region are derived mainly from Deccan Basalt

and also from granites, gneiss and laterite. The gently sloping coastal low

lands are observed in patches and are covered with moderately shallow to

deep soils, mostly lateritic in nature.

The chronological order of the geological formation covering the study is

as follows:

Sr. No. Formation Age

1 Unconsolidated Quaternary

2 Consolidated residual literate Tertiary

3 Clasped granite & Basel

crystalline

Archean

4 Basal crystalline Archean

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

62

3.3.8 Soil Quality

Soil samples were collected from seven locations and subjected to

physical, chemical and microbiological analysis standard methods were

followed for the analysis total seven soil samples were collected around

the Dyes & Dyes Intermediates manufacturing industry Ambernath

locations of villages are depicted in Figure 3.4.1 and summarized in Table

3.4.1.

The international pipette method (Black, 1964) was adopted for

determination of particle size analysis. The textural diagram was

generated using SEE soil class 2.0 version based on United States

Department of Agriculture (ASDA) classification of soils physical

parameters such as bulk density parasite and water holding capacity were

determined by the following KR Box method (Keen and Raczkowski, 921)

The chemical characteristics of soil were determined by preparing soil

extract in distilled water in ratio 1:1 (as per Jackson procedure, 1967)

Organic matter was determined in terms of organic carbon by Walkley &

Black method (1972) fertility status of soil in terms of nitrogen and

phosphorus was determined by extracting soil with KCL (FAO soils

Bulletin, 38/2 Rome) and Olsens method (1954) respectively.

Heavy metals in soil were determined by extracting soil with conc. H

2

SO

4

and conc. HNO

3

followed by analysis on ICP as AAS (APHA, 1995).

The results obtained from analysis are summarized below.

3.3.8.1 Physical Characteristics

Air-dried and sieved samples were used for determination of physical

properties soil. The particle size distribution of soils in terms of percentage

of sand, silt and clay are presented in Table 3.4.2 of particle size

distribution data have been used to classify soil texture through standard

soil texture triangle (Figure 3.4.2).

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

63

The soils at individual locations are classified in different categories of soil

texture, viz. sandy clay loam, slit loam, sandy loam, clayey, and sandy

clay out of which sandy clay loam is predominant.

Bulk density of soil relates to the combined volumes of the solids and pore

spaces soil with a high pare space with loose soiled particles will have

lower bulk density than those that are pore compact and have less pare

space. This is directly related to the movement of air and water through

soil thus affecting the productivity. The bulk density of the soils was

found in the range of 0.8 to 1.7 gm/cm

3

.

Soil porosity is described in terms of air filled pore spaces in indicative of

storage and movement of gases for the inherent moisture and

development of root systems, soil strength etc. The porosity and water

holding capacity were found in the range of 43 % to 88 % and 38 % to 54 %

respectively.

3.3.8.2 Chemical Characteristics

The Chemical parameters selected for determining soil characteristics are:

pH, electrical conductivity, soluble anions and cations, cation exchange

capacity (CEC), exchangeable cations, exchangeable sodium percentage

(ESP), nutrients and organic content as well as heavy metals. The results

obtained for these parameters are presented in Table 3.4.3 to 3.4.9.

PH is an important factor, which indicates the alkaline, acidic and neutral

nature of soil. The pH of the soil in the study area was slightly alkaline in

the range of 7.2 to 8.3. The soluble salts were determined from soil extract

(1:1). The soluble salts were expressed in terms of electrical conductivity

(EC). The EC of the soil samples were in the range of 0.1 to 0.3 ms/cm.

The area receives good rainfall so physical thronged of small particles in

soil due to surface run off and dissolution of minerals is moderate leading

to more conductivity.

Cation Exchange Capacity (CEC) and exchangeable cations were

estimated from the lactates of soil with ammonium acetate and potassium

chloride Exchange able sodium percent (ESP) is calculated using the

relationship

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

64

Exchangeable sodium

ESP= x 100

Cation Exchange Capacity

Cation exchange capacity (CEC) is a consequence of positive electrical

charges in clay and human particles in soil and it is balanced by

adsorption of positively charged counter ions. It is this property that

largely determines the storage capacity of nutrient ions in soil amongst the

exchange able cations, Ca

+2

and Mg

+2

were found in the range of 5.5 to 34.3

meq/l of soil and 0.7 to 38.0 meq/l of soil respectively. Exchangeable

sodium percentage (ESP) was found to vary from 6.6 % to 45.5 % on the

basis of CEC the soil status is divided with respect to its adsorptive

capacity and productivity potential. In general the soil in the region has

low adsorption capacity as evident from the cation exchange capacity,

which was found to be in the range of 24.0 to 75.6 meq/100 gm of soil. The

presences of sodium in exchangeable form may have deleterious effect on

the chemical and physical properties of soil. ESP between 6.6 % and 45.5 %

can be considered as satisfactory. Classification of soils with respect to

cation exchange capacity and its relation with productivity and absorptive

is given in Tables 3.4.5 and 3.4.6.

Organic matters in soils have great importance in relation to its texture

and affect its properties like cohesion\porosity and ion exchange capacity.

It also helps in determining the relation of available nutrients organic

matter which was determined by oxidizing the sample with acidified

potassium dichromate. The percentage of organic matter in the soils was

found in the range of 0.79 % to 5.31 % (Table 3.4.7).

The status of nutrient in soils is judged on the basis of available nitrogen,

phosphorus and total organic matter contents. Available phosphorous was

determined spectrophotometrically where the soil was leached with

sodium bicarbonate and treated with molybdenum blue for colour

development. The nitrogen and phosphorous content of soil in the study

area varied from 37.4 kg/ha to 72.4 kg/ha and 1.9 kg/ha to 67.9 kg/ha

respectively. Soil quality standards as per national bureau of soil sciences

(NBSS) for agricultural activities are shown in Table 3.4.8. Soil samples

Monomer Chemical Industries Pvt. Ltd. : Environmental Impact Assessment

65

were also analyzed for heavy metals using inductively coupled plasma

optical Emission Spectras copy (ICP OES) levels of metals (mg/100 gm).

The heavy metals like Ag found as traces and was absent in most of the

locations. The contents of heavy metals like Cd, Cr, Co, Cu, Ni, Pb, Mn, Zn

and Fe in the study area were 1.2 to 2.2 mg/100 gm, 5.9 mg/100 gm to 9.1

mg/100 gm, 42.2 mg/100 gm to 82.2 mg/100 gm, 8.9 mg/100 gm to 22.8

mg/100 gm, 5.0 mg/100 gm to 16.2 mg/100 gm, 0.9 mg/100 gm to 10.4

mg/100 gm, 12.2 mg/100 gm to 39.1 mg/100 gm, 11.5 mg/100 gm to 19.5

mg/100 gm and 81.1 to 95.8 mg/100 gm respectively. The fertility quality

is presented in Table 3.4.7 and land use pattern and land cover is

presented in Table 3.4.11 and 3.4.12.

3.3.8.3 Soil Microbiology

Various ecological cycles in the Photosphere depend upon the population

of bacteria, fungi and actinomycetes, which are vital components of land

environment. These micro-organisms help in maintaining the stability of

the land environment Phizobium and Azotobactor are symbiotic and non-

symbiotic nitrogen fixing microorganisms respectively, which improve

soil fertility by fixation of Nitrogen Fungal. Also constitute an important

part of the micro-flora of normal soil they are action in initial stages of

decomposition of plant residues and actively participating in the process