Professional Documents

Culture Documents

Site Management Practices

Uploaded by

Madusha TisseraOriginal Title

Copyright

Available Formats

Share this document

Did you find this document useful?

Is this content inappropriate?

Report this DocumentCopyright:

Available Formats

Site Management Practices

Uploaded by

Madusha TisseraCopyright:

Available Formats

SITE MANAGEMENT PRACTICES

Group Members

Thennakoon T.M.V.A. 110571J

Tissera P.M.R. 110582T

Udugama U.D.C.A. 110590P

Wickramage H.S. 110619P

Wickramanayake N.W.S.S. 110620K

1. Human Resource Management

Importance-

Construction is inherently a labour based industry specially in developing countries such as Sri

Lanka. Thus labour can be considered to be one of if not the most important aspect of any

project. With increasing demands for salary increases and more opportunities for experienced

workers throughout Sri Lanka with the boom of the construction industry, it is more important

than ever before to manage the labour resources in a proper manner. With this background in

mind we will now consider how the labour management process is handled in the site we visited,

ie the Maxen Residency project with the client Maxen Residents constructed by Sanken.

Categories-

When considering the human resources in the project, there are various people involved with the

project, including the consultant and the client. While all of them can be considered to be human

resources in the general sense, here we will only be considering about the parties involved in the

construction of the project. As Marslow has stated, there is a hierarchy of needs. It can be seen

that Sanken has identified this and have motivated the different levels of employees by different

methods.

The Site Engineer has a separate table and is granted a significant amount of powers over the

work in the site as he requires a higher level of need. The other engineers too have their separate

work spaces which addresses their needs as well. Furthermore, all of them have been provided

with various degrees of powers over matters such as finance, material etc. This sense of respect

and trust placed on them motivates them to work even better.

In addition to the engineers, there are two kinds of labourers. Those that work directly for

Sanken and those that are working under contract basis. For example, those responsible for site

cleaning and maintenance are directly working for Sanken, while a majority of the carpenters,

and other labourers are contracted.

The labourers working for Sanken are provided accomodation at billets close to the site. Once

the building has been built to a certain degree, the labourers will be given a section of the

buidling to live in. The fact that the organisation looks into the welfare of the workers enhances

their morale. Also, unlike some sites, the workers have the ability to move in and out of the site

without checks or restrictions. This enhances the feeling that they are being trusted and hence

improves the motivation.

The labourers who are working under contracts are contracted from reputed labour

subcontractors such as Pathum, SN and Osanda. The management of these labourers is done in a

different way to those who are directly working in Sanken. Another main difference with respect

to these two types of labour is the hierarchy to which they report. Direct workers of Sanken

report to their line supervisors, while the contract workers have supervisors from their

organisations. Thus, the engineers and other managers at the site do not have complete control

over the contract staff brought from labour subcontractors.

It is also a requirement for the contractor to ensure that the work at the site has the adequate

number of workers at all times. While on normal days this would not be an issue, it has been

identified that there is a tendency among workers to take a holiday on the day after they get their

wages. In order to avoid a site shutdown due to inadequacy of labourers, Sanken pays the

labourers on the site in a staggered manner. So that only half of the workers get the salary on the

same day. This ensures that work at the site will carry on undisturbed.

Labour Planning-

Any kind of management requires a certain degree of planning. Human Resource management

too just like any other management requires planning. It may be stated that the planning required

with regards to human resources is more than that of any other planning since humans are

unpredictable. The labour planning at the site is done in a whole to part method. This is specially

required here since there is a strict deadline of 450 days to complete the work.

First, the work that needs to be completed is broken down into small parts and deadlines are

established for each type of work. Then these small deadlines are further broken down into daily

targets when a particular work is about to start. Since different engineers are in charge of

different tasks, in order to get a combined requirement, each engineer calculates the number of

labourers that he needs for the next day in order to achieve the daily targets. This is known as

tomorrow works. These requirements are then taken to the site engineer who must approve it.

This approved requirement list is in the form of a document called the labor request form, which

is in an ISO format.

These requirments are then sent to the respective sub-contractors before 3pm. Once this is

communicated, the labour subcontractor will provide the required labourers at the required time.

Though these labourers are paid according to the work they complete, there are exceptions if any

unforeseen delays take place. For example, when we visited the site on the 23

rd

of August, we

got to know that no work had taken place on the 22

nd

due to incessant rains. In that sort of a

situation, the contractor (Sanken) had to pay these labourers even though no work had taken

place.

To the benefit of Sanken however, such delays can be informed to the client and the consultant

and an extension for the completion date can be obtained. In order to properly manage this, a

weather report chart is updated daily and is kept at the site. This is required to ensure that the

contractor will not be penalized for delays due to weather that he cannot control.

Bad weather is not the only reason that can require Sanken to pay the contract labour even

without obtaining any output. If the labourers are present but the conditions are not conducive

for them to work still Sanken has to pay the contract price. For example there may be occasions

where an important piece of machinery is not present at the site or when the labourers are

expected to work at night, the lighting may not have been supplied. In order to reduce such

situations, and for many other reasons, site meetings are conducted.

2. Site Security and protection

Site security and protection is one of the main aspect that we should consider when managing a

construction site. Especially the security and protection of the construction site is challenging

area due to professional thieves and loss of equipment, materials due to stealing. And because of

that we have to put some money to recover that materials and equipment.

So therefore to overcome this problem it is better to have proper security plan for the

construction site. For that there are few things that we can practice to achieve good security and

protection at the site.

Appoint a security officer for the site is important and he is the person who consults with the

police on site security issues and he is the responsible person for security at the construction site.

Develop a proper security plan is also very important. The site security plan should be created

before starting the construction project. And according to that we can plan all the related security

aspects, where the security hut should located, types of security equipment (like lightings, CCTV

cameras, remote alarms , locks etc.) needed and where those should place.

And other thing is perimeter protection of the site. For that site boundaries best thing is having

proper fencing around the perimeter of the site. And it should be strong and high enough to

ensure the protection.

And the site should have only one entrance, and comings and goings from the construction site

should be clearly visible to the security hut to ensure the good security at the site.

In our site visit, we found some improvements that can be done. First thing is the security hut

was located away from the main entrance and therefore the visibility problem was there. As an

improvement it is better to shift the security hut near to the entrance. But the problem was the

space is limited at the site.

And all the three sides of the building was bounded by surround buildings and also having fence

Security hut - situated away from the entrance

(about 2.5m high) for necessary side including front side. Because of that the perimeter

protection of the site is ensured.

And lighting at the site should be established and it is better to have standby generator to

maintain site lighting.

Comments about security

Site security can be considered one of the most important control aspects of construction

management. A proper security plan ensures that there is no loss of equipment, material etc due

to stealing or negligence, while ensuring that productivity is not lost due to unnecessary security

measures and demotivation.

There was a site security officer and a security hut at the site in order to ensure site security.

There was also only one entrance, so the safety would be further ensured. The fact that the

security hut had a good view of the entrance was also a good sign.

POINTS FOR IMPROVEMENT

The security hut was situated away from the entrance, thereby reducing the visibility of the

security officer. Thus if this could be moved to the entrance, it would have been ideal. However,

according to the contractor, the security hut had to be placed at the current location due to lack of

space with the current excavations and once the building comes up to a certain degree, the

security hut would be relocated close to the entrance.

While the ability to move in and out of the site at will enhances the motivation of the workers, it

may be considered to be a security liability. However, since this is a small site and the amount of

equipment and material at the site is minimal, any attempts to steal may be seen quite easily.

3. Operating hours, noise and vibration control

Operating hours, noise and vibration control are very much related to the location of the

construction site, because it is the reason for many related problems and difficulties. The

construction site we have visited is by the side of the Gall road, in Bambalapitiya as shown in the

map extracted from Google Maps. As we can see, the site is located between the Bagathale Road

and Alfred House Gardens and any heavy vehicle we are to bring to the site will has to face the

high congestion conditions during day time especially during school/office hours. Hence, the

idea of bringing any heavy machinery during day time will be a start to many unwanted stressful

problems. And also according to the police order, the site is prohibited in using road to park

heavy vehicles under any circumstance. Also, the environmental police has a regulation that the

road and the newly constructed pavement should be cleaned after every work that will violate the

clean, pleasing condition.

The heavy vehicles are to be used for mainly concreting purposes such as transporting and

pumping. Hence, the site management has decided to do concreting work at night time,

specifically from 10.00 pm to 5.00 am on the next day. And also, after every such work, they

bring a water bowser to clean the road and the pavement on the early morning before 5.00 am.

And make sure the road is back to normal condition.

The site is scheduled to be operated from 8.00 am to 5.00 pm over the whole week except on

Sundays, but due to the schedule updates and the unexpected delays due to weather and such

reasons, the site is operating after 5.00 pm and even on the Sundays when it comes to catch up

the missed progress. On extending the working hours, the site management achieves to be within

the schedule with negligible deviations, but this solution brings along with some other problems.

There is a house just behind the construction site. Concreting work makes a lot of noises and

during the night time,

it will be a real

nuisance when the

site keeps going for a

particular time period.

(As scheduled, 450

days) Due to this, the

site management has

talked to the

respective house

owner and explained

the situation and they

Maxons

Residencies

have been able to come to an understanding point to continue with the work.

Like such, the problems arising with the start of the project has been solved by the site

management with their experiences and adoptable nature.

With the continuation of the site work, during the excavating period, the nearby buildings

(especially the TNT Building) has shown cracks increasing. Then the site management again has

to go for a solution to stop further development of cracks.

They have done a photographic survey in the beginning of the project in the nearby buildings

and insured the damages. With the development of the cracks, they have started to use chemical

pressure grouting where they inject cement grout with some chemicals through narrow drilled

holes with pressure guns. This is a technique that is used all over the world by construction

engineers as

a solution to

settlement

problems

arising due to

various

reasons. On

the site we

have visited,

the pressure

grouting has

been used

especially

over the

perimeter. A

floor where

the pressure grouting has been carried out is shown in the picture.

Speaking directly about noise and vibration preventing the steps that the site has been taken are

more managerial than technical. As seen on the site, we also think those are the cost effective,

easy to implement methods with respect to the site and the construction work. But in general and

even in this particular project as it goes on, the management may consider following techniques

to prevent/reduce the noise and vibration generated from onsite work.

The project layout planning can be allocated so that the movement of heavy machinery

are away from the residential units

Reduce/refrain from using earth moving machinery if possible

Allocating demolition, soil compacting works in to different phases if possible

With using these techniques and others which are appropriate, the construction process will go

smoothly with less distractions and this will ultimately lead the construction company to obtain

good will and also the certificates related to environmental friendliness of the project and the

construction firm.

4. Air and dust management

On the construction site we have visited, the air pollution and dust emitting do not seemed to be

an issue because there were no such work going on. The surrounding was much wet due to the

rainy weather conditions. And also, much of the foundation work has been finished and so the

ground that was open were very much limited.

But, on the other hand, when the project proceeds there will be some tasks that will cause these

problems. The best example is the cleaning of formwork to make it free of any alien material

after finishing the fixing of reinforcement using compressed air. During this process, there will

be dust going away and as the building proceeds it will become a problem to the surrounding

people and institutions. As a basic solution, setting up the protective net can be suggested. Other

than that, with simple steps like making the employees aware of the problem and asking them to

work so that the problem will be minimum will be successful. Other than that, regular cleaning

and following acceptable working procedures will also be solutions for the problem of

controlling dust.

5. Waste management

Waste management is an issue that have to be addressed at the construction management. Main

expectation of waste management is to reduce the amount of waste discarded from industrial

sites. That means reusing the waste as much as it can be used until it cannot use again in a useful

way. Main problem in Srilankan legislation is there are no specific laws or regulations

addressing industrial waste management. Even there are few laws they are free of considerable

penalties. So addressing this issue in a legislative manner is so week. And construction agencies

also do not pay much attention on these issues.

In our site visit we could have less information about waste management. Because that site is

ongoing in its primary stages at the same time that land also a barren land prior to the

construction. So there is not much constructional waste to be rehabilitated. But there are some

steps they are taking in order to have a good working environment. Normally they do a site

cleanup in every Sunday which is obviously a closing day of the site. Since there is only one

entrance point to the site which is facing the gall road, they are managing their waste in a

controlled manner. They normally dump their industrial waste near the entrance inside the site.

Although this creates an untidy and unsafe conditions inside the site, they have to do it with the

limited space.

Industrial waste can be divided in to various categories. They are solid waste and fluid waste.

This fluid waste is consists of liquids and gases. In the site we visited there was not much fluid

wastes. And in solid waste also they were managing them to minimize them. As an example they

were using ready mix concrete in their construction. And it helps them to have environment free

with empty cement bags and remaining bulks of sand and aggregate here and there. And we

could see reinforcement also using in economical way as to reduce the wastage by using

remaining steel pieces in curtailments.

Waste management play a crucial role in construction management. Because it helps to carry out

the project more economically and efficiently. Even though construction industry do not pay

much attention on waste rehabilitation considering its economy, it is a good way for preserve

environment with reduction of direct material usage.

6. Traffic management

Traffic management is also a very important aspect when managing the construction site. It

directly affect the efficiency of workers and construction. By maintaining good traffic

management level efficiency will increase due to reducing unnecessary delays during providing

materials and due to improving travel path and distances. Finally the cost and time will save

during the construction process.

Traffic management is totally depend on site layout planning and it is a one task that can be

listed under site layout planning. Accessibility inside the construction site, arrangements of walk

ways and paths, material handling and equipment controlling will be improved by site layout

planning and it will helps to managing traffic.

When workers are traveling and transporting the materials through the access paths in the site

there should be arrange those paths such that the travel time is low and comfortable enough to

travel with heavy loads of materials and the access paths should be without disturbances to travel

easily. And other thing is width of the walkway or the paths should be enough to accommodate

the exchange for both ways.

When handling materials and equipment, they should be well planned to avoid unnecessary

delays and waiting until finish the task of other equipment.

In our visited construction site, traffic management is not good. Major reason for that is lack of

space. Walk ways are too narrow and not enough even to travel one person. It is difficult to

exchange two peoples traveling different sides through the walk way and one person has to be

stay side until others are travel.

Therefore traffic management of that site should be further improved to ensure the performance

of the construction site.

Traffic due to narrow walkways

Labor Supervisor Engineer

Store

Keeper

Labor

7. Material procurement management & storage

Material procurement was done at the site using two main forms.

Common Material

Common material such as cement, sand, coarse aggregate, reinforcement, blocks and bricks were

purchased by the stores at the site. This is directly done under the procurement department of the

site. Stores maintains a buffer stocks in order to avoid any delays in providing materials to the

construction activities. All the invoice will be collected by the quantity surveyor of the site.

Special Material

When a special material is needed for a construction activity, the method of purchasing is

different from the method used for common materials. The required special material will be

informed to supervisor (In-charge for relevant construction activity) by the sub-contractor or

labors. Then supervisor should enter the required special material with the required quantity, in

the MATERIAL ORDER BOOK at the stores, in advance to the construction. Then the

stores will purchase the material and issue it to necessary party at the required time.

Every material comes to the site will be accepted by the stores and then issued to the labors.

Every worker of the site has to follow a formal procedure to release required material for the

construction, from the stores. The procedure follows to issue any material for the construction

work has mentioned below.

The site visit was done at the initial stage of the project. Hence only the foundation has begun

when our team went to visit the site. With the scarcity of the space at the site premises, lot of

material such as sand, blocks and reinforcements were spread everywhere in the site. There

wasnt much organization of the material storage at the site. However there was a storage

container as the main store unit and one storekeeper was there. Some of the construction

equipment, electrical items (bulbs, wires etc.) and few materials were stored at the storage

container. Documentation of the material requisition and purchasing was done at the store

(container) by the store-keeper.

According to the site manager of the site, once the first floor is finished there will be a separate

space for the stores at the first floor. Once that space is constructed, material could be properly

Labor or sub-

contractor will

inform the

requirement of

the materials

Supervisor will

forward the

Material

Requisition (MR)

to Engineer

Engineer will sign

the MR and give

the note to

Stores

Stores will

release the

material to

construction and

send the MR to

QS officer

stored without any problem. Separate space will provide for reinforcement storage and cement

storage at the new stores.

Suggestions

Material procurement method and the issuing method at the site can be consider as good case

practices in this site. It allows site quantity surveyor to have a proper control over the

procurement costs. The method used for special material purchasing will minimize the wastage

of the material. But the time taken for making the material requisition may delay the construction

activity and in a situation where material is needed instantly the current process may not be

practical.

Storage of the site has not been satisfactory. It can cause several adverse effect on the continuity

of the project.

Since labors of the site can go out of the site and come back without any problem, the

probability of stealing the material may increase.

Accidents can be increased by disorganized storage of the material. Hence safety of

the site can be adversely affected.

Wastage can also be high due to improper storing. Therefore total cost of materials

can increase.

Even though the space is scared at the site it is necessary to optimized it for proper storing of the

materials. It is necessary to give proper learning for the site labors about the proper material

storage and moving them to construction activities. Material can be damaged or loss during the

transportation from the storage to place of constructing. Therefore proper equipment such as

wheel barrows should be used to transport the materials. Workers should be given proper safety

wears such as gloves and boots. These practices will minimize the above mentioned adverse

effects on the project.

8. Site meetings

Site meetings are meetings carried out with the parties of different stakeholders in order to

achieve different goals.

Daily Meetings

As mentioned before, (under the human resource management section) there are various

activities taking place in parallel at the site. As such, there is a requirement for all the

stakeholders in the site to be brought to one page regarding the activities taking place in the site.

This objective is achieved by having daily meetings, towards the end of the day.

These meetings are generally headed by the site engineer. However, if there are any important

announcements to be made regarding the progress of work or any major activity is close to

atking place, the project manager heads the meeting. All the supervisors, store keeper, a member

of the electrical department etc take part in these meetings.

OBJECTIVES-

To recap the dayswork :

In order for each stakeholder tobe updated about the current progress of the project, all the

relevant parties give their daily updates. This enables, the different supervisors to get an idea as

to whether their future targets can be achieved. For example, if the formwork laying in one

sector is delayed, it will affect the concreting of all sections not only of the delayed section.

To update targets :

Due to various external and internal reasons, the targets may need to be re assessed. This

can be done at the daily meetings. Major targets are not adjusted in these meetings. Only minor

adjustments are done.

Get the necessary equipment, material and services required for the next day:

In order to ensure that incidents like not having the required equipment, material or

conditions not being present at the site the next day, Each supervisor will speak about what will

happen during the next day and what is required for him to do his work. For example, if there is

work to be done after nightfall the next day, he will request the electrical department to

illuminate the required area.

Meetings with client/consultant

As mentioned earlier, the contractor is only one major stakeholder of the project. In order

to update the consultant about the project and any changes etc a meeting with the consultant is

held weekly.

POINTS FOR IMPROVEMENT

While as a whole, there were not many points that we could address, maybe if the daily meetings

would address the situation of the project for 2or 3 days forward, rather than only the next day, it

may reduce the last minute hectic work of getting down unique pieces of machinery eg

compressor

However, since there was no mention of difficulties in getting down material and equipment, it

can be assumed that their already exists such a method.

10. Health, safety and welfare

Building construction is a vast area that deals with various subjects with man power

management. Man power management is also a vast subject which flows with different varieties.

Building construction is all about managing man power, equipment and material in a given time

frame. When this management process is going on there are different ways that have to follow in

man power managing. Because working with people is way different from working with

equipment and material. Not like machines and material people must have some sort of welfare

facilities, safety requirements, health caring etc. And to have a maximum efficiency from

working forces they must be given a friendly environment to work with. Because man power

efficiency will directly affect the success of the project.

Health, safety and welfare are fundamental issues to be granted in man power management.

Because most of them are related with the lives of the people. Under working environment a

good safety precautions have to be taken to guarantee the safety of the workers.

Even though construction management is about handling billions of rupees human life cannot be

tolerated by money under any circumstance. So health of the workers at the site has to be in a

good condition. In construction sites there are various health hazards that workers have to deal

with. Lots of health issues would arise to workers because of the conditions at work place. Dusty

conditions, humid conditions, exposure to high thermal conditions, exposure to dangerous

chemicals are few of the unhealthy environmental conditions which workers have to face. And

there are various illnesses related with these bad conditions. Chronic obstructive pulmonary

disease, occupational asthma, silicosis are only few examples related with construction industry.

And these unhealthy environmental conditions can be created in various ways. When in our site

visit also we could notice some of such activities and situations at that place. At the same time

we could see some safety precautions they have taken to prevent such situations. In the site there

is a unique officer who deals with safety matters of the site. That safety officer always check

with the site conditions with safety.

We could see lots of notices displayed at the site reminding the workers about safety. And there

were some ethics and rules maintaining at the site in order to maintain the site safety. We could

see every worker at the site wearing head gear to cover up their heads from hazard. And relevant

people who are working with hard tools were wearing gloves. And we could see some workers

without a proper foot wear too.

As a safety practice this site is not allowed to enter any outsiders without any kind of a pre

request. Major problem about this site is the space problem. They have to do all the construction

work in a small area. And that site didnt have proper space to travel here and there. So that

could also cause to some injuries. And we could see some workers working in some dangerous

places as well. But any way there is some sort of a risk that everyone in the site has to take. That

is a normal situation in every site. They cant provide a perfect hazard free environment, but they

are trying to have such an environment as much as they can.

This construction site is a twelve story building which is constructing on raft foundations. At the

time were visiting the site, its form work has done to some extent in raft foundations. So in

order to have a raft foundation, they had to do about 5 meters of excavation. At the same time the

construction site is bordered by few high story buildings. So when the excavations are done they

had to do some safety measurements to prevent settlements of the surrounding buildings. And

they are maintaining a good concentration about their settlements by continuous surveying. And

they have given the allowable tilt of the retaining walls as 100mms. And these walls were well

secured using steel compression beams. And they are maintaining a good communication with

surrounding people about any cracks appearing on their walls. Those steps can be identified as

good safety precautions in order to prevent a huge catastrophe.

To improve the safety level of the site they could add some more steps and features to the site.

They can educate the labors about safety. And they can implement a new rule to wear shoes

inside the site premises. And they can educate them how to give first aid to a person who is

having an injury. And they can maintain a record of day today accidents happening at the site

and take necessary actions to prevent those happening again at the site. If they can improve the

lightening system at the site in night time it will create more safety environment for people who

are working at the night time as well.

When considering about the welfare that is given to the laborers. People at the site were provided

few facilities regarding their welfare. All laborers are insured by the contractor. So in case of an

accident or any kind of a death of a worker they will claim them on behalf of his family or

himself. There are safety regulations introduced on the construction company which guarantee

the labor safety. And when the company is granting ISO standards also they have to complete

some facts regarding labor safety. There they have stated to have an insurance coverage on every

person at the site to have their standards on the site.

All the laborers and workers have being provided the accommodation by the company. They

normally give accommodations for them in nearby places to the site in primary stages of the site.

And after some time if there is enough room in the construction site to give them

accommodation at the site itself, they will be provided accommodation that way. Some days

workers may have to work until mid-night to complete their work. So those days its not easy to

travel to their places. And its quite necessary to give them such a welfare service to them. And it

will improve their resting time after hard day of working at the same time it will ensure their

arrival at the site at the right time.

In addition to those welfare services they are given daily meal and tea at respective time periods.

And all the sanitary facilities also provided in a good way. And there is a separate laborer to

handle all the sanitary work for other construction laborers at the site. Good drinking water

facilities are also provided to the laborers at the site.

In addition to all those welfare services provided to the laborers all other people at the site also

have all those facilities and a good working area. They have a well maintained site office to work

with. It is air conditioned and inside it is well managed in order to have a good working

environment.

Even though this site is in a small plot of land, they have maintained to give them all these

facilities to all the workers. And we could see a good management practice is going on at the site

to achieve construction targets while maintaining healthy and safe working environment. And we

could see site officers are also dealing friendly with the laborers. And they are having a good

relationship between themselves. That is also an important aspect in construction management.

Because good communication has to be maintained at each level to have an efficient construction

project.

You might also like

- Role and ResponsibilityDocument5 pagesRole and Responsibilitysunilsona39No ratings yet

- Technology Innovation in Construction Industry (Engineering Management)Document2 pagesTechnology Innovation in Construction Industry (Engineering Management)AngelaDeviNo ratings yet

- Summer InternshipDocument2 pagesSummer InternshipspinalcordinjuryNo ratings yet

- Key influences driving construction innovationDocument13 pagesKey influences driving construction innovationMaria Lucia Cuellar BustamanteNo ratings yet

- Tanzania Health Sector Strategic Plan IIIDocument89 pagesTanzania Health Sector Strategic Plan IIIJan GoossenaertsNo ratings yet

- Cube Method EstimatingDocument3 pagesCube Method EstimatingAzam DeenNo ratings yet

- Time and Cost Overrun in Construction PR PDFDocument43 pagesTime and Cost Overrun in Construction PR PDFCassio ManoelNo ratings yet

- Project Manager Green BuildingDocument4 pagesProject Manager Green BuildingSaak มอนเตรNo ratings yet

- Management of HR in ConstructionDocument13 pagesManagement of HR in ConstructionHariztsani SabilurrahmanNo ratings yet

- Steps in Planning Function: 1. Establishment of ObjectivesDocument2 pagesSteps in Planning Function: 1. Establishment of ObjectivesShankar SharmaNo ratings yet

- DRAFT CIOB Code of Quality ManagementDocument98 pagesDRAFT CIOB Code of Quality ManagementKeith Cubero100% (1)

- Business Development ConstructionDocument2 pagesBusiness Development Constructionapi-1213523070% (1)

- Implementation of Lean Construction Techniques For Minimizing The Risks Effect On Construction ProjectDocument49 pagesImplementation of Lean Construction Techniques For Minimizing The Risks Effect On Construction ProjectJohn PaulNo ratings yet

- Introduction To Project Appraisal and ManagementDocument4 pagesIntroduction To Project Appraisal and ManagementnaveedrkhanNo ratings yet

- Escalation - 05 ContentsDocument20 pagesEscalation - 05 ContentsSarinNo ratings yet

- Project Management BSS060-6: Evaluating The Use and Application of Project Management Theory and MethodologiesDocument17 pagesProject Management BSS060-6: Evaluating The Use and Application of Project Management Theory and MethodologiesPayalNo ratings yet

- Instructor Kathryn Cassidy ProcoreDocument4 pagesInstructor Kathryn Cassidy ProcoreSrujan NamburiNo ratings yet

- Reducing Energy Consumption Strategies in University Buildings in EgyptDocument14 pagesReducing Energy Consumption Strategies in University Buildings in EgyptIEREKPRESSNo ratings yet

- Quality Control and Quality Assurance in Building ConstructionDocument9 pagesQuality Control and Quality Assurance in Building ConstructionAbdul JabbarNo ratings yet

- Project Management: Cpm/Pert by Dr. Neeraj AnandDocument23 pagesProject Management: Cpm/Pert by Dr. Neeraj AnandAsasAsasNo ratings yet

- Avoiding Cost Overruns in Construction PDocument11 pagesAvoiding Cost Overruns in Construction Pnasru hajiNo ratings yet

- A Critical Literature Review On The Concept of Team Integration in IBS Project.Document17 pagesA Critical Literature Review On The Concept of Team Integration in IBS Project.oioianNo ratings yet

- How Construction Flows Have Been Understood in Lean ConstructionDocument12 pagesHow Construction Flows Have Been Understood in Lean ConstructionlualdanezNo ratings yet

- 1.planning and Organising The Housekeeping DepartmentDocument7 pages1.planning and Organising The Housekeeping DepartmentAviral KumarNo ratings yet

- Project Cost Management 29-08-2016Document108 pagesProject Cost Management 29-08-2016Deepak VindalNo ratings yet

- Factors in Project SuccessDocument68 pagesFactors in Project SuccessAndrew ChungNo ratings yet

- Performance Measurement Systems in Construction: Roshana Takim, Akintola Akintoye and John KellyDocument10 pagesPerformance Measurement Systems in Construction: Roshana Takim, Akintola Akintoye and John KellyAsitha RathnayakeNo ratings yet

- A Short Guide To Writing Your Final Year Project Report: June 2019Document27 pagesA Short Guide To Writing Your Final Year Project Report: June 2019Zahra AhmadNo ratings yet

- Developing a Common WBS for School ProjectsDocument131 pagesDeveloping a Common WBS for School ProjectsWaqas979No ratings yet

- Project Management Failure IssuesDocument3 pagesProject Management Failure IssuesNicole Patricia Alinea NogueraNo ratings yet

- CPB 20004-Engineering Technologist in Society Assignment 1 (Individual) : Codes of Engineering Ethics - 1Document9 pagesCPB 20004-Engineering Technologist in Society Assignment 1 (Individual) : Codes of Engineering Ethics - 1afiqNo ratings yet

- Initiation Phase of Construction ProjectDocument4 pagesInitiation Phase of Construction Projectaymanmomani2111No ratings yet

- PGPM 13Document9 pagesPGPM 13Junaid MohdNo ratings yet

- UET Lahore Chemical Engineering Intern EvaluationDocument1 pageUET Lahore Chemical Engineering Intern EvaluationMohammad ZikriyaNo ratings yet

- Contruction Routes FinalDocument16 pagesContruction Routes FinalAsjad KhanNo ratings yet

- Work Break Down StructureDocument10 pagesWork Break Down StructureFouzia YasminNo ratings yet

- Anas Alam Faizli, Master of Proj MGMT: Assignment International Project Management, EMCM5203Document25 pagesAnas Alam Faizli, Master of Proj MGMT: Assignment International Project Management, EMCM5203Anas Alam FaizliNo ratings yet

- Strategic Management of MitsubishiDocument17 pagesStrategic Management of Mitsubishishailaja reddyNo ratings yet

- Glasgow University's Internationalisation StrategyDocument13 pagesGlasgow University's Internationalisation StrategyAdeel Saeed MirNo ratings yet

- Plan Procurement ManagementDocument24 pagesPlan Procurement Managementsherif9ahmed9sabriNo ratings yet

- PM ProjectDocument21 pagesPM ProjectHamayun RasheedNo ratings yet

- TOPIC 3 Site Supervision and Safety Management in Construction NotesDocument16 pagesTOPIC 3 Site Supervision and Safety Management in Construction NotesF2043 AMMAR AZ-ZHAFRI BIN ABDUL HALIMNo ratings yet

- A Project ReportDocument13 pagesA Project ReportRahul SehgalNo ratings yet

- 1a Communication Plan MemoDocument3 pages1a Communication Plan MemoLuis Maria Bimbo100% (1)

- SWOT Analysis: Lighting Solution ProviderDocument1 pageSWOT Analysis: Lighting Solution Providerreegup100% (1)

- Project Delivery Methods & Contract Types GuideDocument37 pagesProject Delivery Methods & Contract Types GuideArifNo ratings yet

- Foreman Delay Survey Finds Material Wait Top CauseDocument18 pagesForeman Delay Survey Finds Material Wait Top Causevalkiria112No ratings yet

- Assignment 1 - QualityDocument24 pagesAssignment 1 - Qualityfrozenash3sNo ratings yet

- C.V Faiz Ahmad New 25-7-17Document6 pagesC.V Faiz Ahmad New 25-7-17Asif FaizNo ratings yet

- Recruitment and Selection Procedure of ExIm Bank LTDDocument79 pagesRecruitment and Selection Procedure of ExIm Bank LTDsagornondiNo ratings yet

- Consulting Civil EngineerDocument4 pagesConsulting Civil Engineerhabtu tesemaNo ratings yet

- National Highways Authority of India: Kanyakumari Etturvattam Tollway LimitedDocument52 pagesNational Highways Authority of India: Kanyakumari Etturvattam Tollway LimitedKarthi KeyanNo ratings yet

- Resource Costs: Labour, Materials and PlantDocument7 pagesResource Costs: Labour, Materials and PlantmohamedNo ratings yet

- Coursework 1 - CPDocument15 pagesCoursework 1 - CPMufeez Lebbe0% (1)

- State of Maintenance 2021 ReportDocument29 pagesState of Maintenance 2021 ReportJohn AngelopoulosNo ratings yet

- Building Project Performance Evaluation ModelDocument12 pagesBuilding Project Performance Evaluation ModelDavid SabaflyNo ratings yet

- Overview Success Criteria and Critical Success Factors in Projectmanagement 2169 0316 1000244Document7 pagesOverview Success Criteria and Critical Success Factors in Projectmanagement 2169 0316 1000244rivai anwarNo ratings yet

- Quality Control Manager Role in 38 CharactersDocument10 pagesQuality Control Manager Role in 38 Charactershesham33usNo ratings yet

- Construction Personnel ManagementDocument27 pagesConstruction Personnel ManagementKavvindra Mehra100% (1)

- Site management rolesDocument8 pagesSite management rolesMalith De SilvaNo ratings yet

- Colombo Dockyard PLC Employment Application Form 3Document4 pagesColombo Dockyard PLC Employment Application Form 3Madusha TisseraNo ratings yet

- QUESTIONNAIRE SURVEYStudy On Safety Management Practices in Construction Sites (Responses)Document25 pagesQUESTIONNAIRE SURVEYStudy On Safety Management Practices in Construction Sites (Responses)Madusha TisseraNo ratings yet

- TOR For EIADocument10 pagesTOR For EIAMadusha TisseraNo ratings yet

- FLOWCABLE 50 v7Document2 pagesFLOWCABLE 50 v7Madusha TisseraNo ratings yet

- Water Quality Parameter TestingDocument20 pagesWater Quality Parameter TestingMadusha TisseraNo ratings yet

- WIT-PE 500 Design Manual RBDocument24 pagesWIT-PE 500 Design Manual RBMadusha TisseraNo ratings yet

- Design of pile cap reinforcement for 4-pile groupDocument13 pagesDesign of pile cap reinforcement for 4-pile groupShabbir OsmaniNo ratings yet

- Design and Control of Concrete Mixtures, 14th EdDocument360 pagesDesign and Control of Concrete Mixtures, 14th Edelnazeer100% (12)

- S7 11 Revised To DepartmentsDocument3 pagesS7 11 Revised To DepartmentsMadusha TisseraNo ratings yet

- Management Skills Case StudyDocument19 pagesManagement Skills Case StudyMadusha TisseraNo ratings yet

- Sluice GateDocument2 pagesSluice GateMadusha TisseraNo ratings yet

- Effect of Vertical Curvature of Flow at Weir Crest On Discharge CoefficientDocument14 pagesEffect of Vertical Curvature of Flow at Weir Crest On Discharge CoefficientMadusha TisseraNo ratings yet

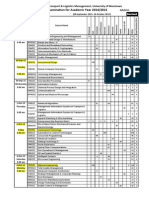

- s8 Ce Academic Timetable DraftDocument2 pagess8 Ce Academic Timetable DraftMadusha TisseraNo ratings yet

- Blockwork foundations and construction techniquesDocument12 pagesBlockwork foundations and construction techniquesMadusha TisseraNo ratings yet

- PahanaDocument1 pagePahanaMadusha TisseraNo ratings yet

- Earthwork For Foundations and Formwork PracticesDocument12 pagesEarthwork For Foundations and Formwork PracticesMadusha TisseraNo ratings yet

- 110582T ReportDocument16 pages110582T ReportMadusha TisseraNo ratings yet

- Structural design process and analysisDocument34 pagesStructural design process and analysisdave4359No ratings yet

- Abs 164Document1 pageAbs 164Madusha TisseraNo ratings yet

- Inspiron 15: 3000 SeriesDocument22 pagesInspiron 15: 3000 SeriesMadusha TisseraNo ratings yet

- Strength of Materials Theory and Problems AuDocument28 pagesStrength of Materials Theory and Problems AuMadusha TisseraNo ratings yet

- Project Title List 2011 Batch-8!5!2015Document14 pagesProject Title List 2011 Batch-8!5!2015Dallas ZimmermanNo ratings yet

- BSR Notes IctadDocument14 pagesBSR Notes IctadDavid Web100% (4)

- Pile Foundation Construction DifficulitiesDocument2 pagesPile Foundation Construction DifficulitiesMadusha TisseraNo ratings yet

- Heaslth and Safety ManualDocument15 pagesHeaslth and Safety ManualMadusha TisseraNo ratings yet

- Submission 110582TDocument6 pagesSubmission 110582TMadusha TisseraNo ratings yet

- Structural Masonry Designers Manual PDFDocument2 pagesStructural Masonry Designers Manual PDFMadusha TisseraNo ratings yet

- Concrete BasicsDocument56 pagesConcrete BasicsMadusha TisseraNo ratings yet

- Reinforcement Fixing For A Beam - Quality Management ProcedureDocument5 pagesReinforcement Fixing For A Beam - Quality Management ProcedureMadusha TisseraNo ratings yet

- How a State's Reputation Impacts Compliance with International LawDocument9 pagesHow a State's Reputation Impacts Compliance with International LawTippy Dos SantosNo ratings yet

- Peace Education g7 q3 w1Document4 pagesPeace Education g7 q3 w1Clifford FloresNo ratings yet

- Intro To SynthesisDocument7 pagesIntro To SynthesisVictor-Jan GoemansNo ratings yet

- N5 Mathematics Revised 2Document32 pagesN5 Mathematics Revised 2Anesu MasirahaNo ratings yet

- 'Devil's Letter' Written by 17th Century Possessed Nun Finally Decoded Thanks To Dark Web CodeDocument2 pages'Devil's Letter' Written by 17th Century Possessed Nun Finally Decoded Thanks To Dark Web CodePaul LauNo ratings yet

- (DC Component) For Renewable Energy Solution - Catalog - EN - 201910Document164 pages(DC Component) For Renewable Energy Solution - Catalog - EN - 201910mas zak danielNo ratings yet

- Chemicals Zetag DATA Powder Zetag 8125 - 0410Document2 pagesChemicals Zetag DATA Powder Zetag 8125 - 0410PromagEnviro.comNo ratings yet

- Earn Real Money Playing Lost Relics Blockchain RPGDocument3 pagesEarn Real Money Playing Lost Relics Blockchain RPGEuvher John VilladolidNo ratings yet

- Wear CoinsDocument3 pagesWear Coinstbejitual100% (1)

- AI Knowledge Representation and Reasoning Week 1 AssessmentDocument3 pagesAI Knowledge Representation and Reasoning Week 1 AssessmentAnonymous ZVbwfcNo ratings yet

- POLYNOMIALS PRACTICE MCQSDocument12 pagesPOLYNOMIALS PRACTICE MCQSSumukh Gowda.MNo ratings yet

- Analytical ChemistryDocument21 pagesAnalytical ChemistryLovelyfaithN.NaduaNo ratings yet

- Unit-1 NATURE AND SCOPE OF ECONOMICS (Part-2Document7 pagesUnit-1 NATURE AND SCOPE OF ECONOMICS (Part-2Poorna RNo ratings yet

- Sociology Optional Test Batch One Year 1Document8 pagesSociology Optional Test Batch One Year 1menakaNo ratings yet

- 2025 2027 SyllabusDocument49 pages2025 2027 SyllabusSheikh Muhammad SiddiqueNo ratings yet

- How To Be A Freelancer in 2021?: What Is A Freelancing Job or The Role of A Freelancer?Document4 pagesHow To Be A Freelancer in 2021?: What Is A Freelancing Job or The Role of A Freelancer?Shreya dubeyNo ratings yet

- SNMP For New-NmsDocument42 pagesSNMP For New-NmsAnwar SniedNo ratings yet

- 1 CBLM Perform Bench111Document154 pages1 CBLM Perform Bench111Jeremy Akilith33% (3)

- Contentonly-Đã M Khóa (001-060)Document60 pagesContentonly-Đã M Khóa (001-060)Định Thái ThànhNo ratings yet

- Arctic Cat - 2002 - zr120 Parts ManualDocument22 pagesArctic Cat - 2002 - zr120 Parts ManualHarold GillNo ratings yet

- Learn About Summer Season Through Hands-On ActivitiesDocument2 pagesLearn About Summer Season Through Hands-On Activitieszulfick nawaziaNo ratings yet

- Determinants of Investment in Manufacturing: A Case Study of Mekelle CityDocument75 pagesDeterminants of Investment in Manufacturing: A Case Study of Mekelle CityAbdulwakil AbareshadNo ratings yet

- Pip-Elemt01 P66 Midstream Projects 0 1/02/18: Document Number S & B Job Number Rev Date SheetDocument9 pagesPip-Elemt01 P66 Midstream Projects 0 1/02/18: Document Number S & B Job Number Rev Date SheetAjay BaggaNo ratings yet

- Communicative StrategiesDocument2 pagesCommunicative StrategiesLawrence ReodavaNo ratings yet

- Greek Mythology Introduction: Lessons on Ancient Greece and Its MythsDocument23 pagesGreek Mythology Introduction: Lessons on Ancient Greece and Its MythsFromjo O. REYESNo ratings yet

- 1-Mini-Link™ SP Technical OverviewDocument19 pages1-Mini-Link™ SP Technical Overviewmustafa SinanNo ratings yet

- PYC3704 - 2021 - 202 - 1 - B ECP Feedback Assignment 2Document18 pagesPYC3704 - 2021 - 202 - 1 - B ECP Feedback Assignment 2meg100% (3)

- Elise Trouble CodesDocument3 pagesElise Trouble Codesrigg61No ratings yet

- Lagoon Lecture PDF 1Document10 pagesLagoon Lecture PDF 1Ndabenhle FlodyNo ratings yet

- Companion Products Carlson Software: Get FREE Technical SupportDocument4 pagesCompanion Products Carlson Software: Get FREE Technical Supportbbutros_317684077No ratings yet