Professional Documents

Culture Documents

BTI Drilling Sawing Cutting

Uploaded by

sebkahnOriginal Description:

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

BTI Drilling Sawing Cutting

Uploaded by

sebkahnCopyright:

Available Formats

04

A F

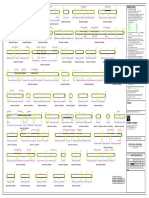

DRILLING, SAWING, GRINDING, CUTTING

Drill and chiseling technology, stone

Diamond drilling technology

Drilling technology, wood

Drilling technology, metal

Sawing and milling technology

Sanding, grinding and

cutting technology

04

04

109 1

0

0

6

Drilling, sawing, grinding, cutting

Table of contents Page

Abrasives for parquet and wooden flooring 198

Adapter/centering drill 131

Arbor-mounted counterbore, Arbor-mounted counterbore set 137

Biathlon SDS plus hammer drill, Biathlon set 113

Brass ring 130

Dust extractor BTI-NTS 20 A 129

Centering drill 131

Chamfer router bit with ball bearing 185

Circular saw blade 177

Cleaning disk 203

Combination thread drill HSSG, combination thread drill set " 150

Conical and deburring countersink bit/HSS CBN 152

Conical and deburring countersink HSS-E CBN 153

Core bits extension 130

Corner rounding bit with ball bearing 184

Cutters for hand held routers and stationary milling machines 184

Cutting wheel 209

Cylindrical saw 175

Cylindrical saw with hole edge counterbore 176

Diamond core drill BTI-DKM 1800 E 125

Diamond core drill BTI-DKB 2200 E, BTI-DKB 2570 E 126

Diamond core drill technology 124

Diamond cup wheel 225

Diamond cutting wheel 214

Diamond drill 121

Diamond socket cutter 122

Diamond drill bit 122

Diamond sharpening stick 226

Disk straight router bit 185

Double-sided parquet sanding disk 200

Double ended drill bit similar to DIN 1897, extra short, roll forged 142

Drill stands 220/250 swivel mounted 127

DTS Abrasive 220

DTS Asphalt Wet/Dry 222

DTS Concrete Wet/Dry 221

DTS Concrete/ Washed Concrete Wet 223

DTS CoolMax Abrasive 219

DTS CoolMax Abrasive Wet/Dry 222

DTS CoolMax High Speed 217

DTS CoolMax Iron King 216

DTS CoolMax No Limit 216

DTS CoolMax Speed Cut 219

DTS CoolMax Universal 217

DTS CoolMax universal Wet/Dry 221

DTS Hard Stone Wet 223

DTS Lime Sandstone Wet 224

DTS Marble 220

DTS Tiles 220

DTS Tiles Wet 224

DTS 218

DTS Universal 218

DTS Universal Wet 224

DTS Asphalt Wet 223

DTS Concrete Wet 222

DTS Window 221

Extraction system diamond drill bit for socket outlets 123

Fast change adapter/centering drill SW 131

Fiber sanding disk 205

04

110 1

0

0

6

Drilling, sawing, grinding, cutting

Table of contents Page

Fine-Cut circular saw blade 178

Flapped sanding disk 206

Fleece brush 203

Flush trim bit with ball bearing 185

Glue joint cutter 184

Hammer core drill 116

Hammer drill bit 116

Hand sander holder 188

Hand saw blade 173

Hard-Cut drill 118

Hard metal cylindrical saw 15 174

Hard metal cylindrical saw MB 22 173

Hard metal reversible blade/reverse board/spurs 183

HM cutter case 185

HM universal bit with spur 136

Hydraulic plate holes assortment metric 155

Japanese hand saw blade 172

Jigsaw blade 160

Jigsaw saw blade/reciprocating saw blade 157

Hook-and-loop sander holder 202

Machine saw blade 172

Master-Cut circular saw blade 179

Material sanding belt 195

Metal hand saw blade/double-sided 171

Metal jigsaw blade 171

Mounting arbor with ball bearing 185

Mounting set, concrete/masonry 127

Mounting shank 204

Multi oil 130

Multi-Cut circular saw 120

Multi-Cut circular saw blade 182

Multi-Cut drill 119

One-sided parquet sanding disk 199

Parquet abrasive sleeves/belt 198

Parquet pad 201

Parquet wire meshes 200

Plate holes 154

Plate holes assortment mectric/PG sanitary 155

Plate shell drill 150

Reciprocating saw blade 166

Rough grinding wheel 207

Rubber sleeve 129

Rubber supporting disk 203

Sand paper ECO//FINE 191

Sand paper roll ECO/FINE/UNI 187

Sand paper unwinder 188

Sanding belt 197

Sanding disk 189

Sanding fleece disk 202

Sanding fleece unwinder 202

Sanding fleece veneer sheets 202

Sanding fleece, Sanding fleece roll 201

Sanding mat, roll 205

Sanding sponge, Sanding mat 204

Saw blade for clamp saws 172

SDS plus chisel bit 116

SDS max punch through drill 115

SDS max/KLW chisel bit 117

04

111 1

0

0

6

Drilling, sawing, grinding, cutting

Table of contents Page

Sealing bit straight 186

Spiral drill bits, very short 145

Spiral flute router bit 186

Spot drill DIN 1897, extra short, roll forged 142

Spot-drill assistance 129

Sprint SDS plus hammer drill 114

Stepped drilling machine 151

Stone drill 117

Stone drill Supra 118

Straight router bits 184

Suction rotor 129

Supporting disk 205

SYSTRA Modul 2 + diamond drill technology accessories 130

Tap wrench DIN 1814 148

Tenon cutter 137

Thread cutter set GSS 149

Thread cutting die 148

Threaded drill 146

Threaded drill bit set GBS 149

Threading die holder DIN 225 148

Timbering and installation drill 139

Tool holder 148

Transverse hole conical and deburring countersink 153

Triangular sand paper 194

Triathlon SDS plus/SDS max hammer drill 114

wood drill 133

wood drill bit 134

wood drill case 134

Twist drill case VA/Inox DIN 338 146

Twist drill DIN 338, ground 143

Twist drill DIN 338, roll forged/DIN 340, extra long, roll forged 141

Twist drill DIN 340, extra long, ground 144

Twist drill set DIN 338, roll forged 142

Twist drill VA/Inox DIN 1897 146

Twist drill VA/Inox DIN 338 145

Uni-Cut circular saw blade 181

Universal drill bit cutter HSS " 144

Universal sander disk 191

Vacuum plate, vacuum pump 128

Water collection ring 128

Water pressure tank 128

Water vent cutter 186

Wire meshes 204

Wood twist drill 138

WS countersink drill 135

WS forstner bit 136

WS router drill bit 135

WS universal bit 136

04

112 1

0

0

6

04

A

113 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

New, extremely robust and aggressive hard metal

plate with centering point

Long working life and resistance to break-

age, reinforcement hits; easy, accurate

centering and fast drilling, no blade wan-

der of the drill

Core reinforced spirals (KVS)

Attenuates oscillations, thereby protecting

user and machine; resistance to breakage is

minimized; maximum energy transfer from

the machine to the drill spiral

2 large volume double spiralled coils all the way

up to the drill head

Saw dust removal directly behind the hard

metal plate, fast saw dust evacuation

despite reinforced core, no fulmination of

the saw dust

SDS plus hammer drill

For use in concrete, masonry and natural stone

Shot blasted

To compress the surface, make the drill

more resistant to bending stress and en-

sure long working life

Special hardness and soldering processing in ac-

cordance with the latest available technology

Guarantees that hard metal plates are

held securely in place

Quality checked

Guaranteed compliance with the require-

ments of the Institute for Structural Engi-

neering for hard metal hammer drills used

for the manufacture of holes of dowel plugs

SDS plus

Item Unit dia. Working Total

number Pieces mm length length

mm mm

014725 1 4 50 110

014726 1 4.8 100 160

014727 5 5 50 110

014728 5 5 100 160

014729 1 5.5 50 110

014730 1 5.5 100 160

014731 5 6 50 110

014732 5 6 100 160

014733 5 6 150 210

014734 1 6 200 260

014735 1 6 250 310

014736 1 6.5 100 160

014737 1 6.5 150 210

014738 1 6.5 200 260

014740 1 6.5 250 310

014741 1 7 100 160

014742 1 8 50 110

014743 5 8 100 160

014744 5 8 150 210

014745 5 8 200 260

014747 1 8 250 310

014748 1 8 350 400

014749 1 8 400 460

014750 1 9 150 210

014751 1 10 50 110

014752 1 10 100 160

014754 1 10 150 210

014755 1 10 200 260

014756 1 10 250 310

Item Unit dia. Working Total

number Pieces mm length length

mm mm

014757 1 10 300 350

014758 1 10 400 450

014805 1 10 550 600

014759 1 11 150 210

014761 1 12 100 160

014762 1 12 150 210

014763 1 12 200 260

014764 1 12 250 310

014765 1 12 400 450

014766 1 12 550 600

014767 1 12 950 1000

014768 1 13 200 260

014769 1 14 100 160

014770 1 14 150 210

014771 1 14 200 260

014772 1 14 250 310

014773 1 14 400 450

014774 1 14 550 600

014775 1 14 950 1000

014776 1 15 100 160

014778 1 15 200 260

014779 1 16 100 160

014780 1 16 150 210

014781 1 16 200 260

014782 1 16 250 310

014783 1 16 400 450

014785 1 16 550 600

014786 1 16 950 1000

04-200

Item Unit dia. Working Total

number Pieces mm length length

mm mm

014787 15 5 50 110

014788 15 5 100 160

014789 15 6 50 110

014790 15 6 100 160

014791 15 6 150 210

017002 15 6 200 260

014792 15 6 250 310

017003 15 6.5 200 260

014793 15 6.5 250 310

014794 10 8 100 160

014795 10 8 150 210

014796 10 8 200 260

014797 10 10 100 160

014798 10 10 150 210

014799 10 10 200 260

014800 10 10 250 310

014801 8 12 100 160

014802 8 12 150 210

014803 6 14 100 160

014804 6 14 150 210

04-180 A/P 04180

HWP

Biathlon set

The most common Biathlon hammer drill from

dia. 5 to 14 mm in a fixed steel case

10 pieces

Scope of supply:

1 piece 5 x 50/ 110 mm, 2 pieces 6 x 50/ 110 mm,

2 piece 6 x 100/160 mm, 2 pieces 8 x 100/160 mm,

1 piece 10 x 100/160 mm, 1piece 12 x 100/160 mm,

1 piece 14 x 100/ 160 mm

Item Unit Designation

number Pieces

016530 1 Biathlon set

04-201

04

A

114 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

SDS plus/ SDS max hammer drill

For use in concrete, masonry and natural stone

3 way cutting hard metal geometry

Optimum drill controls; drills absolutely

circular holes; extremely long working life,

especially in reinforced concrete

Centering point

For point accurate centering and fast

drilling

Chamfered hard metal panels

Vibration free drilling, risk of injury is

avoided when the drill snags against

reinforcements

3 large volume scooping coils

all the way to the drill head

Saw dust removal directly behind the

3 hard metal plates, faster saw dust

removal, no fulmination of the saw dust

Shot blasted

To compress the surface, make the drill

more resistant to bending stress and

ensure long working life

Special hardness and soldering processing in

accordance with the latest available technology

Guarantees that hard metal plates are

held securely in place

Quality approved

Guaranteed compliance with the

requirements of the Institute for Structural

Engineering for hard metal hammer drills,

that are used for the manufacture of holes of dowel

plugs

SDS plus hammer drill

For use in concrete, masonry and natural stone

Hard metal panel with bevelled cutting and

centering point

Risk of injury, due to hooking of the drill

when it hits against reinforcements, is

reduced, easy centering and fast drilling,

as there is no wandering of the drill

2 large volume scooping coils all the way to the

drill head

Saw dust removal directly behind the hard

metal panel, faster saw dust removal, no

fulmination of the saw dust

Shot blasted

To compress the surface, make the drill

more resistant to bending stress and

ensure long working life

Special hardening and soldering process in

accordance with the latest available technology

Guarantees that hard metal plates are

held securely in place

Quality checked

Guaranteed compliance with the

requirements of the Institute for Structural

Engineering for hard metal hammer drills,

that are used for the manufacture of holes of dowel

plugs

Item Unit dia. Working Total

number Pieces mm length length

mm mm

012690 1 20 540 600

011530 1 20 950 1000

012691 1 22 200 260

012692 1 22 400 460

011547 1 22 550 600

011554 1 22 950 1000

Item Unit dia. Working Total

number Pieces mm length length

mm mm

012693 1 24 200 260

012694 1 24 400 460

012695 1 25 200 260

012696 1 25 400 460

012697 1 26 200 260

012699 1 26 400 460

04-200 A/P 04200

SDS plus

Item Unit dia. Working Total

number Pieces mm length length

mm mm

012686 1 18 200 250

012687 1 18 400 460

011509 1 18 550 600

011516 1 18 950 1000

012688 1 20 200 260

012689 1 20 400 460

SDS plus

Item Unit dia. Working Total

number Pieces mm length length

mm mm

012384 1 16 200 270

012391 1 16 400 470

012407 1 16 540 610

012438 1 18 200 270

012452 1 18 400 470

012469 1 20 200 270

012490 1 20 400 470

012506 1 20 540 610

Item Unit dia. Working Total

number Pieces mm length length

mm mm

012520 1 22 200 270

012537 1 22 400 470

012544 1 24 200 270

012551 1 24 400 470

012568 1 25 200 270

012575 1 25 400 470

012582 1 26 200 270

012605 1 26 400 470

Item Unit dia. Working Total

number Pieces mm length length

mm mm

012612 1 28 250 320

012636 1 28 450 520

04-220 A/P 04220

04

A

115 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

SDS max

Item Unit dia. Working Total

number Pieces mm length length

mm mm

002010

1)

1 12 200 340

002011

1)

1 12 400 540

002012

1)

1 12 550 690

002013

1)

1 14 200 340

002014

1)

1 14 400 540

012643 1 16 200 340

012650 1 16 400 540

012667 1 16 560 720

012681 1 18 200 340

012698 1 18 400 540

460028 1 20 200 340

460036 1 20 400 540

460044 1 22 200 340

460052 1 22 400 540

460060 1 22 675 830

010999

2)

1 22 800 920

011051

2)

1 22 1200 1320

011052

2)

1 22 1400 1520

460079 1 24 200 340

460087 1 24 400 540

SDS max punch through drill

For use in concrete, masonry and natural stone

Bit shaped hard metal teeth

Faster drilling progress; long working life, especially

in reinforced concrete

Centering point

For point accurate centering and fast drilling

3 large volume double spiral coil nuts all the way

up to the drill head

Saw dust removal directly behind the drill head, fast

and trouble-free saw dust removal

1 piece tool

Maximum energy transfer without attentuation loses

from the machine on the tool, fast assembly and

simple to use, assembly of adapters and centering

drills not required

Shot blasted

To compress the surface, ensures long working life

Special hardness and soldering processing in

accordance with the latest available technology

Guarantees that hard metal plates are held securely

in place

SDS max

Item Unit dia. Working Total

number Pieces mm length length

mm mm

267511 1 45 450 550

267520 1 45 850 990

267805 1 55 450 550

267848 1 55 850 990

267872 1 65 450 550

268097 1 65 850 990

04-290 A/P 04290

Item Unit dia. Working Total

number Pieces mm length length

mm mm

460095 1 25 200 340

460109 1 25 400 540

460117 1 25 675 830

011053

2)

1 25 800 920

011054

2)

1 25 1200 1320

011055

2)

1 25 1380 1500

460125 1 28 250 390

460133 1 28 450 590

014935

2)

1 28 1200 1320

460141 1 30 250 390

460150 1 30 450 590

460168 1 32 250 390

460176 1 32 450 590

460184 1 32 675 830

460532 1 35 450 590

460192 1 37 250 390

460206 1 37 450 590

460214 1 37 675 830

460222 1 42 450 590

460230 1 42 675 830

04-280

1)

Monoblock Sprint A/P 04280

2)

Four way cutter Sprint 4-S

Improved design!

04

A

116 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Hammer drill bit

With hard metal teeth for use in hammer drills and

light rotary hammer drills up to 4kg

For working on concrete and masonry

Connection thread M16

Application oriented dimensions, suitable for 3/ 8"

pipe above switch and socket up to the ventilation

and stovepipe

Max drill depth for all dimensions = 60 mm

Required machine-tool efficiency

dia. 50 mm, min. 400 W

> dia. 50 mm, min. 600 W

Important:

Suitable adapters and centering drills must

be ordered separately!

Item Unit dia. No.

number Pieces mm teeth

399760 1 25 4

399779 1 30 4

399787 1 35 4

399795 1 40 4

399809 1 50 4

326011 1 68 5

326020 1 82 5

326038 1 90 5

399817 1 100 6

399825 1 112 6

04-270 A/P 04270

Hammer core drill

Two piece hammer drill bit with special

screw fastening

Core bit body length 80 mm for improved control

Low noise due to asymmetrical ordering of teeth

Reduced friction due to saw dust spiral

Centering drill replacement without requiring a

special tool

Supplied complete with centering drill in PE pipe

Range of application:

In drill hammers in conjunction with relevant adapter,

for concrete, masonry and natural stone

Important:

Adapter must be ordered separately.

With thread intake

Item Unit dia. Core bit body

number Pieces mm length mm

003185 1 50 80

003186 1 55 80

003187 1 68 80

003188 1 82 80

003189 1 90 80

003190 1 100 80

003192 1 125 80

003193 1 150 80

04-305 A/P 04305

SDS plus chisel bit

Bullpoint bit

Flat bit

Spade chisel bit

Channel bit

Channel bit / blade

Exact tool contours ensure long working life

Consistent packing due to saline bath hardening

Chisel bits can be reforged and reground

Laser compressed material for higher resistance

to bending stress

Hardened surface due to shot blasting

Item Unit Designation Total

number Pieces length mm

389820 1 Bullpoint bit SDS plus 250

389838 1 Flat bit SDS plus 250

389846 1 Spade chisel bit SDS plus 250

389854 1 Channel bit SDS plus 240

004399 1 Channel bit / blade SDS plus 260

04-210 A/P 04210

04

A

117 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

KLW Chisel bit

Spade chisel bit

Bullpoint bit

Flat bit

SDS max/ KLW chisel bit

Hollow bit

Channel bit

Flat bit

Spade chisel bit

Broad bit

Bullpoint bit

SDS max chisel bit

Channel bit / blade

Exact tool contours ensure long working life

Consistent packing due to saline bath hardening

Chisel bits can be reforged and reground

Laser compressed material for higher resistance

to bending stress

Hardened surface due to shot blasting

Item Unit Designation / Chisel bit Total

number Pieces Model cut mm length mm

260983 1 Bull point bit SDS max 400 4 400

273880 1 Bull point bit SDS max 600 600

264172 1 Flat bit SDS max 400 25 400

265853 1 Flat bit SDS max 600 25 600

265870 1 Hollow bit SDS max 300 26 300

266035 1 Spade chisel bit SDS max 400 50 400

266051 1 Spade chisel bit SDS max 300 80 300

266060 1 Broad bit SDS max 350 115 350

004400 1 Channel bit / blade SDS max 380 32 380

266833 1 Channel bit SDS max 300 32 300

04-310 A/P 04310

Item Unit Designation / Chisel bit Total

number Pieces Model cut mm length mm

278297 1 Flat bit SK 19/ 400 22 400

278327 1 Spade chisel bit SK 19/ 400 50 400

278270 1 Bullpoint bit SK 19/ 400 400

04-315 A/P 04315

Note: Chisel bit with 19 mm six-edged shaft SK 19 suitable for hammer and chisel drill with KLW shaft

Stone drill

Similar to DIN 8039

Cylindrical shaft

Item Unit dia. Working length Total length

number Pieces mm mm mm

043656 1 4 35 70

043672 1 5 40 80

043834 1 5 90 150

043699 1 6 50 100

043842 1 6 90 150

043729 1 8 65 120

043850 1 8 150 200

043753 1 10 70 120

043770 1 12 70 120

04-230 A/P 04230

04

A

118 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Stone drill Supra

Long working life and optimum drilling

performance

Extra tough hard metal cutting

Fast saw dust removal

Large volume coils

Item Unit dia. Working Total

number Pieces mm length length

mm mm

017921 1 3.0 40 70

017945 1 4.0 40 75

017952 1 5.0 50 85

017969 1 5.0 90 150

017990 1 6.0 60 100

018003 1 6.0 90 150

018034 1 7.0 60 100

018041 1 8.0 80 120

018058 1 8.0 150 200

018089 1 10.0 80 120

018096 1 10.0 150 200

018102 1 11.0 90 150

018119 1 12.0 90 150

018126 1 12.0 150 200

018140 1 14.0 90 150

04-240 A/P 04240

Item Unit dia. Working Total

number Pieces mm length length

mm mm

010989 10 4,0 40 75

010990 10 5,0 50 85

010992 10 6,0 60 100

010993 10 6,0 90 150

010995 10 8,0 80 120

04-239 A/P 04239

Only to be bored when turning,

Switch off hammer action!

Hard-Cut drill

The specialist for hard construction materials

Extremely long working life

Diamond ground special hard metal cutting

Point accurate drilling also for hard surfaces

Centering geometry

Fast saw dust removal and limited friction losses

Large volume coils

Item Unit dia. Working Total

number Pieces mm length length

mm mm

011439 1 4.0 40 75

011440 1 5.0 50 85

011441 1 6.0 60 100

011442 1 8.0 80 120

011443 1 10.0 80 120

011444 1 12.0 90 150

011445 1 14.0 200 250

04-253 A/P 04253

Item Unit dia. Working Total

number Pieces mm length length

mm mm

011435 10 4,0 40 75

011436 10 5,0 50 85

011437 10 6,0 60 100

011438 10 8,0 80 120

04-252 A/P 04252

Quality checked

Guaranteed compliance with the

requirements of the Institute for Structural

Engineering for hard metal hammer drills

used for the manufacture of holes of dowel plugs

Range of application:

Ideal for masonry and concrete roofing tiles

HWP

Quality checked

Guaranteed compliance with the

requirements of the Institute for Structural

Engineering for hard metal hammer drills

used for the manufacture of holes of dowel plugs

Range of application:

Ideal for hard materials such as roofing tiles, klinker,

ceramics, tiles (up to scratch hardness 8)

Processing instructions:

Drilling in hard construction materials with reduced

rotational speed (approx. 400 600 U/ min)

HWP

For use in concrete and masonry

The most popular stone drill Supra from dia. 5 to

10 mm in a plastic case

Scope of supply:

1 piece 4 x 40/ 75, 1 piece 5 x 50/ 85,

1 piece 6 x 60/ 100, 1 piece 8 x 80/ 120,

1 piece 10 x 80/ 120 mm

Item Unit Designation

number Pieces

019198 1 Stone drill Supra set 5 piece

04-241

04

A

119 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Multi-Cut drill

Item Unit Designation dia. Working length Total length

number Pieces mm mm mm

010985 10 MC drill 4.0 50 85

010986 10 MC drill 5.0 50 85

010987 10 MC drill 6.0 60 100

010988 10 MC drill 8.0 80 120

04-249 A/P 04249

Only to be bored when turning,

switch off hammer action!

HWP

Long working life

Diamond ground hard metal cutting

Point accurate drilling

Centering geometry

Fast saw dust or chip removal and limited friction

losses

Large volume coils

Quality checked

Guaranteed compliance with the

requirements of the Institute for Structural

Engineering for hard metal hammer drills

used for the manufacture of holes of dowel plugs

Multi-purpose drill for different construction materials

Range of application:

For wood, chip boards, metal, gypsum carton, tiles (up

to scratch hardness 6), ceramics, cement asbestos,

aerated concrete, light construction materials, plastics,

insulation materials, coated panels and cast metal

Processing instructions:

Resharpen blunt mult-cut drill using silicon or diamond

sander disk

SDS plus

Item Unit Designation dia. Working length Total length

number Pieces mm mm mm

353027 1 MC drill 4.0 50 85

339881 1 MC drill 5.0 50 85

339903 1 MC drill 6.0 60 100

339962 1 MC drill 6.0 90 150

016971 1 MC drill 6.0 250 310

353051 1 MC drill 7.0 60 100

339920 1 MC drill 8.0 80 120

339989 1 MC drill 8.0 200 250

016972 1 MC drill 8.0 250 310

339946 1 MC drill 10.0 80 120

340006 1 MC drill 10.0 200 250

016973 1 MC drill 10.0 250 310

353078 1 MC drill 12.0 90 150

340022 1 MC drill 12.0 200 250

340049 1 MC drill 14.0 200 250

340065 1 MC drill SDS plus 6.0 100 160

002045 1 MC drill SDS plus 6.0 250 310

340081 1 MC drill SDS plus 8.0 100 160

340103 1 MC drill SDS plus 8.0 150 210

016974 1 MC drill SDS plus 8.0 250 310

340120 1 MC drill SDS plus 10.0 100 160

340146 1 MC drill SDS plus 10.0 200 260

016975 1 MC drill SDS plus 10.0 250 310

340162 1 MC drill SDS plus 12.0 100 160

340189 1 MC drill SDS plus 12.0 200 260

340200 1 MC drill SDS plus 14.0 100 160

340227 1 MC drill SDS plus 14.0 200 260

04-250 A/P 04250

04

A

120 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Connection thread M16

For use in:

Drills with hexagonal shaft

Hammer drills with SDS plus shaft

Max drill depth for all dimensions = 60 mm

Required machine-tool efficiency

dia. 50 mm, min. 400 W

> dia. 50 mm, min. 600 W

Safety Information:

Fixed tool clamping required

Use only in machines with security attachment and

additional handle

Wear protective glasses for materials that splinter

Attention:

Suitable adapters and centering drills must be

ordered separately.

Multi-Cut circular saw

Ideal for electricians, tilers, sanitation engineers, heating engineers, carpenter and furniture makers, kitchen

studios etc. For solid wood, plywood, chip boards (raw, varnished, laminated), plastics, perspex, tiles (up to

scratch hardness 6), gypsum carton, gypsum blocks, porous concrete, heraklith panels, cement asbestos, solid

brick.

The Multi-Cut circular saw is only

used when turning, i.e. hammer

or hammer action should be

switched off!

Item Unit dia. No. teeth Examples of use

number Pieces mm

384879 1 25 3 Sanitary and heating pipes

384887 1 30 3 Sanitary and heating pipes

384895 1 35 3 Sanitary and heating pipes

384909 1 40 3 Sanitary drain pipe, water and

heating pipes with insulating covering

384925 1 50 3 Sanitary drain pipe, water and

heating pipes with insulating covering

010793 1 55 3 Built in lights dia. 55 mm

010823 1 60 5 Cable outlets dia. 60 mm

010830 1 65 5 Hollow wall sockets dia. 65 mm

384941 1 68 5 Hollow wall sockets dia. 68 mm

002024 1 70 5 Hollow wall branch sockets dia. 70 mm

384950 1 74 5 Branch sockets dia. 74 mm

384968 1 80 5 Distributor sockets dia. 80 mm

04-260 A/P 04260

Hole edge counterbore for Multi-Cut circular saw

for exact counterboring of hollow wall sockets

Item Unit Designation

number Pc.

431893 1 Hole edge counterbore for MC 68

04-260 A/P 04260AB

Item Unit Designation Components

number Pc.

431915 1 MC Circular saw set 1 MC Circular saw 68, Hole edge counterbore,

MC mounting shaft hexagonal a/f 11/ 78

MC centering drill HM 8.0 x 120

431907 1 MC Circular saw set 2 MC Circular saw 68, Hole edge counterbore,

MC mounting shaft SDS 105

MC centering drill HM 8.0 x 120

04-260 A/P 04260AA

04

B

121 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Diamond drill

Galvanized diamond drill for extremely hard materials

No damage to edges of drill hole in addition to

completely clean and precise drilling

Can be used in all commercially available cordless

screwdrivers or all drills

Special diamond drill with water connection is not

required

Range of application:

Hard tiles, tiles, fine stoneware, ceramics, granite slabs

Diamond drill full set

Complete set in SYSTRA Modul 2 consisting of a

diamond drill in each of the following sizes dia. 4,

6, 8, 10, 12 mm, 1 centering device,

1 pressure spray, 1 flexible hose

Diamond drill set

5 piece set consisting of a diamond drill in each of

the following sizes dia. 4, 6, 8, 10, 12 mm,

Centering device

For accurate centering of the diamond drill as well

as for the water cooling connected to the pressure

spray

For diamond drills of dia. 4, 6, 8, 10, 12 mm

Pressure spray

Pressure spray with 1 liter container for water

cooling of the diamond drill connected to the

centering device

Flexible hose 2m

In order to connect the pressure spray and the

centering device

Usage guidelines:

A rotational speed of approx. 500 rpm is the ideal

setting in order to achieve the optimum ratio between

drilling progress and service life.

Do not exert any extra force when drilling: Let the drill

do its work!

Always use the diamond drill in combination with the

centering device. This ensures that the diamond drill

is correctly used and prevents it from slipping off the

workpiece. Using the centering device also reduces the

risk of cracking tiles.

At every opportunity when working use water to cool it

down, this substantially increases the service life of

the drill.

Item Unit dia. Total Fig.

number Pieces mm length mm no.

006951 1 4 65 C

006952 1 6 65 C

006953 1 8 65 C

006954 1 10 65 C

006955 1 12 65 C

04-905

Item Unit dia. Total Fig.

number Pieces mm length mm no.

006963 5 4 65 C

006970 5 6 65 C

006987 5 8 65 C

006988 5 10 65 C

006989 5 12 65 C

04-905

Item Unit Designation Fig.

number Pieces No.

006991 1 Diamond drill complete set in SYSTRA Modul

006990 1 Diamond drill set 4 12 mm C

006994 1 Centering device

006992 1 Pressure spray 1 l

006993 1 Flexible hose 2 m 1

04-905

HWP

When working with water cooling, only use the cordless

machine! There is a risk of electric shock when using

mains operated drills!

Once the tiles or fine stoneware have been bored

through, a normal hammer or stone drill should be used

for further drilling depending on the subsurface. When

used on concrete, masonry or similar, the diamond

drill's operating life is reduced considerably in compari-

son with hard materials.

C

C

C

C

C

C

1

04

B

122 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Diamond socket cutter

Item Unit dia. Drill depth Connection Number

number Pieces mm mm thread segments

025674 1 68 60 M16 4

025681 1 82 60 M16 4

04-901 A/P 06362

DDS CoolMax Universal

Range of application:

Concrete, reinforced concrete, washed concrete, high

density lime sand brick, hard clinker, tiles, porous

concrete, masonry, firebrick

Speed

Tool life

Cutting quality

Item Unit dia. Drill depth Connection Number

number Pieces mm mm thread segments

009902 1 68 70 M16 3

009919 1 82 70 M16 4

04-901 A/P 06362AA

DDS Universal

Range of application:

Concrete, washed concrete, clinker, tiles,

porous concrete, masonry, firebrick

Speed

Tool life

Cutting quality

Item Unit dia. Drill depth Connection Number

number Pieces mm mm thread segments

007730 1 68 60 M16 3

007732 1 82 60 M16 4

04-901 A/P 06362AD

DDS CoolMax Abrasive

Range of application:

Soft lime sand brick, porous concrete, poroton, firebrick,

soft clinker and red brick, expanded clay

Item Unit dia. Drill depth Connection Number

number Pieces mm mm thread segments

002802 1 68 70 M16 3

002803 1 82 70 M16 4

04-901 A/P 06362AE

DDS Abrasive

Range of application:

Soft lime sandstone, poroton, plaster, masonry

Speed

Tool life

Cutting quality

Ideal for effortless and rational drilling and socket cutting when installing electrical and sanitary fittings

Premium quality

Standard

Designed for use in all diamond

Dry drills in addition to all drills of at least

1,000 watts and 2,000 rpm.

Important:

Suitable adapters and centering drills must be

ordered separately.

Usage guidelines:

In general operates by rotating, with the exception of:

in the BTI-SB 1150 E and BOSCH GSB 90-2 E using

soft hit drill mode; remove the centering drill once

drilling has started; wear protective glasses; best drill-

ing results when used in conjunction with the hammer

drill BTI-SB 1150 E; resharpen blunt drill bits with BIT

diamond sharpening stick.

Speed

Tool life

Cutting quality

04

B

123 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

DDS Extraction device

To extract dust during dry drilling with diamond socket cutters

Clean dust free operation through greatly

minimised dust production

For renovation work in inhabited buildings

Suits all diamond drill bits dia. 68 and 82 mm with

extract vent n/ holes

Light spring centering pin that can be replaced

quickly

Machine connectionM16, a/f 24

Drill bit connection M16

Important:

Centering pin and suitable adapter must be ordered

separately.

Item Unit Designation

number Pieces

002123 1 DDS Extraction device

002134 1 DDS Centering pin ASV

04-903 A/P 04

DDS CoolMax Universal ASV

With extraction slots for DDS Extraction device

Range of application:

Concrete, reinforced concrete, washed concrete, high

density lime sand brick, hard clinker, tiles, porous

concrete, masonry, firebrick

Item Unit dia. Drill depth Connection number

number Pieces mm mm thread segments

002103 1 68 70 M16 3

002111 1 82 70 M16 4

04-902 A/P 04

DDS Universal ASV

With extraction slots for DDS Extraction device

Range of application:

Concrete, washed concrete, clinker, tiles, porous

concrete, masonry, firebrick

Item Unit dia. Drill depth Connection number

number Pieces mm mm thread segments

002120 1 68 70 M16 3

002121 1 82 70 M16 4

04-902 A/P 04

Speed

Tool life

Cutting quality

Speed

Tool life

Cutting quality

04

B

124 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Diamond core drill technology

The complete range for commercial diamond drilling in mounting and installation technology. The advantages of

diamond drilling technology over conventional boring tools:

Economical

No requirement to plan openings and apertures

Opening sizes can be created as they are required

Faster than drilling with a hammer drill

True to dimension, precise and clean

Reinforcement bars are cleanly cut through

No structure damage

Clean and true to dimension drilling

Vibration-free and low noise

User protection

Can be used during normal business hours in

office buildings, hospitals, schools

Minimum disruption to occupants when used in

private residences or appartments

Diamond core bit

Universal for dry and wet drilling

7 mm segment heights give long operating life

Optimum protection against segment loss by

special soldering system

1/2" or 1 1/4" connection thread

Range of application for wet drilling:

Reinforced concrete, concrete without reinforcement,

high density lime sandstone, hard clinker, (soft lime sand

stone, porous concrete, red brick, poroton, soft clinker)

Range of application, dry drilling:

Soft lime sandstone, porous concrete, tiles, poroton,

soft clinker

Segment shape dia. 10 42 mm

Ring shaped segments

For dowel drilling (limited tolerance)

Segment shape dia. 51 200 mm

Roof shaped individual segments

Easy centering and fast drilling, higher feed rate

over the entire service life (economy of time and

effort), low contact pressure required (protects user

and machine)

DBK 1/2" G, a/f 24

New DBK DBK Exchange Unit dia. Working length Segments Number

Item Item Pieces mm mm L x W x H segments

number number mm

002135 002391 1 10 200 2.5 x 7 Ring

002136 002393 1 12 200 2.5 x 7 Ring

002137 002394 1 14 200 2.5 x 7 Ring

002138 002398 1 16 200 2.5 x 7 Ring

002139 002399 1 18 200 2.5 x 7 Ring

002140 002400 1 20 300 2.5 x 7 Ring

002141 002401 1 22 300 2.5 x 7 Ring

002142 002403 1 24 300 2.5 x 7 Ring

002143 002405 1 25 300 2.5 x 7 Ring

002144 002406 1 28 300 2.5 x 7 Ring

002145 002407 1 30 300 2.5 x 7 Ring

002146 002409 1 32 300 2.5 x 7 Ring

002147 002411 1 35 300 2.5 x 7 Ring

002148 002412 1 37 300 2.5 x 7 Ring

002150 002413 1 40 300 2.5 x 7 Ring

002151 002414 1 42 300 2.5 x 7 Ring

002152 002415 1 51 300 24 x 3 x 7 5

002153 002416 1 56 300 24 x 3 x 7 5

002154 002417 1 62 300 24 x 3.5 x 7 6

002155 002418 1 67 300 24 x 3.5 x 7 7

002157 002419 1 71 300 24 x 3.5 x 7 7

002158 002420 1 81 300 24 x 3.5 x 7 8

002159 002421 1 92 300 24 x 3.5 x 7 9

002160 002422 1 102 400 24 x 3.5 x 7 9

002161 002423 1 112 400 24 x 3.5 x 7 10

002162 002424 1 122 400 24 x 3.5 x 7 11

002164 002438 1 132 400 24 x 4 x 7 12

04-906

Note:

Your BTI sales engineer or a BTI center will be

happy to take back your used diamond core bits for

reconditioning.

Roof segment Ring shaped block

segment

04

B

125 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

DBK 1 1/4" UNC, a/f 41

New DBK DBK Exchange Unit dia. Working length Segments Number

Item Item Pieces mm mm L x W x H segments

number number mm

002239 002442 1 25 400 3 x 7 Ring

002240 002443 1 30 400 3 x 7 Ring

002247 002445 1 35 400 3 x 7 Ring

002249 002446 1 40 400 3 x 7 Ring

002283 002450 1 52 400 24 x 3.5 x 7 5

002284 002451 1 57 400 24 x 3.5 x 7 5

002285 002452 1 62 400 24 x 3.5 x 7 6

002287 002462 1 67 400 24 x 3.5 x 7 7

002288 002469 1 72 400 24 x 3.5 x 7 7

002289 002470 1 77 400 24 x 3.5 x 7 8

002297 002481 1 82 400 24 x 3.5 x 7 8

002299 002482 1 87 400 24 x 3.5 x 7 8

002303 002483 1 92 400 24 x 3.5 x 7 9

002304 002485 1 102 400 24 x 3.5 x 7 9

002305 002486 1 107 400 24 x 3.5 x 7 9

002306 002487 1 112 400 24 x 3.5 x 7 10

002307 002492 1 117 400 24 x 3.5 x 7 10

002309 002498 1 122 400 24 x 3.5 x 7 11

002310 002499 1 127 400 24 x 3.5 x 7 11

002312 002500 1 132 400 24 x 3.5 x 7 11

002313 002501 1 152 400 24 x 3.5 x 7 13

002314 002502 1 162 400 24 x 3.5 x 7 14

002315 002503 1 172 400 24 x 3.5 x 7 14

002317 002504 1 186 400 24 x 3.5 x 7 15

002318 002511 1 200 400 24 x 4 x 7 15

04-907

Note:

Your BTI sales engineer or a BTI center will be

happy to take back your used diamond core bits for

reconditioning.

Diamond core drill BTI-DKB 1800 E

1 gear shift machine for dry and wet drilling of dia. 60 to 102 mm (concrete) or dia. 70 to 162 mm (abrasive)

Scope of delivery:

1 diamond core drill

1 hand grip

1 PRCD safety switch

1 water connection

1 toolbox

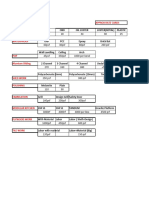

Technical data

Input power 1,800 W

Drilling performance, concrete dia. 60 102 mm

Drilling performance, abrasive dia. 70 162 mm

Idle speed 1st gear 830 rpm

Load speed 1st gear 580 rpm

Torque, spindle 1st gear 16.5 Nm

Socket double spindle thread

1/2" G + 1 1/4" UNC, a/f 32

Weight 4.6 kg

Item Unit Designation

number Pieces

002389 1 BTI-DKB 1800 E

50-011 A/P 50

Recommended peripheral speed 2 4 m/s

C

i

r

c

u

m

f

e

r

e

n

t

i

a

l

s

p

e

e

d

m

/

s

1

st

gear

Diamond core drill

High performance engines with multi-functional electronics, for dry and wet drilling, hand-operated or for use

in drill stands

Starting current restriction

easy and careful drilling

Idle speed restriction

Noise reduction and low levels of wear on engine

bearings and carbon brushes

Overload restriction

Adapts the motor speed to the current contact

pressure and prevents the motor from being

overloaded; this almost completely removes the need

for repairs due to burned out motors or switches

04

B

126 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Diamond core drill BTI-DKB 2200 E

3 gear shift machine for dry and wet drilling of dia. 20 to 150 mm (concrete) or dia. 20 to 250 mm (abrasive)

Scope of supply:

1 diamond core drill

1 hand grip

1 PRCD safety switch

1 water connection

1 covering box

Technical data

Input power 2,200 W

Drilling performance, concrete dia. 20 150 mm

Drilling performance, abrasive dia. 20 250 mm

Idle speed 1st gear 750 rpm

Load speed, 1st gear 530 rpm

Torque, spindle 1st gear 28.2 Nm

Idle speed, 2nd gear 1,800 rpm

Load speed, 2nd gear 1,280 rpm

Torque, spindle 2nd gear 11.7 Nm

Idle speed, 3rd gear 2,500 rpm

Load speed, 3rd gear 1,780 rpm

Torque, spindle 3rd gear 8.4 Nm

Socket double spindle thread

1/2" G + 1 1/4" UNC, a/f 32

Weight 7.3 kg

Item Unit Designation

number Pieces

002390 1 BTI-DKB 2200 E

50-011 A/P 50

Recommended peripheral speed 2 4 m/s

C

i

r

c

u

m

f

e

r

e

n

t

i

a

l

s

p

e

e

d

m

/

s

1

st

gear

2

nd

gear

3

rd

gear

Diamond core drill BTI-DKB 2570 E

3 gear stationary machine for dry and wet drillings of dia. 35 to 220 mm (concrete) or dia. 35 to 250 mm

(abrasive)

For use only with drill stands

Scope of supply:

1 diamond core drill

1 PRCD safety switch

1 water connection

4 mounting bolts for drill stands

1 covering box

Technical data

Input power 2,570 W

Drilling performance, concrete dia. 35 220 mm

Drilling performance, abrasive dia. 35 250 mm

Idle speed, 1st gear 440 rpm

Load speed, 1st gear 330 rpm

Torque, spindle 1st gear 45 Nm

Idle speed, 2nd gear 755 rpm

Load speed, 2nd gear 570 rpm

Torque, spindle 2nd gear 26 Nm

Idle speed, 3rd gear 1,045 rpm

Load speed, 3rd gear 790 rpm

Torque, spindle 3rd gear 19 Nm

Socket spindle thread 1 1/4" UNC, a/f 32

Weight 9.8 kg

Recommended peripheral speed 2 4 m/s

C

i

r

c

u

m

f

e

r

e

n

t

i

a

l

s

p

e

e

d

m

/

s

1

st

gear

2

nd

gear

3

rd

gear

Item Unit Designation

number Pieces

004057 1 BTI-DKB 2570 E

50-011 A/P 50

04

B

127 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Drill stands 220

Stationary drill stands for core bits up to dia. 220 mm

For all core drills with collar dia. 60 mm

(e.g. BTI machines)

Entire feed unit can be removed from above

This makes it considerably easier for the user, as

the rigs can be installed without the feed unit or the

core drill

Drill stand mounting with impact anchor or using

vacuum (vacuum plate available as accessory)

Technical data

Max. core bit dia. 220 mm

Max. core bit length 450 mm

Weight 10.3 kg

Item Unit Designation

number Pieces

002319 1 Drill stands 220

04-908 A/P 04

Drill stands 250 swivel-mounted

Swivel-mounted drill stands for core bits up to dia. 250 mm

For all core drills with collar dia. 60 mm

(e.g. BTI machines)

Continuous swivel-mounted up to 45

Transport rollers

Easy handling

Drill stands mounting with concrete anchors or

integrated vacuum plate

Technical data

Max. core bit dia. 190 mm (with

250 mm spacer supplied)

Max. core bit length 500 mm

Weight 15.0 kg

Item Unit Designation

number Pieces

002321 1 Drill stands 250 swivel-mounted

04-908 A/P 04

Concrete mounting set

For mounting drill stands in concrete

Concrete anchor DKB particularly recommended

for diamond drill technology

Drill dia. for concrete anchor 15 mm

Scope of supply:

1 knurl threaded pin

1 U disk

1 wing nut

10 concrete anchor M12 DKB

1 concrete tool M12

Item Unit Designation

number Pieces

002325 1 Concrete mounting set

002326 50 Concrete anchor M12 DKB

515418 1 Concrete tool M12

014776 1 Biathlon SDS plus hammer drill

15.0 x 100/ 160

04-908/ 02-836/ 04-200 A/P 04

Masonry mounting set

For mounting drill stands in masonry (solid material)

Masonry anchor can be used several times

Drill dia. for masonry anchor 20 mm

Scope of supply:

1 knurl threaded pin

2 U discs

1 nut

1 wing nut

5 masonry anchors M12 DKB

Item Unit Designation

number Pieces

002327 1 Masonry mounting set

004226 25 Masonry anchors M12 DKB

012688 1 Sprint SDS plus hammer drill

20.0 x 200/ 260

04-908/ 04-200 A/P 04

04

B

128 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Vacuum plate

To secure the drill stand 220 using a vacuum

Including a vacuum connection, pressure gauge

and foam rubber insulation

Important:

Secure mounting of the drill stand using a vacuum

plate is only possible on smooth surfaces and from a

low pressure of 0.7 bar.

Item Unit Designation

number Pieces

002345 1 Vacuum plate

04-908 A/P 04

Vacuum pump

To extract from the vacuum plates

High level of safety because of the

10-I-pressure tank

No sudden loss in pressure if power is cut

Including pressure gauge

With power switch

Item Unit Designation

number Pieces

002346 1 Vacuum pump

04-908 A/P 04

Technical data

Intake volume 190 l / min

Performance 1.1 kW (1.5 hp)

Pressure tank capacity 10 l

Weight 17 kg

Water pressure tank

To supply coolant water to the core drill on worksites that do not have a water supply

Filling volume 10 liters

Including 2.5m static fabric hose

With pressure gauge and safety valve (max. 6 bar)

1/2" plug-in coupling with water stop, direct fit for

almost all core drills

Item Unit Designation

number Pieces

002348 1 Water pressure tank

04-908 A/P 04

Water collection ring

To extract surplus coolant water

Used with dust extractor

Water collection ring adheres to the subsurface to

be drilled

For core bits dia. up to 142 mm

Including 2.5 m extraction hose

Important:

Rubber sleeve for extractor connection must be

ordered separately.

Item Uni Designation

number Pieces

002349 1 Water collection ring

04-908 A/P 04

04

B

129 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Spot-drill assistance

For easy drilling during hands-free wet drilling

Can be used for core bits up to dia. 120 mm

Is attached to the machine's hand grip

Item Unit Designation

number Pieces

002331 1 Spot-drill assistance 120 mm

04-908 A/P 04

Suction rotor

For extracting dust during dry drilling with 1 1/4" core bits

Simple core bit centering during hands-free dry

drilling with light spring centering pin that can be

replaced quickly

Machine connection M16

Core bit connection 1 1/4"

Important:

Spring centering sp ke and suitable adapters as

well as a rubber sleeve where required for the dust

extractor connection must all be ordered separately.

Item Unit Designation

number Pieces

002369 1 Suction rotor 1 1/4"

002380 1 Spring center point 400 mm

04-908 A/P 04

Rubber sleeve

Universal rubber sleeve for dust extraction

connection

To connect from the suction rotor or water

collection ring with the dust extractor

(e.g. BTI-NTS 20 A)

Item Unit Designation

number Pieces

002379 1 Rubber sleeve

04-908 A/P 04

Dust extractor BTI-NTS 20 A

Item Unit Designation

number Pieces

020104 1 BTI-NTS 20 A

50-013 A/P/T 50

Technical data

Input power 1,400 W

Dust receptacle volumes 20 l

Water receptacle volumes 15 l

Overall height 56 cm

Sound pressure level 69 dB

Application category M

Filter area 8,600 cm

2

Max. air flow 64 l / s

Max. underpressure on fan 248 mbar

Power cable 8 m

Weight 11.5 kg

Wet/ dry extractor for extractions in diamond drilling technology

Ideal for extracting coolant water (wet drilling) or

drill dust (dry drilling)

04

B

130 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Core bits extension

To increase the drill depth

Length 300 mm

Connection thread 1/2" can be used from

dia. 32 mm

Connection thread 1/1/4" can be used from

dia. 52 mm

Item Unit Designation

number Pieces

002350 1 Extension 1/2" 300 mm

002366 1 Extension 1 1/4" 300 mm

04-908 A/P 04

Brass ring

For easy release of the core bits from the drill

For M16- 1/2" or 1 1/4" bits

Brass rings are positioned between the core bits and

the drill intake

Item Unit Designation Dimensions

number Pieces mm

004688 10 Brass ring M16 16 x 22 x 1.5

002367 10 Brass ring 1/2" 21 x 25 x 1.5

002368 10 Brass ring 1 1/4" 33 x 39 x 2.0

04-908 A/P 04

Multi oil

Item Unit Container Cont.

number Pieces ml

015900 6 Aerosol 300

08-504 A/P 08509AC

Coating the drill stand and the drill support prior

to commencing work makes it easier to clean

afterwards

Keeps it in good condition and protects against

corrosion

For lubrication, protection and cleaning when working with diamond drill technology

SYSTRA Modul 2 + diamond drill technology accessories

The complete set of accessories for diamond drill technology

Scope of supply:

1 Biathlon SDS plus hammer drill 15.0 x 100/ 160

1 concrete mounting set

1 concrete tool M12

1 sprint SDS plus hammer drill 20.0 x 200/ 260

1 masonry mounting set

10 1/2" Brass rings 1/2"

10 1 1/4" Brass rings

per 1 double flat wrench

a/f 17 x 19/ 24 x 27/ 30 x 32/ 36 x 41

1 carpenter's pencil medium

1 measure 2m

1 lump hammer 1,000g

1 profi PH 2 screwdriver

1 right-angle screwdriver a/f 2,5/ 4,0/ 6.0

1 SYSTRA Modul 2 with workpiece insert

Item Unit Designation

number Pieces

002388 1 SYSTRA Modul 2

+ diamond drill technology

accessories

10-160 A/P 04

04

B

131 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

SW point adapter on M16 point

SDS plus adapter on M16 point

Item Unit Designation Length

number Pieces mm

434108 1 SW 9.5 point adapter on M16 point 76

340375 1 SW 11 point adapter on M16 point 78

340391 1 SDS plus adapter on M16 point 105

340278 1 SDS plus adapter on M16 point 220

010885 1 SDS plus adapter on M16 point 370

326062 1 Centering drill Supra HM 8 x 120 120

340251 1 Centering drill Multi-Cut 8 x 120 120

434116 1 Centering drill HSS 7.2 x 109 109

04-262 A/P 04260AE

Centering drill Supra HM

Adapter / centering drill

For hammer core drill with thread intake

Item Unit Designation Total

number Pieces length mm

003194 1 SDS max HBK adapter 200

003195 1 SDS max HBK adapter 460

003198 1 Centering drill 11 x 135 135

04-305 A/P 04305AA

Item Unit Designation

number Pieces

273503 1 SDS max /SDS plus adapter

04-319 A/P 04319

Multi-Cut centering drill

HSS centering drill

Adapter and centering drill for hammer core bits,

hammer core bits, multi cut hole saws, diamond drill bits

and diamond core bits

Fast change adapter/centering drill SW

Adapter / centering drill

Item Unit Designation Length

number Pieces mm

018443 1 SW adapter SW 9.5 point on M16 point 118

018444 1 SW adapter SW 11 point on M16 point 118

018445 1 SDS plus SW adapter on M16 point 118

018446 1 SDS plus SW adapter on M16 point 220

018448 1 SDS plus SW adapter on M16 point 370

018449 1 SW centering drill Supra HM 8.0 x 130 130

018450 1 SW centering drill HSS 7.4 x 109 109

04-262 A/P 04260AE

Adapter

SDS max on SDS plus

For hammer core bits, Multi-Cut hole saws and diamond drill bits

SW Centering drill Supra HM

SW Centering drill HSS

SW adapter SW point on M16 point

SDS plus SW adapter on M16 point

For hammer core bits, Multi-Cut hole saws and diamond drill bits

With fast change intake for centering drill

Easy adjustment and fast replacement of the

centering drill using sliding jack

No damage to the insert workpiece

SDS plus intake with reduced grooves prevents

hammer use (SW intake SDS plus is therefore not

suitable for hammer core bits)

04

B

132 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Adapter / centering drill

To use diamond socket cutters directly on the drill holder

Item Unit Designation Length Suitable

number Pieces mm for machine types

003008 1 Adapter 5/8" sleeve on M16 points 80 BTI-SB 1150 E, Bosch

002122 1 Adapter 1/2" points on M16 points 70 BTI-DDKB, BTI-DKB

001331 1 Adapter M18 sleeve on M16 points 80 AEG

003017 1 Centering drill HM 8.0 x 120 120 BTI, Bosch, AEG

04-903 A/P 04

Adapter ASV

To use the BTI extraction device for diamond socket cutters or for the use of BTI suction rotor for 1 1/4"

diamond core bits directly on the drill holder

Item Unit Designation Length Suitable

number Pieces mm for machine types

002129 1 ASV Adapter 5/8" sleeve on M16 points 48 BTI-SB 1150 E, Bosch

002133 1 ASV Adapter 1/2" points on M16 points 54 BTI-DDKB, BTI-DKB

002124 1 ASV Adapter M18 sleeve on M16 points 50 AEG

04-903 A/P 04

Adapter

For diamond core bits 1/2" and 1 1/4"

Item Unit Designation Length Suitable

number Pieces mm for machine types

002381 1 Adapter 1/2" points on 1 1/4" points 105 Diverse

002382 1 Adapter 1/2" sleeve on 1 1/4" points 100 Diverse

004058 1 Adapter W sleeve on 1/2" sleeve 65 Wrth

004059 1 Adapter W sleeve on 1/1/4" points 110 Wrth

04-908 A/P 04

Important:

All adapters are supplied without centering drill, please order these separately!

Adapter 1/2" points on M16 points

HM centering drill

ASV Adapter 5/8" sleeve on M16 points

ASV Adapter 1/2" points on M16 points

ASV Adapter M18 sleeve on M16 points

Adapter 1/2" points on 1 1/4" points

Adapter 1/2" sleeve on 1 1/4" sleeve

Adapter 5/8" sleeve on M16 points

Adapter M18 sleeve on M16 points

Adapter W sleeve on 1/2" sleeve

Adapter W sleeve on 1/1/4" points

04

C

133 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

wood drill

Turbo fast drilling and fiberless broaching

No blocking with damp wood

Point accurate drilling through long

centering screw

Drill dia. 6 mm: cylindrical shaft,

from drill dia. 7 mm: hexagonal holder

Operating instructions:

1. Position and center drill

2. Set drill to highest rotation speed

3. Drill

Range of application in carpentry:

Through holes for construction screws, rafter nails,

bung holes

Range of application roller shutter construction:

Holes for running of the belt in roller shutter boxes

Range of application wood construction business:

For all drill work in wood

Item Unit dia. Working Total

number Pieces mm length length

mm mm

046256 1 6.0 100 165

318680 1 6.0 180 230

046302 1 6.0 250 320 *

007721 1 6.0 350 460

046540 1 7.0 250 320 *

007722 1 7.0 350 460

046558 1 8.0 100 165

318698 1 8.0 180 230

046604 1 8.0 250 320*

046639 1 8.0 400 460

046779 1 9.0 250 320*

046787 1 10.0 100 185

318760 1 10.0 165 235

046833 1 10.0 250 320

046914 1 10.0 350 460

049883 1 12.0 100 185

050130 1 12.0 250 320

050172 1 12.0 350 460

178497 1 12.0 460 650

050326 1 13.0 250 320

050423 1 13.0 350 460

053910 1 14.0 130 200

053929 1 14.0 250 320

053953 1 14.0 350 460

178519 1 14.0 460 650

054070 1 16.0 130 200

054089 1 16.0 250 320

054127 1 16.0 350 460

178705 1 16.0 460 650

SDS plus

Item Unit dia. Working Total

number Pieces mm length length

mm mm

427314 1 6.0 100 200

427322 1 8.0 100 200

427330 1 10.0 100 200

427365 1 8.0 220 300

427373 1 10.0 220 300

427381 1 12.0 220 300

427390 1 14.0 220 300

427403 1 16.0 220 300

427411 1 12.0 360 450

427420 1 14.0 360 450

427438 1 16.0 360 450

427446 1 18.0 360 450

427454 1 20.0 360 450

427462 1 22.0 360 450

04-405 A/P 04405

Item Unit dia. Working Total

number Pieces mm length length

mm mm

054186 1 18.0 130 200

054194 1 18.0 250 320

054208 1 18.0 350 460

178721 1 18.0 460 650

054216 1 20.0 130 200

054232 1 20.0 250 320

054240 1 20.0 350 460

178888 1 20.0 460 650

054283 1 22.0 130 200

054291 1 22.0 250 320

054305 1 22.0 350 460

179000 1 22.0 460 650

054330 1 24.0 250 320 **

054348 1 24.0 350 460 **

179027 1 24.0 460 650

054364 1 25.0 250 320

054372 1 25.0 350 460

179035 1 25.0 460 650

054402 1 26.0 350 460

054445 1 28.0 350 460

054470 1 30.0 350 460

179051 1 30.0 460 650

054500 1 32.0 350 460

054534 1 34.0 350 460

054550 1 36.0 350 460

054577 1 38.0 350 460

054593 1 40.0 350 460 **

054615 1 45.0 350 460

04-404* * Special dimensions to pre-drill rafter nails

** For Simplex wood connectors

A/P 04404

Only to be drilled when turning

hammer action is switched off.

04

C

134 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Item Unit Designation dia. dia.

number Pieces mm inches

266850 1 wood drill bit 25 mm 25 1

266876 1 wood drill bit 29 mm 29 1

1

/8

266884 1 wood drill bit 32 mm 32 1

1

/4

266906 1 wood drill bit 35 mm 35 1

3

/8

266914 1 wood drill bit 38 mm 38 1

1

/2

266922 1 wood drill bit 44 mm 44 1

3

/4

267031 1 wood drill bit 51 mm 51 2

267040 1 wood drill bit 54 mm 54 2

1

/8

267104 1 wood drill bit 57 mm 57 2

1

/4

267112 1 wood drill bit 65 mm 65 2

9

/16

427969 1 wood drill bit 68 mm 68

427977 1 wood drill bit 74 mm 74

267147 1 wood drill bit 76 mm 76 3

267155 1 wood drill bit 92 mm 92 3

5

/8

267244 1 wood drill bit 118 mm 118 4

5

/8

04-425 A/P 04425

For boring of beams, laminated wood, planks, plasterboard and various plastics

Smaller nails and wire frame are sheared away

Shavings ejected at rear; no setting in material

Prominent centering tip makes it easier to use on

a sloping surface and on the outer edges

Centering tip can be replaced

2 centering tips are supplied (coarse / fine thread)

Range of application:

Electrical and heating installations for through holes

and blind holes in beams and timber construction

panels, in carpentry and timber construction tasks to

sink heavy plain and Geka washers; when using

wood drill bits the performance of the drill should be

calibrated to the diameter

wood drill bit

Item Unit Designation

number Pieces

395986 1 wood drill bit set 180

1 piece each wood drill 6 x 165, 8 x 165, 10 x 185, 12 x 185

and 16 x 205 mm in a beech wood case

395994 1 wood drill bit set 200

1 piece each wood drill 12 x 185, 14 x 205, 16 x 205, 18 x 205

and 20 x 205 mm in a beech wood case

396001 1 wood drill bit case 320

1 piece each wood drill 12 x 320, 14 x 320, 16 x 320, 18 x 320

and 20 x 320 mm in a beech wood case

396010 1 wood drill bit case 460

1 piece each wood drill bit 12 x 460, 14 x 460, 16 x 460, 18 x 460

and 20 x 460 mm in a beech wood case

04-407 A/P 04407

wood drill case

04

C

135 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Accessories

Rough centering point, for fast boring in soft wood

Item Unit Designation dia.

number Pieces mm

014183 1 Centering cylinder 10 mm 10

014184 1 Centering cylinder 12 mm 12

014185 1 Centering cylinder 14 mm 14

014186 1 Centering cylinder 16 mm 16

207381 1 Rough centering tip

210986 1 Fine centering tip

210994 1 Allen key for wood drill bit

267252 1 Extension 150 mm

267260 1 Extension 300 mm

267279 1 Extension 450 mm

267287 1 Extension 600 mm

04-425 Separate centering tip and centering cylinder only suitable

for wood drill bits up to and including dia. 74 mm A/P 04425AA

Fine centering tip for controlled counter sinking and

boring in hard wood

Extension for wood drill bit,

several extensions can be linked together

Centering cylinder, especially for counter sinking of

Geka washers and heavy plain washers

WS countersink drill

Tool steel 90

Pentagonal cutting

Total length 90 mm

With stepped cylinder shaft

Item Unit Designation Drill dia. Shaft dia.

number Pieces mm mm

277924 1 WS countersink drill 10 10 8

277932 1 WS countersink drill 13 13 8

277940 1 WS countersink drill 16 16 8

277959 1 WS countersink drill 20 20 8

277967 1 WS countersink drill 25 25 10

04-412 A/P 04412

Item Unit Designation

number Pieces

278009 1 WS countersink drill bit 5 piece set.

1 piece each WS countersink drill 10, 13, 16, 20 and 25 mm

in a beech wood case

04-413 A/P 04413

WS router drill bit

Tool steel 2 edged

Completely cylindrical

With chip breaker and bare grooves

Item Unit Designation Drill dia. Length

number Pieces mm mm

279293 1 WS router drill bit 6 6 110

279455 1 WS router drill bit 8 8 120

279463 1 WS router drill bit 10 10 130

279595 1 WS router drill bit 12 12 140

279617 1 WS router drill bit 14 14 150

04-420 A/P 04420

Item Unit Label

number Pieces

279633 1 WS router drill cassette 5 piece case

each 1 piece WS router drill bit 10, 6, 8, 12 and 14 mm

in a beech wood case

04-421 A/P 04421

04

C

136 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

WS universal bit

HM universal bit with spur

2 carbide cutters

2 carbide spurs

Tool steel with 2 cutters

2 spurs

Centering point

Item Unit Designation Drill Shaft

number Pieces dia. mm dimension mm

280542 1 HM universal bit with spur 15 15 10 x 75

280550 1 HM universal bit with spur 20 20 10 x 75

280569 1 HM universal bit with spur 25 25 10 x 75

280739 1 HM universal bit with spur 30 30 10 x 75

280755 1 HM universal bit with spur 35 35 10 x 30

280895 1 HM universal bit with spur 40 40 10 x 30

04-417 A/P 04417AB

Item Unit Designation

number Pieces

278874 1 WS universal drill bit 5 piece set

1 piece each WS mortice bit drill 25, 15, 20, 30 and 35 mm

in a beech wood case

04-418 A/P 04418AA

Machine sanded off true-to-size

Stepped cylinder shaft

Total length 90 mm

Excellently suited for use in high-RPM operating hand drills

For use with extremely hard woods, coated panels and plastics with high-RPM hand drills

1 carbide centering point

Total length 90 mm

WS forstner bit

Tool steel

With centering point and peripheral cutter

Machine sanded off true-to-size

Total length 90 mm

Stepped cylinder shaft

Very true-to-size and clean holes, also in the

edge area

For use in supported/ stationary machines

Item Unit Designation Drill Shaft

number Pieces dia. dimension

mm mm

278041 1 WS forstner bit 15 15 8 x 30

278181 1 WS forstner bit 20 20 8 x 30

278190 1 WS forstner bit 25 25 8 x 30

278416 1 WS forstner bit 30 30 8 x 30

278424 1 WS forstner bit 35 35 10 x 30

278645 1 WS forstner bit 40 40 10 x 30

04-416 A/P 04416

Item Unit Label

number Pieces

278653 1 WS Forstner bits set

1 piece each WS Forstner bit 25, 15, 20, 30 and 35 mm

in a beech wood case

04-418 A/P 04418

04

C

137 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Tenon cutter

Tenon cutter inside (excess 0.2 mm)

Easy positioning of the knot hole dowel

Special version

Internally and externally machine sanded

Item Unit Designation Internal dia. External dia. Shaft

number Pieces (tenons) (borehole) dimension

mm mm mm

278890 1 Tenon cutter 15 15 26 13 x 50

278939 1 Tenon cutter 20 20 31 13 x 50

278955 1 Tenon cutter 25 25 38 13 x 50

278963 1 Tenon cutter 30 30 44 13 x 50

278971 1 Tenon cutter 35 35 48 16 x 50

04-419 A/P 04419

To repair knotholes

Arbor-mounted counterbore

Tool steel sharpened

Arbor-mounted counterbore

Depth stop

Made from hardened tool steel

Supplied with suitable Allen key

Item Unit Designation for drilling Working

number Pieces dia. mm depth mm

188824 1 Arbor-mounted counterbore 3 3.0 7.0

188913 1 Arbor-mounted counterbore 4 4.0 6.0

189111 1 Arbor-mounted counterbore 5 5.0 5.0

189138 1 Arbor-mounted counterbore 6 6.0 5.0

189529 1 Arbor-mounted counterbore 8 8.0 6.5

189596 1 Arbor-mounted counterbore 10 10.0 6.0

189600 1 Arbor-mounted counterbore 12 12.0 5.0

04-410 A/P 04410

With 5 cutters, large space for shavings and fully concealed internal hexagon bit

Range of application:

Can be used in conjunction with wood twist drill for

sinking and counter-sinking of screw heads as well as

a depth stop, e.g. when drilling the holes for dowels, in

solid wood and uncoated panel material

Arbor-mounted counterbore set

Arbor-mounted counterbore and wood twist drill in a stable and practical wooden case

Item Unit Designation/ Assortment

number Pieces

382949 1 Arbor-mounted counterbore 14 piece set.

1 piece each arbor-mounted counterbore and wood twist drill

dia. 3/ 4/ 5/ 6/ 8/ 10/ 12 mm = 14 parts + suitable Allen key

04-411 A/P 04411

04

C

138 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Wood twist drill

Tool steel sharpened

With cylindrical shaft

Tempered and grinded centrically

Surface bronzed and cylindrically grinded

Item Unit Designation Drill Total

number Pieces dia. mm length mm

331961 10 Wood twist drill 3 3.0 61

332046 10 Wood twist drill 4 4.0 75

193496 10 Wood twist drill 5 5.0 86

193500 10 Woodtwist drill 6 6.0 93

005496 5 Wood twist drill 7 7.0 105

193518 5 Wood twist drill 8 8.0 117

005497 5 Wood twist drill 9 9.0 120

193526 5 Wood twist drill 3 10.0 120

311006 5 Wood twist drill 12 * 12.0 151

04-410 * Shaft at full extension dia. 8 mm, clamping length 30 mm A/P 04410AA

Item Unit Designation

number Pieces

005498 1 8 piece wood twist drill set.

1 piece each wood twist drill bits dia. 3, 4, 5, 6, 7, 8, 9, 10 mm

04-411 * Shaft at full extension dia. 8 mm, clamping length 30 mm A/P 04411AA

Machine wood twist drill similar to DIN 7487

Range of application:

Suitable for drilling of hardboards, chip boards, pine,

beech, oak and similar timbers and dowel holes

04

C

139 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Timbering and installation drill

Offset transition from bit to shaft avoids jamming

in the borehole

Shock resistant and impervious to the most

extreme stresses through a special connection

between the bit and the shaft (not soldered)

Easy to resharpen Only to be bored when turning,

Switch off hammer action!

Timbering drill, cylindrical holder

Item Unit Drill dia. Shaft dia. Total

number Pieces mm mm length mm

037158 1 8 6 400

037165 1 8 6 600

037189 1 10 7 400

037196 1 10 7 600

037219 1 12 9 400

037226 1 12 9 600

037240 1 14 9 400

037257 1 14 9 600

037264 1 16 9 400

037271 1 16 9 600

037288 1 18 9 400

037295 1 18 9 600

037301 1 20 9 400

037318 1 20 9 600

037325 1 22 9 400

037332 1 22 9 600

037349 1 30 11 600

04-430 A/P 04430

Timbering drill, SDS plus holder

Item Unit Drill dia. Total

number Pieces mm length mm

037356 1 10 400

037363 1 10 600

037394 1 12 400

037417 1 12 600

037431 1 14 400

037448 1 14 600

037455 1 16 400

037462 1 16 600

037479 1 18 400

037486 1 18 600

037493 1 20 400

037509 1 20 600

037516 1 22 400

037523 1 22 600

037530 1 24 400

037547 1 24 600

037554 1 26 600

037561 1 28 600

037578 1 30 600

037585 1 32 600

04-431 A/P 04431

Cylindrical and SDS plus holder

Manufactured in accordance with professional

association regulations

Application:

Sanitary, heating and electrical building, piping

installation in wood, plasterboards, light construction

panels, construction firms for sheeting

Material: CV steel

04

C

140 1

0

0

6

04

D

141 1

0

0

6

W

W

W

.

B

T

I

-

G

R

O

U

P

.

C

O

M

Twist drill DIN 338, roll forged

More powerful and stable with good working life;

even after being resharpened several times highly

resistant to breakage

N Type, right cut