Professional Documents

Culture Documents

Debis Tower

Uploaded by

cloudclimberCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Debis Tower

Uploaded by

cloudclimberCopyright:

Available Formats

PERFORMATIVE DOUBLE LAYERED SYSTEMS : THE DEBIS TOWER BY RENZO PIANO

MARIO DARTISTA

PETER OH

YEHRE SUH

ANDREW VARELA

GSD 6204 BUILDING TECHNOLOGY

A

r

c

h

i

t

e

c

t

u

r

e

d

a

u

j

o

u

r

d

h

u

i

,

n

.

3

0

8

,

D

e

c

e

m

b

e

r

1

9

9

6

,

p

.

7

0

The fall of the Berlin Wall has resulted in the reconstruction of the reunited

German capital. A frenzied mechanism of property development and relocation

has been set in motion, including the relocation of the government back to its

old seat.

The development of the Postdamer Platz has become the great symbol of the

unification of Berlin. Historically very significant, it was the social, cultural and

economic center during the 1920s and 30s. It was the wonder of Europe. The

destruction from World War II and the political arrangements of the Cold War

transformed the site into a deserted strip dividing East and West Berlin.

In addition to the new complex of buildings, the site also comprises the great

complex of the Kulturforum, made up of the National Gallery, the Berlin

Philharmonie, and the State Library.

Pianos master plan for the Potsdamer Platz held to the Hilmer & Sattler

scheme established a year earlier. The plan conformed to Berlins traditional

pattern of city blocks. The underlying philosophy was to bring the historic

buildings and streets of Berlin back to life. It also sought to reinterpret the old

models and to establish a bridge with the past.

The Workshop generated a series of guidelines that were made into regulations

which governed the design of the whole site. These included alignments, widths

of streets, hierarchy, construction heights and sizes as well as formal obliga-

tions and material palettes: terra-cotta and clear glass for the facades, with

copper for the roofs.

The desired variety would be generated out of the individual interpretation each

architect would give to their respective commissions. The architects included

Arata Isozaki, Hans Kolhoff, Lauber & Wohr, Rafael Moneo, Richard Rogers,

and Renzo Piano.

MASTER PLAN FOR THE POSTDAMER PLATZ

POSTDAMER PLATZ

A

r

c

h

i

t

e

c

t

u

r

e

d

a

u

j

o

u

r

d

h

u

i

,

n

.

3

0

8

,

D

e

c

e

m

b

e

r

1

9

9

6

,

p

.

6

2

,

P

h

o

t

o

b

y

A

n

d

r

e

a

s

M

u

h

s

The Debis Tower by the Renzo Piano Workshop is situated at the corner

site, acting as a gateway into the newly developed complex. The Debis

Tower, houses the offices of the Debis company, Daimler-Benzs (now

Daimler-Chryslers) real estate division. The building asserts the identity

of the site by its height, as well as by its characteristic appearance of

terra-cotta and non-reflecting glass.

Based on the traditional typology of the New York skyscraper, the

building is formed by a base and a tower. The building was conceived

as two thin bars bordering an internal street. Refusing to design a

commercial center along the lines of an American shopping mall, Piano

was able to persuade the client to build a covered shopping street. This

typology was related to the large galleries that existed in the 19th

century, such as the Galleria in Milan.

PLANS OF THE DEBIS TOWER

DEBIS TOWER

DEBIS TOWER

A

r

c

h

i

t

e

c

t

u

r

a

l

R

e

c

o

r

d

,

v

.

1

8

6

,

n

.

1

0

,

O

c

t

o

b

e

r

1

9

9

8

,

p

.

1

3

2

A

r

c

h

i

t

e

c

t

u

r

a

l

R

e

c

o

r

d

,

v

.

1

8

6

,

n

.

1

0

,

O

c

t

o

b

e

r

1

9

9

8

,

p

.

1

2

5

,

P

h

o

t

o

b

y

R

i

c

h

a

r

d

B

r

y

a

n

t

/

A

r

c

a

i

d

Half of all the energy in the world is used to heat, light, cool, and

ventilate buildings. As a consequence, buildings are the main

culprits in the production of carbon dioxide, which produces the

greenhouse gases that are changing the worlds climate. As a

result of this, new policies, such as new building codes, are

being implemented so that the sustainability of our planet is not

undermined. In this context, there has been a proliferation of

sytems and technologies designed by architects and engineers

to reduce the amount of energy consumption of buildings. This

new trend is a response primarily to the need for a sutainable

environment. It is also economically prudent and practical. The

cost of a degraded environment and a damaged ecosystem is

estimated to be much higher.

Piano has always been at the forefront of architectural innovation.

This is partly due to his collaborative approach, which stresses

teamwork between the various design parties, as can be seen in

the especially substantive relationship between Piano and the

engineering firm of Ove Arup. In the Debis Tower, Piano has

created an urbanistically sophisticated, environmetally progres-

sive, and technologically advanced workplace. This is achieved

through the design of performative double layered systems:

glazed/terra-cotta, glazed/glazed, and terra-cotta/terra-cotta.

Each system is designed according to various factors, such as

its location and its position relative to the sun, its assembly and

its maintenance. These performative double layered systems

together with the way they are assembled and maintained form

an energy-efficient, low pollution building. As a result, it trans-

THESIS

forms the office-building type and has [captured] the long lost

romance of the skyscraper.

In this sense, the building is designed to make the most out of

daylight and reduces heating and cooling by means of shallow

floor plates as well as a sophisticated curtain wall. The curtain

wall is formed by a system of double skin facades that contain

a layer of tempered air so that when office windows are

opened, air at extreme temperatures cannot be drawn in.

Chilled ceilings are provided in areas of unusual heat produc-

tion. The use of high thermal insulation produces a building

that is expected to run on 70kWh/m2, reducing primary energy

consumption by 50 per cent when compared to normally air-

conditioned buildings.

Other environmentally driven decisions include the use of

rainwater to irrigate landscaping and to flush lavatories, saving

20,000 cubic meters of water per year. Another innovation is

the use of construction materials which minimize pollution,

such as the bio-degradable plant oil required for the lubrication

of all shuttering.

Based on the system used in the Cite International

in Lyons (another Piano project), the added layer

consists of a glass membrane with pivoting shut-

ters placed 27 inches in front of a simple facade

skin. Fabricated by the German manufacturer Gotz,

the outer glass panels pivot up to 70 degress. The

membrane has the ability to be fully closed in the

winter to help heat the interior. At the same time, it

ensures better sound proofing. During the sum-

mer, the electrically operated louvers can be opened

to allow for cooling. At night it can evacuate the hot

air accumulated in the building.

Occupants are protected from glare by external

blinds, which can be operated from the inside.

The maintenance catwalks set between the glass

layers act as a sunshading device and are topped

with laminated safety glass to stop the spread of

fire and smoke in the event of an emergency.

Climatic Double Skin

like an extra coat

PIVOTING SHUTTERS OF THE DOUBLE SKIN

PLAN DETAIL AT SPANDREL

laminated glass

maintenance grating

pivot motor

external blind

operable window

tilt mechanism

laminated glass blades

SECTION THROUGH CURTAIN WALL

CITE INTERNATIONAL IN LYON

heat-strengthened glass

maintenance grating

track for

maintenance cradle

A

r

c

h

i

t

e

c

t

u

r

a

l

R

e

c

o

r

d

,

v

.

1

8

6

,

n

.

1

0

,

O

c

t

o

b

e

r

1

9

9

8

,

p

.

1

2

8

,

C

o

u

r

t

e

s

y

o

f

G

o

t

z

G

M

B

H

A

r

c

h

i

t

e

c

t

u

r

a

l

R

e

c

o

r

d

,

v

.

1

8

6

,

n

.

1

0

,

O

c

t

o

b

e

r

1

9

9

8

,

p

.

1

2

8

,

C

o

u

r

t

e

s

y

o

f

G

o

t

z

G

M

B

H

A

r

c

h

i

t

e

c

t

u

r

e

d

a

u

j

o

u

r

d

h

u

i

,

n

.

3

0

8

,

D

e

c

e

m

b

e

r

1

9

9

6

,

p

.

7

1

The lower parts of the building and the parts most

exposed to the sun are clad in the terra-cotta/

terra-cotta system. Following the logic of the

double skin system, the outer terra-cotta is an

added layer which insulates and waterproofs the

inner terra-cotta wall. The outer wall also

provides shading from the sun

As is typical for the Piano Workshop, much

energy was employed in the design of the terra-

cotta module. The terra-cotta is a mix of care-

fully selected clays which yields higher density

and greater strength when compared to tradi-

tional clay material. This makes glazing of the

terra-cotta unnecessary.

Intended to provide functional flexibility, the terra-

cotta can be assembled in several modes: single

or double skin, solid, or open work. This allows

the solidity of the wall to be calibrated according

to the opacity desired while at the same time

providing an overall unity to the building.

TERRA-COTTA

baguettes

terra-cotta panel

external blind

operable window

terra-cotta rod

SECTION THROUGH TERRA-COTTA WALL

CITE INTERNATIONAL IN LYON

SECTION THROUGH TERRA-COTTA WALL

horizontal

terra-cotta rod

terra-cotta fitting

terra-cotta mullion

operable window

terra-cotta mullion

PLAN DETAIL

A

r

c

h

i

t

e

c

t

u

r

e

d

a

u

j

o

u

r

d

h

u

i

,

n

.

3

0

8

,

D

e

c

e

m

b

e

r

1

9

9

6

,

p

.

7

0

A

r

c

h

i

t

e

c

t

u

r

a

l

R

e

c

o

r

d

,

v

.

1

8

6

,

n

.

1

0

,

O

c

t

o

b

e

r

1

9

9

8

,

p

.

1

3

1

,

C

o

u

r

t

e

s

y

o

f

G

o

t

z

G

M

B

H

A

r

c

h

i

t

e

c

t

u

r

a

l

R

e

c

o

r

d

,

v

.

1

8

6

,

n

.

1

0

,

O

c

t

o

b

e

r

1

9

9

8

,

p

.

1

3

1

,

C

o

u

r

t

e

s

y

o

f

G

o

t

z

G

M

B

H

The interior facade which faces the atrium and

the interior street also follows the layered

approach. A double glazed system is used, in

which a frame carrying screen-printed glass

blades is superimposed on the glazed panel of

the window. The blades are tilted and screen-

printed in white to insure privacy as well as to

deflect the sightlines of the occupants up-

wards. In addition, they intensify daylight in

the interior street.

Internal Facade

INTERIOR WALL SECTION

INTERIOR ATRIUM

glaze control curtain

smoke control curtain

fixed glass fins

A

r

c

h

i

t

e

c

t

u

r

e

d

a

u

j

o

u

r

d

h

u

i

,

n

.

3

0

8

,

D

e

c

e

m

b

e

r

1

9

9

6

,

p

.

7

5

A

r

c

h

i

t

e

c

t

u

r

a

l

R

e

c

o

r

d

,

v

.

1

8

6

,

n

.

1

0

,

O

c

t

o

b

e

r

1

9

9

8

,

p

.

1

3

5

,

P

h

o

t

o

b

y

G

.

B

.

G

a

r

o

i

n

The surface of the roof has been designed as a

landscape. Following German law which requires

large greenery areas, the roof structure uses two

innovative systems for the different conditions within

the project:

Derived from the DeMenil Foundation in Houston, the

glazed part of the building is constituted by screen-

printed glass shutters which are hung obliquely under

the glazing. Such a system allows solar protection

as well as natural ventilation.

The terrace parts consist of a double roof which

enables all technical ducts to be hidden. The upper

parts act as a sort of false floor. Its steel trays are

covered with a thin layer of earth planted with a highly

resistant moss, which requires very little upkeeping.

This sytem is used as an insulation mechanism as

well as a water recycling system.

ROOF STRUCTURE

ROOF SECTION DE MENIL FOUNDATION

GLASS SHUTTERS ON ATRIUM ROOF

DETAIL SKETCH

A

r

c

h

i

t

e

c

t

u

r

e

d

a

u

j

o

u

r

d

h

u

i

,

n

.

3

0

8

,

D

e

c

e

m

b

e

r

1

9

9

6

,

p

.

7

4

A

+

U

:

A

r

c

h

i

t

e

c

t

u

r

e

a

n

d

U

r

b

a

n

i

s

m

,

v

.

3

2

9

,

n

.

2

,

F

e

b

r

u

a

r

y

1

9

9

8

,

p

.

1

2

3

A

+

U

:

A

r

c

h

i

t

e

c

t

u

r

e

a

n

d

U

r

b

a

n

i

s

m

,

v

.

3

2

9

,

n

.

2

,

F

e

b

r

u

a

r

y

1

9

9

8

,

p

.

1

2

3

,

P

h

o

t

o

b

y

B

e

r

e

n

g

o

G

a

r

d

i

n

Much energy was devoted to the design of the

components of the building and their assembly. As

part of the overall Potsdamer Platz master plan, the

Workshop designed a prototype panel that can be

assembled in several models: single, double skin,

solid or openwork.

As is typical of the office, they worked in close

collaboration with other design fields for the develop-

ment of such prototypes. In the case of the terra-

cotta panel the Workshop collaborated with two

German building firms: Janinhoff-NBK and Wendker.

The panel was developed to meet tight specifications

such as the possibility of extrusion to considerable

lengths, uniformity of kiln-firing and drying to ensure

minimum assembly tolerance, and thermic quality.

The terra-cotta panels have two types of components:

1. moulded mullion pieces obtained by pressing,

which are modules 113 mm wide whose shape varies

slightly according to whether they are attached to the

bars.

2. the bars themselves, which are square in section

with 48 mm sides. They are extruded to a maximum

length of 1.35 m, and are fixed to the profile that

carries the plates by aluminum reinforcement set in

their hollow section. Each panel is factory-

assembled.

ASSEMBLY

PREFABRICATED

PANEL ELEMENTS

PANEL ASSEMBLY

A

r

c

h

i

t

e

c

t

u

r

e

d

a

u

j

o

u

r

d

h

u

i

,

n

.

3

0

8

,

D

e

c

e

m

b

e

r

1

9

9

6

,

p

.

7

0

,

P

h

o

t

o

b

y

M

i

c

h

e

l

D

e

n

a

n

c

e

A

+

U

:

A

r

c

h

i

t

e

c

t

u

r

e

a

n

d

U

r

b

a

n

i

s

m

,

v

.

3

2

9

,

n

.

2

,

F

e

b

r

u

a

r

y

1

9

9

8

,

p

.

1

2

4

,

P

h

o

t

o

b

y

M

i

c

h

e

l

D

e

n

a

n

c

e

The glazing for the various facade systems also

required exacting procedures and development. It is

likely that the installation of the glazing panels was

very labor intensive. Prefabricated single bays were

made off-site and transported to the construction site.

In addition to normal building construction crews, the

operable panels required additional mechanical and

electrical labor in order to install the motorized

rotation units on site. This probably meant that sub-

contractors were brought into the construction

process to insure acceptable finish quality. Finally,

the installation of the electrically operated exterior

blinds also required delicate and specialized labor.

The overall cost for the assembly of the glazing

panels was probably costly.

ELEVATION MOCK-UP

A

r

c

h

i

t

e

c

t

u

r

e

d

a

u

j

o

u

r

d

h

u

i

,

n

.

3

0

8

,

D

e

c

e

m

b

e

r

1

9

9

6

,

p

.

7

1

-

7

2

,

P

h

o

t

o

b

y

M

i

c

h

e

l

D

e

n

a

n

c

e

Since the glazing is a clear surface, the issue of accessability and

cleaning had to be addressed by Piano. In the roof of the atrium, the

double-layered facade has a cavity with maintenance platforms

which act as a sunshade and as surface deflectors.

The added costs of the mechanical equipment and the energy

necessary to operate and to maintain the various building systems

was considered. The louvers were considered to be a high mainte-

nance item, as well as the affiliated mechanized glazing panels. By

contrast, the terra-cotta was deemed to be easily maintainable, due

to the rigidity and impermeability of the high density clay used in its

manufacture. The moss-roof was deemed to require low mainte-

nance as well.

In the line of energy efficiency and economy of means the buildings

initial cost as well as the maintenance cost even out though they

seem to be large at first glance. The increased share of design and

construction was argued to be actually neglectable compared to the

overall cost of the building through its entire life cycle.

MAINTENANCE

Double glazed facade and glazed atrium

MAINTENANCE OF ATRIUM

CURTAIN WALL MAINTENANCE PLATFORM

A

r

c

h

i

t

e

c

t

u

r

e

d

a

u

j

o

u

r

d

h

u

i

,

n

.

3

0

8

,

D

e

c

e

m

b

e

r

1

9

9

6

,

p

.

7

8

A

r

c

h

i

t

e

c

t

u

r

a

l

R

e

c

o

r

d

,

v

.

1

8

6

,

n

.

1

0

,

O

c

t

o

b

e

r

1

9

9

8

,

p

.

1

2

8

,

P

h

o

t

o

b

y

M

i

c

h

a

e

l

B

a

r

t

h

e

l

m

e

In the context of a German political and social atmosphere in

which energy conservation and environmentally non-harmful

buildings are encouraged and promoted, the Debis Tower follows

a lineage of recent buildings built in Germany, such as the

extension to the Reichstag in Berlin, RWE in Essen, and the

Commerzbank in Frankfurt. The Debis Tower is innovative and

provides enormous advantages in the areas of energy conserva-

tion, lighting, and building ventilation. This results in an environ-

ment which is extremely favorable for office workers since it

allows them to work in comfortable areas which can be con-

trolled individually according to heat, light, and humidity. This, in

turn, is beneficial for the company since it offers workers better

protection and promotes productivity.

However, the Debis Tower demands a high level of maintenance

and initial cost. The articulation of the different facade systems

is very delicate and although Piano designed them to be as

rugged and reliable as possible, it is feasible to think that the

building will require extensive maintenance and repair. This is

similar to the situation of an earlier Piano building, the Centre

Pompidou, which only after twenty-five years, required an

overhaul and reconstruction of all major building systems. The

cost is palatable because the building generates a high interna-

tional profile and has, indeed, become an icon of Paris. The

Debis company probably harbors similar hopes for their tower

and is willing to invest in the cost of the building.

CONCLUSION

The unique societal circumstances surrounding the Debis Tower

probably means that such environmentally-friendly buildings will

probably be feasible only in Europe for the forseeable future. In the

U.S., for example, such buildings would be very advantageous due to

the generally warmer and sunnier climate. A building such as the

Debis Tower would conserve a large amount of energy and create

glare-free work environments for workers. However, much of the U.S.

exists in high-humidity regions, and this would render the natural

ventilation systems almost useless, especially in the summer.

Historically, the prevalence of air-conditioning in the U.S. also would

be a major hindrance for the Debis Tower. Many companies and

potential clients would probably weigh the price of constructing such

a high-maintenance building such as the Debis Tower as being

simply too high and unjustifiable.

Such buildings can be built in the U.S.; in general, the cost of

building skyscrapers in the U.S. is much less than in Europe.

However, the specialized technology and knowledge of customized

curtain wall systems is heavily based in Europe, which means that

the cost of importing the required technology and labor would add too

much onto the overall cost of materials and construction.

BIBLIOGRAPHY

Architektur in Berlin: Jahrbuch / herausgegeben von der Architektenkammer Berlin. Hamburg:

Junis, 1998.

Arnaboldi, Mario Antonio, Cognitivo e Conoscitivo: Debis Haus, Berlin, Arca, n.136, April 1999,

pp. 4-11.

Fromoonot, Francoise, Piano: Berlin, Vertus du Compromis, Architecture daujourdhui, n.308,

December 1996, pp. 58-81.

Piano at Potsdamer Platz, Architectural Review, v.205, n.1223, January 1999, pp. 35-42.

Piano, Renzo, Renzo Piano Building Workshop: Debis Building Potsdamer Platz

Reconstruction, Berlin, Germany 1992," A+U: Architecture and Urbanism, v.329, n.2, February

1998, pp. 104-125.

Russell, James S., A Striking Presence on the Berlin Skyline, the Debis Tower, by the Renzo

Piano Building Workshop, Revises the Skyscraper, Architectural Record, v.186, n.10, October

1998, pp. 125-135.

Wefing, Heinrich. Der Neue Potsdamer Platz. Verlag Gmbh, Berlin, 1998.

Yeang, Ken. Designing with Nature: The Ecological Basis for Architectural Design. New York:

McGraw-Hill, 1995, p. 130-136.

You might also like

- Paris Mansions and Apartments 1893: Facades, Floor Plans and Architectural DetailsFrom EverandParis Mansions and Apartments 1893: Facades, Floor Plans and Architectural DetailsRating: 4.5 out of 5 stars4.5/5 (3)

- Commerzbank. Frankfurt. Foster and PartnersDocument8 pagesCommerzbank. Frankfurt. Foster and Partnersalamin r.aNo ratings yet

- (Architecture Ebook) Detail Praxis - Timber ConstructionDocument55 pages(Architecture Ebook) Detail Praxis - Timber ConstructionEduardo RioNo ratings yet

- Blower Door Tests (En 13829) For Quality Assurance - Getting Air-Tight Buildings in Retrofitting, TooDocument6 pagesBlower Door Tests (En 13829) For Quality Assurance - Getting Air-Tight Buildings in Retrofitting, TooSam WeberNo ratings yet

- Antony Wood CTBUH GreenLecture 05Document105 pagesAntony Wood CTBUH GreenLecture 05bansaldhruvNo ratings yet

- Green Building Materials GuideDocument9 pagesGreen Building Materials GuideRushika KothuruNo ratings yet

- Lever House Curtain Wall 1952Document9 pagesLever House Curtain Wall 1952Ignacio Fernández Solla100% (1)

- Building With Large Clay Blocks (Theodor Hugues)Document118 pagesBuilding With Large Clay Blocks (Theodor Hugues)backsu100% (1)

- FosterDocument1 pageFostercandflossmafiamuffinNo ratings yet

- Renzo PianoDocument20 pagesRenzo PianoRingo AlcaldeNo ratings yet

- Membrane StructureDocument7 pagesMembrane StructuretheartsyfebNo ratings yet

- Reichstag BuildingDocument13 pagesReichstag BuildingDon JoviNo ratings yet

- Buenos Aires City HallDocument8 pagesBuenos Aires City HallSenouiiNo ratings yet

- Microclimates to cool public places using 3D printed sand structuresDocument36 pagesMicroclimates to cool public places using 3D printed sand structuresAndreea MNo ratings yet

- FXBFDBN GNGFN TTHRDocument3 pagesFXBFDBN GNGFN TTHRpauldasman1No ratings yet

- Portola Valley Town Center Goes GreenDocument7 pagesPortola Valley Town Center Goes GreenmymalvernNo ratings yet

- Architectural Trends Thru The Looking GlassDocument7 pagesArchitectural Trends Thru The Looking GlassdumbfactorNo ratings yet

- Waterproofing Systems for Green Roofs GuideDocument72 pagesWaterproofing Systems for Green Roofs Guideharry wibowoNo ratings yet

- Gherkin & Bloomberg HQ s under 40 charsDocument9 pagesGherkin & Bloomberg HQ s under 40 charsSohailaa MohamedNo ratings yet

- AR 1110 E-Master 300610Document32 pagesAR 1110 E-Master 300610aminzbbNo ratings yet

- Paolo Cappellacci PortfolioDocument8 pagesPaolo Cappellacci PortfolioPaolo CappNo ratings yet

- Chapter 1: The Project Background The ProjectDocument7 pagesChapter 1: The Project Background The ProjectEna Elaine LensicoNo ratings yet

- Bio PollutionDocument5 pagesBio PollutionNikki BarenaNo ratings yet

- White Collar FactoryDocument14 pagesWhite Collar FactoryAnder AndersenNo ratings yet

- Arend Benkert Defilippis TillmaandDocument36 pagesArend Benkert Defilippis TillmaandSap IensNo ratings yet

- Kim RWEDocument11 pagesKim RWERobert HughesNo ratings yet

- Taichung Convention Centre Mixed-Use Development: Arup Awarded Design of TheDocument51 pagesTaichung Convention Centre Mixed-Use Development: Arup Awarded Design of The8986103tNo ratings yet

- CONTEMPORARYDocument10 pagesCONTEMPORARYTRILZ ARIS MILO ARREOLANo ratings yet

- PI Phaeno en 150dpiDocument16 pagesPI Phaeno en 150dpiRoberto S L NaboniNo ratings yet

- Design, Birkhäuser, 1999Document105 pagesDesign, Birkhäuser, 1999Enciu AlexandraNo ratings yet

- Enameled Glass Panels For Solar Thermal Building Envelopes: SciencedirectDocument7 pagesEnameled Glass Panels For Solar Thermal Building Envelopes: SciencedirectPutri MentariNo ratings yet

- Case Studies AnnaDocument11 pagesCase Studies AnnaJoNo ratings yet

- Case StudyDocument2 pagesCase StudyLudovico Fernandez PeRalta IIINo ratings yet

- Sarah Hospital - Joao Filgueiras LimaDocument35 pagesSarah Hospital - Joao Filgueiras LimaJoao Pedro LacerdaNo ratings yet

- ZinCo Corporate BrochureDocument24 pagesZinCo Corporate BrochureAlexandru NacuNo ratings yet

- Controlling the Environment in RWE's Double Skin Façade TowerDocument5 pagesControlling the Environment in RWE's Double Skin Façade TowerCornelius CahyoNo ratings yet

- Solar Shading SystemsDocument40 pagesSolar Shading SystemsAnca CrețuNo ratings yet

- Book Vershinin S 88 String Po 177 String - Ru.enDocument71 pagesBook Vershinin S 88 String Po 177 String - Ru.enEsmail MostafaNo ratings yet

- Innovative Building Skins: Double Glass Wall Ventilated FacadeDocument26 pagesInnovative Building Skins: Double Glass Wall Ventilated Facadeeatonrob100% (4)

- ITC Green Centre, Gurgaon: General InformationDocument7 pagesITC Green Centre, Gurgaon: General Informationbintang avgustaNo ratings yet

- Double Skin Façades and Their Influence On The Form of Contemporary BuildingsDocument7 pagesDouble Skin Façades and Their Influence On The Form of Contemporary BuildingsbsantaceciliaNo ratings yet

- Bodegas PortiaDocument3 pagesBodegas PortiaAleksandra BrcinaNo ratings yet

- Richard RogersDocument17 pagesRichard RogersTintu ThambiNo ratings yet

- Arjan02freidone PDFDocument2 pagesArjan02freidone PDFVuTienAnNo ratings yet

- B 0 Afe 979Document8 pagesB 0 Afe 979Marco MilazzoNo ratings yet

- Academic Buildings) : General InformationDocument17 pagesAcademic Buildings) : General InformationAfreen BandayNo ratings yet

- Disposable Formwork For Ventilated Under-Fl Oor CavitiesDocument24 pagesDisposable Formwork For Ventilated Under-Fl Oor CavitiesDaliform GroupNo ratings yet

- Agrob Buchtal - FatadeDocument98 pagesAgrob Buchtal - Fatademada009No ratings yet

- 2005 04RooftopGardeningBeijingDocument12 pages2005 04RooftopGardeningBeijingManesg KapoorNo ratings yet

- Sustainable Renovation: Strategies for Commercial Building Systems and EnvelopeFrom EverandSustainable Renovation: Strategies for Commercial Building Systems and EnvelopeNo ratings yet

- Document A Tie 1Document117 pagesDocument A Tie 1Nicole HallNo ratings yet

- Engineering International enDocument20 pagesEngineering International enadventure11111No ratings yet

- Tensinews 17Document24 pagesTensinews 17seba villeNo ratings yet

- Fabric in ArchitectureDocument28 pagesFabric in ArchitecturesubalakshmiNo ratings yet

- FlowCon Project Tornado Tower QatarDocument5 pagesFlowCon Project Tornado Tower QatarJupremae MacadangdangNo ratings yet

- Isover IzolacijaDocument59 pagesIsover IzolacijaBezimeni Usamljeni VukNo ratings yet

- Le Corbusier 5 Points PDFDocument3 pagesLe Corbusier 5 Points PDFmyersalNo ratings yet

- Scientific American Supplement, No. 821, September 26, 1891From EverandScientific American Supplement, No. 821, September 26, 1891No ratings yet

- Scientific American Supplement, No. 821, September 26, 1891From EverandScientific American Supplement, No. 821, September 26, 1891No ratings yet

- Ejectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsFrom EverandEjectors for Efficient Refrigeration: Design, Applications and Computational Fluid DynamicsNo ratings yet

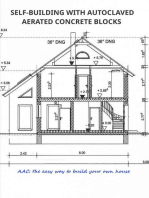

- SELF-BUILDING WITH AUTOCLAVED AERATED CONCRETE BLOCKS: AAC: the easy way to build your own houseFrom EverandSELF-BUILDING WITH AUTOCLAVED AERATED CONCRETE BLOCKS: AAC: the easy way to build your own houseNo ratings yet

- Menara Mesiniaga Ken YeangDocument11 pagesMenara Mesiniaga Ken Yeangrcmvera0% (1)

- WholeDocument334 pagesWholeSamuel GGonzálezNo ratings yet

- Integrating Cleaner Production into Sustainability StrategiesDocument10 pagesIntegrating Cleaner Production into Sustainability StrategiesSamuel GGonzálezNo ratings yet

- Acerca Dee Lev AdoresDocument14 pagesAcerca Dee Lev AdoresSamuel GGonzálezNo ratings yet

- Federal BuildingDocument18 pagesFederal BuildingSamuel GGonzálezNo ratings yet

- Program For International StudentDocument8 pagesProgram For International StudentSamuel GGonzálezNo ratings yet

- UED Special Issue of 2012 HYP CompetitionDocument43 pagesUED Special Issue of 2012 HYP CompetitionSamuel GGonzálezNo ratings yet