Professional Documents

Culture Documents

Portal Frames Final - 2

Uploaded by

Ar Vivek Karelia0 ratings0% found this document useful (0 votes)

301 views19 pagesportal frames

Original Title

Portal Frames Final_2

Copyright

© © All Rights Reserved

Available Formats

DOCX, PDF, TXT or read online from Scribd

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this Documentportal frames

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

0 ratings0% found this document useful (0 votes)

301 views19 pagesPortal Frames Final - 2

Uploaded by

Ar Vivek Kareliaportal frames

Copyright:

© All Rights Reserved

Available Formats

Download as DOCX, PDF, TXT or read online from Scribd

You are on page 1of 19

Vivek Kamlesh Karelia

Fifth year B.Arch

Roll no 13

Asmita college of architecture

PORTAL FRAMES

PORTAL FRAMES

Definition A Portal Frame can be defined as a continuous or rigid frame which has the characteristic of a rigid or restrained joint between the

supporting member (or column) and the spanning member (or beam).

Portal frames are generally low-rise structures, comprising columns and horizontal or pitched rafters, connected by moment-resisting connections.

Resistance to lateral and vertical actions is provided by the rigidity of the connections and the bending stiffness of the members, which is increased by

a suitable haunch or deepening of the rafter sections.

This form of continuous frame structure is stable in its plane and provides a clear span that is unobstructed.

The main objective of this form of design is to reduce bending moment in the beam which allows the frame to act as one structural unit.

They are very efficient for enclosing large volumes; therefore they are often used for industrial sheds, factories storage, ware houses, sports halls as well

as for agricultural purposes.

Generally, the centre-to-centre distance between frames is 6 to 7.5m, with eaves height ranging from 6 --15 m.

Generally designed for two types of loads that are roof load and wind load.

The most common form of portal frame used in the construction industry is the pinned-base frame with different rafter and column member size and

with haunches at both the eaves and apex connections.

Portal frames are made in steel, concrete and timber.

But now a days they are mainly made from steel.

A TYPCAL ARRANGEMENT OF A PORTAL FRAME

ANATOMY OF A TYPICAL PORTAL FRAME

Portal frames are the most commonly used structural forms for single-storey industrial structures.

They are constructed mainly using hot-rolled sections, supporting the roofing and side cladding via cold-formed purlins and sheeting rails.

They may also be composed of tapered stanchions and rafters fabricated from plate elements.

A portal frame building comprises a series of transverse frames braced longitudinally.

The primary steelwork consists of columns and rafters, which form portal frames, and bracing.

The end frame (gable frame) can be either a portal frame or a braced arrangement of columns and rafters.

PRIMARY COMPONENTS OF A PORTAL FRAME CROSS SECTION SHOWING THE PORTAL FRAMEN AND ITS RESTRAINTS

The light gauge secondary steelwork consists of side rails for walls and purlins for the roof.

The secondary steelwork supports the building envelope, but also plays an important role in restraining the primary steelwork.

The roof and wall cladding separate the enclosed space from the external environment as well as providing thermal and acoustic insulation.

The structural role of the cladding is to transfer loads to secondary steelwork and also to restrain the flange of the purlin or rail to which it is

attached.

TYPES OF PORTAL FRAMES ACC. TO THE USE OF HINGED JOINTS

A. FIXED OR RIGID PORTAL FRAMES

All connections between frame members are rigid.

This will give bending moments of lower magnitude more evenly distributed than other forms.

Used for small to medium size frames where the moments transferred to the foundations will not be excessive.

B. TWO PIN PORTAL FRAMES

Hinges are used at the base connections to eliminate the tendency of the base rotate.

The bending moments resisted by the supporting members will be greater than those encountered in the rigid portal frame.

Main use is where high base moments and weak ground conditions are encountered.

C. THREE PIN PORTAL FRAMES

This form of the frame has high hinged joints at the base connections and at the centre of the spanning member.

The effect of the third hinge is to reduce the bending moments in the spanning member but to increase deflection.

To overcome this latter disadvantage a deeper beam must be given a moderate pitch to raise the apex well above the eaves level.

Two other advantages of the three pin portal frame are that the design is simplified since the frame is statically determined and on the

site they are easier to erect, particularly when preformed in sections.

Portal frames constructed of steel, concrete or timber can take the form of the usual roof profiles used for single or multi-span buildings

such as flat, pitched, north light, monitor and arch.

The frames are generally connected over the spanning members with purlins designed to carry and accept the fixing of lightweight roof

coverings or decking.

The walls can be of similar material fixed to sheeting rails attached to the supporting members or alternatively clad with brick or infill

panels.

TYPES OF PORTAL FRAMES ACC. TO THE USE MATERIALS

A. CONCRETE PORTAL FRAMES

Concrete portal frames are invariably manufactured from high quality precast concrete suitably reinforced.

In the main use of precast concrete portal frames is confined to low pitch (4 to 22) single a wide range of design from only a few

standard components.

Wall finishes can be varied and intermixed since they are non-load bearing and therefore have to provide only the degree of resistance

required for fire, thermal and sound insulation, act as a barrier to the elements and resist positive and negative wind pressures.

Precast reinforced concrete portal frames are supplied for the economic benefit of repetitive casting in standard moulds and close control

of mixing, placing and compaction of concrete that is possible only in the factory conditions.

For the convenience of casting, transport and erection on site, precast concrete portal frames are generally cast in two or more sections

which are bolted together on site either at the point of contraflexure in rafters or at the junction of post and rafter, or both.

CONCRETE PORTAL FRAME

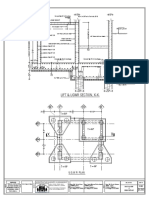

FOUNDATION AND FIXING

The foundation for a precast concrete portal frame usually consists of a reinforced concrete isolated base or pad designed to suit loading and

ground bearing conditions.

The frame can be connected to the foundations by variety of methods:

1. POCKET CONNECTIONS:

The foot of the supporting member is located and housed in a void or pocket formed in the base so that there is an all-round

clearance of 25mm to allow for plumbing and final adjustment before the column is grouted into the foundation base.

2. BASE PLATE CONNECTION:

A steel base plate is welded to the main reinforcement of the supporting members, or alternatively it could be cast into the

column using fixing lugs welded to the back of the base plate.

Holding down bolts are cast into the foundation base; the erection and fixing procedure is same as that of steelwork.

3. PIN JOINT OR HINGED CONNECTION

A special or bearing plate is bolted to the foundation and the mechanical connection is made when the frames are

erected.

The choice of connection method depends largely upon the degree of fixity required and the method adopted by the

manufacturer of his particular system.

ADVANTAGES

Maintenance not usually required.

Own built in resistance to fire.

Wind resistance is such that wind bracing is not required.

Aesthetically pleasing.

B. STEEL PORTAL FRAMES

Steel portal frames can be fabricated from standard universal beam, column and box sections.

Alternatively a lattice construction of flats, angles or tubular can be used.

Most forms of roof profiles can be designed and constructed giving a competitive range when compared with other materials used in portal

frame construction.

The majority of systems employ welding techniques for the fabrication of components which are joined together on site using bolts or

welding.

An alternative system uses special knee joint, apex joint and base joint components which are joined on site to square cut standard beam or

column sections supplied by the main contractor or by the manufacturer producing the jointing pieces.

The frames are designed to carry lightweight roof coverings of the same loading conditions as those given for precast concrete portal

frame.

STEEL PORTAL FRAME

FOUNDATION AND FIXING

The foundation is usually a reinforced concrete isolated base or pad foundation designed to suit loading and ground bearing conditions.

The connection of the frame to the foundation can be by:

1. POCKET CONNECTIONS:

The foot of the supporting member is supported and grouted into a pocket formed in the concrete foundation as described

for precast portal frames.

To facilitate levelling, some designs have gussets welded to the flanges of the column.

2. BASE PLATE CONNECTION:

Traditional structural steel work column to foundation connection using a slab or a gusset base fixed to a reinforced concrete

foundation with cast in holding down bolts.

3. PIN JOINT OR HINGED CONNECTION

Special bearing plates designed to accommodate true pin or rocker devices are fixed by holding down bolts to the concrete

foundation to give the required low degree of rigidity at the connection.

ADVANTAGES

Standard range of manufactures systems.

Less overall dead load.

Good wind resistance.

Quick assembly.

DISADVANTAGES

Corrosive material hence regular protective maintenance required.

Lower fire resistance.

C. TIMBER PORTAL FRAMES

Timber portal frames can be manufactured by several methods which produce a light, strong frame of pleasing appearance which renders

them suitable for buildings such as churches, halls and gymnasiums where clear space and appearance are important.

A TYPICAL TIMBER PORTAL FRAME

The common methods used are:

1. GLUED LAMINATED PORTAL FRAMES

The main objective of forming a laminated member consisting of glued layers of thin section timber members is to obtain an

overall increase in strength of the complete component over that which could be expected from a similar sized solid section

of a particular species of timber.

The selection of suitable quality softwoods of the right moisture content is important for a successful design.

Site work is simple consisting of connecting the foot of the supporting member to the metal shoe fixing or to a pivot housing

bolted to the concrete foundation and connecting the joint at the apex or crown with a bolt fixing or hinge device.

Any form of walling can be used in conjunction with these frames as long as they comply with the applicable building

regulations.

2. PLYWOOD PORTAL FRAMES

These frames are suitable for small halls, churches and schools with spans in the region of 9m.

The portal frames are in boxed beams consisting of a skeleton core of softwood members faced on both sides with plywood

which rakes the bending stresses.

The hollow form of the construction enables electrical and other small services to be accommodated within the frame

members.

3. SOLID TIMBER AND PLYWOOD PORTAL FRAMES

These frames are placed close to each other and are cladded with a plywood sheath so that the finished structure acts as a

shell giving a lightweight building which is very rigid and strong.

The foundations of this type of frame consist of a ground beam or alternatively the frames can be fixed to the edge of the

raft slab.

A timber spreader or a sole plate is used along the entire length of the building to receive and distribute the thrust loads of

the frames.

Connection to this spreader plate is made by using standard galvanized steel joists hangers or by using galvanized steel

angle cleats.

ADVANTAGES

Constructed from readily available materials at an economic cost.

Light in weight.

Easy to transport and erect.

Can be trimmed and easily adjusted on site.

Protection against fungi can be done by impregnation Pleasing finish.

Wood has greater thermal qualities than steel.

Wood will not reverberate sound as clearly as steel would and so will not create high resonance.

Thick wood will last longer in fire than steel.

DISADVANTAGES

Lower fire resistance.

Wood will wrap, crack and root when exposed to moisture unless properly treated.

Wood can shrink over time.

Wood has impurities such as knots, splits and slope of grain unless steel which has quality control.

Wood can be attacked by termites.

Wooden members are non-recyclable once used.

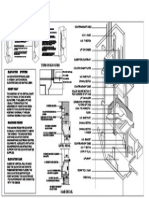

JOINTS IN PORTAL FRAMES

A. BASE JOINT

The legs or stanchions of the portal frame need connecting at the bottom to a foundation.

Here we can see the base joint connection in place.

FIXING OF THE COLUMN TO THE FOUNDATION

B. APEX JOINT

Shown here is a ridge joint or apex joint.

It is Important that this joint is strong hence the use of wedge shaped pieces called gusset pieces to strengthen and increase the bolt area.

C. KNEE JOINT

Again the knee joint must be strong to support the roof loads and prevent bending.

Gusset pieces will be used to increase strength, give greater bolt area and prevent deflection under load.

If the base, apex and the knee joints are not rigid, they will open up and the frame will be unstable when subjected to loads.

This is the pack of cards effect.

Vertical loading resulting in pushing the knee joint outwards.

If the foundation cant resist horizontal push, outward movement will occur and the frame will lose strength.

Wind subjects the frame to uplift forces.

Overturning forces on the sides & ends of the building.

Drag forces on the roof and sides.

These destabilizing forces are resisted essentially by the weight of the building and in this regard, the foundations contribute significantly to this weight.

The foundations are regarded as buildings anchors.

BRACING

With all types of frameworks one must think on stability i.e. movement.

Bracing is an essential part of each and every structure being erected in almost every country in the world today.

To help strengthen the framework and prevent movement diagonal bracing will be used to make the structure more rigid.

Its function is essentially to increase the structures strength in order to prevent it from falling down while having a load such as wind, rain or snow

applied, as well as being able to support its dead load.

A. FLY BRACING

Fly bracing is an essential element in every long-span portal frame warehouse design, as it not only prevents the purlins from twisting and

overturning, but it also lengthens the influence of the rafter by increasing the roofs strength, which is especially useful for the builders

cladding the roof.

Fly bracing is also sometimes used on the columns and girts of a portal frame to also prevent these elements from twisting, however fly

bracing does add cost to the building and therefore should only be used where needed.

FLY BRACING USED ON COLUMN

B. ROOF BRACING

Crossed roof bracing is another type of bracing which is essential to the erection of long-span design.

Its function is to prevent the rafters/beams of the structure from moving apart from one-another due to a wind load by being placed under

either tension or compression.

BRACING ON ROOF BRACING ON THE WALLS

The primary functions of vertical bracing in the side walls of the frame are:

To transmit the horizontal loads to the ground. The horizontal forces include forces from wind and cranes.

To provide a rigid framework to which side rails and cladding may be attached so that the rails can in turn provide stability to the columns

To provide temporary stability during erection.

STIFFENING PLATES

Stiffening plates are another type of bracing used to prevent 'Universal Beams and Columns' from bending and twisting.

HAUNCHING

For spans of over 20 meters, extra bracing is required to keep the steel substructure from collapsing in on itself.

This bracing is known as 'haunching' and is usually made of a cut-to-shape universal 'I' beam which fits into the corner made by the stanchion and

the rafters.

A haunch's depth is usually about the same as the depth of the rafter, and in terms of length, is usually in the order of about 10-15% of the span of

the rafter.

FIXINNG OF HAUNCH BENDING MOMENT DIAGRAM

Another location where haunching can be found in long-span construction is at the apex of the structure.

Again, the haunch's depth is usually about the same as the depth of the rafter, however in terms of length, the apex haunching is closer to between

30-40% of the span of the rafter.

You might also like

- Analysis of Portal Frame Building in Accordance To EN 1993-1-1 (2005) 1 DescriptionDocument36 pagesAnalysis of Portal Frame Building in Accordance To EN 1993-1-1 (2005) 1 DescriptionSami Abdelgadir MohammedNo ratings yet

- Removing chimney breastsDocument2 pagesRemoving chimney breastsThe Lone GunmanNo ratings yet

- Building Design PDFDocument7 pagesBuilding Design PDFkbkwebsNo ratings yet

- Space Frame Structures ExplainedDocument40 pagesSpace Frame Structures ExplainedB-05 ISHA PATELNo ratings yet

- Portal Frames-Building ConstructionDocument18 pagesPortal Frames-Building ConstructionDivya chowdaryNo ratings yet

- Design of Roof SystemDocument3 pagesDesign of Roof SystemkarthikuddNo ratings yet

- Portal Frame ConstructionDocument2 pagesPortal Frame Constructionriz2010No ratings yet

- An Intro To Tensile Structures PDFDocument20 pagesAn Intro To Tensile Structures PDFSuraj De SilvaNo ratings yet

- StaircaseDocument1 pageStaircaseSejal jalanNo ratings yet

- Façade Treatment: Submitted To:-Submitted ByDocument17 pagesFaçade Treatment: Submitted To:-Submitted ByShivam ShanuNo ratings yet

- National Building Code Document SectionsDocument367 pagesNational Building Code Document SectionsCaleb James100% (1)

- HCW 14-Us HalfenDocument36 pagesHCW 14-Us HalfenALBERT100% (1)

- Waterfront - Design Calculation - Railings - Rev.00Document54 pagesWaterfront - Design Calculation - Railings - Rev.00Rhem Aldrin CordovaNo ratings yet

- Roofs 2Document56 pagesRoofs 2david adawo100% (1)

- Bernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGDocument1 pageBernard D. Marquez Eduardo M. Axalan Engr. William A.L.T. NGRhon Nem KhoNo ratings yet

- Finite-Element Investigation of Cold-Formed Steel Portal Frames in FireDocument17 pagesFinite-Element Investigation of Cold-Formed Steel Portal Frames in FireMohamedNo ratings yet

- Structural Design Brief - Rev 0Document6 pagesStructural Design Brief - Rev 0Umesh ChamaraNo ratings yet

- Kingspan Structural KSP Multideck Technical Handbook LR 122018 en UKDocument140 pagesKingspan Structural KSP Multideck Technical Handbook LR 122018 en UKdion2110No ratings yet

- She-Lea-Concrete Construction DetailsDocument2 pagesShe-Lea-Concrete Construction Detailsapi-515610659No ratings yet

- Pad Footing Detail-2 (B) 1Document1 pagePad Footing Detail-2 (B) 1Ajimu SulaimanNo ratings yet

- Truss BracingDocument4 pagesTruss BracingTuanQuachNo ratings yet

- Sathya Consultants: For Thermal ComfortDocument10 pagesSathya Consultants: For Thermal ComfortJappu KumarNo ratings yet

- Kirby Sheeting Panel Charts PDFDocument2 pagesKirby Sheeting Panel Charts PDFAnonymous ELujOV3No ratings yet

- 25 AsmitaS Long Span BeamsDocument9 pages25 AsmitaS Long Span BeamsAsmita SutarNo ratings yet

- Trench Plan and Foundation DetailsDocument1 pageTrench Plan and Foundation DetailsGsUpretiNo ratings yet

- Composite Slab DesignDocument8 pagesComposite Slab DesignOladunni AfolabiNo ratings yet

- Cavity Wall Construction Guide: Insulation Methods, Advantages & DetailsDocument30 pagesCavity Wall Construction Guide: Insulation Methods, Advantages & DetailsTejas JoshiNo ratings yet

- Holedeck Brochure 2013Document17 pagesHoledeck Brochure 2013Fredy Humpiri RojoNo ratings yet

- "Hybrid" Light Steel Panel and Modular Systems PDFDocument11 pages"Hybrid" Light Steel Panel and Modular Systems PDFTito MuñozNo ratings yet

- Structural Steel Beam Calculations For Loft Conversion ExampleDocument4 pagesStructural Steel Beam Calculations For Loft Conversion ExamplePetar ValevNo ratings yet

- Shear Walls - An OverviewDocument6 pagesShear Walls - An OverviewTabish IslamNo ratings yet

- Precast ConcreteDocument5 pagesPrecast ConcreteSurya TejNo ratings yet

- Tied Foundations-Portal FrameDocument3 pagesTied Foundations-Portal FrameJaime Manalili LandinginNo ratings yet

- Installation Manual E-Brick en LoresDocument80 pagesInstallation Manual E-Brick en LoresvideoramirezNo ratings yet

- Beam Schedule: 250 3Rd FloorDocument1 pageBeam Schedule: 250 3Rd FloorNhel AlbrechtNo ratings yet

- Mactan Belmont Luxury Hotel – Cast in Channel Loading AnalysisDocument9 pagesMactan Belmont Luxury Hotel – Cast in Channel Loading AnalysisJonathanNo ratings yet

- EXECUTION AND COMPLETION OF ROOF WORKSDocument70 pagesEXECUTION AND COMPLETION OF ROOF WORKSTOM YEENo ratings yet

- Multi Deck 146Document36 pagesMulti Deck 146bondar1100% (1)

- COLUMN SCHEDULE (7) - ModelDocument1 pageCOLUMN SCHEDULE (7) - ModelPiyush ShahaneNo ratings yet

- 0.1advanced Structures - Sustainable SteelDocument64 pages0.1advanced Structures - Sustainable Steelsilvinus clissonNo ratings yet

- Portal Frames ConstructionDocument47 pagesPortal Frames ConstructionYashi GuptaNo ratings yet

- Roof Details for Steel Sheet and FlashingDocument24 pagesRoof Details for Steel Sheet and FlashingVinh HoàngNo ratings yet

- Advantages CFSTDocument14 pagesAdvantages CFSTprajjwal patidarNo ratings yet

- Fig. 1: Types of Shear Wall, (A) Single Storey, (B) Multi-StoreyDocument3 pagesFig. 1: Types of Shear Wall, (A) Single Storey, (B) Multi-StoreyAmer GonzalesNo ratings yet

- Ead 020002 00 0404 Balcony and Terrace Glazing System Without Vertical Frames 2016Document9 pagesEad 020002 00 0404 Balcony and Terrace Glazing System Without Vertical Frames 2016bmnNo ratings yet

- Types of False Ceilings & Their Installation ProblemsDocument23 pagesTypes of False Ceilings & Their Installation ProblemsEng HatemNo ratings yet

- Diaphragm Action and Design - SpringerDocument3 pagesDiaphragm Action and Design - SpringerGuillermo Agustín Yáñez QuezadaNo ratings yet

- Seismic Analysis and Design of R.C.C Tall Building With Shear WallDocument9 pagesSeismic Analysis and Design of R.C.C Tall Building With Shear WallNaveen JatavNo ratings yet

- CPCI Disclaimer for Precast Concrete Design DetailsDocument1 pageCPCI Disclaimer for Precast Concrete Design DetailsSahand JeffNo ratings yet

- Long SpanDocument113 pagesLong SpanHasan KazimNo ratings yet

- Abcm - Long Span - ReportDocument27 pagesAbcm - Long Span - ReportShalin KapdiNo ratings yet

- Portal FrameDocument4 pagesPortal Frameakankshapen100% (1)

- Industrial ConstDocument34 pagesIndustrial Constkirti0% (1)

- Building ConstructionDocument15 pagesBuilding Constructionnikitadusing100% (1)

- Portal Frame SampleDocument70 pagesPortal Frame SampleVincent 20200% (1)

- Reinforced Concrete Portal Frame ConstructionDocument6 pagesReinforced Concrete Portal Frame ConstructionolomizanaNo ratings yet

- Submitted By:-Jahnvi Gulati B.Arch (Ar) 4 Year, 8 SemDocument22 pagesSubmitted By:-Jahnvi Gulati B.Arch (Ar) 4 Year, 8 SemJahnvi Gulati100% (3)

- Large Unobstructed Floor Space Portal Frame StructureDocument35 pagesLarge Unobstructed Floor Space Portal Frame StructurejkaliwonNo ratings yet

- Construction Methods in Industrialized BuildingsDocument37 pagesConstruction Methods in Industrialized BuildingsJoseph EzekielNo ratings yet

- Arc314 L14Document16 pagesArc314 L14Ar Vivek KareliaNo ratings yet

- Site Analysis B - 19Document1 pageSite Analysis B - 19Ar Vivek KareliaNo ratings yet

- Buildings Surviving EarthquakeDocument9 pagesBuildings Surviving EarthquakeAr Vivek KareliaNo ratings yet

- Chapter 14 ADocument18 pagesChapter 14 AWalid ThohariNo ratings yet

- Escalator ModelDocument1 pageEscalator ModelAr Vivek KareliaNo ratings yet

- Roof Truss - King PostDocument2 pagesRoof Truss - King PostAr Vivek KareliaNo ratings yet

- Space Requirement Analysis for Arts and Crafts CenterDocument6 pagesSpace Requirement Analysis for Arts and Crafts CenterAr Vivek KareliaNo ratings yet

- Escalator ModelDocument1 pageEscalator ModelAr Vivek KareliaNo ratings yet

- Elevators ModelDocument1 pageElevators ModelAr Vivek KareliaNo ratings yet

- Portal Frames: Vivek Kamlesh KareliaDocument2 pagesPortal Frames: Vivek Kamlesh KareliaAr Vivek KareliaNo ratings yet

- Portal Frames: Vivek Kamlesh KareliaDocument2 pagesPortal Frames: Vivek Kamlesh KareliaAr Vivek KareliaNo ratings yet

- Case StudyDocument1 pageCase StudyAr Vivek KareliaNo ratings yet

- ShilpgramDocument1 pageShilpgramvivek9022No ratings yet

- Guidelines For Case Studies & Case Study AnalysisDocument1 pageGuidelines For Case Studies & Case Study AnalysisAr Vivek Karelia100% (1)

- ShilpgrammmDocument1 pageShilpgrammmAr Vivek KareliaNo ratings yet

- Snow Load Analysis Based On ASCE 7-05 / IBC 2006: Input Data & Design SummaryDocument5 pagesSnow Load Analysis Based On ASCE 7-05 / IBC 2006: Input Data & Design SummaryJEMAYERNo ratings yet

- Retrofitting of Heritage and Historical BuildingsDocument8 pagesRetrofitting of Heritage and Historical BuildingsAyushDwivediNo ratings yet

- Setty - Schematic Bid 1145 19th Street 8th FloorDocument1 pageSetty - Schematic Bid 1145 19th Street 8th FloorsuhasNo ratings yet

- Residential Design PlansDocument5 pagesResidential Design Plansmichelle995No ratings yet

- Holcim Masonry Cement PDDocument2 pagesHolcim Masonry Cement PDTin NguyenNo ratings yet

- Interior & Exterior Plastering Method StatementDocument7 pagesInterior & Exterior Plastering Method StatementGabriel GabeNo ratings yet

- Underwater Restaurant: A Tribute to Norway's CoastDocument9 pagesUnderwater Restaurant: A Tribute to Norway's CoastNiyandha PupNo ratings yet

- Roofing Handbook 2ed 2000 - Scharff & KennedyDocument552 pagesRoofing Handbook 2ed 2000 - Scharff & KennedyCarl Williams100% (1)

- Rate Analysis 21.65Document9 pagesRate Analysis 21.65Nouman AkhtarNo ratings yet

- Bs II KLCC ReportDocument31 pagesBs II KLCC ReportChin HongruiNo ratings yet

- Construction Techniques and Equipment and Practice - Lecture Notes, Study Material and Important Questions, AnswersDocument5 pagesConstruction Techniques and Equipment and Practice - Lecture Notes, Study Material and Important Questions, AnswersM.V. TVNo ratings yet

- Technical Specifications & BOQ For PEB at KasnaDocument6 pagesTechnical Specifications & BOQ For PEB at KasnaAbhinav Tewari100% (2)

- Fenestration in BuildingsDocument38 pagesFenestration in Buildingsrohit14oct100% (1)

- Glass and Glazing Products IIDocument46 pagesGlass and Glazing Products IIKArthik AustinNo ratings yet

- 1992GIVONIComfort, Climate Analysis and Building Design GuidelinesDocument13 pages1992GIVONIComfort, Climate Analysis and Building Design GuidelinesMarcelleVilarNo ratings yet

- Under Ground Reservoir DetailsDocument1 pageUnder Ground Reservoir DetailsShekh Muhsen Uddin AhmedNo ratings yet

- SRV Engineering College Lecture Notes on Prefabricated StructuresDocument57 pagesSRV Engineering College Lecture Notes on Prefabricated Structuresg.rajaNo ratings yet

- Geosynthetics For Ground Improvement of Embankments On SoftDocument28 pagesGeosynthetics For Ground Improvement of Embankments On SoftkonetinarendraNo ratings yet

- Itp For Formworks (Ringlock System)Document3 pagesItp For Formworks (Ringlock System)damianNo ratings yet

- Appendix G - Soldier Pile and Lagging Wall DesignDocument10 pagesAppendix G - Soldier Pile and Lagging Wall Designbusta299No ratings yet

- ConcreteCentre - EC2 Bridges ExtractDocument6 pagesConcreteCentre - EC2 Bridges Extractmrzap500713% (8)

- CIBSE Guide B2 2016 - Ventilation & DuctworkDocument161 pagesCIBSE Guide B2 2016 - Ventilation & DuctworkpsriariyananNo ratings yet

- ResumeDocument2 pagesResumeLuiyyi EspinoNo ratings yet

- ANH House by Sanuki + NishizawaDocument13 pagesANH House by Sanuki + NishizawabatcavesNo ratings yet

- WP-MPS Revision 01 - GBT219 - 7.19.2019Document42 pagesWP-MPS Revision 01 - GBT219 - 7.19.2019Ann Jeannette PerezNo ratings yet

- Variation Order (AS-STAKED) U.P. Biodiversity Building Phase IIDocument10 pagesVariation Order (AS-STAKED) U.P. Biodiversity Building Phase IIHonesto LorenaNo ratings yet

- Waffle SlabDocument7 pagesWaffle SlabANSMARIA SUNNYNo ratings yet

- Project Estmate (Final)Document65 pagesProject Estmate (Final)Bilal Ahmed BarbhuiyaNo ratings yet

- Truss Details PDFDocument1 pageTruss Details PDFdnl_vicarsNo ratings yet

- Design of TiesDocument6 pagesDesign of TiesNATHAN NATENo ratings yet