Professional Documents

Culture Documents

Control of Non-Conforming Products Procedure

Uploaded by

Almario SagunCopyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Control of Non-Conforming Products Procedure

Uploaded by

Almario SagunCopyright:

Available Formats

DOCUMENT NO.

:

M4CMSI-

NCP-13-001

REVISION NO.:

REV. 0

DOCUMENT TITLE

CONTROL OF NON-

CONFORMING PRODUCTS

COMPANY LOGO

EFFECTIVE

DATE:

DEC. 2013

PAGE NO.:

4 PAGES

Rev. No. Page No. Revision History Originator Date

Rev. 0 4 Pages Initial Release. Almario J. Sagun Dec. 2013

SIGNATURE DATE

PREPARED BY:

ALMARIO J. SAGUN

Pre-Execution Head

CHECKED BY:

ADRIAN MANLUNAS

Project Implementation & Control Head

REVIEWED BY:

RESTY B. DE CASTRO

Project Engineering & Const. Head

APPROVED BY:

ENGR. CARLO M. MERCADO

President and General Manager

DOCUMENT NO.:

M4CMSI-

NCP-13-001

REVISION NO.:

REV. 0

DOCUMENT TITLE

CONTROL OF NON-

CONFORMING PRODUCTS

COMPANY LOGO

EFFECTIVE

DATE:

DEC. 2013

PAGE NO.:

4 PAGES

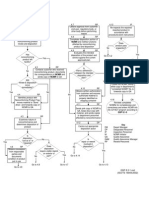

1.0 PURPOSE

1.1 This procedure describes the methods for identifying, reporting and

controlling non-conforming products and services, so that these items do not

go into the project materials.

2.0 SCOPE

2.1 This procedure shall be used for all activities performed by the company.

3.0 REFERENCES

3.1 ISO 9001 2008 Section 4.13

3.2 M4CMSI-RIT-13-001 - Receiving Inspection and Testing

3.3 M4CMSI-IIT-13-001 - In process Inspection and Testing

3.4 M4CMSI-FIT-13-001 - Final Inspection and Testing

4.0 RESPONSIBILITIES

4.1.1 The QA/QC Personnel / Discipline Engineer(s) is responsible for

describing nonconformance report and for the verifying the

disposition, on completion of the same.

4.1.2 The construction manager / Department Manager(s) is responsible for

deciding the disposition and the corrective actions.

4.1.3 The Concerned Engineer / Supervisor ensures that the

nonconformance are corrected within the agreed upon time frame.

4.1.4 The General Manager (Tech.) shall review the recurring nature of

nonconformities and initiate necessary corrective and preventive

action.

5.0 PROCEDURE

5.1 GENERAL

5.1.1.1 QA/QC Supervisor / Discipline Engineer describes the non-

conformance, in detail, in the Non-conformance Report (Form:

M4CMSI/QA/002).

5.1.1.2 Concerned Department Manager / Project Manager

establishes disposition with appropriate Engineer and/or

Supervisor, or QC Personnel.

5.1.1.3 Upon completion of correction action QC Personnel will verify

compliance to disposition requirements.

5.1.1.4 Disposition requiring approval from Client shall be advised to

them for their concurrence.

DOCUMENT NO.:

M4CMSI-

NCP-13-001

REVISION NO.:

REV. 0

DOCUMENT TITLE

CONTROL OF NON-

CONFORMING PRODUCTS

COMPANY LOGO

EFFECTIVE

DATE:

DEC. 2013

PAGE NO.:

4 PAGES

5.1.1.5 Recurring non-conformance will be brought to the attention of

the QA/QC Manager, for necessary corrective and preventive

action.

5.2 CONTROL OF NON-CONFORMING MATERIAL

5.2.1 Nonconforming materials, if any, shall be quarantined (Form:

M4CMSI-M-003 and segregated until resolutions are arrived at and

necessary corrective actions completed.

5.2.2 Nonconforming materials that were mixed in bulk allocations will be

placed in a separately marked quarantine area or properly tagged to

avoid misuse on the project.

5.3 NON-CONFORMING WORKMANSHIP

5.3.1 Minor Non-conformity

5.3.1.1 Any decision from procedure, standard or practice or

workmanship, which can be corrected by minor rectification

work, shall be considered as minor non-conformity.

5.3.1.2 Minor nonconformity shall be verbally reported to the

concerned Supervisor / Foreman and also provide

recommendation on the required corrective action.

5.3.1.3 The concerned Supervisor / Foreman initiate immediate

corrective action to comply with the requirements.

5.3.1.4 The QC Personnel verifies the rectification work and approved

for further processing.

5.3.2 Major Non-conformity

5.3.2.1 A non-conformance report (Form: M4CMSI-QA-NCR-13-002)

shall be prepared for nonconformity requiring major

rectification work.

5.3.2.2 Such item / activity shall be put on hold, either segregated or

identified with a HOLD, tag.

5.3.2.3 The QC Personnel shall write the reason for the

nonconformity, if it is known to him at the time of preparation

of the NCR.

5.3.2.4 The Project Manager or Department Manager(s) provide the

necessary disposition for the conformity.

5.3.2.5 The concerned Supervisor / Foreman initiate the necessary

rectification work.

5.3.2.6 The QC Personnel shall verify the completion of the disposition

and close the NCR.

5.3.2.7 The item or activity shall be released for further processing.

DOCUMENT NO.:

M4CMSI-

NCP-13-001

REVISION NO.:

REV. 0

DOCUMENT TITLE

CONTROL OF NON-

CONFORMING PRODUCTS

COMPANY LOGO

EFFECTIVE

DATE:

DEC. 2013

PAGE NO.:

4 PAGES

5.3.2.8 Nonconformity, which can be rectified and are unacceptable,

shall be rejected. In this case the QC Personnel shall issue a

Rejection Note (Form: M4CMSI-NCP-13-004).

5.4 RECURRING NONCONFORMITIES

5.4.1 Nonconformance of recurring nature shall be evaluated by the

General Manager (Technical).

5.4.2 Such non-conformances shall be reviewed during management review

meeting to agree on the required corrective and preventive action.

5.4.3 The General Manager (Tech.) shall arrange for necessary follow up on

the agreed corrective and preventive action.

5.4.4 If the corrective and preventive action requires changes to the quality

system procedure, necessary revisions shall be effected.

6.0 QUALITY FORMS AND RECORDS

6.1 Form: M4CMSI-/M/003 - Quarantine Note

6.2 Form: M4CMSI-NCR-13-002 - Non-Conformance Report (NCR)

6.3 Form: M4CMSI-RN-13-004 - Rejection Note

You might also like

- ISO - Control of Non-Conforming ProductsDocument5 pagesISO - Control of Non-Conforming ProductsAlmario SagunNo ratings yet

- Continual Improvement ProcedureDocument6 pagesContinual Improvement ProcedureRonald SarillanaNo ratings yet

- A6. Control of Nonconforming ProductDocument6 pagesA6. Control of Nonconforming ProductStanley MtamboNo ratings yet

- Corrective Action ProcedureDocument3 pagesCorrective Action Procedureasderbva100% (1)

- Procedure For Control of Non-Conforming ProductsDocument4 pagesProcedure For Control of Non-Conforming Productsmatrixmaze100% (3)

- Sta-P08-02 Non Conforming ProductDocument6 pagesSta-P08-02 Non Conforming ProductAnonymous B7pghhNo ratings yet

- Process For Control of Non-Conforming ProductDocument8 pagesProcess For Control of Non-Conforming ProductselvamuthukumarNo ratings yet

- F Control of Non - Conforming Product ProcedureDocument3 pagesF Control of Non - Conforming Product ProcedureNgonidzashe Zvarevashe100% (1)

- Control of Nonconforming ProductDocument2 pagesControl of Nonconforming ProductAliyantahir100% (2)

- Control Non-ConformancesDocument6 pagesControl Non-ConformancesSandraNo ratings yet

- IMSP 01 Control of DocumentsDocument8 pagesIMSP 01 Control of Documentsemeka20120% (1)

- Non Conformance Control ProcedureDocument12 pagesNon Conformance Control ProcedurePanneer Bala100% (9)

- QP Nonconforming Product Sample 2014Document2 pagesQP Nonconforming Product Sample 2014Anna Maree100% (1)

- Operating Procedure for Internal & External CommunicationDocument4 pagesOperating Procedure for Internal & External CommunicationnomanNo ratings yet

- Nonconformance Control ProcedureDocument5 pagesNonconformance Control ProcedureAlex Dcosta50% (2)

- ISO PlanDocument12 pagesISO PlanTamara Johnson-PariagNo ratings yet

- SILCOTECH Management Review ProcedureDocument3 pagesSILCOTECH Management Review ProcedureQuality Unit 1 Ajay PandeyNo ratings yet

- Standard Procedure RecallDocument3 pagesStandard Procedure RecallLinda Setya Wati100% (2)

- Managemnet Review SOP & RecordsDocument3 pagesManagemnet Review SOP & RecordsPritam MitraNo ratings yet

- Non Conformance ManagementDocument22 pagesNon Conformance Managementssoni_famycare100% (1)

- FCP-Nonconforming Product ProcedureADocument7 pagesFCP-Nonconforming Product ProcedureAjirt2011No ratings yet

- Non-Conforming Products ProcedureDocument10 pagesNon-Conforming Products ProcedureniteshNo ratings yet

- Mgt Review MinutesDocument6 pagesMgt Review Minutesmgamal1080100% (1)

- Sample Management Review ChecklistDocument4 pagesSample Management Review Checklistpoetoet100% (1)

- Procedure For Control of RecordsDocument3 pagesProcedure For Control of Recordsmatrixmaze50% (2)

- Supplier EvaluationDocument4 pagesSupplier EvaluationAmi Kar100% (1)

- Method Statement Procedure For Control of Non Conforming ProductDocument6 pagesMethod Statement Procedure For Control of Non Conforming Productmangeshshinde124No ratings yet

- Sampling plan for elastomer parts inspectionDocument1 pageSampling plan for elastomer parts inspectionLOGANATHAN V100% (1)

- 4 Context of The Organization 4.1 Understanding The Organization and Its ContextDocument5 pages4 Context of The Organization 4.1 Understanding The Organization and Its ContextkarthiksaadhanaNo ratings yet

- Quality Record Procedure Rev-JDocument4 pagesQuality Record Procedure Rev-JherminNo ratings yet

- Happy Forgings EMS PerformanceDocument3 pagesHappy Forgings EMS Performancemool raj100% (1)

- MRF Management ReviewDocument4 pagesMRF Management ReviewhastinkakaNo ratings yet

- Supplier Assessment ChecklistDocument2 pagesSupplier Assessment ChecklistCOLONEL ZIKRIA100% (1)

- Dilg r1 Management Review Minutes-SignedDocument8 pagesDilg r1 Management Review Minutes-SignedQuality Hosur100% (1)

- SHEWS Non-Conformance ReportingDocument2 pagesSHEWS Non-Conformance ReportingHaroonAbdulRahim0% (1)

- Quality Procedure 8.7 Supplier Corrective ActionDocument5 pagesQuality Procedure 8.7 Supplier Corrective ActionPariksha Arya100% (1)

- Procedure Risk ManagementDocument2 pagesProcedure Risk ManagementAnbuNo ratings yet

- MDSAP Corrective Actions ProcedureDocument11 pagesMDSAP Corrective Actions ProcedureNixNo ratings yet

- Procedure - Control of RecordsDocument4 pagesProcedure - Control of RecordsMarjorie Dulay DumolNo ratings yet

- Medford Fabrication Management Review Procedure SP-010Document2 pagesMedford Fabrication Management Review Procedure SP-010Bisma MasoodNo ratings yet

- QMS PROCEDURE IDENTIFICATION & TRACEABILITYDocument3 pagesQMS PROCEDURE IDENTIFICATION & TRACEABILITYRainer-SlawetzkiNo ratings yet

- NCR Flow ChartDocument1 pageNCR Flow ChartPramod AthiyarathuNo ratings yet

- Control of Records ProceduresDocument7 pagesControl of Records ProceduresShin Mey100% (8)

- Management Review: ISO 9001:2015 GuidanceDocument3 pagesManagement Review: ISO 9001:2015 GuidanceMadan R HonnalagereNo ratings yet

- NCR Control ProcedureDocument6 pagesNCR Control ProcedureRomi Abdul Rahman100% (5)

- Continual ImprovementDocument3 pagesContinual ImprovementMohanad100% (1)

- Internal Quality Audit ProcedureDocument2 pagesInternal Quality Audit ProceduremahendraNo ratings yet

- QSP 621 01customer Satisfaction ProcedureDocument6 pagesQSP 621 01customer Satisfaction ProcedureMacel100% (1)

- Management Review ProcedureDocument3 pagesManagement Review Procedurechahi100% (1)

- Iso ProceduresDocument57 pagesIso ProceduresShin Mey100% (4)

- Quality Management System Master18 February 2014Document27 pagesQuality Management System Master18 February 2014shani5573No ratings yet

- Procedure - Control of DocumentsDocument5 pagesProcedure - Control of Documentsjamal nasirNo ratings yet

- Control of Non-ConformityDocument8 pagesControl of Non-ConformitynorlieNo ratings yet

- Quality Manual: ISO/TS 16949:2009 Quality Management SystemDocument47 pagesQuality Manual: ISO/TS 16949:2009 Quality Management Systemluismi081300No ratings yet

- Control of Non-Conforming Products ProcedureDocument4 pagesControl of Non-Conforming Products ProcedureSolomon GamanuelNo ratings yet

- ISO 9001:2008 Standard Operating Procedures Manual: A P & C, IDocument88 pagesISO 9001:2008 Standard Operating Procedures Manual: A P & C, IBuenoflor GrandeaNo ratings yet

- Good Distribution Practices A Complete Guide - 2021 EditionFrom EverandGood Distribution Practices A Complete Guide - 2021 EditionNo ratings yet

- 8.5.2-3 Corrective and Preventive ActionDocument4 pages8.5.2-3 Corrective and Preventive ActionAhmed HussienNo ratings yet

- Procedure For Corrective ActionDocument5 pagesProcedure For Corrective Actionndayiragije JMVNo ratings yet

- WAIR Employer's Work-Accident-Illness ReportDocument2 pagesWAIR Employer's Work-Accident-Illness ReportAlmario Sagun80% (5)

- Work Contract SampleDocument1 pageWork Contract SampleAlmario SagunNo ratings yet

- Annual medical report form insightsDocument5 pagesAnnual medical report form insightsGemarie Adarlo CastilloNo ratings yet

- Typical Concrete Slab and Beam DetailsDocument1 pageTypical Concrete Slab and Beam DetailsAlmario SagunNo ratings yet

- Typical Concrete Slab and Beam DetailsDocument1 pageTypical Concrete Slab and Beam DetailsAlmario SagunNo ratings yet

- AEDR Annual Work Accident-Illness Exposure Data ReportDocument4 pagesAEDR Annual Work Accident-Illness Exposure Data ReportAlmario Sagun100% (1)

- Power Center CoverpageDocument1 pagePower Center CoverpageAlmario SagunNo ratings yet

- Petcoke Doors ScheduleDocument6 pagesPetcoke Doors ScheduleAlmario SagunNo ratings yet

- Power Center Building Electrical System-E-05Document1 pagePower Center Building Electrical System-E-05Almario SagunNo ratings yet

- Roof Plan, Reflected Ceiling, Detail PlanDocument1 pageRoof Plan, Reflected Ceiling, Detail PlanAlmario SagunNo ratings yet

- Approved For Construction: Etron Bataan RefineryDocument1 pageApproved For Construction: Etron Bataan RefineryAlmario SagunNo ratings yet

- Sanitary P 01 Petcoke BuildingDocument1 pageSanitary P 01 Petcoke BuildingAlmario SagunNo ratings yet

- Structural S 02 Petcoke BuildingDocument1 pageStructural S 02 Petcoke BuildingAlmario SagunNo ratings yet

- Petron Bataan Refinery Power Center Plans and ElevationsDocument1 pagePetron Bataan Refinery Power Center Plans and ElevationsAlmario SagunNo ratings yet

- Structural S 01 Petcoke BuildingDocument1 pageStructural S 01 Petcoke BuildingAlmario SagunNo ratings yet

- Power Center Building Electrical System-E-01Document1 pagePower Center Building Electrical System-E-01Almario SagunNo ratings yet

- Sanitary P 02 Petcoke BuildingDocument1 pageSanitary P 02 Petcoke BuildingAlmario SagunNo ratings yet

- Power Center Building Electrical System-E-04Document1 pagePower Center Building Electrical System-E-04Almario SagunNo ratings yet

- Perspective - Petcoke BuildingDocument1 pagePerspective - Petcoke BuildingAlmario SagunNo ratings yet

- Power Center Building Electrical System-E-03Document1 pagePower Center Building Electrical System-E-03Almario SagunNo ratings yet

- Power Center Building Electrical System-E-02Document1 pagePower Center Building Electrical System-E-02Almario SagunNo ratings yet

- Architectural 01 - Petcoke BuildingDocument1 pageArchitectural 01 - Petcoke BuildingAlmario SagunNo ratings yet

- Mechanical DWNG - M02 Petcoke BuildingDocument1 pageMechanical DWNG - M02 Petcoke BuildingAlmario SagunNo ratings yet

- Power Center Building Electrical System-E-02Document1 pagePower Center Building Electrical System-E-02Almario SagunNo ratings yet

- Petcoke Transformer Plan & Elevation.p2Document1 pagePetcoke Transformer Plan & Elevation.p2Almario SagunNo ratings yet

- Petcoke Transformer Plan & Elevation-01Document1 pagePetcoke Transformer Plan & Elevation-01Almario SagunNo ratings yet

- Mechanical DWNG M-01 Petcoke BuildingDocument1 pageMechanical DWNG M-01 Petcoke BuildingAlmario SagunNo ratings yet

- Fire Rated Stainless Steel Double Panel DoorDocument2 pagesFire Rated Stainless Steel Double Panel DoorAlmario SagunNo ratings yet

- Architectural Drawing 01 - Petcoke BuildingDocument1 pageArchitectural Drawing 01 - Petcoke BuildingAlmario SagunNo ratings yet

- Proposed Man Ladder DesignDocument1 pageProposed Man Ladder DesignAlmario SagunNo ratings yet

- Heidelberg Cement Plant Maintenance ManagementDocument23 pagesHeidelberg Cement Plant Maintenance ManagementPradeep Sahoo100% (8)

- Capstone Spring 2018 Qualifier ResultsDocument5 pagesCapstone Spring 2018 Qualifier ResultsJigmee SherpaNo ratings yet

- Supporting Employer Training of CIMA StudentsDocument18 pagesSupporting Employer Training of CIMA StudentsAbu MusaNo ratings yet

- Project - OmDocument30 pagesProject - OmSesha Sai KumarNo ratings yet

- PAC Resources Inc A Case StudyDocument42 pagesPAC Resources Inc A Case Studyloyclay100% (2)

- Vitamin Water PresentationDocument27 pagesVitamin Water PresentationSyed Abdul Ahad TirmidhiNo ratings yet

- Investment Analyst Cevian Capital 2017Document1 pageInvestment Analyst Cevian Capital 2017Miguel Couto RamosNo ratings yet

- Activity-Based Costing and Activity-Based ManagementDocument60 pagesActivity-Based Costing and Activity-Based ManagementpinakindpatelNo ratings yet

- The IKea ApproachDocument16 pagesThe IKea ApproachYashikaNo ratings yet

- Leading Maritime Hub Port Shipping Services Offshore EngineeringDocument2 pagesLeading Maritime Hub Port Shipping Services Offshore EngineeringSahil FarazNo ratings yet

- How Businesses Can Stay Innovative and Create Unique Selling Propositions (USPsDocument3 pagesHow Businesses Can Stay Innovative and Create Unique Selling Propositions (USPsNishchal AnandNo ratings yet

- Personal Swot AnalysisDocument9 pagesPersonal Swot AnalysisAdil Aftab100% (5)

- WIPRODocument20 pagesWIPROVikas Kumar67% (3)

- Kimia FarmaDocument2 pagesKimia FarmaRamaNo ratings yet

- HRP Final PPT Seimens Case StudyDocument17 pagesHRP Final PPT Seimens Case StudyAmrita MishraNo ratings yet

- Activity 1 OM-TQMDocument2 pagesActivity 1 OM-TQMShr BnNo ratings yet

- Workplace Equalization's Impact on Organizational SuccessDocument33 pagesWorkplace Equalization's Impact on Organizational SuccessDominic AsiloNo ratings yet

- BarillaDocument22 pagesBarillaWeiwei ShaoNo ratings yet

- 08.03.04-Quality Assurance of Materials - Approval of Source-R2Document4 pages08.03.04-Quality Assurance of Materials - Approval of Source-R2tanmayascribdNo ratings yet

- Human Resource Management: Project On The Recruitment Process of WIPRODocument21 pagesHuman Resource Management: Project On The Recruitment Process of WIPRONamita KothariNo ratings yet

- 3 - Nota Cc603 Topic 2 Project Life Cycle Jun 2015.doc (BM)Document12 pages3 - Nota Cc603 Topic 2 Project Life Cycle Jun 2015.doc (BM)Lance YapNo ratings yet

- Sgs Iso 9001 2015 Update Dis Version A4 en 14Document3 pagesSgs Iso 9001 2015 Update Dis Version A4 en 14오동욱No ratings yet

- Work Instruction Manual: Document ControlDocument10 pagesWork Instruction Manual: Document ControlAriel OrtizNo ratings yet

- Mba Vtu 3 Sem SyullabusDocument8 pagesMba Vtu 3 Sem SyullabusShiva KumarNo ratings yet

- Iso 9001 2015Document15 pagesIso 9001 2015Julio NogueraNo ratings yet

- Unit 1Document8 pagesUnit 1Nidhya Nadarajan100% (1)

- Written Analysis of Case: Onefinestay: Building A Luxury Experience in The Sharing EconomyDocument3 pagesWritten Analysis of Case: Onefinestay: Building A Luxury Experience in The Sharing EconomymeghanaNo ratings yet

- MPOBDocument14 pagesMPOBCraaft NishiNo ratings yet

- Report On Total Productive MaintenanceDocument8 pagesReport On Total Productive MaintenanceshahzafNo ratings yet

- CVTemplate EnglishDocument2 pagesCVTemplate EnglishatuweneNo ratings yet