Professional Documents

Culture Documents

Vesda Accessories Product Guide 10258

Uploaded by

kmlowpg2Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Vesda Accessories Product Guide 10258

Uploaded by

kmlowpg2Copyright:

Available Formats

Vision Fire & Security

Accessories

Product Guide

March 7, 2005

Part: 30012

VESDA

Accessories Product Guide

i

Copyright Information

This document is protected by copyright under the laws of Australia and other jurisdictions throughout the world. It must not by any means,

either in whole or part, be reproduced, communicated to the public, adapted, distributed, sold, modified, published except as permitted by

any laws or statute or with prior written consent of VFS International Pty Ltd. Copyright 2004 VFS International Pty Ltd ACN 100 259 381

Disclaimer

The manufacturer reserves the right to change designs or specifications without obligation and without further notice. VESDA,

LaserTEKNIC, LaserPLUS, LaserSCANNER, LaserCOMPACT, LaserFOCUS, VESDAnet, VESDAlink, ASPIRE, ASPIRE2, AutoLearn,

VSM, VConfig, InfoWORKS, PROACTIV, PRECISION, VSC, ADPRO, FastTrace, FastVu, FastScan, Axiom, PRO, Amux, Video Central,

Millbank and VxLAN are brands and trade marks used under license by the distributor.

FCC Compliance Statement

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instruction, may cause

harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, the user is encouraged to try to correct the interference by

one or more of the following measures; re-orientate or relocate the receiving antenna, increase the separation between the equipment and

receiver, connect the equipment to a power outlet which is on a different power circuit to the receiver or consult the dealer or an

experienced radio/television technician for help.

General Warning

This product must only be installed, configured and used strictly in accordance with the General Terms and Conditions and the technical

documentation available from VFS International Pty Ltd (VFS). You acknowledge that you have read and agree to those terms and

conditions. All proper health and safety precautions must be taken during the installation, commissioning and maintenance of the product.

The product should not be connected to a power source until all the components have been installed. Proper safety precautions must be

taken during tests and maintenance of the products when these are still connected to the power source. Failure to do so or tampering with

the electronics inside the products can result in an electric shock causing injury or death and may cause equipment damage. VFS is not

responsible and cannot be held accountable for any liability that may arise due to improper use of the equipment and/or failure to take

proper precautions. Only persons trained through an accredited VFS training course can install, test and maintain the product.

Limitation of Liability

This product must only be installed, configured and used strictly in accordance with the General Terms and Conditions, this manual and the

technical documentation available from VFS International Pty Ltd. You acknowledge that you have read and agree to those terms and

conditions.

You acknowledge that you have been provided with a reasonable opportunity to appraise the product and have made your own

independent assessment of the fitness or suitability for your purpose. You acknowledge that you have not relied on any oral or written

information, representation or advice given by or on behalf of VFS or its representatives.

VFS has no liability to you or any person for incidental or consequential loss, expense or damages including, without limitation, loss of

business, loss of profits or loss of data. You indemnify VFS for any claim, amount or liability brought against VFS in connection with the

product.

You expressly agree that you assume the entire risk as to the results and performance of the product resulting from the configuration of the

product. VFS does not warrant, guarantee or make any representations, either expressly or implied, regarding the current or future use, or

the results of the use, of the product, with respect to its correctness, accuracy, reliability, completeness, interworking, functionality,

currentness or otherwise resulting from the configuration of the product.

To the full extent permitted by law, VFS expressly excludes all conditions, warranties and liability, whether imposed or implied by statute or

by rule of law or otherwise, which are not expressly set out in the General Terms and Conditions.

To the extent permitted by law, your sole recourse for any defect of, damage to, or performance standard of the product will be under the

express warranties the General Terms and Conditions (if applicable) and VFS will in no event be liable to pay any amount or damages

resulting from or in connection with the product.

To the extent by law that any limitation or exclusion can not apply, the total liability of VFS in relation to the product is limited to:

(i) in the case of services, the cost of having the services supplied again; or

(ii) in the case of goods, the lowest cost of replacing the goods, acquiring equivalent goods or having the goods repaired.

To the extent permitted by law, VFS has no liability with respect to damage to or arising out of, or the condition or performance of, the

product resulting from (i) negligence or improper use, storage, installation, configuration commission, service maintenance or handling of

the product (where 'improper' includes treatment other than in accordance with the product manual, these terms and conditions or the

information provided at a training session); (ii) accident, unforeseeable circumstances or disaster; (iii) modifications to the product other

than in accordance with VFS's instructions; (iv) attachment of or interoperation with features, software or products not approved by VFS in

writing; or (v) where the product has been serviced by persons not authorized by VFS in writing to service the product.

Product Warranty Conditions

VFS International Pty Ltd (VFS) warrants that new products (excluding consumable items) will conform to its published specifications and

remain in good working order during the warranty period of 24 (twenty four) months from the date an invoice is issued by VFS to its

distributor.

VFS also warrants that products serviced or repaired by its service department will remain in good working order for a warranty period of

12 (twelve) months from the date of service. This service or repair warranty is only available on products less than 7 (seven) years old and

only covers those component parts of the products serviced, repaired or replaced.

Should product under warranty not be in good working order, VFS will, at its option, either repair or replace the product or its component

parts at no additional charge.

Spare parts and replacement product, covered under this warranty, will be furnished on an exchange basis and will, at the option of VFS

either be new, equivalent to new or reconditioned. Returned parts and products to VFS become the property of VFS.

This warranty does not cover the repair or damage to the product resulting from or arising out of (i) negligence or improper use storage,

installation, configuration, commission, service, maintenance or handling of the product (where 'improper' includes treatment other than in

accordance with any manual or instructions for use of the product); (ii) accident, unforeseeable circumstances or disaster; (iii)

modifications to the product other than in accordance with VFS's instructions; (iv) attachment of features or interoperation with features,

software or products not approved by VFS in writing; or (v) where the product has been serviced by persons not authorized by VFS in

writing to service the product.

Accessories Product Guide VESDA

ii

Document Conventions

The following typographic conventions are used in this document.

The following icons are used in this document

Contact Us

www.vesda.com www.adpro.com.au www.millbank.co.uk

Codes and Standards Information

We strongly recommend that this document is read in conjunction with the appropriate local codes and standards for smoke detection

systems and electrical connections. This document contains generic information and some sections may not comply fully with all local

codes and standards. In these cases, the local codes and standards must take precedence.

FM 3611 Hazardous Approval Warning

Exposure to some chemicals may degrade the sealing of relays used on the detector. Relays used on the detector are marked "TX2-5V" or

"G6S-2-5V" or "EC2-5NU".

UL Warning

The fire alarm threshold (signal) that initiates an evacuation procedure via the Fire Alarm Panel must not be set higher than 0.625%/ft. The

detector can send this signal either via the Fire Alarm Panel Output signal or the Pre-alarm output signal.

Safety Label

This VESDA product incorporates a laser device and is classified as a Class 1 laser product that complies with FDA regulations 21 CFR

1040.10. The laser is housed in a sealed detector chamber and contains no serviceable parts. This laser emits invisible light and can be

hazardous if viewed with the naked eye. Under no circumstances should the detector chamber be opened.

Convention Description

Bold Used to denote: emphasis

Used for names of menus, menu options, toolbar buttons

Italics Used to denote: references to other parts of this document or

other documents. Used for the result of an action

Convention Description

Caution: This icon is used to indicate that there is a danger to

equipment. The danger could be loss of data, physical damage,

or permanent corruption of configuration details.

Warning: This icon is used to indicate that there is a danger of

electric shock. This may lead to death or permanent injury.

Warning: This icon is used to indicate that there is a danger of

inhaling dangerous substances. This may lead to death or

permanent injury.

Australia and Asia The Americas Europe & Middle East

Vision Systems

Private Bag 215

495 Blackburn Road

Mount Waverley VIC 3149

Australia

Toll free: 1800 700 203

Tel: +61 (0) 3 9211 7200

Fax: +61 (0) 3 9211 7201

Vision Systems

700 Longwater Drive

Norwell,

Massachusetts, 02061

USA

Toll free: 800 229 4434

Tel: +1 78 740 2223

Fax: +1 78 740 4433

Vision Systems

Vision House, Focus 31,

Mark Road

Hemel Hempstead

Hertfordshire HP2 7BW

United Kingdom

Tel: +44 (0) 1442 242 330

Fax: +44 (0) 1442 249 327

VESDA

Accessories Product Guide

iii

Document: 10258_02

Accessories Product Guide VESDA

iv

VESDA

Accessories Product Guide

v

Contents

Scope ............................................................................................................................................... 1

Introduction to accessories ........................................................................................................... 1

Remote Mounting Options ............................................................................................................. 2

Remote Box ............................................................................................................................ 2

Product Information ............................................................................................................ 3

Mounting a Remote Box ..................................................................................................... 3

Cabling the Remote Box ..................................................................................................... 3

19 Subrack ............................................................................................................................ 4

Product Information ............................................................................................................ 4

Mounting a 19 Subrack ..................................................................................................... 5

Cabling the 19 Subrack ..................................................................................................... 5

Installing Modules ............................................................................................................... 6

Wiring Remote Systems ......................................................................................................... 6

Remote Termination Card .................................................................................................. 6

Wiring Relay Processor Card and Remote Termination Card .......................................... 10

Wiring the Modules in the 19 Subrack ............................................................................. 10

Power Source ................................................................................................................... 10

Back Up Battery ................................................................................................................ 11

The Modules ................................................................................................................................. 11

The Display Module .............................................................................................................. 11

Features of the Display Module ........................................................................................ 11

Operation of the Display Module ...................................................................................... 11

Product Specification ........................................................................................................ 12

Display Module Dimensions ............................................................................................. 13

Mounting a Display Module .............................................................................................. 13

Wiring up the Display Module ........................................................................................... 13

VESDA LCD Programmer .................................................................................................... 14

LCP Programmer Specifications ...................................................................................... 14

Introduction to VESDAnet Socket Module ........................................................................ 14

Dimensions of VESDAnet Socket ..................................................................................... 15

Operation of VESDAnet Socket ........................................................................................ 16

VESDA Remote Termination Card ....................................................................................... 16

Features of Remote Termination Card ............................................................................. 17

Operation of the Remote Termination Card ..................................................................... 17

Remote Termination Card Module Specifications ............................................................ 17

Mounting the Remote Termination Card .......................................................................... 17

Wiring the Remote Termination Card Module .................................................................. 18

System Relay Module ........................................................................................................... 18

Features of System Relay Module ................................................................................... 18

Operation of the System Relay Module ............................................................................ 18

System Relay Module Specifications ............................................................................... 19

Mounting the System Relay Module ................................................................................. 19

Wiring the System Relay Module ..................................................................................... 19

Other Accessories ........................................................................................................................ 20

Labels ................................................................................................................................... 20

Accessories Product Guide VESDA

vi

VESDA

Accessories Product Manual

1

1.1 Scope

The VESDA Accessories Product Manual outlines the mounting systems and the modules,

mentioning their features, technical specifications and an understanding of the components and

their function. It provides the reader with instructions on installing and cabling the respective

modules.

The VESDA Accessories Product Manual is written for those people who are involved with the

design specifications, maintenance and purchase of VESDA systems.

It is assumed that persons using this guide have knowledge of the local codes and standards.

Installers should hold appropriate certification for electrical installations.

1.2 Introduction to accessories

Vision Systems offers two systems for the remote mounting of modules:

The remote box

The 19 subrack

The VESDA range of modules have been designed to complement the VESDA family of laser

detectors. The modules available for remote mounting are:

The display module

The LCD programmer module

VESDAnet socket module

7 and 12 relay remote termination cards and relay processor card module

system relay module

analogue output module

multiple relay module

Other accessories include:

Labels for sample points and pipes

Accessories Product Manual VESDA

2

1.3 Remote Mounting Options

Remote Box

The remote box can house a single module with a termination card. The remote box offers the

option to mount modules at site specific locations. The remote mounting option is normally

exercised where there is a need to monitor and/or manage a stand alone detector, or one

connected to VESDAnet, from a remote location.

Figure 1 - Remote Unit

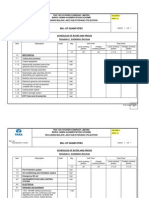

Table 1 - Remote Unit Configurations

PRODUCT NAME No. of Relays Product Code

Remote Programmer Unit 0 VRT-100

Remote LaserPLUS Display Unit 7 VRT-200

LaserPLUS Remote Display Without Relays 0 VRT-600

Remote Scanner Display Unit 7 VRT-400

Remote Scanner Display without Relays 0 VRT-700

Remote Scanner Display 12 RTC 12 VRT-800

Remote LaserCOMPACT Display RTC0 0 VRT-K00

Remote LaserCOMPACT Display RTC7 7 VRT-J00

Remote VESDAnet Socket Unit 0 VRT-300

System Relay Module 7 VRT-S07

Non Scan 7 relay processor Only 7 VRT-500

12 RTC Processor Only Remote 12 VRT-900

AOM 0 VRT-A10

MRM 16 VSP-R00

VESDA

Accessories Product Manual

3

Product Information

The remote box comes in two sections. The mounting box to house the remote termination card

or VESDAnet socket card and the front cover to mount the module with a processor card. The

VESDAnet socket does not have a relay processor card.

Figure 2 - Remote Box

Mounting a Remote Box

The remote box can be mounted on any flat surface. To mount the remote box, first unscrew the

front cover. Then use the four screw holes to secure the mounting box onto a flat surface

ensuring that it is horizontally straight. Connect the power and VESDAnet cables and replace the

front cover. The dimensions of the box are width 140 mm (5.5 in), height 150 mm (5.9 in) depth

70 mm (2.75 in).

Cabling the Remote Box

The remote box has six cable entry ports. Determine the port most appropriate for use and press

out the knockouts taking care not to damage any relays or terminals on the remote termination

card.

Legend

A Mounting Box

B Front Cover

A

B

Accessories Product Manual VESDA

4

19 Subrack

The 19 Subrack is used for grouping up to 4 Remote modules. The 19 in. subrack assembly is

used when multiple modules are required to be located in standard 19 in. racks. An optional wall

mounting bracket is available for a single 19 in. Subrack.

Table 2 - 19 Subrack Modules

The 19 Subrack is normally pre-configured at the factory with the appropriate remote

termination cards and modules to meet site requirements.

Product Information

The front section of the 19 Subrack (VRT-6610) houses the relevant VESDA Module.

Figure 3 - 19 Subrack Front View

Product Name No. of Relays Module Number

Blank Plates 0 0

LCD Programmer 0 1

LaserPLUS Display 7 2

VESDAnet Socket 0 3

LaserSCANNER Display 7 4

(DRP) 7 Relay Remote Termination Card 7 5

LaserPLUS Display (no relays) 0 6

LaserSCANNER Display (no relays) 0 7

LaserSCANNER Display 12 8

(DRP) 12 Relay Remote Termination Card 12 9

LaserCOMPACT Display with Relays 7 J

LaserCOMPACT Display (no relays) 0 K

VESDA

Accessories Product Manual

5

Figure 4 - 19 Subrack - Isometric View

The back section of subrack houses the remote termination cards or the VESDAnet socket card.

Figure 5 - 19 Subrack Back View

Mounting a 19 Subrack

The 19 Subrack is secured by bolts to a Standard 3U Subrack System. If the 19 Subrack is to

be mounted onto a wall, first fasten the optional wall mounting bracket to the wall and then install

the 19subrack onto the wall mounting bracket. The dimensions of the box are Width 482 mm (19

in), height 120 mm (5 in), depth 128 mm (4.75 in).

Other mounting options include the 2 and 5 glazed boxes used in Europe.

Connect the power, VESDAnet and relay cabling to the remote termination cards.

Cabling the 19 Subrack

The 19 Subrack is open at the back facilitating easy cabling between the power source, or

VESDAnet and the remote termination card or the VESDAnet socket card. There are four holes

in the dividing panel of the 19 Subrack for wiring between the front and the back. VESDAnet and

power connections are installed by default in the factory.

Legend

A Mounting Holes

B Front Section

Legend

A Back Section C Cable Entry Holes

B Cable Tie Bar D Mounting Holes

Accessories Product Manual VESDA

6

Installing Modules

The 19 Subrack may have a blank plate over any of the openings. A module can replace the

blank plate as and when required. To replace an empty cavity with a module:

1. Disconnect the power to the 19 Subrack

2. If necessary remove the 19 Subrack from the rack (The rack may be designed to allow

access to the rear).

3. Secure the remote termination Card or the VESDAnet Socket in the back of the Subrack

4. Connect the relevant wire looms to the connectors on the remote termination card and pass

the looms to the front side of the 19 Subrack through the hole in the dividing panel

5. Connect the wire loom to the respective 10 way and/or 11 way connector(s) on the Module

Processor Card

6. Secure the modules to the 19 Subrack

7. Remount the 19 Subrack onto the rack if appropriate

8. Reconnect the power and turn it on

Wiring Remote Systems

Remote Termination Card

The remote termination card can be with or without relays. The remote termination card acts as

the interface for VESDAnet terminals, power supply terminals, relays and relay terminals.

Figure 6 - Remote Termination Card with 7 Relays

Legend

A VESDAnet Terminals

B Power Terminals

C Relays

D Relay Terminals

E 10 Way Connector

F 11 Way Connector

A

B

C

D

E

F

VESDA

Accessories Product Manual

7

Figure 7 - Remote Termination Card with 12 Relays

VESDAnet Terminals - The module is connected to VESDAnet through VESDAnet terminals on

the remote termination card. The terminals enable VESDAnet communication wires to be

brought into the remote box or the 19 Subrack and looped out to another device. Data

communication on VESDAnet are bidirectional. The polarity of the data wires must be maintained

throughout the network. It is recommended that RS 485 (Belden 9841 - 120 ohm) twisted pair

cables be used, however compatible cabling can be used.

Legend

A VESDAnet Terminals

B Power Terminals

C Relays

D General Purpose Input

E 10 Way Connector

F 11 Way Connector

A

B

C

D

E

F

Accessories Product Manual VESDA

8

Figure 8 - An example of the wire connection for VESDAnet (Closed Loop)

Relays - The relays interface with auxiliary external items, such as loop interface modules,

beacons or sounders. These may also be interfaced with external devices through a fire

indication device, or to fire alarm panels using a High Level Interface (HLI). The relays can be

programmed via a PC or the LCD programmer. The relays can be assigned multiple

assignments. Refer to software guides and LCD programmer guides for details. Relays 3 and 6

are set for urgent fault and fire 1 respectively and can be programmed for additional functions.

For factory default settings and energized/de-energized status refer to table 3, Relay Change

State Conditions on page 9.

VESDA

Accessories Product Manual

9

Table 3 - Relay Change State Conditions

Note: Assignments to relays 3 and 6 are fixed to Urgent Fault and Fire 1 respectively.

7 Relay

Card

12 Relay

Card

Default

Function

State Change

(when in factory default configuration)

1 1 Isolate

Energizes when an operator isolates the detec-

tor by pressing the Isolate key on the display

module or by activating the command via a PC

or a LCD Programmer or GPI option.

2 2 Minor Fault De-energizes when a Minor Fault is detected.

3 3 Urgent Fault

De-energizes when an Urgent Fault is

detected.

4 4 Alert Energizes when the Alert alarm is initiated.

5 5 Action Energizes when the Action alarm is initiated.

6 6 Fire 1 Energizes when the Fire 1 alarm is initiated.

7 7 Fire 2 Energizes when the Fire 2 alarm is initiated.

8

First Alarm

Sector 1

Energizes when the First Alarm Sector 1 has

been identified

9

First alarm

Sector 2

Energizes when the First Alarm Sector 2 has

been identified

10

First alarm

Sector 3

Energizes when the First Alarm Sector 3 has

been identified

11

First alarm

Sector 4

Energizes when the First Alarm Sector 4 has

been identified

12 Scan

Energizes when the Scanner is scanning the

inlet ports.

Accessories Product Manual VESDA

10

Wiring Relay Processor Card and Remote Termination Card

The remote termination card has a 10 way and a 11 way connector. The 10 way connector is for

connecting the relays and the 11 Way connector is for connecting the power supply and

communications to the relay processor card.

Figure 9 - Internal wiring between Module Processor Card and Remote

Termination Card

Wiring the Modules in the 19 Subrack

The VESDAnet and power connections are looped internally from the factory. It is only necessary

to connect power on to the rack and VESDAnet in and out of each end of the rack.

Power Source

The power terminals on the remote termination card connect to a 24 VDC power supply. The four

power terminals enable power to be brought to the remote termination card via a single wire pair

and looped out to another device via another wire pair. The modules have reverse polarity

protection to minimize the risk of reverse power connection to the modules. The modules will not

operate when the supply is reversed.

Note: Operating a module when DC supply voltage is outside the voltage range of 18 VDC

and 30 VDC may cause damage to the device.

Figure 10 - Power Connection for a Remote Termination Card

All connectors are polarized and can only be inserted one way into a socket.

Do not attempt to force a connector into its socket. If there is any difficulty, reverse the orientation

of the connector before inserting again.

VESDA

Accessories Product Manual

11

Back Up Battery

The power supply for each detector can switch to a back up battery in the event of a mains power

supply disruption. The size of the back up battery is determined by local standards and codes,

the total power required by the system, back up time required, allowance for reduction in capacity

with age and expected temperature variations.

If an intelligent VESDA power supply is fitted it will report power failures (F15) on VESDAnet.

VLP & VLS with GPI terminals connected will maintain their aspirator speed for an hour after the

loss of mains power. After which, the aspirator speed will be limited to 3000 rpm to conserve

power.

See the detector product guides for information on how to calculate the size of battery backup

required.

1.4 The Modules

The Display Module

The display module reports smoke levels and alarm stages for the assigned detector. It has

buttons to enable various systems functions. The display module also indicates faults with the

detector and VESDAnet.

Features of the Display Module

The display module features:

Immediate status reporting for assigned VESDA Address (also called Zones)

High intensity alarm LEDs

Remote relay option

20 segment vertical bar graph display

Alarm threshold indicators

In built sounder for audible warning

Comprehensive fault reporting

Multi-mode numeric Display

Operation of the Display Module

A display module can be installed directly onto a detector, or at a remote location on a remote

box or the 19 Subrack. A display module is assigned to only one detector, however up to 19

display modules can be assigned to one detector. The display module is connected to the

detector through the termination card.

LEDs and Buttons

The Threshold Indicators provide at a glance the visual representation of the programmable

alarm thresholds.

The Bar Graph continuously displays the current level of detected smoke. The top segment

indicates FIRE 1 smoke threshold level.

The Numeric Display has a two digit readout of:

FIRE 1 threshold

Current smoke levels (in % obs/m OR % obs/ft)

The VESDA Address (also called Zones) number

First Alarm Sector (LaserSCANNER only).

Accessories Product Manual VESDA

12

The Alarm LEDs indicate the respective thresholds set for ALERT, ACTION, FIRE 1 and FIRE 2

have been reached if an smoke is detected.

The Fault LEDs indicate a fault with the assigned detector or with VESDAnet.

Push Button Keys enable the user to Reset, Isolate or Silence the detector and control the

mode of the display module. These buttons can be disabled by the Systems Administrator to

prevent operation of its functions.

Each detector in the laser series has a display module specifically designed to meet the reporting

functions of a particular detector model. The reporting functions of these display modules have

been discussed in detail in the respective detector guides.

Product Specification

Table 4 - Specifications for display module

Supply Voltage 18 to 30 VDC

Dimensions (WHD) 105 mm x 130 mm x 30 mm (4.1 in x 5.3 in x 1.2 in)

Operating

Temperature

0 to 39 C (32 F to 103 F)

Humidity 10-99 % RH non-condensing

Alarm Indicators High Intensity LEDs with 70 degree viewing angle

Push Button Keys Mode/Test

Silence/Scan

Reset

Isolate

Can be disabled during commissioning (except Silence)

Fault Indicators System, Power, Airflow, VESDA Address (also called

Zones), Network, Filter, Urgent (This indicator will only

illuminate in conjunction with another fault indicator)

VESDA

Accessories Product Manual

13

Display Module Dimensions

Figure 11 - Display Module Dimensions

Mounting a Display Module

The display module is easily snapped into place in a detector, remote mounting box, or the 19

subrack.

Wiring up the Display Module

The display module is connected to the remote termination card. For further information see

Wiring Remote Systems on page 6.

Legend

A Threshold Indicators D Alarm LEDs G Front Decal

B Bargraph E Fault LEDs H Module Processor Card

C Numerical Display F Push button Keys

A

B

C

D

E

F

G H

Accessories Product Manual VESDA

14

VESDA LCD Programmer

The VESDA LCD Programmer allows configuration, commissioning and maintenance of the

VESDA system. It is used to program and maintain the detector. The LCD Programmer Module

can be mounted into a detector, remote box, or a 19 Subrack. It is also available as a Handheld

model. For detailed description and use of the LCD Programmer please refer to the VESDA LCD

Programmer Product Manual.

Figure 12 - The LCD Programmer Module

LCP Programmer Specifications

Introduction to VESDAnet Socket Module

The VESDAnet Socket is a 15 Pin Female Connector. It enables external devices to be

connected to VESDAnet. The hand-held LCD Programmer and the HLI are connected to

VESDAnet using the VESDAnet Socket.

A VESDAnet socket is located on the detector termination card of VESDAnet capable detectors.

However the VESDAnet Socket Module can be mounted onto a remote box or a 19 Subrack,

enabling access to VESDAnet from a remote location.

Figure 13 - VESDAnet Socket Module

Supply Voltage 18 to 30 VDC

Dimensions (WHD) 105 mm (4.1 in.) x 130 mm (5.3 in.) x 26 mm (1.02 in.)

Operating Temp. 0 to 39 C (32 F to 103 F)

Humidity 10-99%RH non-condensing

Legend

A Display

B Control keys

C Hard keys

Legend

A VESDAnet Socket

VESDA

Accessories Product Manual

15

Dimensions of VESDAnet Socket

Figure 14 - Dimensions of VESDAnet Module

Figure 15 - VESDAnet Interface Socket Card

Legend

A VESDAnet Terminals

B 10 Pin Connector

C Power supply terminals

A

B

C

Accessories Product Manual VESDA

16

Operation of VESDAnet Socket

The VESDAnet socket is connected to the (24 VDC) VESDAnet socket card. The terminals on

the VESDAnet socket card enable VESDAnet communication wires to be brought into the

VESDAnet socket module and looped out to another device. Data communication on VESDAnet

is bidirectional. The polarity of the data wires must be maintained throughout the network. It is

recommended that RS 485 (Belden 9841 - 120 ohm) twisted pair cables be used, however

compatible cabling can be used.

Figure 16 - VESDAnet Wiring (Closed Loop)

VESDA Remote Termination Card

The remote termination card is available with 7 relays or 12 relays. The remote termination card

is used when there is a requirement for reporting and/or triggering an external device, through a

fire alarm control panel that is located away from the detector. The remote termination card

copies the attributes of the head termination card of the detector to which it is assigned. It can

also be programmed to provide remote relay assignments that are different to those of the

assigned detector.

Figure 17 - Remote Termination Card

VESDA

Accessories Product Manual

17

Features of Remote Termination Card

7 programmable relays (or 12 relays for VESDA LaserSCANNER)

The default values for the relays correspond to respective default values for 7 and 12 Relay

Head termination cards. The remote termination card does not have GPI Function.

Can be wired to a secondary reporting device (e.g. a sounder or a beacon)

Comprehensive reporting and system management using PC based software or the LCD

Programmer

Option for recessed mounting

Interfaces with all existing VESDA Laser family product range

Operation of the Remote Termination Card

The remote termination card is housed in the remote box or the 19 Subrack. The remote

termination card provides the terminals for VESDAnet and power supply to the relay processor

card.

Remote Termination Card Module Specifications

Mounting the Remote Termination Card

The remote termination card module is easily mounted onto a remote box and the 19 Subrack.

For details on mounting refer to Mounting a Remote Box on page 3 and Mounting a 19 Subrack

on page 5.

Supply Voltage 18 to 30 VDC

Power

Consumption

Power Consumption (W) @24

VDC

Silent With Alarm

Remote Termination Card 7

Relay and relay processor card

- Power

1.44 W 2.52 W

Remote Termination Card 7

Relay and relay processor card

- Current

60 mA 105 mA

Remote Termination Card 12

Relay and relay processor card

- Power

Remote Termination Card 12

Relay and relay processor card

- Current

Dimensions (WHD) 105 mm (4.1 in.) x 130 mm (5.3 in.) x 26 mm (1.02 in.)

Dimensions in

Remote Mounting

Unit

140 mm (5.5 in.) x 150 mm (5.9 in.) x 85 mm (3.4 in.)

Operating Temp. 0 to 39C (32 F to 103 F)

Humidity 10-99%RH non-condensing

Accessories Product Manual VESDA

18

Wiring the Remote Termination Card Module

The relay processor card is connected to a 7 or 12 relay remote termination card. For details on

wiring the remote termination card and relay processor Module please refer to Wiring Remote

Systems on page 6.

System Relay Module

The system relay module is a 7 relay remote termination card with specialized software. The

product software allows reporting of any alarm or fault condition initiated by any VESDA Address

(also called Zones) on the VESDAnet loop.

Where dedicated VESDA Address (also called Zone) monitoring and management is not

required, the system relay module provides an alternative to the remote termination card and

relay processor card module.

Figure 18 - System Relay Module

Features of System Relay Module

Earliest possible reporting of alarms and faults for all VESDA Addresses (also called Zones)

on a single VESDAnet loop

Reports on the VESDA Address (also called Zones) on the VESDAnet loop

7 programmable relays

Can be wired to a secondary reporting device (e.g. a sounder or a beacon)

Option for recessed mounting

Programmable with VConfig Pro

Interfaces with all existing VESDA Laser family product range. Refer to Operation of the

System Relay Module on page 18 for software versions required to interface with the

system relay module.

Operation of the System Relay Module

The system relay module is connected to the VESDAnet loop and always assumes VESDA

Address (also called Zones) 0 for itself. This is the default setting and cannot be changed. It will

report on any alarm or fault condition that occurs with any device on the VESDAnet loop. Further

investigation can be conducted using VESDA software monitoring package VSM3, VESDA

Displays, VESDA LCD Programmer or through a Fire Alarm Control Panel.

VESDA

Accessories Product Manual

19

System Relay Module Specifications

Mounting the System Relay Module

The system relay module is mounted onto a remote box. For details on mounting refer to

Mounting a Remote Box on page 3.

Wiring the System Relay Module

The relay processor card in a system relay module is connected to a 7 relay remote termination

card. For details on wiring the system relay module please refer to Wiring Remote Systems on

page 6.

Supply Voltage 18 to 30 VDC

Power Consumption

Power Consumption

(W) @24 VDC

Silent With Alarm

Power 1.44 W 2.52 W

Current 60 mA 105 mA

Dimensions (WHD) 105 mm (4.1 in.) x 130 mm (5.3 in.) x 26 mm (1.02 in.)

Dimensions When

Mounting in Remote

Mounting Unit

140 mm (5.5 in.) x 150 mm (5.9 in.) x 85 mm (3.4 in.)

Operating Temperature 0 to 39 C (32 F to 103 F)

Humidity 10-99%RH non-condensing

Software Compatibility

Version:

VESDA LaserPLUS detector - Ver. 3.05.00

VESDA LaserSCANNER detector - Ver. 3.05.00

VESDA LaserCOMPACT detector -Ver. 3.07.05

High Level Interface (HLI) - Ver. 3.05.04

LCD Programmer - Ver. 3.02.*1 (*denotes language)

The LCD Programmer cannot configure the system

relay module.

Displays - do not need upgrading

VSM3 - Ver. 3.10.05

VConfig - Ver. 3.10.03

Accessories Product Manual VESDA

20

1.5 Other Accessories

Labels

Sampling point labels There are two labels to identify sampling holes:

Miniature sampling point label These are round labels with a hole in

the centre to fit around the miniature sampling points

Sampling point decal This decal is

wrapped around a pipe on the sampling

hole. The decal has a hole in the centre.

The hole in the decal must be aligned to

the sampling hole drilled into the pipe.

Pipe label This label identifies the

pipe as being a smoke detector pipe

and warns against tampering with it.

VESDA

Accessories Product Guide

21

Index

Numerics

12 Relay Card........................................ 9

19 Subrack .......................................... 4

3U Subrack ........................................... 5

7 Relay Card ......................................... 9

A

Alarm LEDs......................................... 12

B

Bar Graph........................................... 11

Battery back up ................................... 11

Blank Plates.......................................... 4

C

Closed Loop ......................................... 8

Conventions .......................................... ii

D

Display Module.............................. 11, 13

F

Fault LEDs.......................................... 12

Female Connector ............................... 14

L

LaserPLUS Remote Display .................... 2

LCD Programmer................................. 14

M

Miniature sampling point label .............. 20

N

Numeric Display .................................. 11

P

Pipe label............................................ 20

polarity............................................... 16

Power Source...................................... 10

Programmed relays................................ 8

Push Button Keys................................ 12

R

Relay Processor Card .......................... 10

Relays.................................................. 8

Remote Box .......................................... 2

remote box ........................................... 3

Remote Display Unit .............................. 2

Remote Mounting .................................. 2

Remote Programmer Unit ....................... 2

Remote Scanner Display Unit.................. 2

Remote Systems ................................... 6

Remote Termination Card........... 6, 10, 16

S

Sampling point decal ........................... 20

socket card......................................... 16

Socket Unit ........................................... 2

stand alone detector .............................. 2

Subrack Modules................................... 4

Accessories Product Guide VESDA

22

System Relay Module............................. 2

system relay module............................ 18

T

termination card.................................. 16

Threshold Indicators............................ 11

V

VESDAnet Terminals.............................. 7

W

Wiring ................................................ 10

You might also like

- Vesda Aspire2 Technical DatasheetDocument2 pagesVesda Aspire2 Technical Datasheetalfredcl35No ratings yet

- 00 VESDA VFT Acessories TDS AQ LoresDocument2 pages00 VESDA VFT Acessories TDS AQ Loreskmlowpg2No ratings yet

- 08 Vesda VLQ Tds Aq Ie LoresDocument2 pages08 Vesda VLQ Tds Aq Ie Loreskmlowpg2No ratings yet

- 05 VESDA 19inch Subrack Enclosure TDS A4 IE LoresDocument2 pages05 VESDA 19inch Subrack Enclosure TDS A4 IE Loreskmlowpg2No ratings yet

- 04 Xtralis Inline Filter TDS A4 IE LoresDocument2 pages04 Xtralis Inline Filter TDS A4 IE Loreskmlowpg2No ratings yet

- MAN3046 ProSens Technical ManualDocument166 pagesMAN3046 ProSens Technical Manualkmlowpg2No ratings yet

- 02 Xtralis Internal Power Supply TDS A4 LoresDocument2 pages02 Xtralis Internal Power Supply TDS A4 Loreskmlowpg2No ratings yet

- 01 Xtralis Power Supply StyleE Tds A4 LoresDocument2 pages01 Xtralis Power Supply StyleE Tds A4 Loreskmlowpg2No ratings yet

- 01 VESDA VFT-15 Accessories TDS A4 IE LoresDocument2 pages01 VESDA VFT-15 Accessories TDS A4 IE Loreskmlowpg2No ratings yet

- 11 Vesda Vft-15 Tds A4 Ie LoresDocument2 pages11 Vesda Vft-15 Tds A4 Ie Loreskmlowpg2No ratings yet

- 18 Osid Tds Aq Ie LoresDocument2 pages18 Osid Tds Aq Ie Loreskmlowpg2No ratings yet

- Vision System Vesda - PsuDocument2 pagesVision System Vesda - Psukmlowpg2No ratings yet

- Vesda Partner Pocket GuideDocument16 pagesVesda Partner Pocket Guidekmlowpg2No ratings yet

- Communications GuideDocument16 pagesCommunications Guideಆದಿತ್ಯ ಜೋಯಿಸ್No ratings yet

- Vesda Software Guide 10254Document20 pagesVesda Software Guide 10254kmlowpg2100% (1)

- 08 Xtralis Warehouse ArticleDocument4 pages08 Xtralis Warehouse Articlekmlowpg2No ratings yet

- Vesda VLP Data SheetDocument2 pagesVesda VLP Data Sheetkmlowpg2No ratings yet

- The Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeFrom EverandThe Subtle Art of Not Giving a F*ck: A Counterintuitive Approach to Living a Good LifeRating: 4 out of 5 stars4/5 (5783)

- The Yellow House: A Memoir (2019 National Book Award Winner)From EverandThe Yellow House: A Memoir (2019 National Book Award Winner)Rating: 4 out of 5 stars4/5 (98)

- Never Split the Difference: Negotiating As If Your Life Depended On ItFrom EverandNever Split the Difference: Negotiating As If Your Life Depended On ItRating: 4.5 out of 5 stars4.5/5 (838)

- Shoe Dog: A Memoir by the Creator of NikeFrom EverandShoe Dog: A Memoir by the Creator of NikeRating: 4.5 out of 5 stars4.5/5 (537)

- The Emperor of All Maladies: A Biography of CancerFrom EverandThe Emperor of All Maladies: A Biography of CancerRating: 4.5 out of 5 stars4.5/5 (271)

- Hidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceFrom EverandHidden Figures: The American Dream and the Untold Story of the Black Women Mathematicians Who Helped Win the Space RaceRating: 4 out of 5 stars4/5 (890)

- The Little Book of Hygge: Danish Secrets to Happy LivingFrom EverandThe Little Book of Hygge: Danish Secrets to Happy LivingRating: 3.5 out of 5 stars3.5/5 (399)

- Team of Rivals: The Political Genius of Abraham LincolnFrom EverandTeam of Rivals: The Political Genius of Abraham LincolnRating: 4.5 out of 5 stars4.5/5 (234)

- Grit: The Power of Passion and PerseveranceFrom EverandGrit: The Power of Passion and PerseveranceRating: 4 out of 5 stars4/5 (587)

- Devil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaFrom EverandDevil in the Grove: Thurgood Marshall, the Groveland Boys, and the Dawn of a New AmericaRating: 4.5 out of 5 stars4.5/5 (265)

- A Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryFrom EverandA Heartbreaking Work Of Staggering Genius: A Memoir Based on a True StoryRating: 3.5 out of 5 stars3.5/5 (231)

- On Fire: The (Burning) Case for a Green New DealFrom EverandOn Fire: The (Burning) Case for a Green New DealRating: 4 out of 5 stars4/5 (72)

- Elon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureFrom EverandElon Musk: Tesla, SpaceX, and the Quest for a Fantastic FutureRating: 4.5 out of 5 stars4.5/5 (474)

- The Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersFrom EverandThe Hard Thing About Hard Things: Building a Business When There Are No Easy AnswersRating: 4.5 out of 5 stars4.5/5 (344)

- The Unwinding: An Inner History of the New AmericaFrom EverandThe Unwinding: An Inner History of the New AmericaRating: 4 out of 5 stars4/5 (45)

- The World Is Flat 3.0: A Brief History of the Twenty-first CenturyFrom EverandThe World Is Flat 3.0: A Brief History of the Twenty-first CenturyRating: 3.5 out of 5 stars3.5/5 (2219)

- The Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreFrom EverandThe Gifts of Imperfection: Let Go of Who You Think You're Supposed to Be and Embrace Who You AreRating: 4 out of 5 stars4/5 (1090)

- The Sympathizer: A Novel (Pulitzer Prize for Fiction)From EverandThe Sympathizer: A Novel (Pulitzer Prize for Fiction)Rating: 4.5 out of 5 stars4.5/5 (119)

- Her Body and Other Parties: StoriesFrom EverandHer Body and Other Parties: StoriesRating: 4 out of 5 stars4/5 (821)

- 9310 Parts ManualDocument162 pages9310 Parts ManualdcclancyNo ratings yet

- TRX Vu2hmyDocument10 pagesTRX Vu2hmyokuraokuNo ratings yet

- Testing and Analyzing Methods For Truncated Binary MultiplicationDocument94 pagesTesting and Analyzing Methods For Truncated Binary MultiplicationA. VillaNo ratings yet

- Fountaine Fifth WheelDocument24 pagesFountaine Fifth Wheelfdpc1987No ratings yet

- A Generic High Bandwidth Data Acquisition Card For Physics ExperimentsDocument9 pagesA Generic High Bandwidth Data Acquisition Card For Physics ExperimentsekaNo ratings yet

- Description: FEC26 ControllerDocument3 pagesDescription: FEC26 Controllersomma_0No ratings yet

- SickDocument84 pagesSickmilves1No ratings yet

- Microsoft Office - Wikipedia, The Free Encyclopedia1Document9 pagesMicrosoft Office - Wikipedia, The Free Encyclopedia1beta2009No ratings yet

- RDP 2000 User Manual Chapter GuideDocument378 pagesRDP 2000 User Manual Chapter GuideAlexandru Sorin Leotescu0% (1)

- Handling The Flat File That Exist in The Application ServerDocument3 pagesHandling The Flat File That Exist in The Application ServerFarooq AhmedNo ratings yet

- Digital ELCB Tester KM 1812ELDocument1 pageDigital ELCB Tester KM 1812ELindustrialindiaNo ratings yet

- Upgrade Database Using OEM 12C Cloud Control DBACLASSDocument9 pagesUpgrade Database Using OEM 12C Cloud Control DBACLASSVinod KumarNo ratings yet

- The Tata Power Company Limited Bhira 100Mw-Augmentation Scheme Including Mulshi Lake Sub-Storage UtilizationDocument7 pagesThe Tata Power Company Limited Bhira 100Mw-Augmentation Scheme Including Mulshi Lake Sub-Storage Utilizationpavankumar001No ratings yet

- zpc2 Users Manual PDFDocument124 pageszpc2 Users Manual PDFrenegarsNo ratings yet

- RemoteConnect and SCADAPack x70 Utilities R2.6.1-Release NotesDocument12 pagesRemoteConnect and SCADAPack x70 Utilities R2.6.1-Release NotesVictor OlguinNo ratings yet

- HawkJaw 65K-ALS Operation, Maintenance and Service ManualDocument139 pagesHawkJaw 65K-ALS Operation, Maintenance and Service ManualHailan ChengNo ratings yet

- DX DiagDocument10 pagesDX Diaghenrik_nordstrom94No ratings yet

- 2006 Belden CatalogDocument824 pages2006 Belden CatalogLuis Gonzalez100% (1)

- Oxygen ManualDocument2 pagesOxygen ManualntovasNo ratings yet

- Elcometer 456 Coating Thickness Gauge - DatasheetDocument16 pagesElcometer 456 Coating Thickness Gauge - DatasheetVallik TadNo ratings yet

- Mysql 5.1 Relnotes En.Document322 pagesMysql 5.1 Relnotes En.Ionut Santiago de CompostelaNo ratings yet

- Image4K Datasheet ENDocument2 pagesImage4K Datasheet ENMohamed Abdalla AlarabiNo ratings yet

- ACOPOSDocument4 pagesACOPOSBals GaddaNo ratings yet

- VM 15 0 CG BookDocument200 pagesVM 15 0 CG BookDavid WangNo ratings yet

- RGC Mini PC ComparisonDocument4 pagesRGC Mini PC ComparisonitqonabdulkhoirNo ratings yet

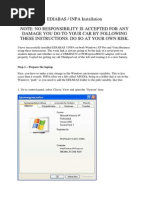

- Ediabas and Inpa How To InstallDocument10 pagesEdiabas and Inpa How To InstallBijouxBratariHandMadeNo ratings yet

- Computer AssignmentDocument7 pagesComputer Assignmentaroosh16No ratings yet

- Abdul Hakeem SAP FICO Consultant Mobile No: +91 9533330964Document4 pagesAbdul Hakeem SAP FICO Consultant Mobile No: +91 9533330964dharmendra undavalliNo ratings yet

- Wireless DC Moor Speed and Direction ControlDocument2 pagesWireless DC Moor Speed and Direction ControlJoseph JohnsonNo ratings yet